Actual measurement device and method of ultrahigh earth-rock dam internal 3D deformation

A three-dimensional deformation, earth-rock dam technology, applied in the measurement device, electromagnetic measurement device, electric/magnetic solid deformation measurement and other directions, can solve the problems of neglected coupling, large internal deformation, large error, etc. The effect of long time and late investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

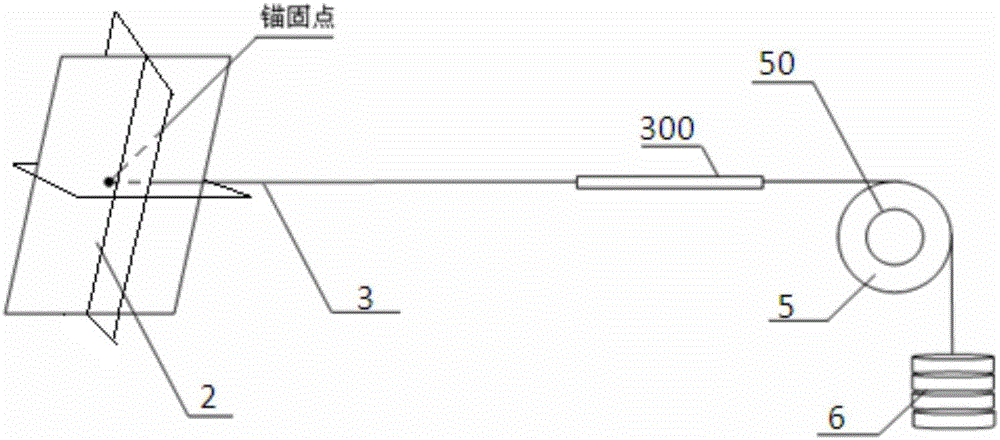

[0058] A three-dimensional deformation measurement device inside a super-high earth-rockfill dam

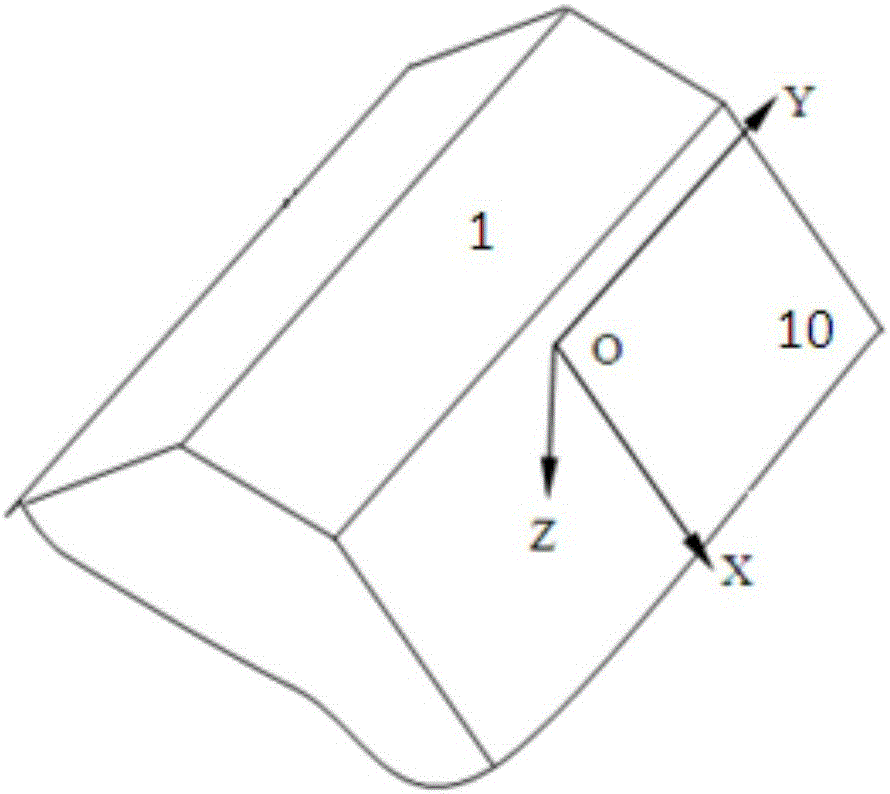

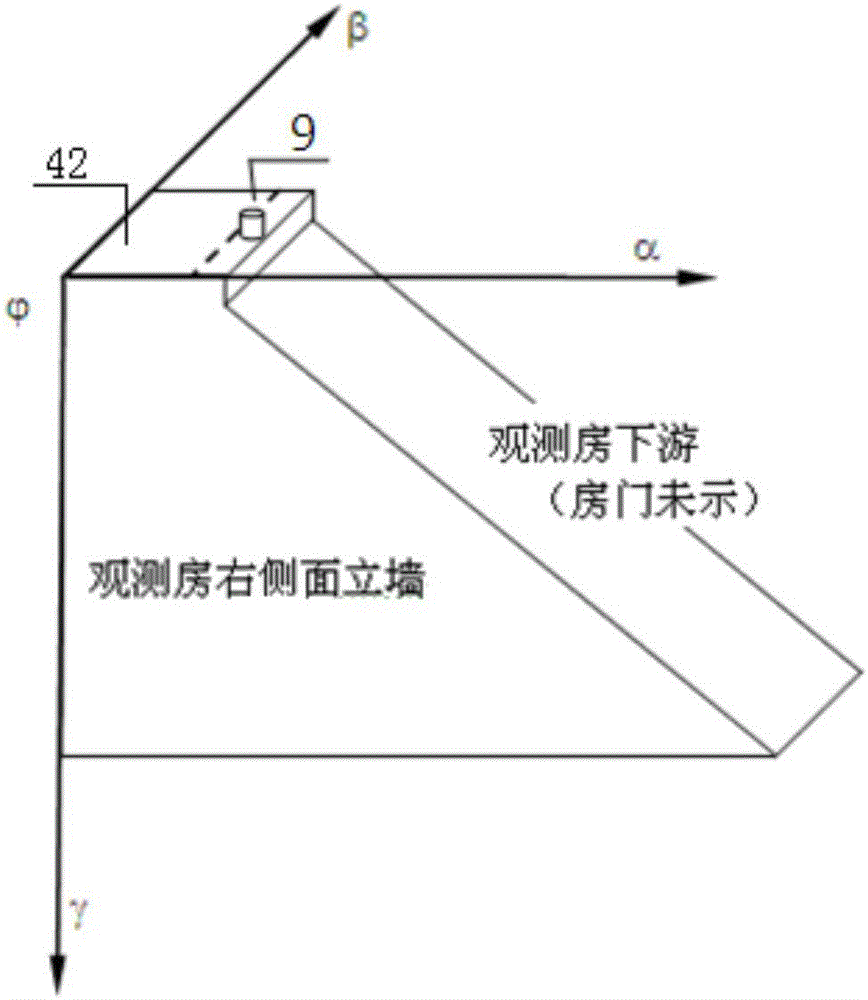

[0059] like figure 1 , 2 As shown, the stainless steel plate 2 is embedded inside the dam body 1 as a representative of the measuring point, and the vector line body 3 is anchored in the center of the stainless steel plate 2. Compared with the drawing line body in the prior art, the vector line body 3 is only used as a reference and not Simultaneously measuring azimuth and length is different, it obtains line body azimuth and length at the same time; Downstream dam body 11 is buried with wedge-shaped combined ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com