Copper-carbon composite material and preparing method thereof

A composite material and carbon material technology, applied in the field of copper-carbon composite material and its preparation, can solve the problems of peeling, poor wettability, peeling, etc., and achieve the effects of improving interface bonding, improving comprehensive performance, and reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

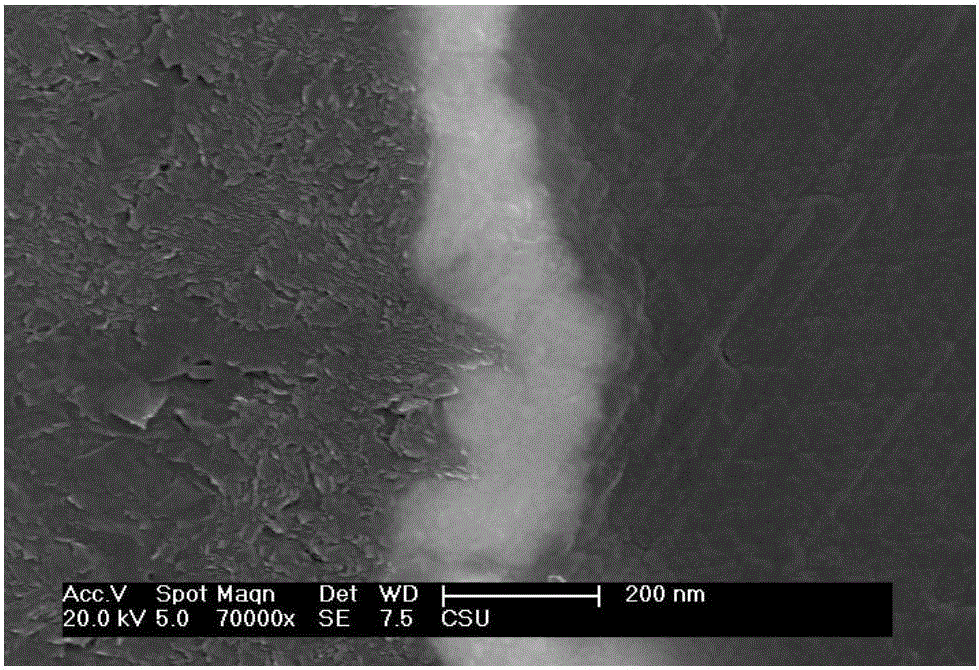

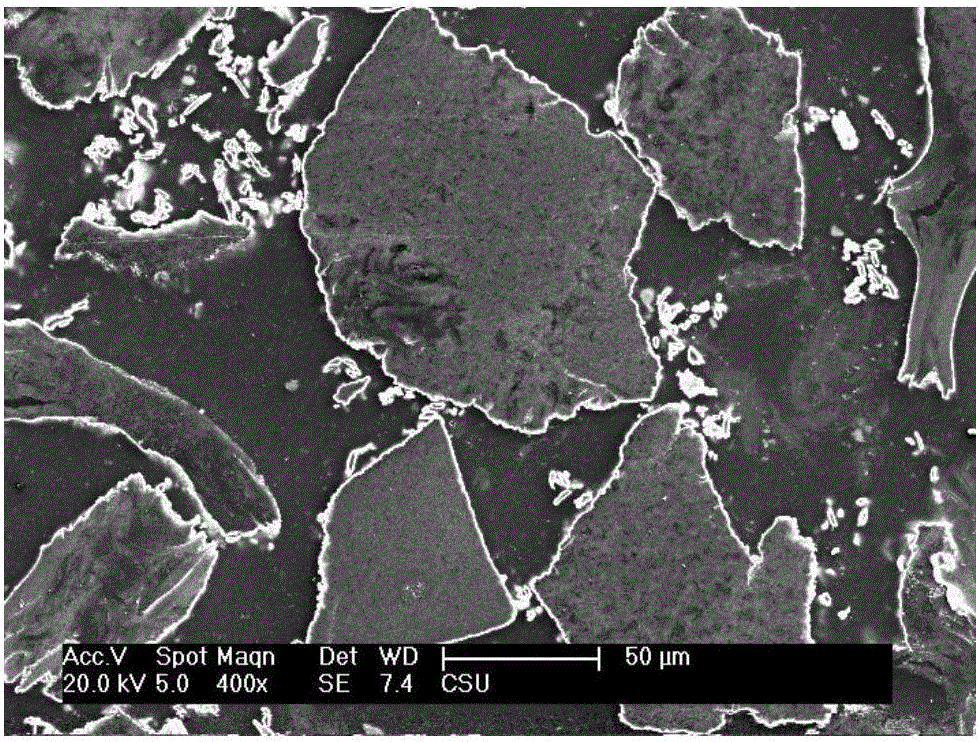

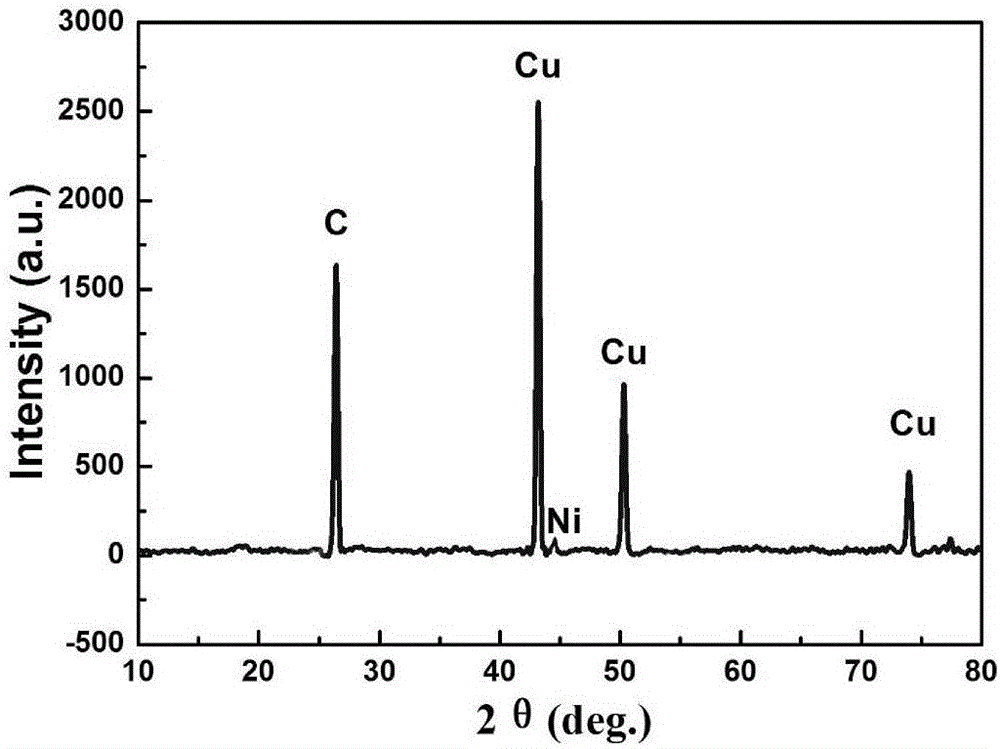

[0031] Choose natural flake graphite as raw material, the particle size range is 50-150μm, the thickness is 5-20μm, and the nickel plating + copper graphite powder is prepared under electromagnetic stirring according to the following steps: (1) The natural flake graphite is in 3mol / L concentrated sulfuric acid + 3mol / L concentrated nitric acid was oxidized, the temperature was 100℃, the treatment time was 2h, then washed with deionized water to neutrality and dried; (2) The graphite oxide powder was in 0.3mol / L tin dichloride solution Carry out sensitization treatment at a temperature of 20℃ and a treatment time of 30min, then wash with deionized water to neutrality and dry; (3) Activate the sensitized graphite powder in 0.2mol / L silver nitrate solution at a temperature of 20℃, treatment time is 30min, then rinse with deionized water to neutrality and dry; (4) Electroless plating of activated graphite powder in nickel sulfate solution, reducing agent is ethylenediamine, adding r...

Embodiment 2

[0033] Select carbon fiber as raw material, with a diameter range of 10-50μm and a length of 20-100μm. Prepare nickel+copper-plated carbon fiber under electromagnetic stirring according to the following steps: (1) The carbon fiber is oxidized in 3mol / L concentrated sulfuric acid + 0.5mol / L potassium chromate, the temperature is 50℃, and the treatment time is 3h. Then rinse with deionized water until it is neutral and dry; (2) sensitize the oxidized carbon fiber in a 0.3mol / L tin dichloride solution at a temperature of 20℃ and a treatment time of 30min, then use deionized water Wash to neutral and dry; (3) Activate the sensitized carbon fiber in a 0.2mol / L silver nitrate solution at a temperature of 20°C and a treatment time of 30min, then rinse with deionized water to neutral and dry; ( 4) The activated graphite powder is electrolessly plated in a nickel sulfate solution, the reducing agent is ethylenediamine, the addition rate is 2g / L, the plating temperature is 20°C, and the ...

Embodiment 3

[0035] Using nano graphite as raw material, the particle size range is 1-5μm, and the nickel-plated graphite powder is prepared under electromagnetic stirring according to the following steps: (1) Colloidal flake graphite is processed in 3mol / L concentrated sulfuric acid + 3mol / L concentrated nitric acid Oxidation treatment, the temperature is 100℃, the treatment time is 1h, then rinse with deionized water to neutrality and dry; (2) Sensitize graphite oxide powder in 0.3mol / L tin dichloride solution, temperature The temperature is 20℃, the treatment time is 30min, and then it is washed with deionized water to neutrality and dried; (3) The sensitized graphite powder is activated in a 0.2mol / L silver nitrate solution, the temperature is 20℃, and the treatment time is 30min, then wash with deionized water to neutrality and dry; (4) Electroless plating of activated graphite powder in nickel sulfate solution, reducing agent is ethylenediamine, adding rate is 2g / L, plating temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com