All-radial-direction discharging ball mill

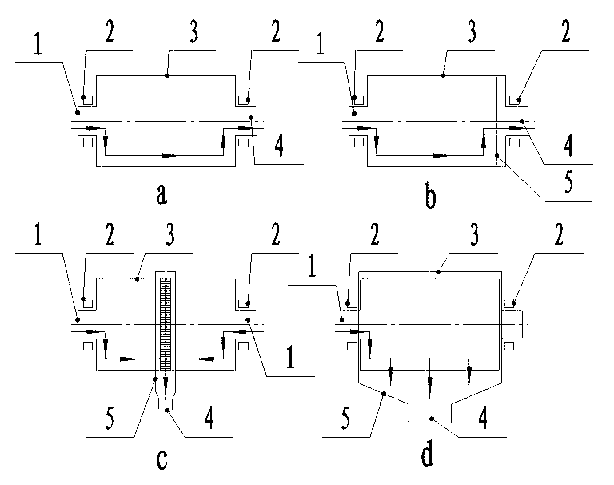

A ball mill and mill technology, which is applied in grain processing and other directions, can solve the problems of low material recovery rate and low grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

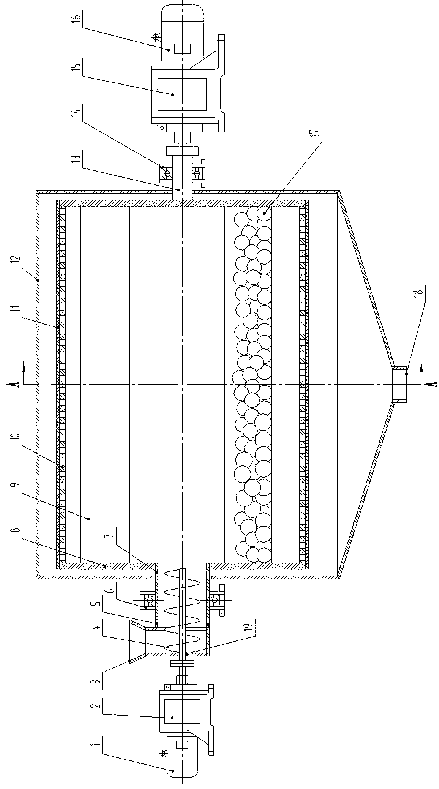

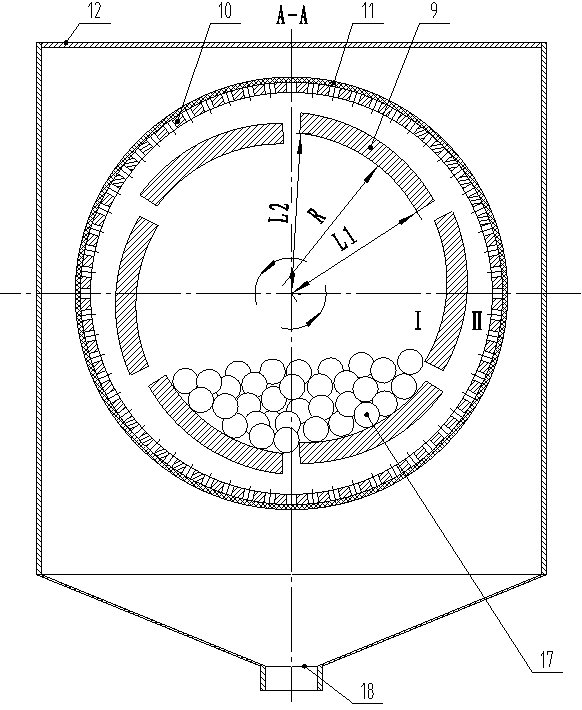

[0022] Refer to attached figure 2 , attached image 3, the full radial discharge ball mill of the present invention includes a feed motor 1 and a feed frequency conversion speed control device 2, a main motor 16 and a frequency conversion speed control device 15, a feed hopper device 3 and a screw propeller 4, and a ball mill rotary cylinder 10 and its internal components, feed end bearing support seat assembly 6, rotary shaft bearing support seat assembly 14 and discharge box 12.

[0023] The feeding of the ball mill is through the front end of the feeding motor 1 with frequency conversion speed regulation, and the coupling is used to drive the screw feeder 4 to push the materials to be ball milled into the rotary ball mill cylinder 10 in the axial direction. There is a fixed feed hopper 3 between the hollow rotary feed shaft 7 that the ball mill rotates and the feed motor, and the material enters from the top and enters the lower rectangular feed bin downwards by gravity. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com