Large size rock quartz optical fibre prefabricated bar manufacturing method

A quartz optical fiber, large-scale technology, applied in the field of optical fiber manufacturing, can solve the problems of fluctuation of core-skin ratio, limited size, difficult to control geometric accuracy, etc., to achieve the effect of low-cost manufacturing and prevention of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

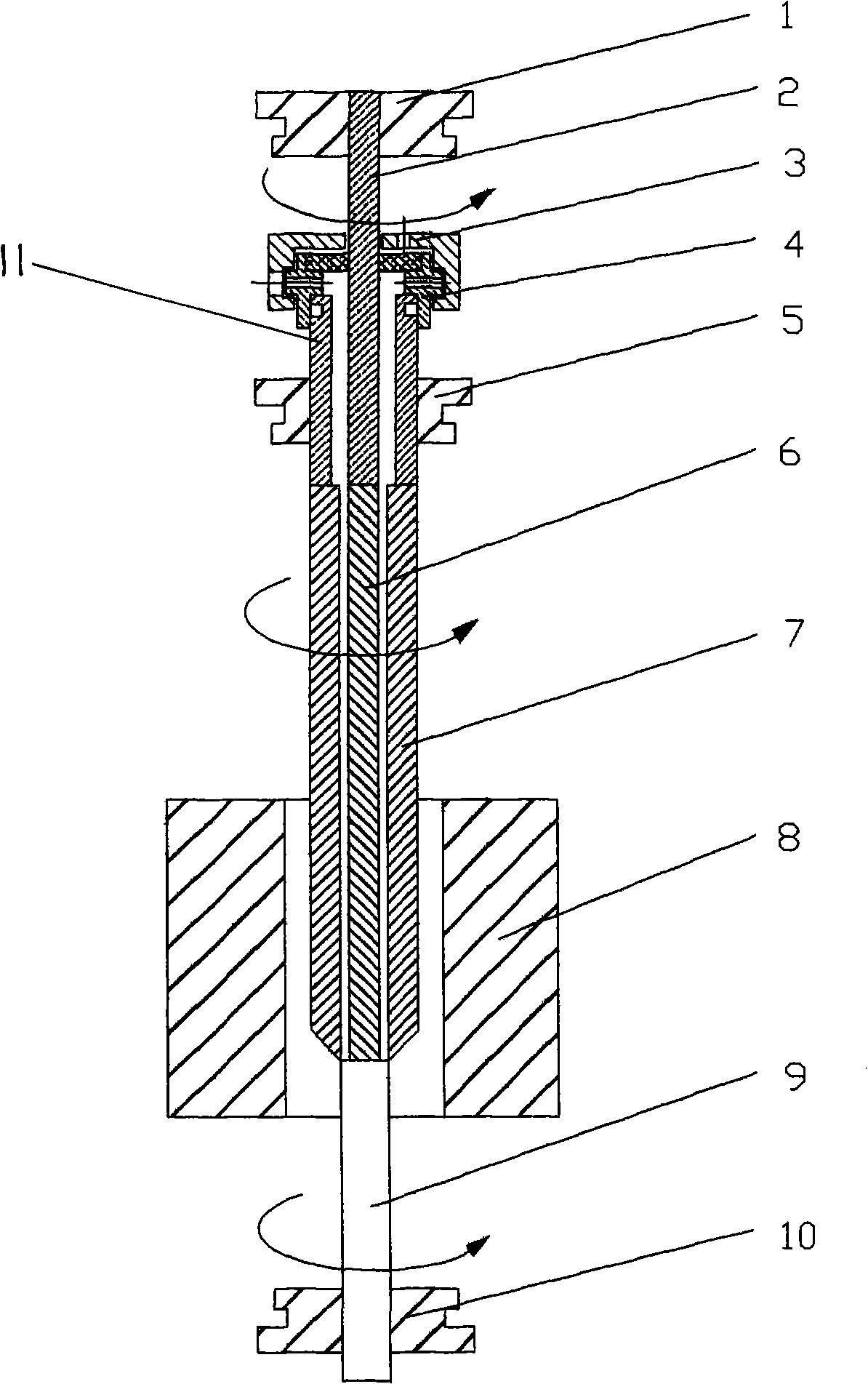

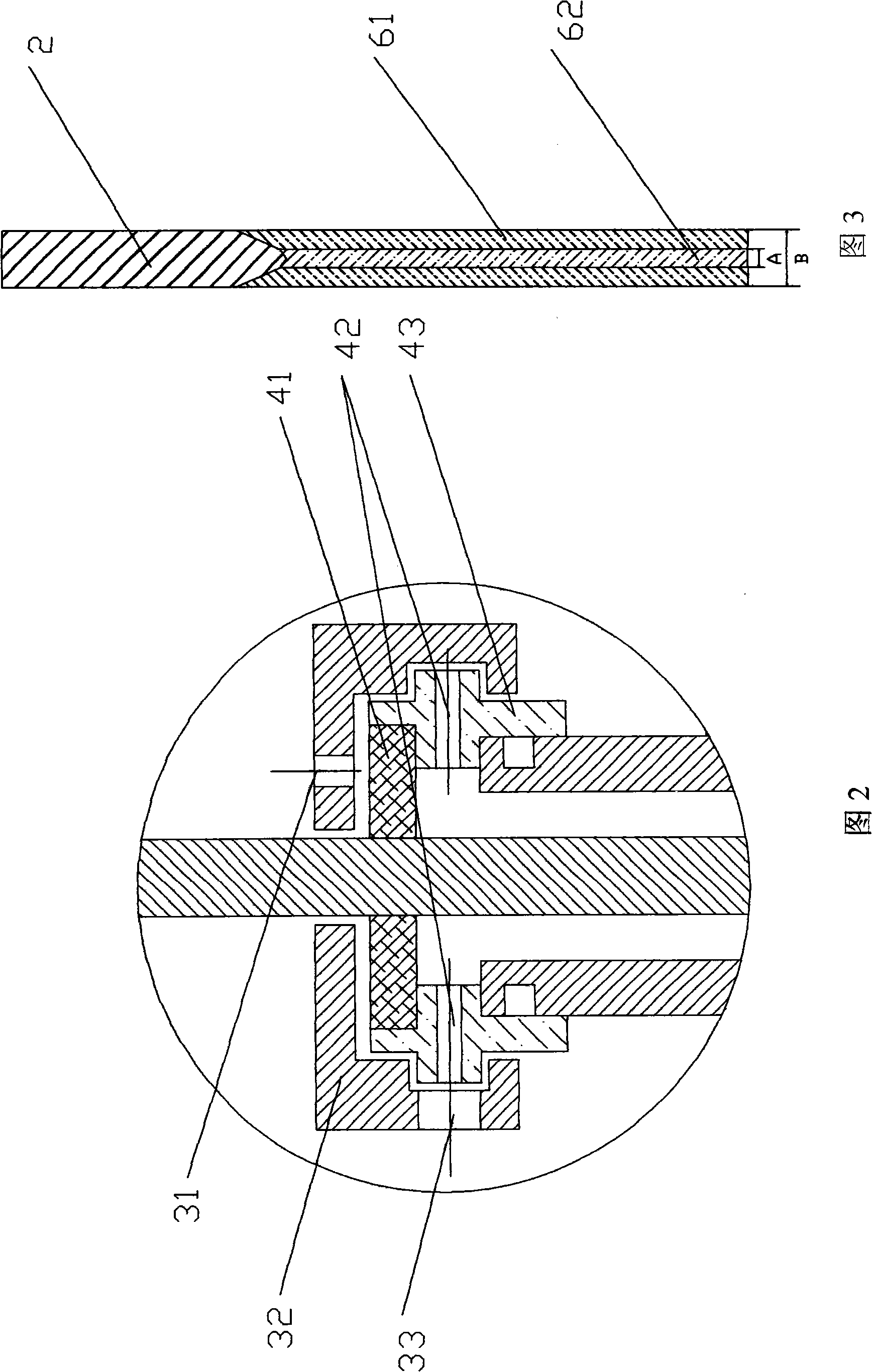

[0024] Manufacture Φ120mm×1500mm optical fiber preform.

[0025] The G652D single-mode fiber is produced by using a sleeve 7 with an inner diameter of 55mm, an outer diameter of 158mm, and a length of 1500mm. The bare fiber diameter of the target fiber is 125um, the core diameter of the fiber is 8um, and the cladding ratio Rf of the fiber is 15.625. Because a certain space needs to be left between the sleeve pipe 7 and the mandrel 6, the main sample can allow the mandrel 6 to have certain curvature and unevenness, so the diameter of the mandrel 6 after extension is set to be 50 mm. by the formula Dr 2 ×V=Rr 2 ×[(Do 2 -Di 2 ) / (Rf 2 -Rr 2 )] It can be calculated that when the speed of the mandrel 6 is the same as that of the sleeve 7, that is, when V is 1, the reference Rr=4.997. Therefore setting the design core wrapping ratio of the core rod 6 prepared by the VAD process in the present invention is 5.0, subject to the limitation of VAD equipment and technology, the stand...

Embodiment 2

[0033] Manufacture Φ80mm×2000mm optical fiber preform.

[0034] The G652D single-mode fiber is produced by using a sleeve 7 with an inner diameter of 50mm, an outer diameter of 180mm, and a length of 3000mm. The bare fiber diameter of the target fiber is 125um, the core diameter of the fiber is 8um, and the cladding ratio Rf of the fiber is 15.625. Because there needs to be a certain space between the casing 7 and the mandrel 6, the mandrel 6 can be allowed to have a certain degree of curvature and unevenness, so the diameter of the mandrel 6 after extension is set to be 45 mm. by the formula Dr 2 ×V=Rr 2 ×[(Do 2 -Di 2 ) / (Rf 2 -Rr 2 )] It can be calculated that the reference Rr=3.9352 when the speed of the mandrel 6 is the same as that of the casing 7, that is, when V is 1. Therefore, the design core wrapping ratio of the mandrel 6 prepared by the VAD process is set to be 4.0, subject to the limitations of the VAD equipment and technology, the standard deviation of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Core diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com