Chamber internal stress test method of screw oil press

A test method and oil press technology, applied in the direction of presses, measuring force, measuring devices, etc., can solve the problems of unresolved pressure distribution, unresolved internal stress, single method, etc., to achieve convenient testing and true test data accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

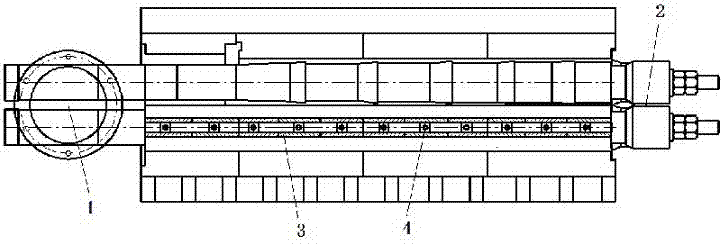

[0018] Such as figure 1 As shown in -4, the present invention provides a method for testing the internal stress of a screw press, wherein the press cage of the screw press is surrounded by a plurality of pressing bars, and the internal stress testing method includes the following steps :

[0019] Step 1. On the press cage of the screw press, select any press bar 3 parallel to the axial direction from the feed inlet 1 to the cake outlet 2 of the screw press, and set N probe hole 4;

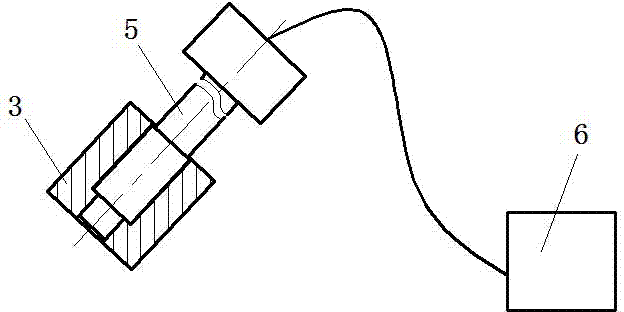

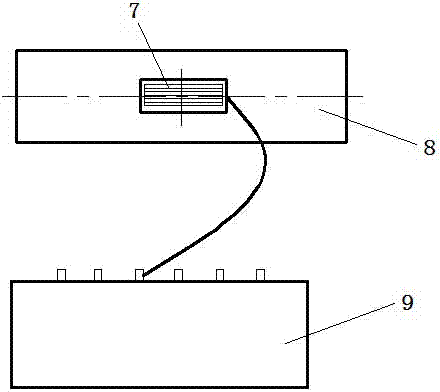

[0020] Step 2: Attach N upper resistance strain gauges corresponding to the N probe holes 4 on the outer walls of the upper and lower squeeze bars up and down adjacent to the squeeze bar 3 with N probe holes 4 With the N lower strain gauges, the upper strain gauges, the lower strain gauges and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com