Collapsing manufacture method with improved axial evenness for core rods of optical fiber preforms

A technology of optical fiber preform and manufacturing method, which is applied in the field of optical fiber manufacturing, and can solve the problems of no improvement in the axial uniformity of the core layer parameters of the prefabricated rod, and achieve the reduction of optical fiber preparation costs, the increase of the length of the core rod, and the improvement of production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

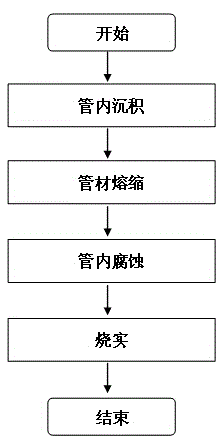

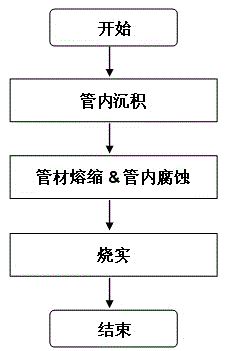

Method used

Image

Examples

Embodiment 1

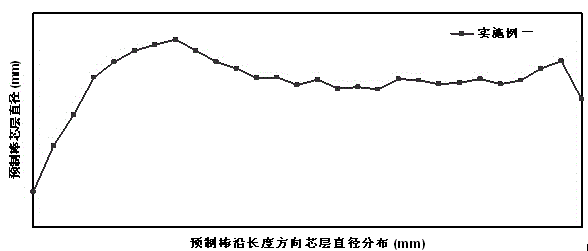

[0025] Example 1: For the detection of the axial distribution of the core diameter of the doped quartz liner, the deposited SiO has an outer diameter of 45mm, a wall thickness of 15mm, and a length of 2.5m. 2 Liner with doped SiO deposited on the inner wall 2 (with GeO 2 etc.), place it on the preform (mandrel) shrinkage equipment;

[0026] Use the graphite heating furnace jacket to provide the heat source, set the power of the heating element, the furnace body moves at a speed of 40~45mm / min, the rotation speed of the quartz liner is 24rad / min, and the surface temperature of the liner is about 2000~2100°C;

[0027] When the temperature of the heating element rises to 2000°C, the first melting and shrinkage begins, and the mixed gas (O 2 and C 2 f 6 ), the gas flow is accurately controlled by the flow controller, and the gas pressure at the gas outlet end of the liner is controlled at the same time, and it is stabilized within a certain range to ensure a uniform and contro...

Embodiment 2

[0030] Embodiment 2: take the SiO that the outer diameter is 45mm, the wall thickness is 15mm, and the length is 2.5m. 2 Liner, inner wall core deposited doped SiO 2 (with GeO 2 etc.), the quartz liner and the deposition process parameters are the same as in the first embodiment, which is placed on the same shrinkage equipment as in the first embodiment;

[0031]Use the graphite heating furnace jacket to provide the heat source, set the power of the heating element, the furnace jacket moves at a speed of 40~45mm / min, the rotation speed of the quartz liner is 24rad / min, and the surface temperature of the liner is about 2000~2100℃;

[0032] According to the core layer diameter distribution of the preform produced by the same process parameters of the same equipment measured in advance (same as embodiment one, image 3 ), set each trip C 2 f 6 The curve of the relationship between the dosage and the position of the graphite heating furnace. The position of the graphite heatin...

Embodiment 3

[0035] Embodiment three: get outside diameter and be 45mm, wall thickness is 15mm, and length is the deposited SiO of 2.5m Liner, inner wall core layer deposits doped SiO 2 (with GeO 2 etc.), the quartz liner and the deposition process parameters are the same as in the first embodiment, which is placed on the same shrinkage equipment as in the first embodiment;

[0036] A graphite heating furnace is used to provide the heat source, the furnace moves at a speed of 40-45mm / min, the rotation speed of the quartz liner is 24rad / min, and the surface temperature of the liner is about 2000-2100oC. In this example, the method of melting and shrinking first and then corroding will be used to sinter the prefabricated core rod.

[0037] When the temperature of the heating element rises to 2000°C, the first melting and shrinkage begins, and O2 gas is introduced from one end of the pipe, and the gas flow is precisely controlled by the flow controller, while the gas pressure at the gas outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com