Patents

Literature

39results about How to "No oil spill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

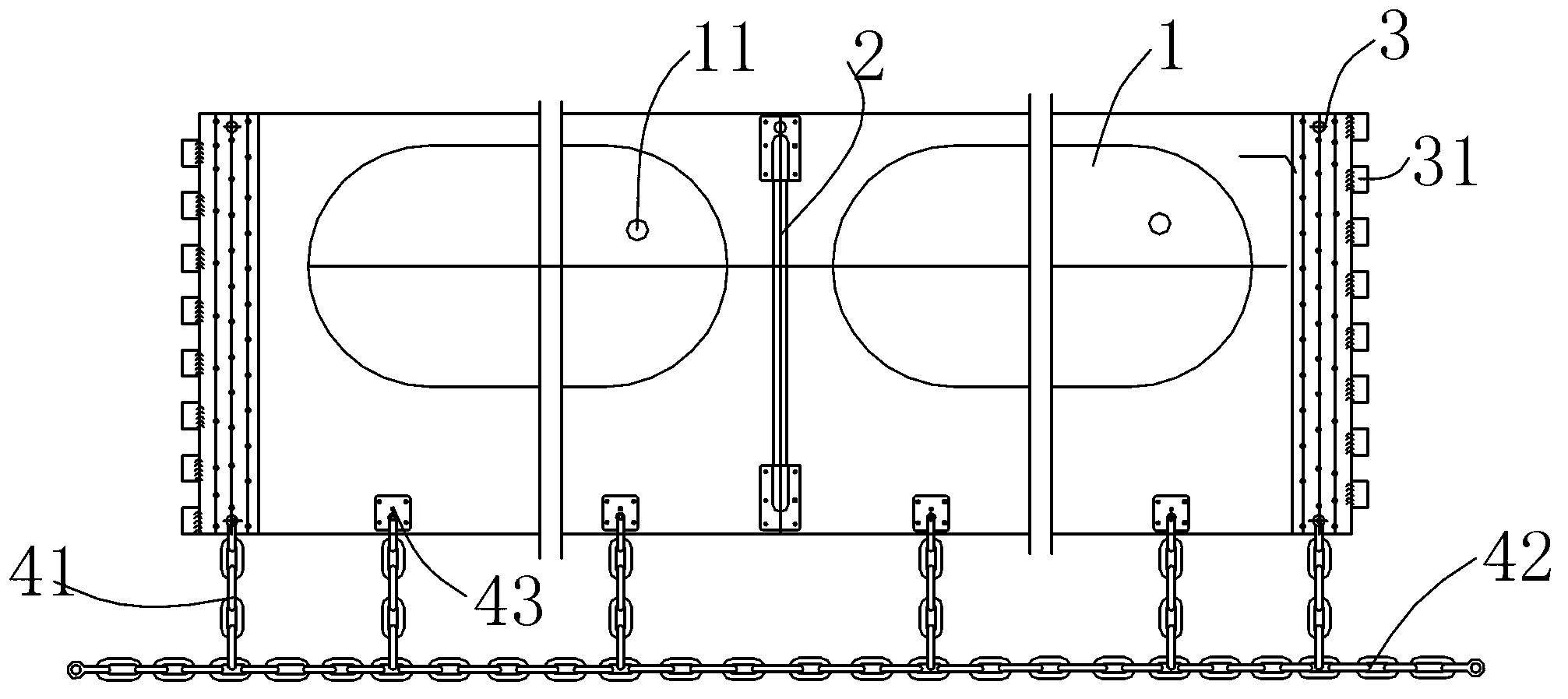

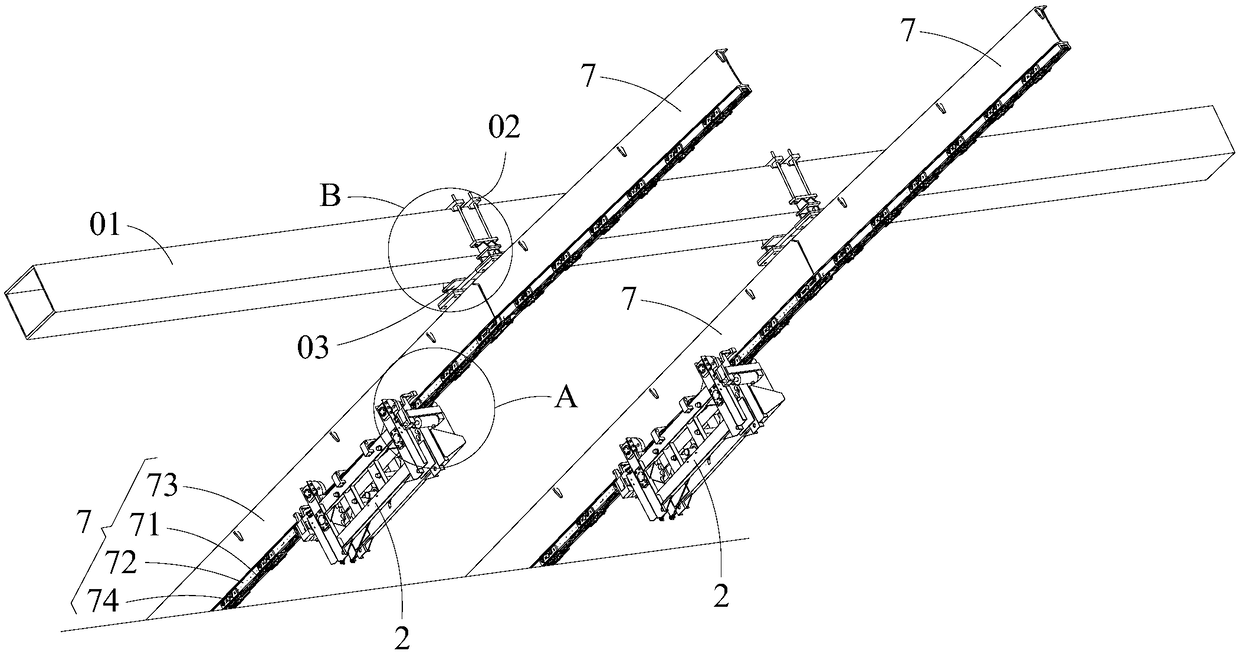

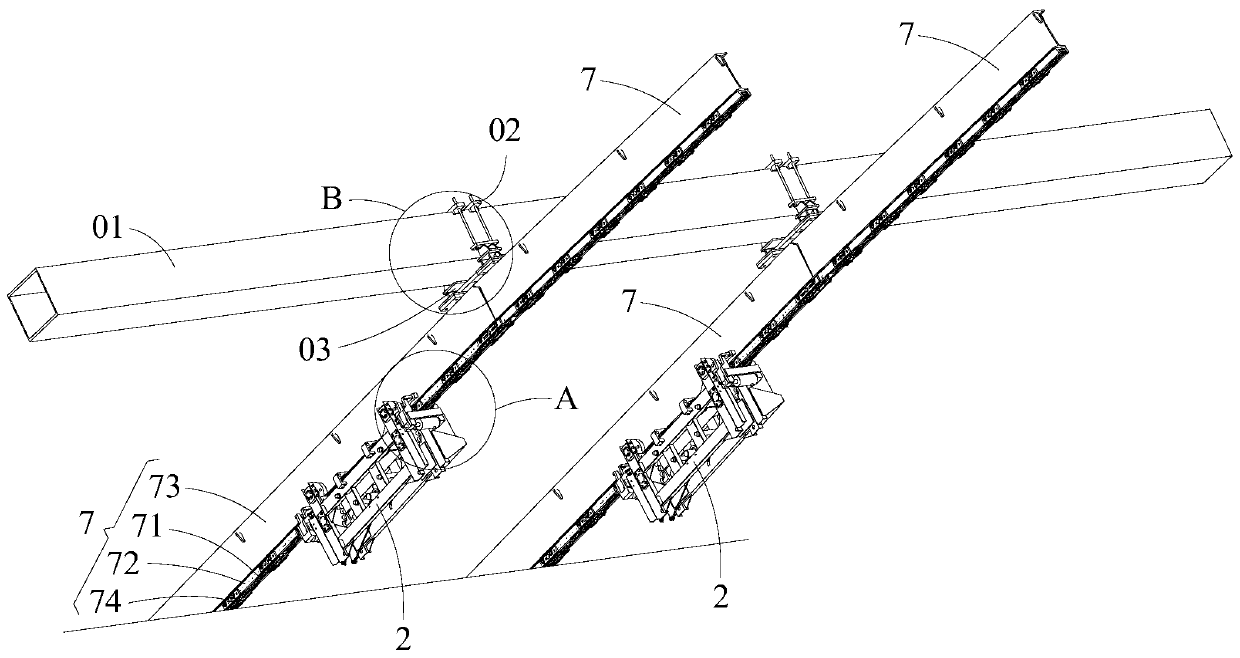

Fast deployment and control heavy oil containment boom

InactiveCN103321198AQuick deployment and recovery functionEasy rideWater cleaningGeneral water supply conservationWind speedPetroleum engineering

The invention provides a fast deployment and control heavy oil containment boom which comprises a plurality of oil containment boom units, wherein the oil containment boom units are connected in sequence to form an oil containment boom body. The upper area of each oil containment boom unit is a floating body zone, the middle area of each oil containment boom unit is a skirt zone, the lower area of each oil containment boom unit is provided with a counterweight chain, the floating body zone of each oil containment boom unit is at least provided with two inflation floating bodies, fast connector assemblies are arranged at two ends of each oil containment boom unit, and the adjacent oil containment boom units are connected through the fast connector assemblies respectively. Each inflation floating body is independent, and the adjacent inflation floating body can still keep the section of oil containment boom floating on the water if one inflation floating body is pierced. The adjacent oil containment boom units are fast connected through the fast connector assemblies respectively so that the oil containment boom units can be connected conveniently. The fast deployment and control heavy oil containment boom is fast in connection, can effectively achieve a fast launching and retrieval function and is especially applicable to the sea conditions with the wind speed at 25m / s and the tide at 4kn.

Owner:青岛华海环保工业有限公司

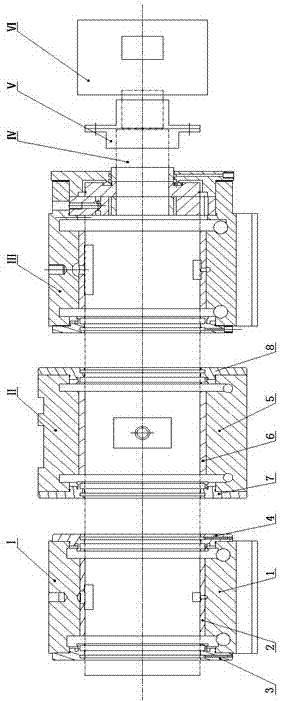

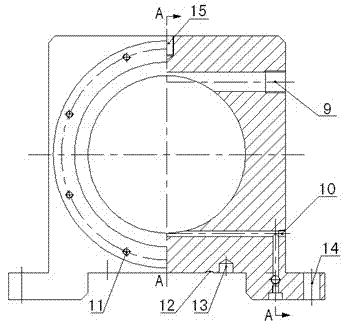

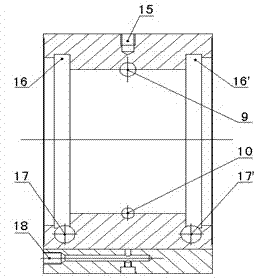

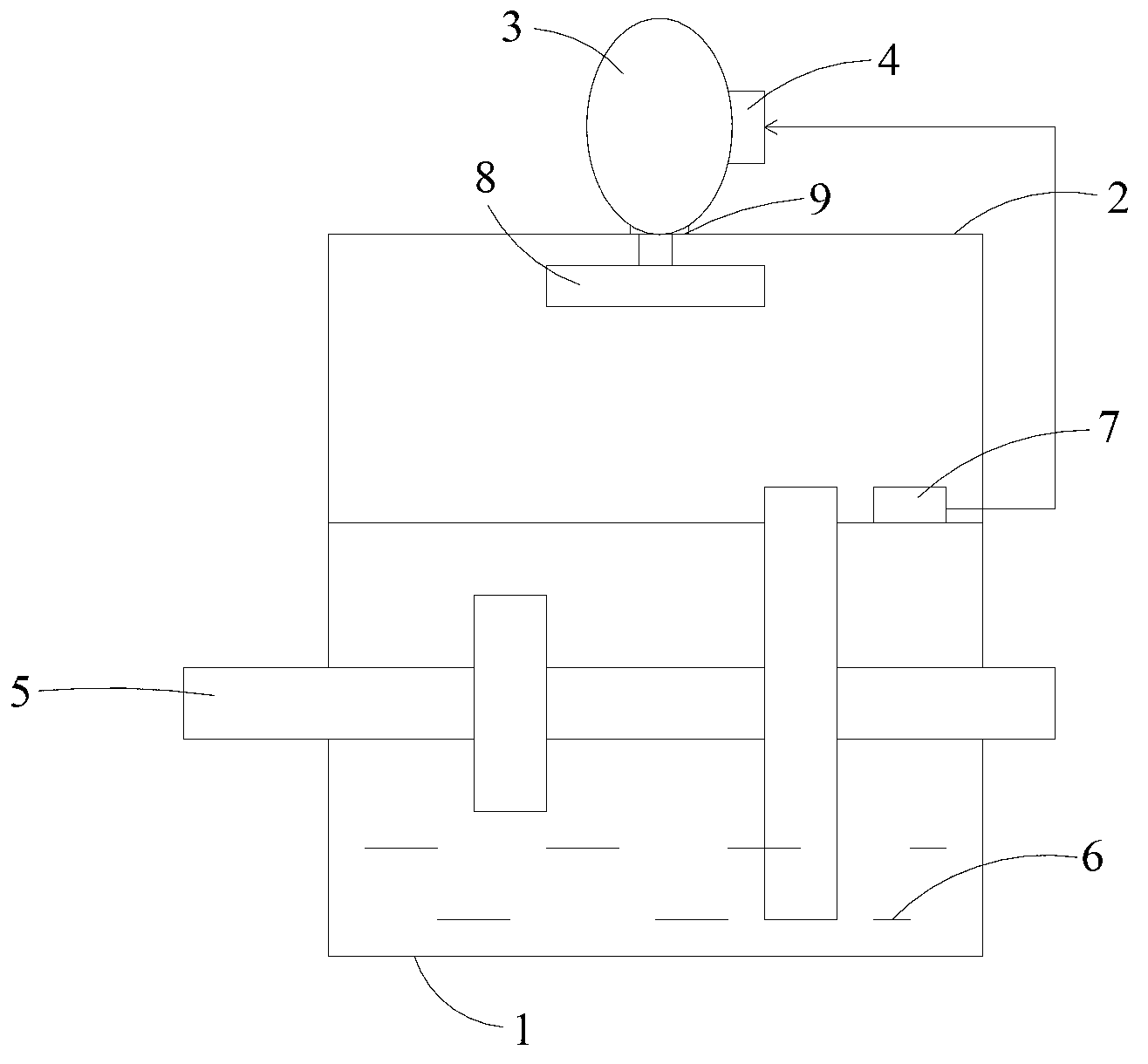

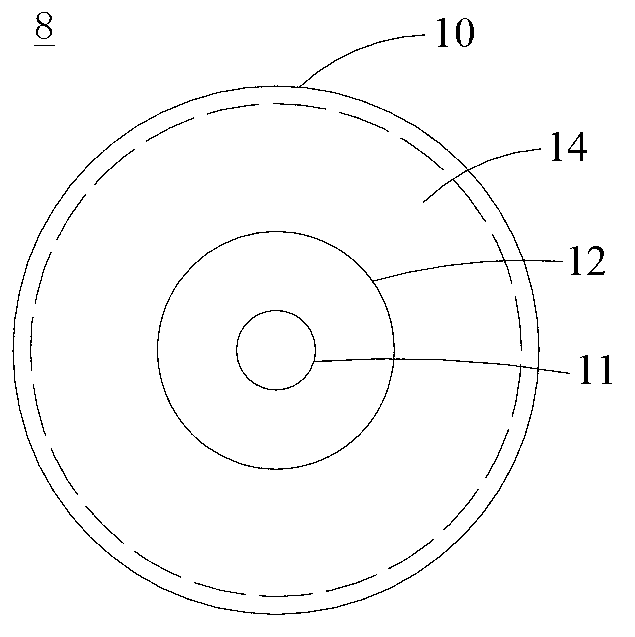

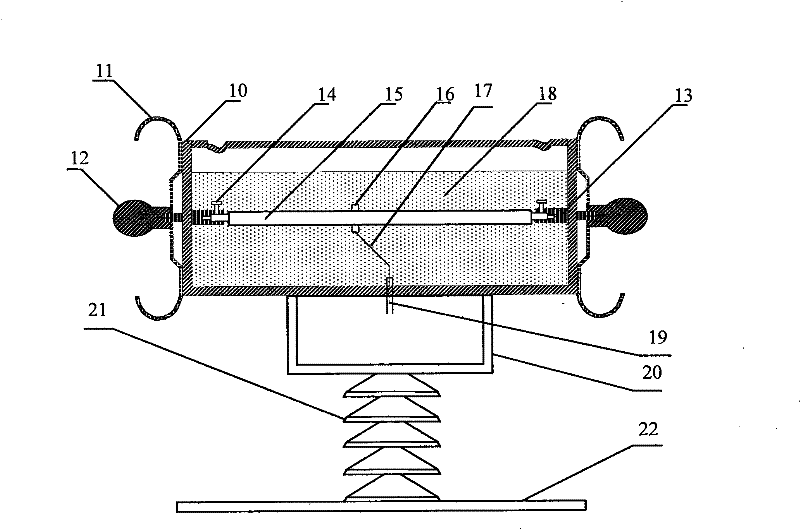

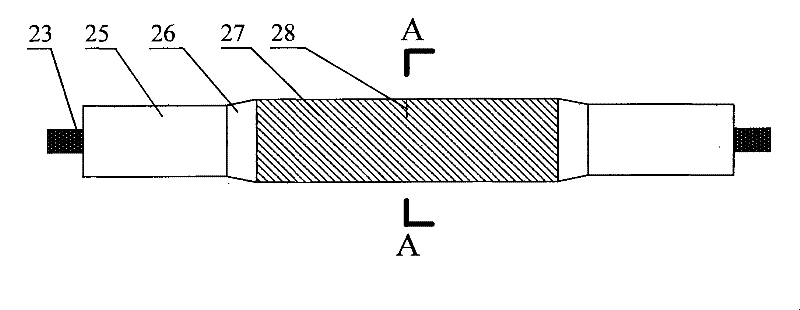

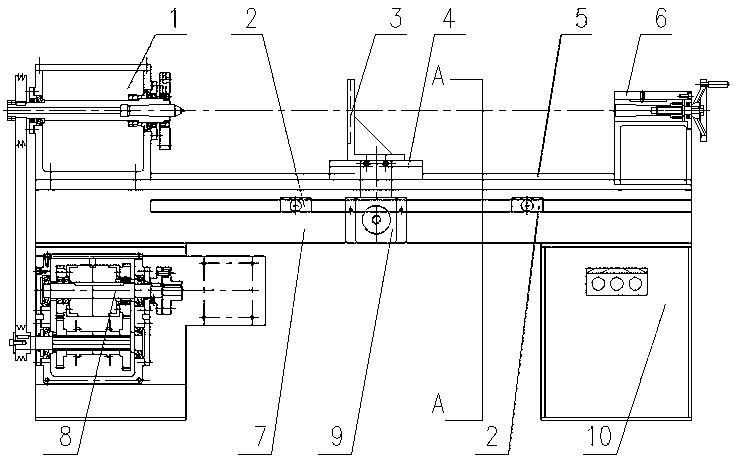

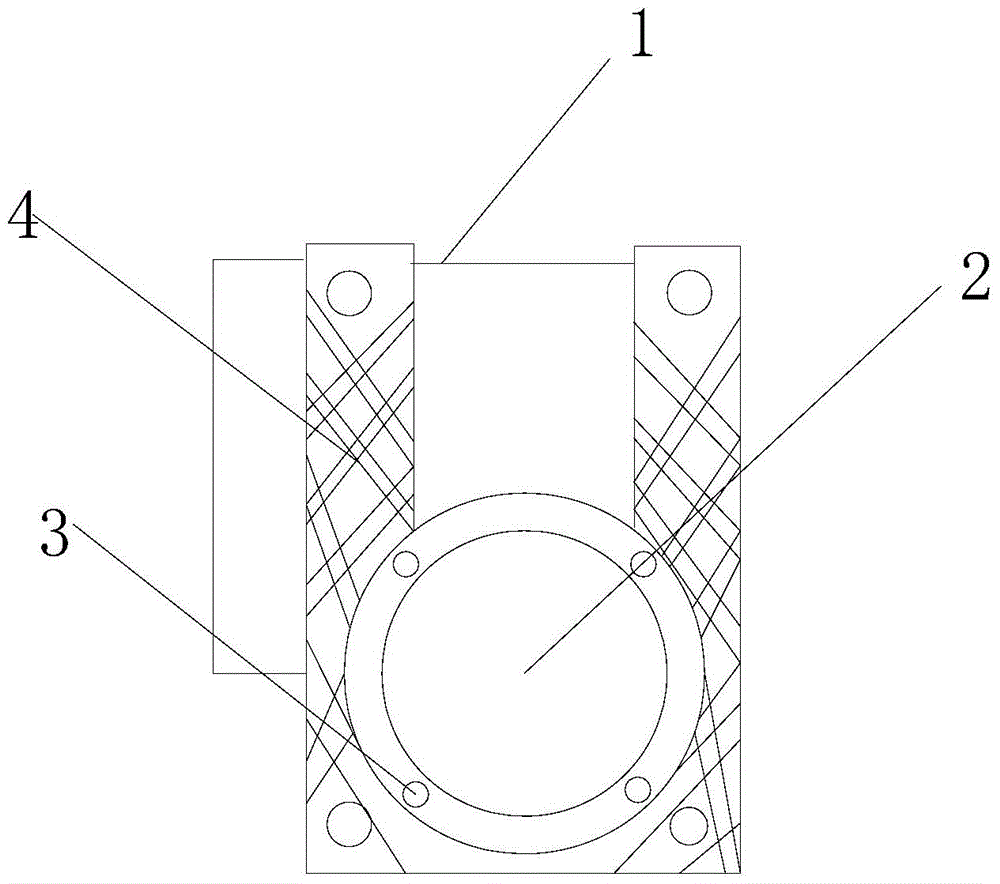

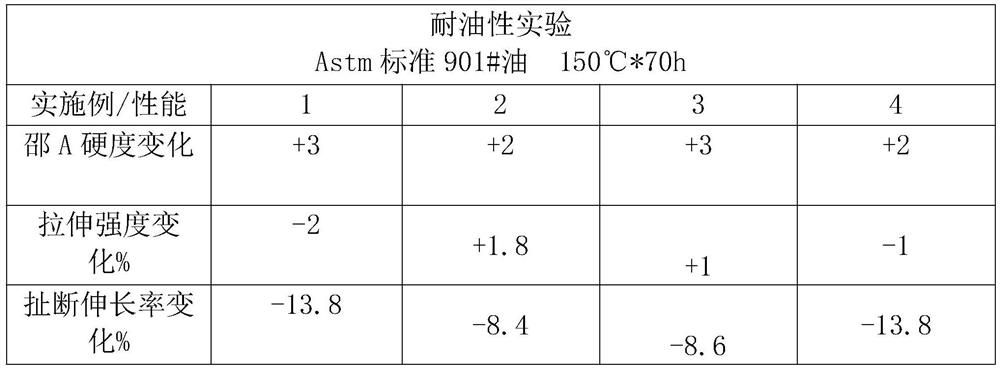

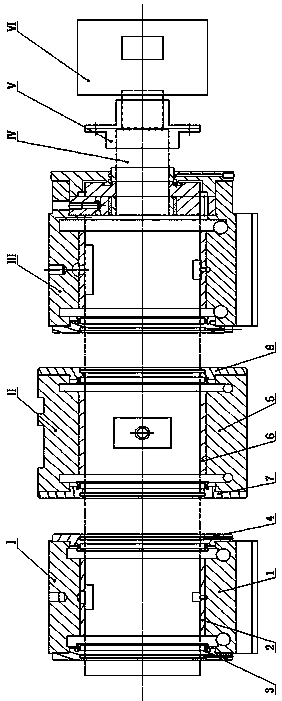

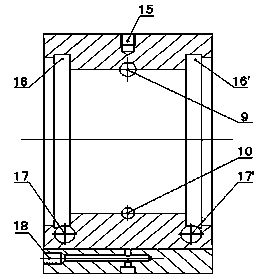

Comprehensive test device of oil film bearing

ActiveCN102854013AImprove poor oil circuit designNo frictionMachine bearings testingMiddle lineOil film

A comprehensive test device of an oil film bearing belongs to the technical field of the oil film bearing. The structure is as follows: a left bearing, a middle bearing and a right bearing are sequentially arranged from left to right; a shaft connected with a motor through a coupling is arranged inside a bearing hole; an oil path of the left bearing is provided with a dynamic press-in oil hole and a static press-in oil hole at upper and lower top points of a bearing block; oil grooves are arranged inside axle holes at the left end and the right end; the bottom part of each oil groove is communicated with an oil return hole; the dynamic press-in oil hole and a dynamic press-in oil cavity are arranged at the upper part of a vertical center line of a bush; the static press-in oil hole and a static press-in oil cavity are arranged at the lower part; the oil grooves communicated with the oil return hole are arranged on the inner surfaces of the axle holes of a left end cover and a right end cover; the oil path of the middle bearing is respectively provided with the dynamic press-in oil hole at the front and rear top points of the bearing block; the oil grooves are arranged inside the axle holes at the left end and the right end; the bottom part of each oil groove is communicated with the oil return hole; the dynamic press-in oil hole and the dynamic press-in oil cavity are arranged at the front end part and the rear end part of a radial center line of the bush; and the oil grooves communicated with the oil return hole are arranged at the inner surfaces of the axle holes of the left end cover and the right end cover.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

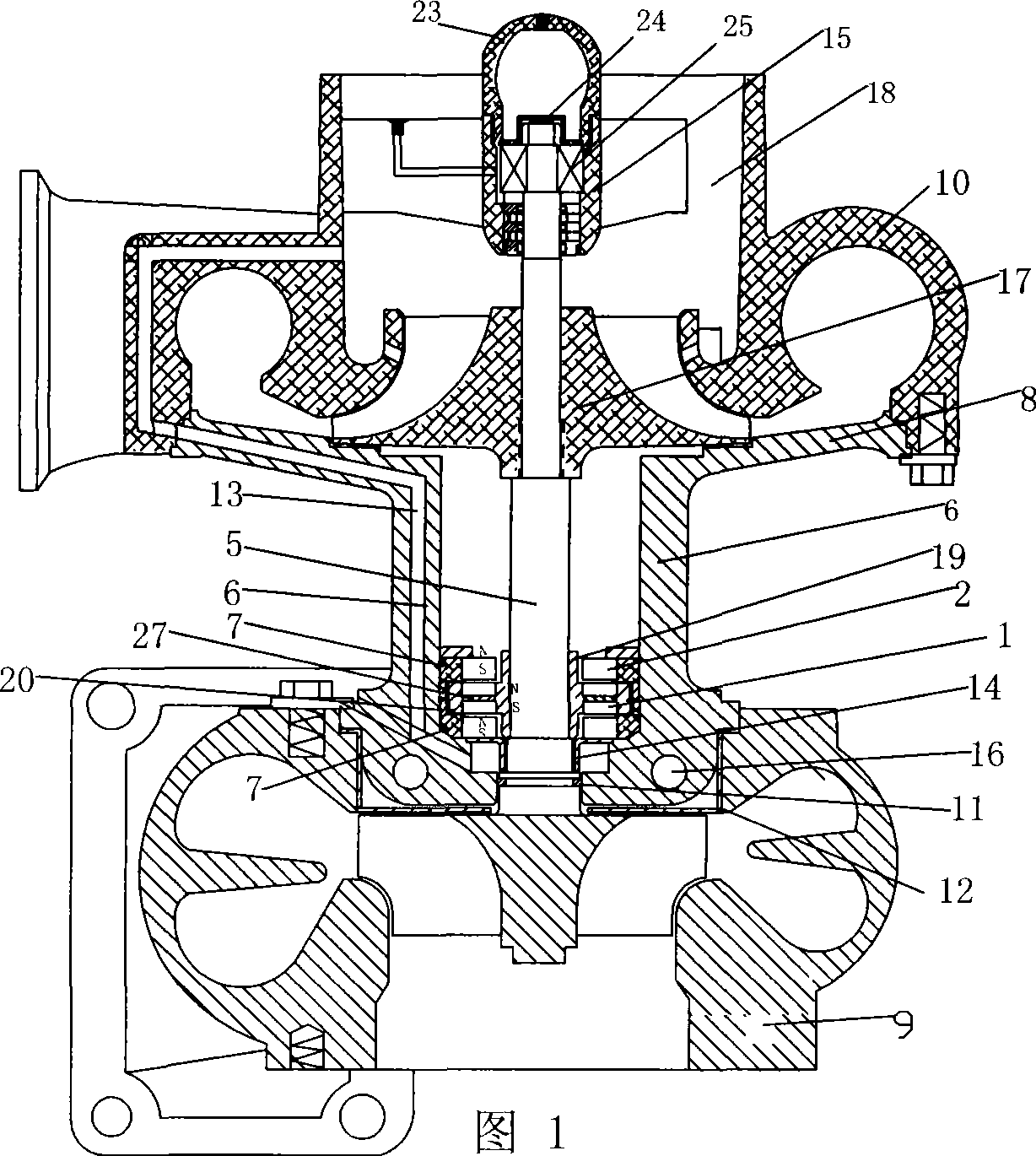

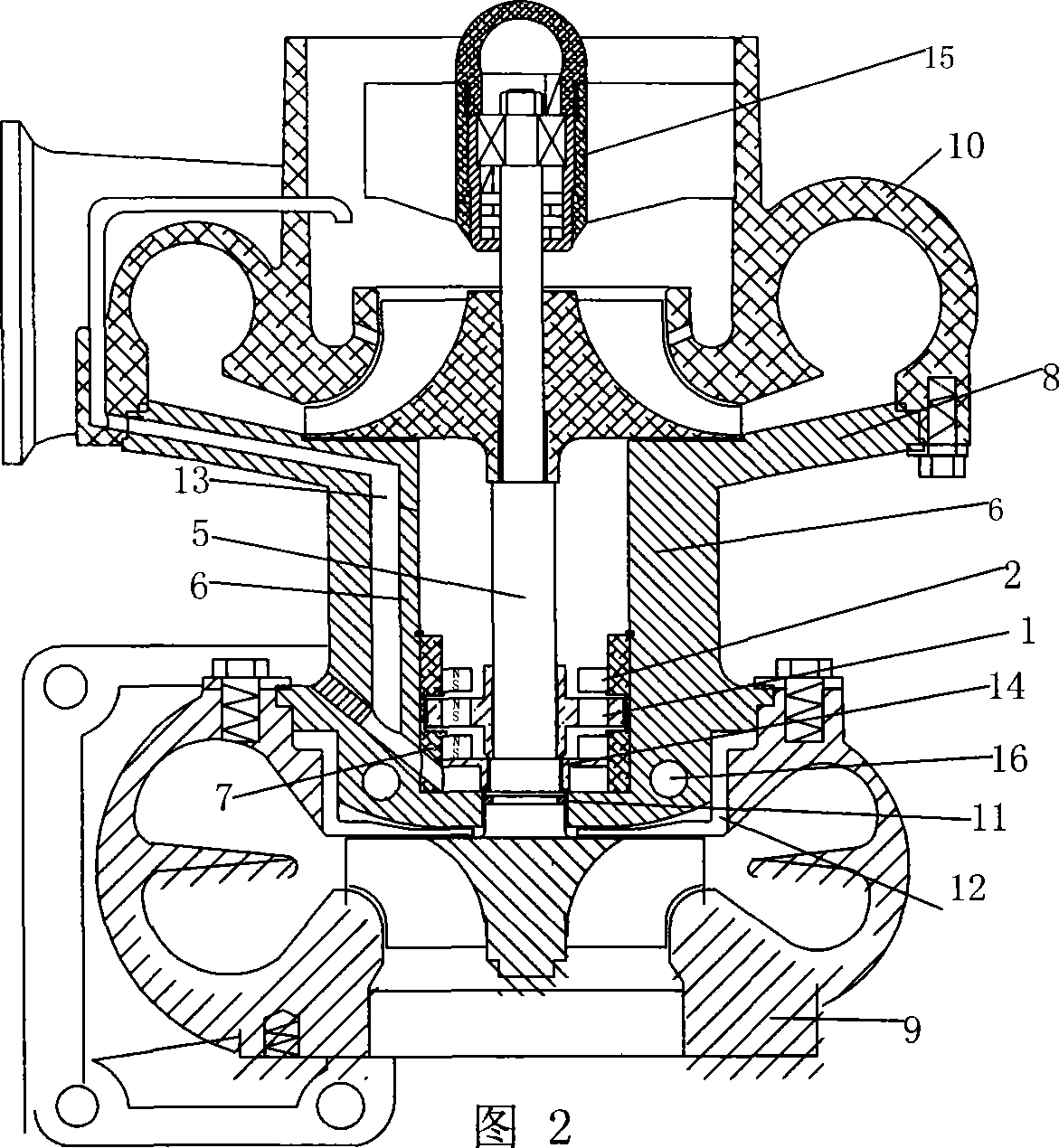

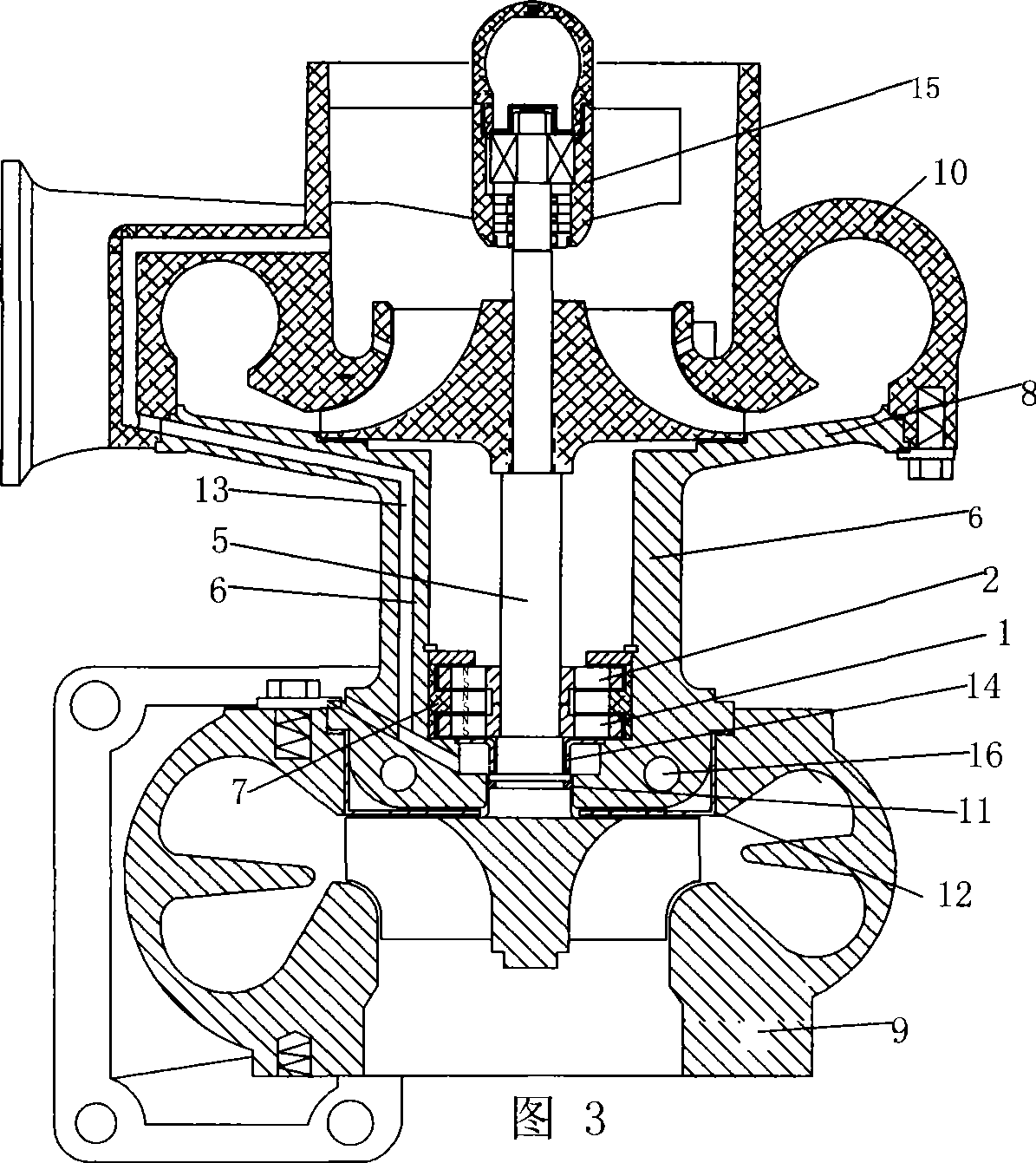

Turbocharger

InactiveCN101429878AImprove efficiencyNot vulnerableCombustion enginesGas turbine plantsImpellerTurbocharger

The invention discloses a turbocharger. The invention adopts a technical proposal that the turbocharger comprises a turbine rotor shaft assembly, an intermediate, a pressure housing, a diffusion plate fixedly connected with or integrally formed with the pressure housing, wherein the turbine rotor shaft assembly is at least provided with a set of permanent magnet rings matched with each other between a turbine and a compressor impeller. The permanent magnet rings comprise at least one permanent magnet dynamic ring and at least one permanent magnet static ring which are matched with each other to suspend a rotor shaft of the turbine rotor shaft assembly. The invention provides a friction-free turbocharger which uses permanent magnet rings to suspend the rotor shaft of the turbine. The turbocharger can solve the problems of susceptibility to damage, oil leakage and pollution, reduce response lags, and does not cause serious influence on the engine except for reduction in power when damaged. The turbocharger solves the problems of susceptibility to damage, oil leakage and pollution of the prior turbocharger and overcomes the drawbacks such as high price, large volume and complex structure of electromagnetic suspension bearing exhaust turbocharger.

Owner:南通通州江华纺织有限公司

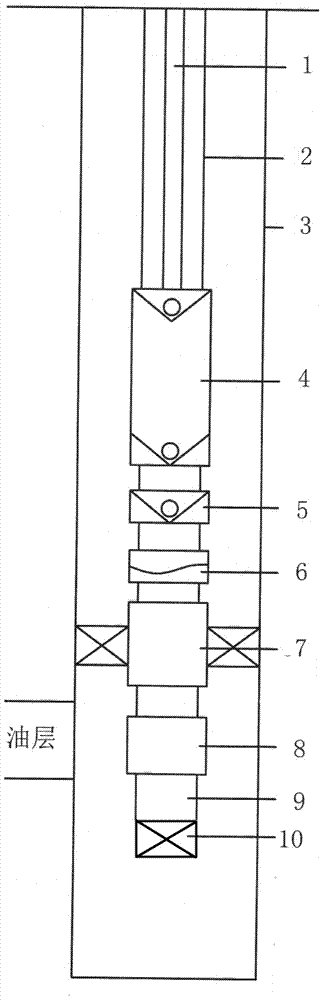

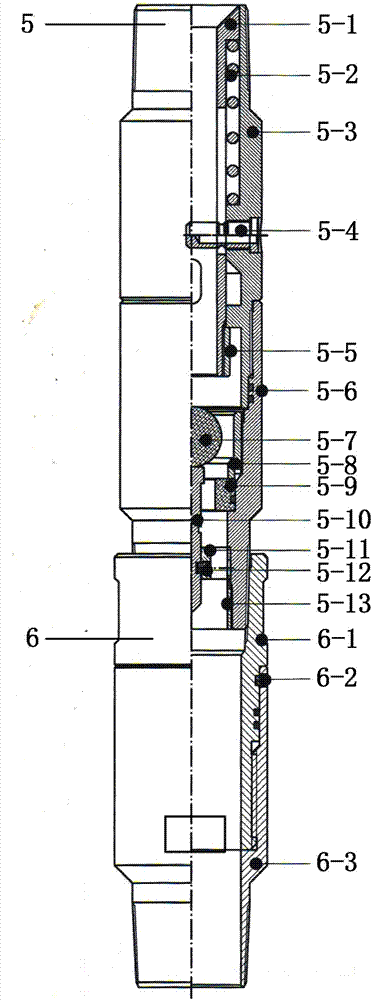

Steam flooding well production string and implementation method

PendingCN107013190AReduce operating proceduresReduce operating costsConstructionsFluid removalProduction stringOil well

The invention discloses a steam flooding well production string and an implementation method. The steam flooding well production string comprises a sucker rod, an oil tube, a sleeve, an oil well pump, an overpressure restrictor valve, a safety joint, an insertion pipe bridge plug, a bottom valve, a tail pipe and a pipe plug. The steam flooding well production string is characterized in that the oil tube is in threaded connection with the oil well pump; the lower part of the oil well pump is in threaded connection with a plunger and penetrates into the oil well pump through the oil tube; the oil well pump is in threaded connection with the overpressure restrictor valve through an oil tube nipple; the overpressure restrictor valve is in threaded connection with the safety joint; the safety joint is in threaded connection with the insertion pipe bridge plug; the insertion pipe bridge plug is in threaded connection with the bottom valve through an outer pipe; the bottom valve is threaded connection with the tail pipe; and the lower end of the tail pipe is in threaded connection with the pipe plug. Casual stopping and casual operation of a steam flooding well are achieved, the production time efficiency of the well is improved and the problem of leakage of a kill fluid in the operation process is solved. The steam flooding well production string has the key technology that the steam flooding well production string is provided for achieving crude oil pumping production through structural design and processing of the overpressure restrictor valve, the insertion pipe bridge plug and the insertion pipe bottom valve.

Owner:CHINA PETROLEUM & CHEM CORP +1

Welding method of stainless steel rectangular air pipe

InactiveCN102922100ANo oil spillImprove labor efficiencyArc welding apparatusRaw materialComposite material

The invention relates to a welding method of a stainless steel rectangular air pipe and belongs to the technical field of air exhaust, dust removal and oil-smoke exhaust pipelines. The welding method comprises the following steps: sleeving assembled two stainless steel plates by using a manufactured reinforcing frame, fixing by using a fixture and carrying out longitudinal argon arc welding; putting the two sections of formed stainless steel air pipe on a fixture table, fixing the stainless steel air pipe by using the fixture and then carrying out transverse argon arc welding; and finally pickling, passivating and cleaning. The welding method has the beneficial effects that no oil leakage exists, the labor efficiency and the quality are improved, and the labor cost and the raw materials are saved.

Owner:DALIAN ZHONGYING ENERGY MANAGEMENT

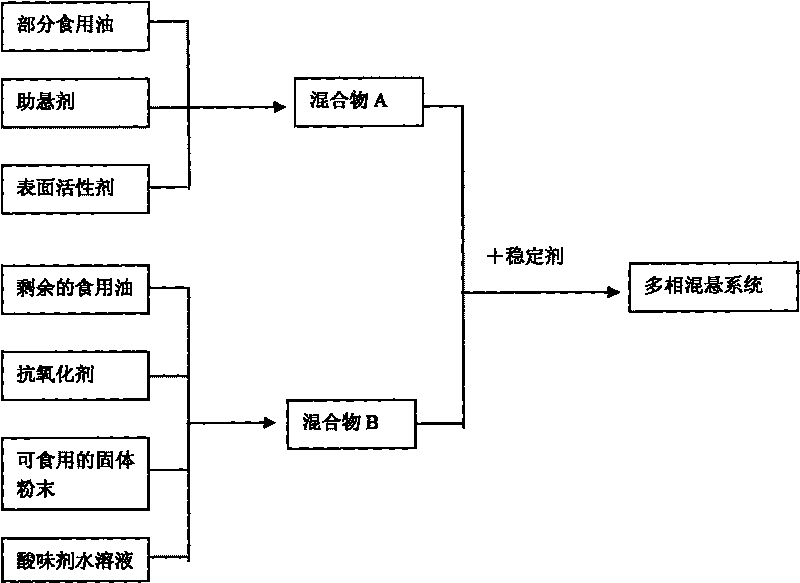

Multi-phase suspension system, preparation method and application thereof

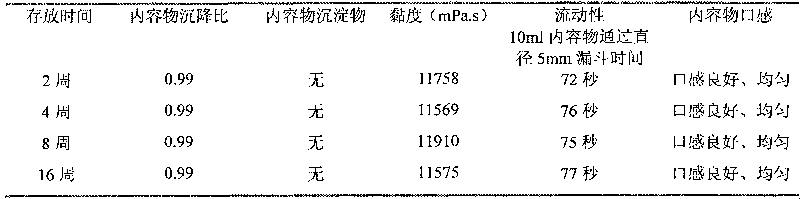

The invention discloses a multi-phase suspension system which is used in the field of foods and is formed by water, oil and solid powder, and a preparation method and application thereof. The multi-phase suspension system of the invention comprises the following components: 45 to 70 percent of edible oil, 1 to 10 percent of water, 10 to 40 percent of edible solid powder, 1 to 5 percent of surface active agent, 2 to 10 percent of stabilizer, 1 to 5 percent of suspending agent, 0.02 to 0.5 percent of antioxidant and 0 to 2 percent of acidity agent. The suspension system has uniformly distributed water, oil and solid powder, stable formed system, and difficultly separated water phase, oil phase and solid phase, thereby effectively preventing the hardening of a rubber sheet and avoiding the appearance of the phenomena of oil leakage and adhesion of soft capsules. Simultaneously, the suspension system has reduced greasy feel, and good taste, and is particularly suitable for the content of a chewable capsule. The multi-phase suspension system of the invention also can be added with flavor substances such as a sweetening agent, an essence and the like to adjust taste and flavor, and to satisfy market demand.

Owner:GUANGZHOU PROCEPT BIOTECH

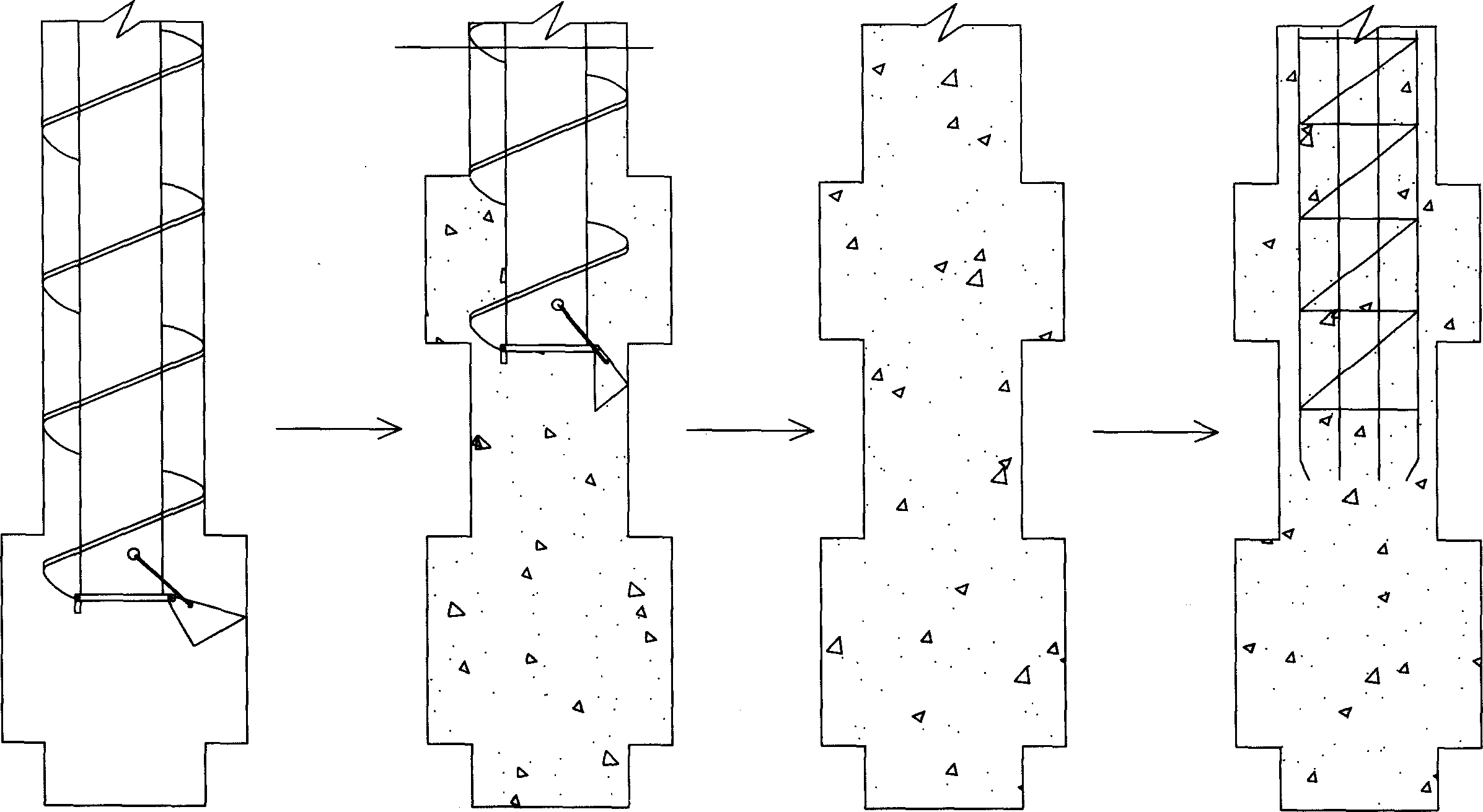

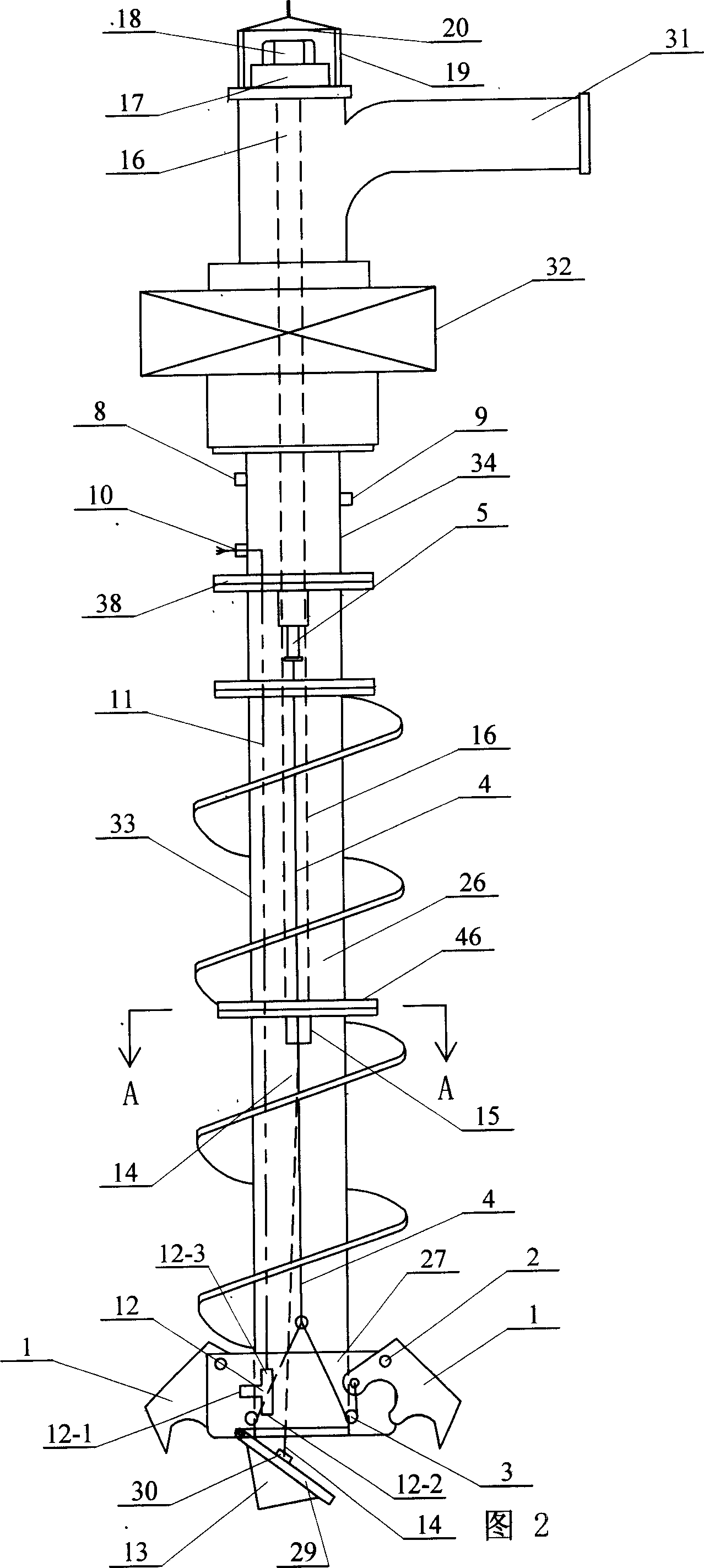

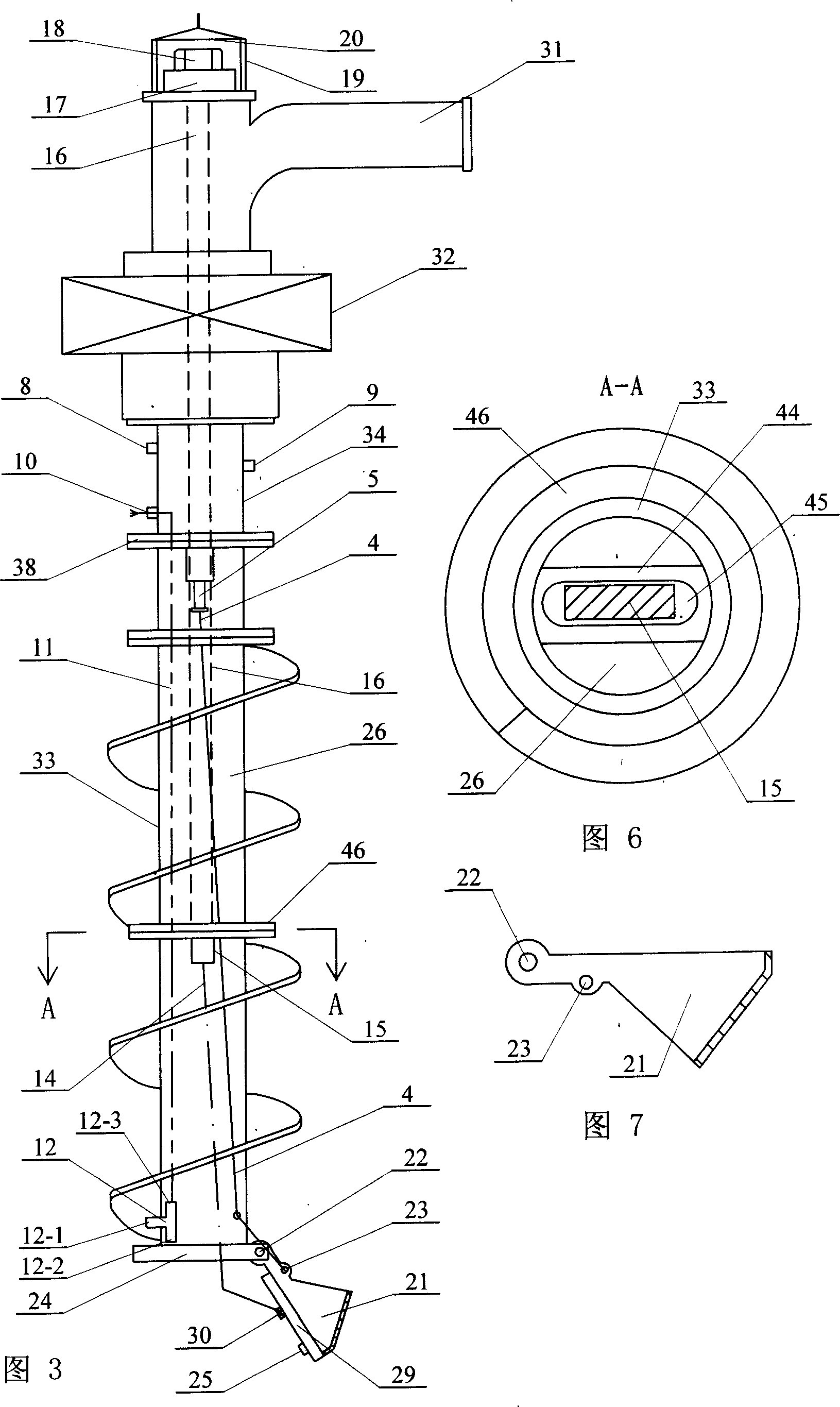

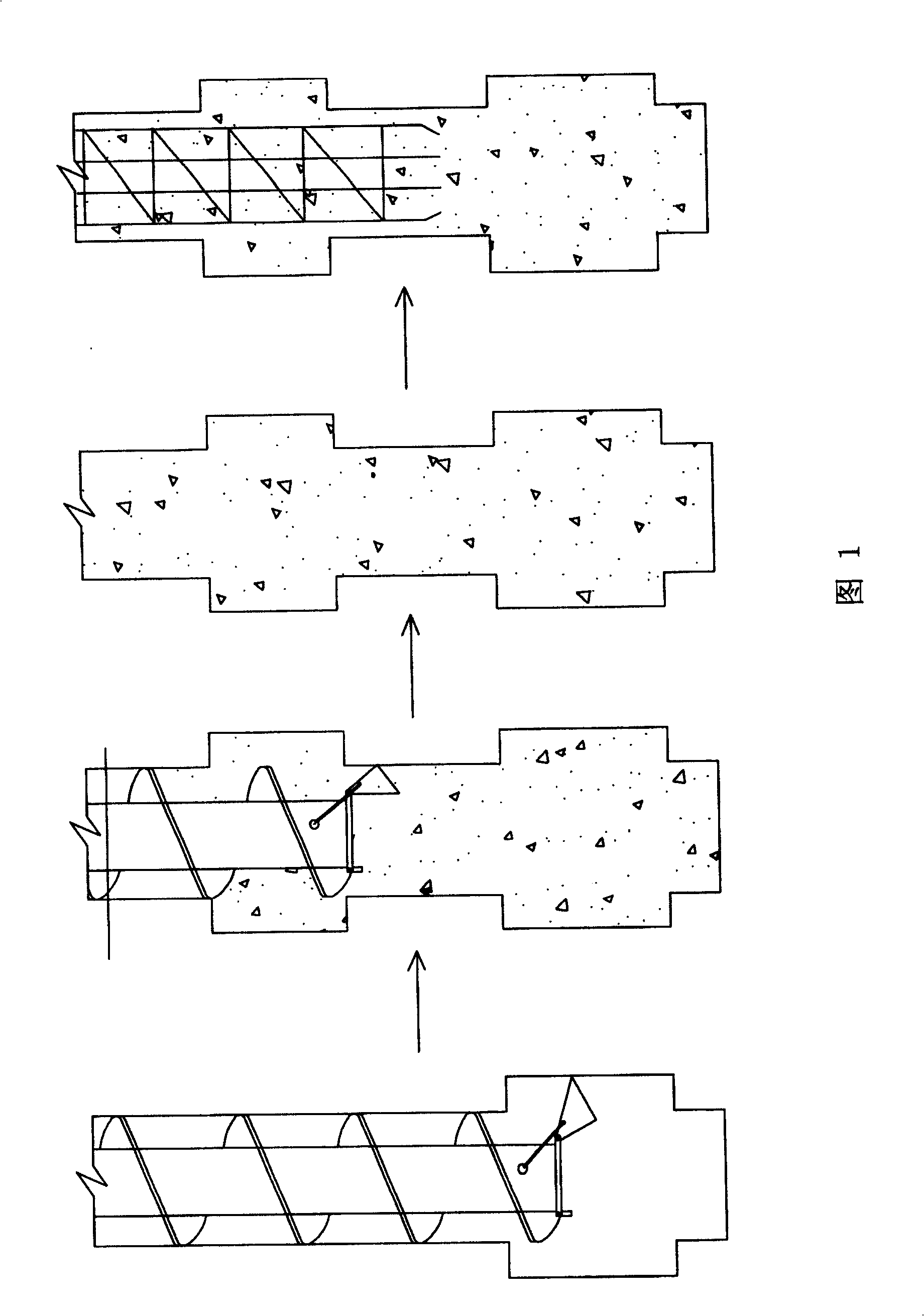

Piling method and piling device for borehole pump pouring large flow concrete ring pile

InactiveCN1888324AAvoid broken pilesEasy to open and closeBulkheads/pilesFoundation engineeringSlurry pump

The present invention relates to a concrete pile-forming method used in pile foundation engineering and its pile-forming equipment. Said invention is aimed at solving the problem of forming pile in poor subgrade with high underground water level and thick sand bed. Te invented method is characterized by that at the same time of forcedly injecting concrete, lifting the drill bit to designed height and making secondary diameter expansion, at the same time of opening drill bit plate, starting slurry pump to inject slurry, the height of diameter-expanded body is 800-1000 mm.

Owner:刘润郊

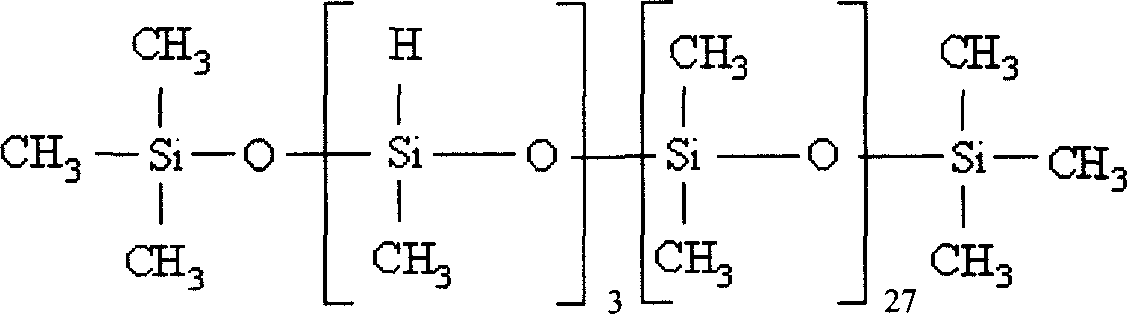

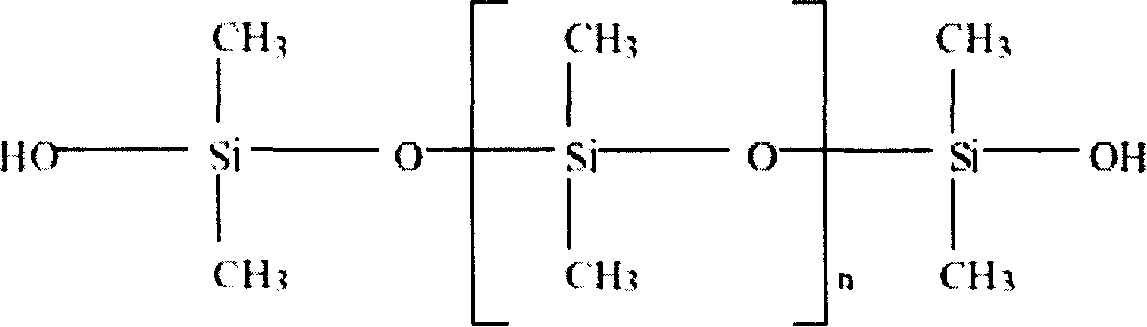

Heat conducting polysiloxane composition

This invention discloses a heat-conductive polysiloxane composition, which comprises components A, B, C and D. Component A is organic polysiloxane containing at least two alkenyl groups (viscosity at 25 deg.C is 10-100,000 mm2 / s). Component B is organic hydrogenated polysiloxane containing at least two hydrogen atoms directly bonded to silicon atom. Component C is highly heat-conductive aluminum powder or metal oxide powder filler. Component D is titanate coupling agent or aluminum coupling agent. The heat-conductive polysiloxane composition has such advantages as stable condition and no oil spill.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

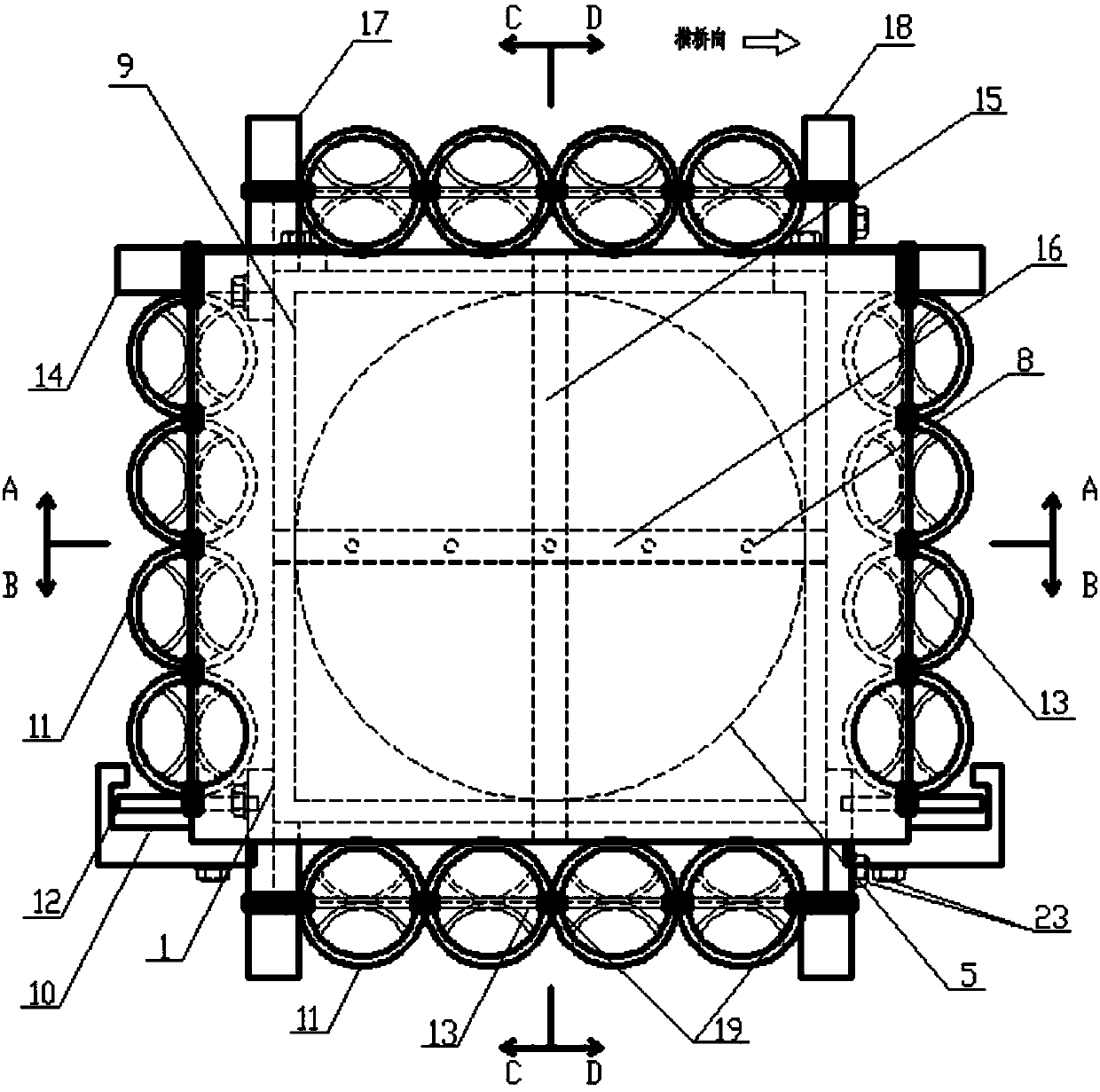

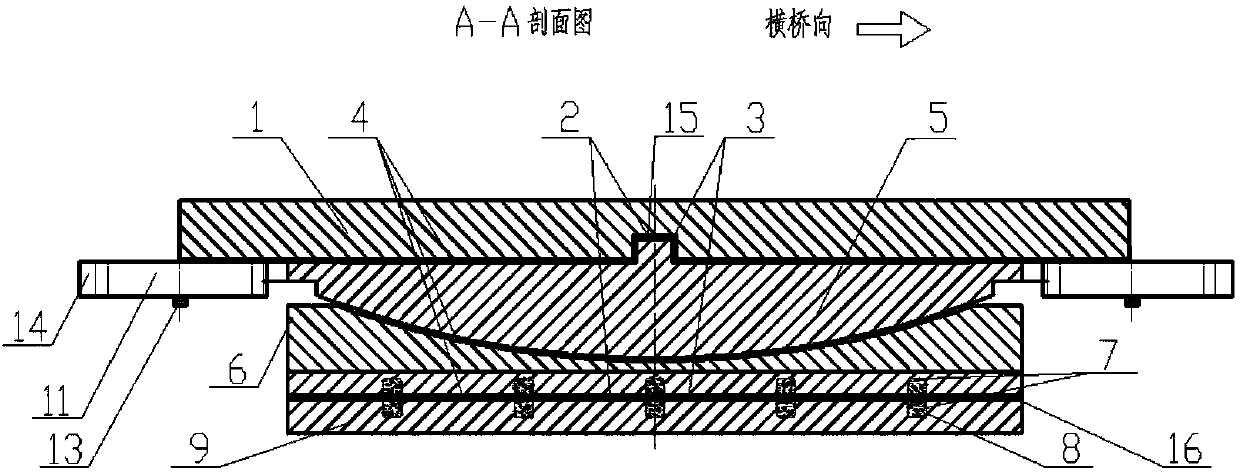

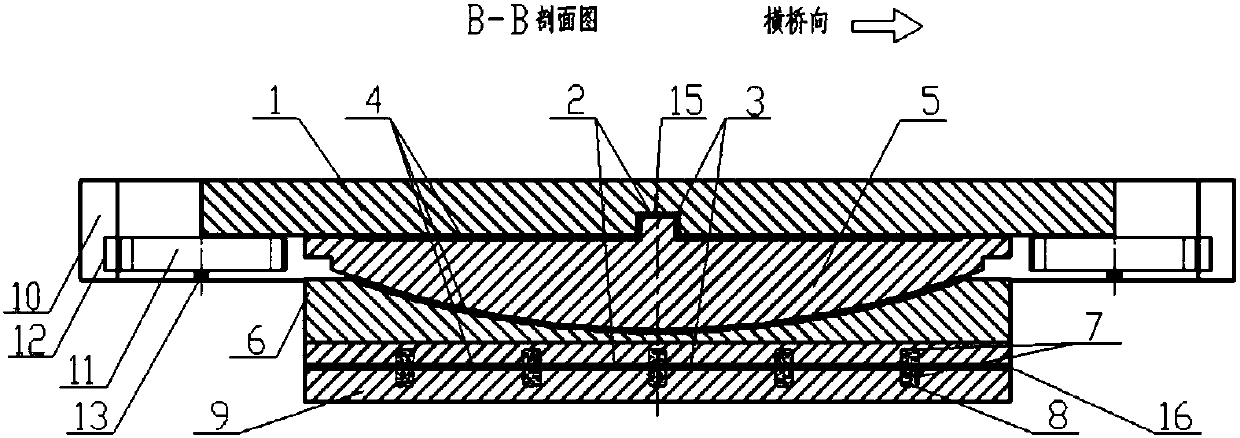

Elastic-plastic structure damping support

ActiveCN110306426AGuaranteed stabilityControl Relative DisplacementBridge structural detailsBridge materialsElastic plasticEnergy consumption

The invention relates to an elastic-plastic structure damping support which comprises a supporting module and a damping module. The supporting module comprises an upper top plate, a spherical crown, amiddle lining plate and a lower bottom plate which are arranged in an overlapped manner from top to bottom, wherein sliding faces capable of moving relatively in the longitudinal direction of a bridge and the transverse direction of the bridge are machined between the upper top plate and the spherical crown and between the lower bottom plate and the middle lining plate correspondingly, and the spherical crown and the middle lining plate are in contact connection through a spherical face. The damping module comprises limiting energy consumption assemblies which are arranged in the longitudinaldirection of the bridge and the transverse direction of the bridge correspondingly, wherein the two ends of the limiting energy consumption assembly arranged in the longitudinal direction of the bridge are connected with the upper top plate and the spherical crown correspondingly, and the two ends of the limiting energy consumption assembly arranged in the transverse direction of the bridge are connected with the lower bottom plate and the middle lining plate correspondingly. Compared with the prior art, the elastic-plastic structure clamping support can adapt to telescopic deformation of a main beam under the temperature effect, circular ring parts have an energy consumption effect and a limiting effect, the problems of oil leakage, blockage and the like do not exist, demounting and mounting can be conducted according to practical needs, and daily support maintenance and post-earthquake replacement are facilitated.

Owner:TONGJI UNIV

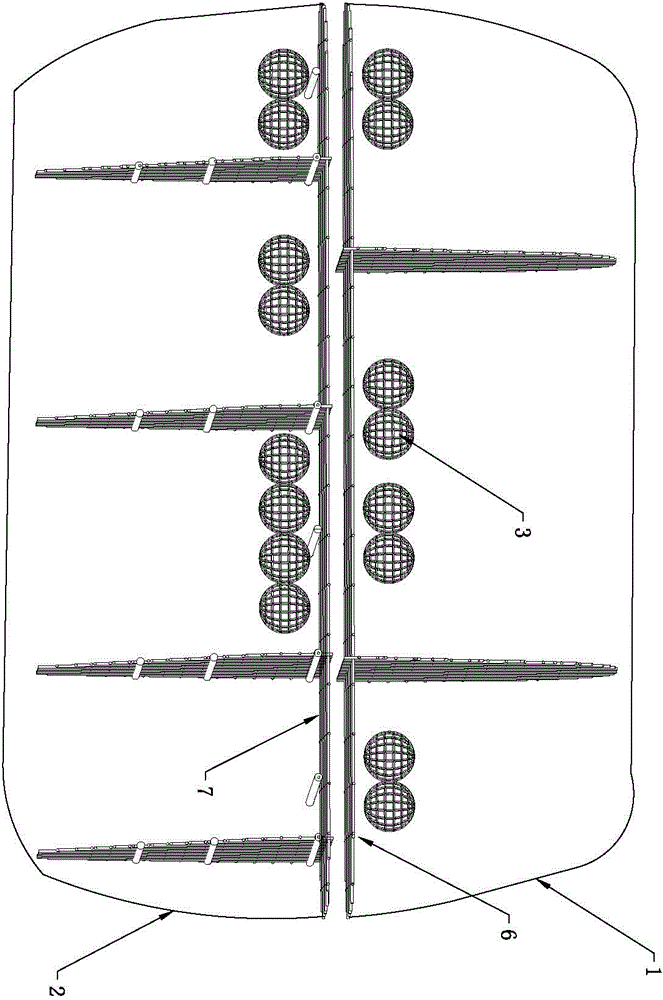

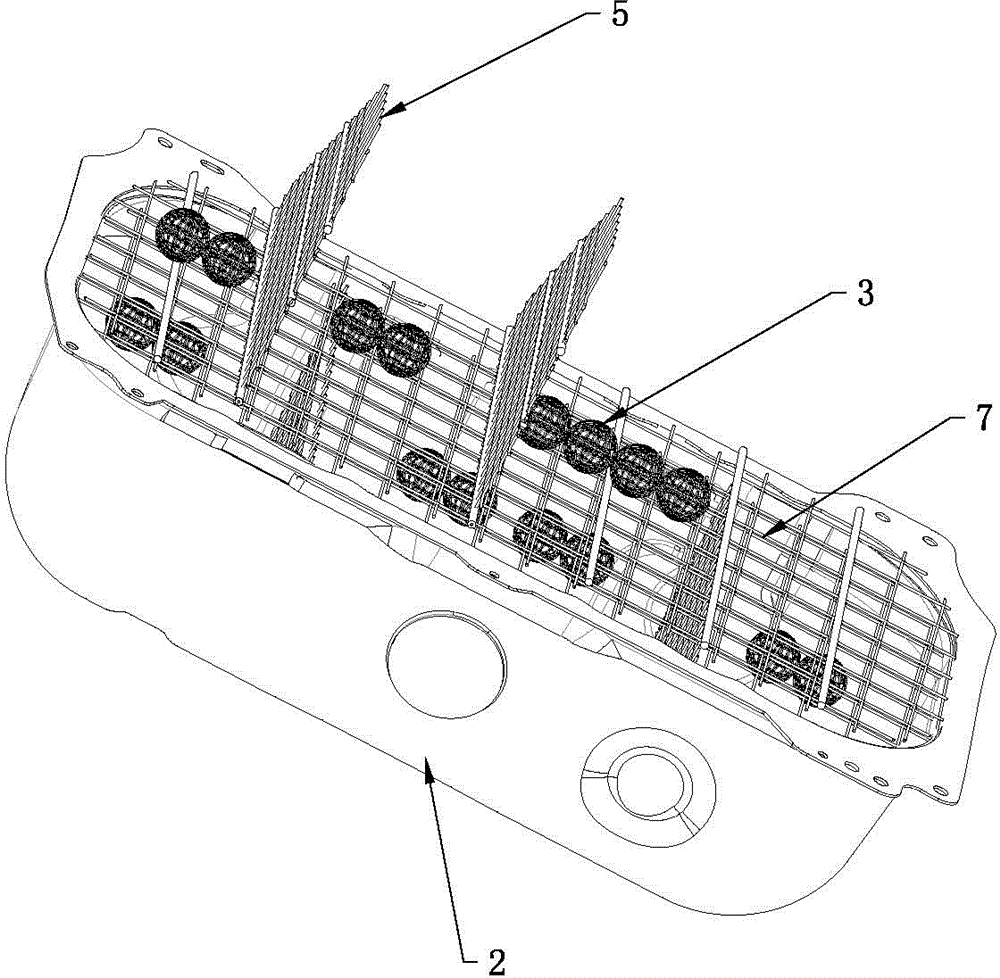

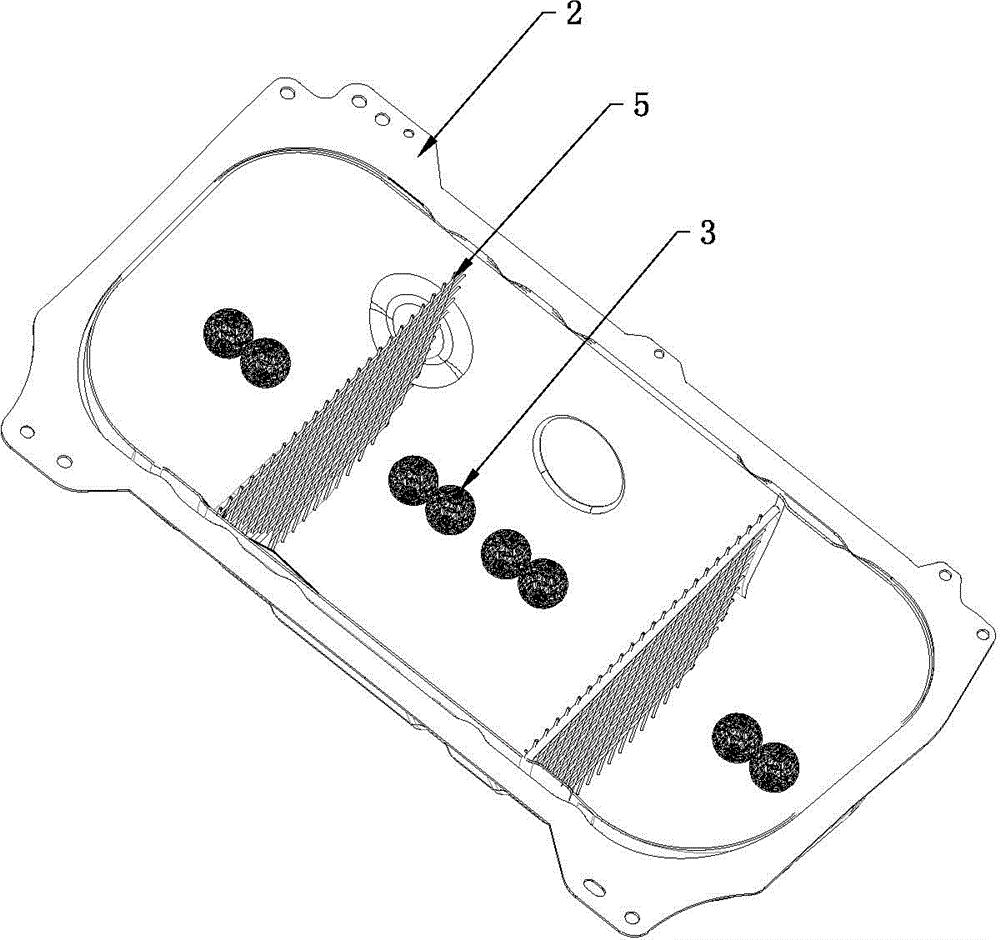

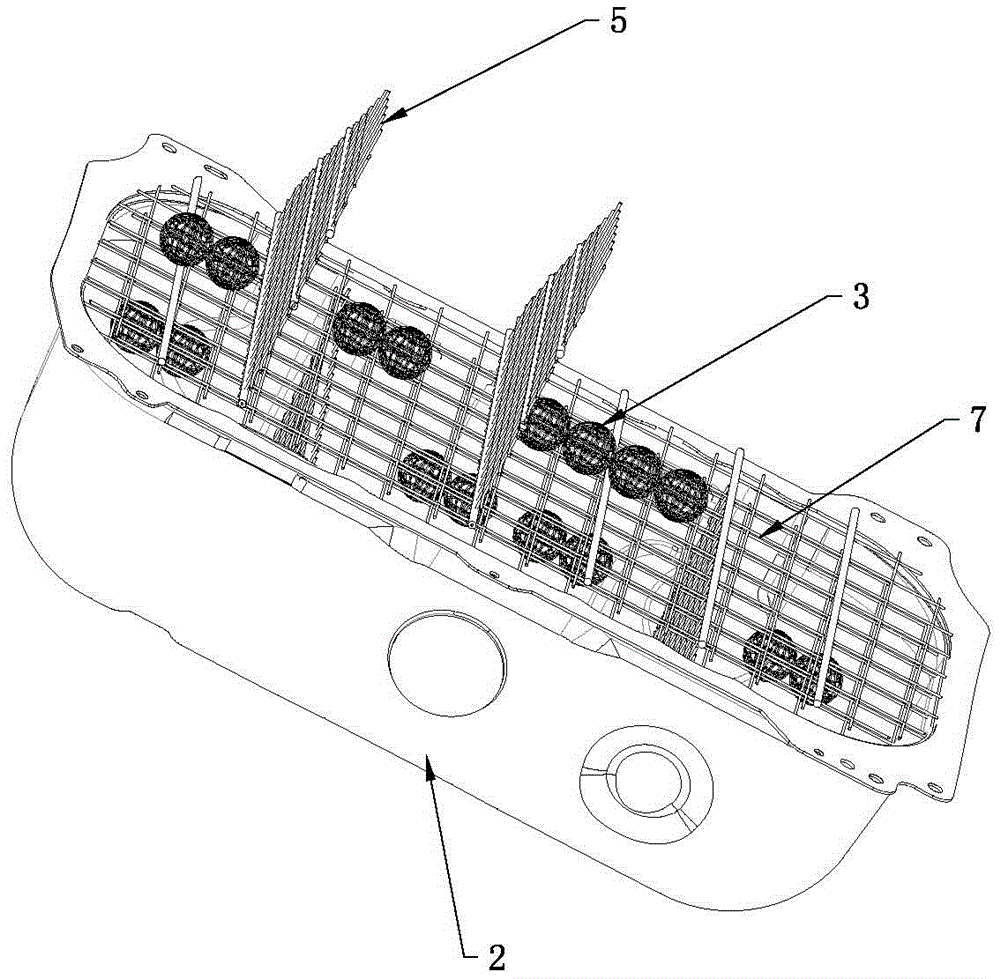

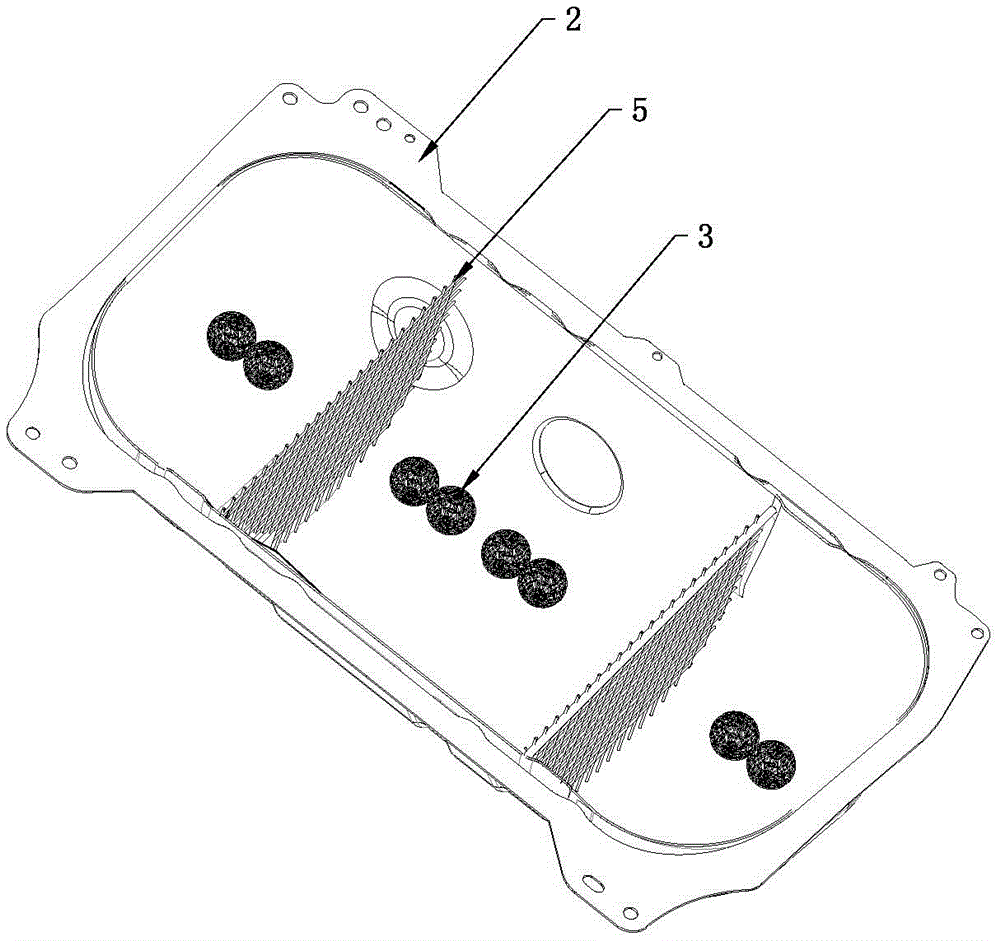

Explosion suppression oil tank

InactiveCN103600652ARapid responseAvoid situations that affect normal workUnderstructuresFuel supplyOil canThermodynamics

The invention discloses an explosion suppression oil tank which comprises a tank, explosion suppression bodies and grid protective covers. The explosion suppression bodies are filled in the tank, the grid protective covers are sleeved on the outsides of oil level sensors, the explosion suppression bodies are of porous structures and are made of aluminum foils which are blocking explosion suppression materials for oil tanks of petrol stations, and a publication patent number of the aluminum foils is CN102181756B; gratings which divide the inside of the tank into more than two cavities are arranged in the tank, and the explosion suppression bodies are arranged in the cavities; an oil filling shield is arranged at an oil filling port of the tank. Compared with the prior art, the explosion suppression oil tank has the advantages that the oil level sensors can be effectively prevented from being jammed by the explosion suppression bodies filled in the tank, and oil through holes are formed in the surface of the oil filling shield, so that oil can smoothly flows into the tank, the explosion suppression bodies can be effectively prevented from jamming the oil filling port, and phenomena of gun jumping and oil spilling can be effectively prevented; a gas expansion degree of the oil tank can be effectively controlled by the explosion suppression bodies, so that the pressure of the inside of the oil tank is low in variation, and explosion can be suppressed.

Owner:茂名市亚泰铝合金抑爆材料有限公司

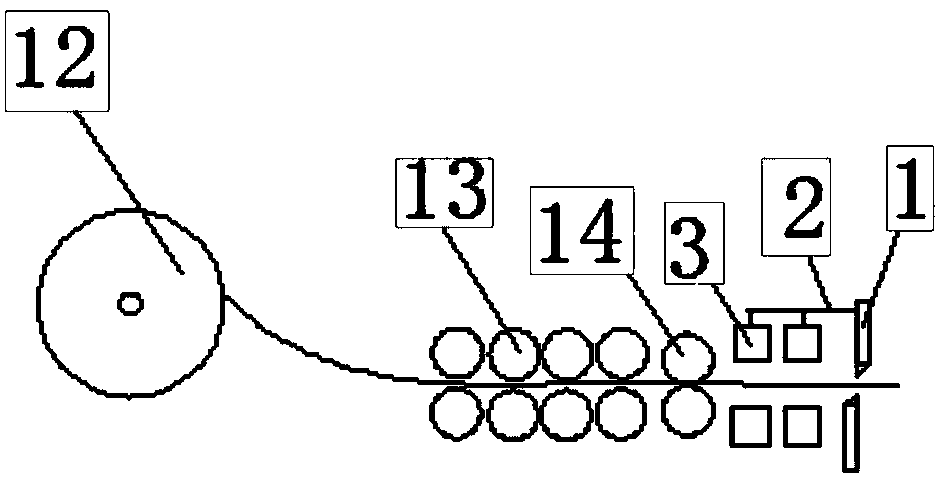

Air flue plate processing device and method

InactiveCN103862291AWill not blockHigh structural production efficiencyOther manufacturing equipments/toolsProduction linePunching

The invention relates to the field of machinery, in particular to an air flue plate processing device and an air flue plate processing method. The original fully oil pressure driving production line is created into a mechanical production line, an oil pressure type plate shearing machine is modified into a mechanical plate shearing machine, the comprehensive assistance is realized, meanwhile, large openings and small openings are punched, when the cutting is needed, a template needs to be used for punching, an air cylinder shaft of a moving air cylinder extends out, during the descending cutting of a plate shearing upper knife, an upper template is also driven to be downwards pressed and is in contact with a lower template for punching holes. Compared with the prior art, the air flue plate processing device and the air flue plate processing method adopting the technical scheme have the following beneficial effects that the production efficiency is higher than that of the original oil pressure structure; no oil leaks, and an electromagnetic valve cannot be blocked; the cost (including the manufacturing cost and the processing cost) is reduced; the stability and the uniformity of processed products are better, equipment is not influenced by temperature, and the work of the equipment is stable and reliable.

Owner:张建军

Low-pressure anti-seepage device of gearbox

ActiveCN103277495ARealize automatic controlNo pollutionGearing detailsAutomatic controlControl system

The invention provides a low-pressure anti-seepage device of a gearbox. The low-pressure anti-seepage device comprises a gearbox casing, a transmission shaft system arranged in the casing, lubricating media contained in the casing and used for lubricating the transmission shaft system, a vacuum pump and a control system which are arranged above the casing, a pressure sensor located on the inner wall of the casing and used for detecting pressure in the casing and a porous material rotating disk arranged on the surface of the inner wall of the casing and used for adsorbing the lubricating media. The vacuum pump is arranged on the casing so that pressure in the casing can constantly keep being lower than pressure of the external environment. The porous material rotating disk is arranged at the position corresponding to an air exhaust of the vacuum pump so that the lubricating media can be prevented from being sucked into the external environment. Automatic control on starting and stopping of the vacuum pump can be achieved through the pressure sensor and the control system. Therefore, the low-pressure anti-seepage device has the advantages of being free of oil seepage, not polluting the environment and being capable of achieving automatic control.

Owner:TAIZHONG TIANJIN BINHAI HEAVY MACHINERY

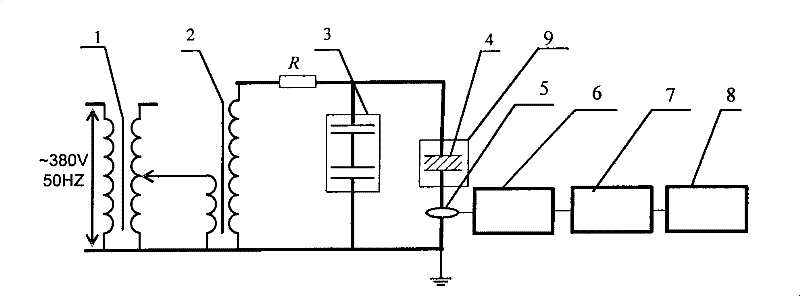

Test method and apparatus for polymer power cable insulation accelerated electric tree aging

InactiveCN101464235BEasy to makeGood choiceTesting dielectric strengthPreparing sample for investigationTransformerCurrent sensor

The invention provides a polymer power cable insulation acceleration electrical tree aging test method and a device, which relate to a testing device for monitoring polymer power cable insulation electrical tree aging and a method thereof. The device provided by the invention comprises a non-vignetting testing transformer, an induction voltage regulator, a capacitance voltage divider, a testing electrode, a broad band current sensor, an amplification filter, a digital oscillograph, a microcomputer and an electrothermal combined aging oven. The method provided by the invention comprises the following steps: the testing preparation is carried out with the device provided by the invention; a test sample is subjected to local discharge data acquisition and processing through a program; and the image and the basic data of the insulation electrical tree branching of the test sample are obtained through slicing and photographing. The device provided by the invention has the advantages of high pressure resistance and heat resistance level, small amount of self-local discharge, and safe and reliable use. The method provided by the invention has the characteristics of convenient and accurate use, and the like. The invention can be widely applied to the field of monitoring the insulation aging of a power cable, in particular to the field of monitoring the insulation electrical tree agingof a polymer power cable.

Owner:CHONGQING UNIV

Composition object of heat conducting polusiloxane, and electronic component combination of using the composition object

InactiveCN101050356AAvoid easy separationImprove reliabilityHeat-exchange elementsCooling/ventilation/heating modificationsHeat conductingElectronic component

This invention discloses a heat-conducting silicone composition used in electronic combined component. The heat-conducting silicone composition comprises: component A (organic silicone with hydroxyls), and component B (highly heat-conducting inorganic filler). The heat-conducting silicone composition has such advantages as high application stability and no oil overflow.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

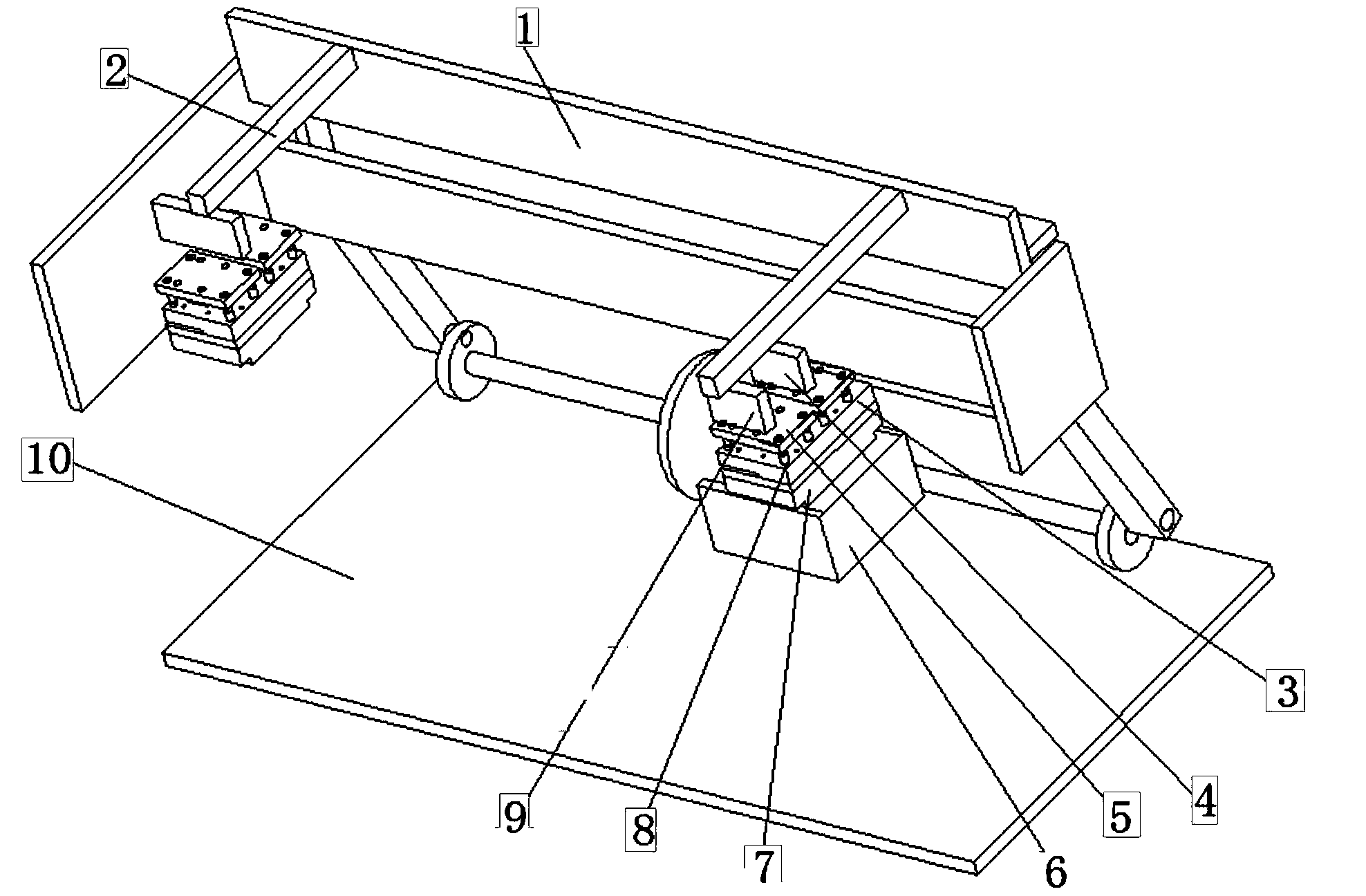

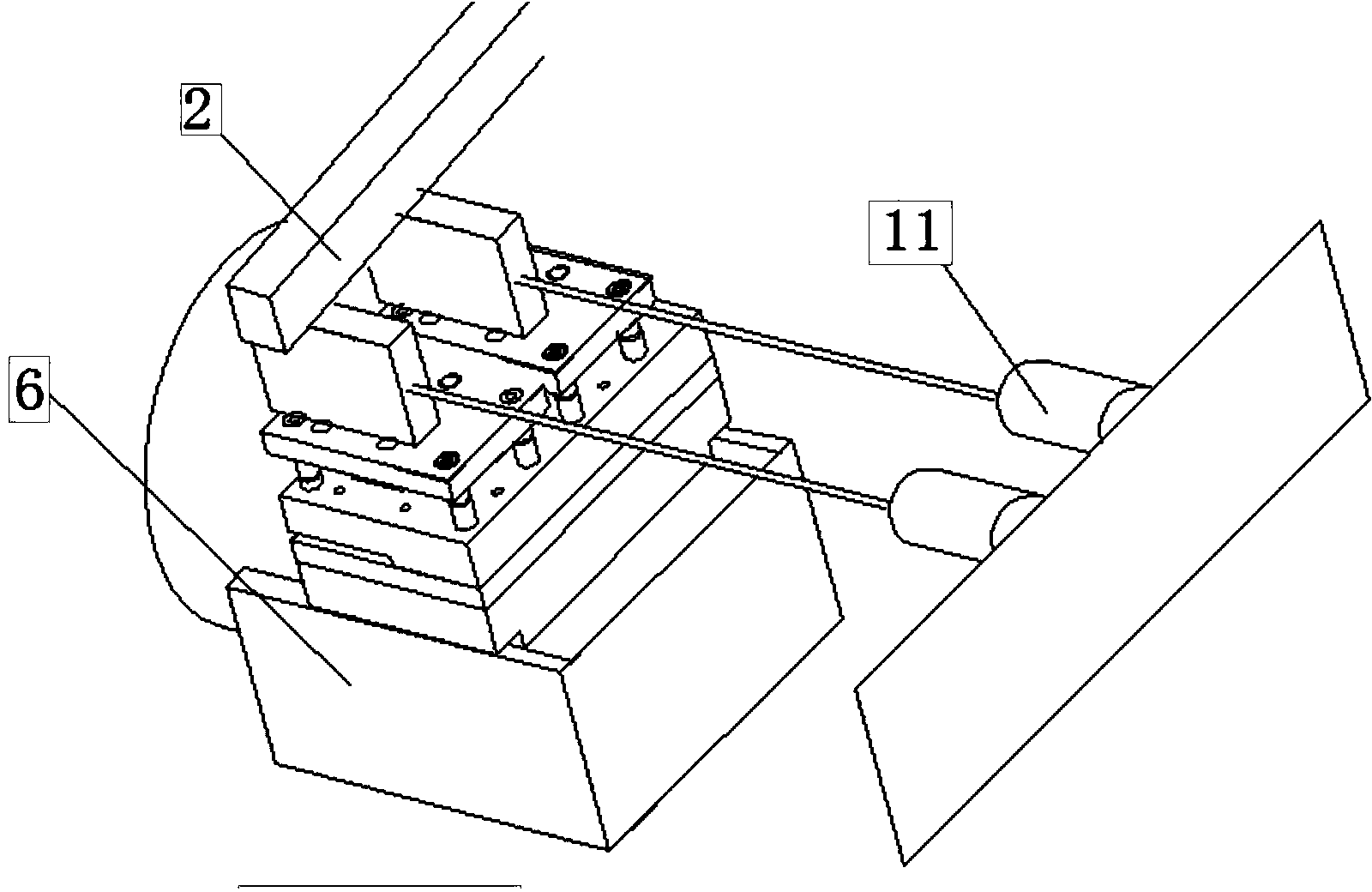

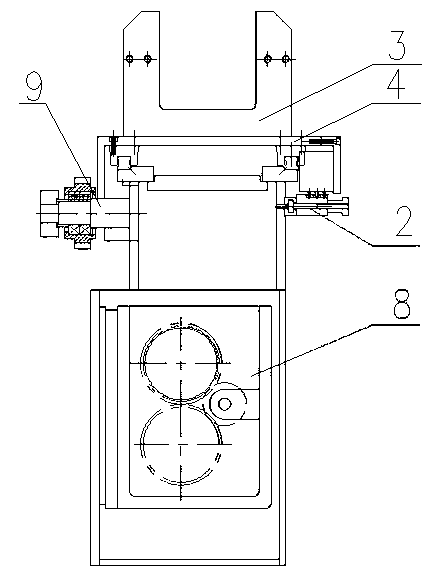

Running-in testing method of loading running-in device for ball screw pair

InactiveCN102445340BImprove factory performanceGood running-in effectMachine gearing/transmission testingTest performanceBrake

Owner:中润海精密科技有限公司

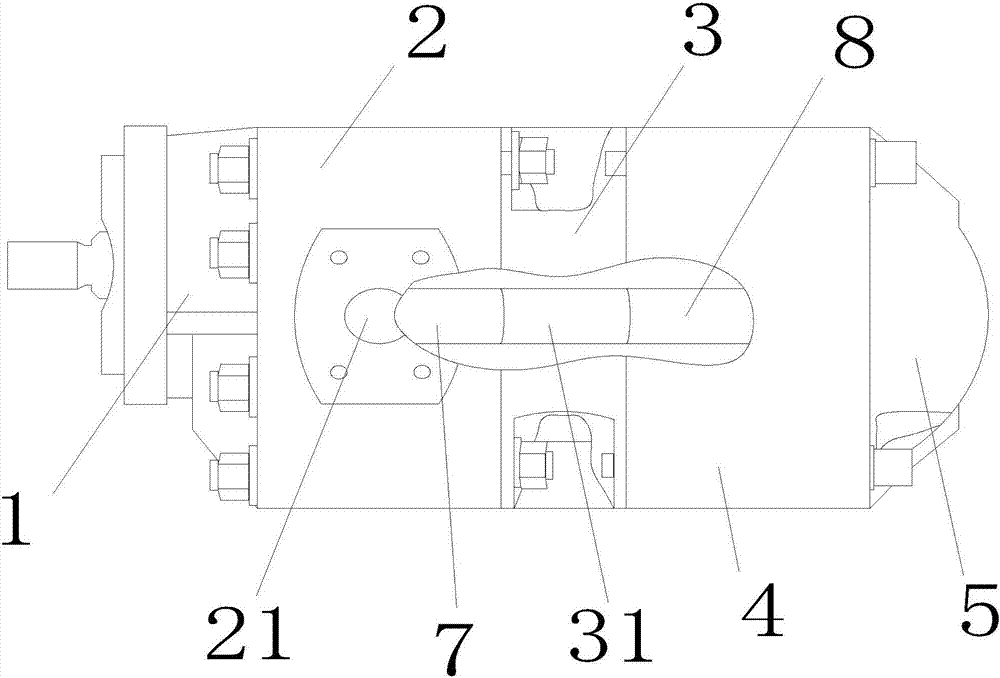

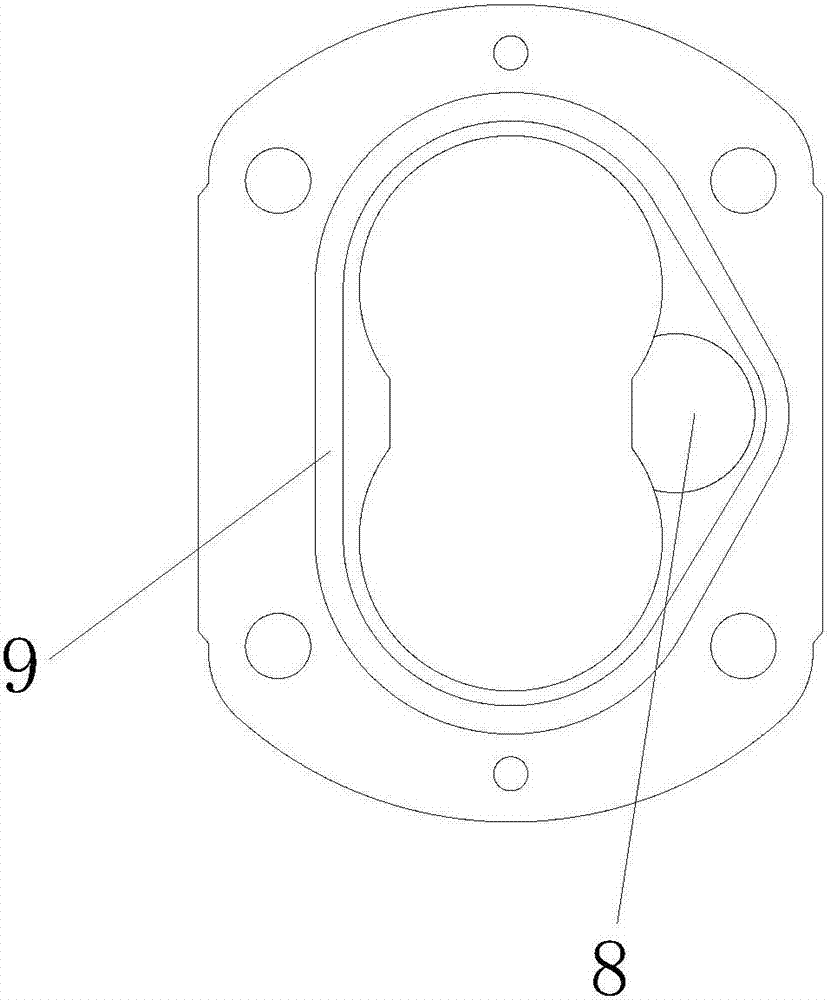

Duplex hydraulic gear pump

InactiveCN107503936ANo oil spillReduce use costRotary piston pumpsRotary piston liquid enginesGear pumpEngineering

The invention discloses a duplex hydraulic gear pump comprising a front cover, a first pump body, a connection plate, a second pump body and a back cover, wherein the front cover, the first pump body, the connection plate, the second pump body and the front cover are sequentially connected, a first driving gear shaft and a first driven gear shaft are installed in an inner cavity defined by the front cover, the first pump body and the connection plate, a second driving gear shaft and the first driven gear shaft are installed in an inner cavity defined by the connection plate, the second pump body and the back cover. The connection plate is provided with an installation hole penetrating through the connection plate. A spline sleeve is arranged in the installation hole. The first driving gear shaft is connected with the second driving gear shaft through the spline sleeve. The side wall of the first pump body is provided with an oil inlet. The inner side wall of the first pump body is provided with a first groove communicating with the oil inlet. The inner side wall of the second pump body is provided with a second groove. The connection plate is provided with a communication hole. The first groove is connected with the second groove through a communication hole. Hence, compared with the prior art, the duplex hydraulic gear pump has the advantages of reducing use cost and preventing oil leakage.

Owner:合肥赛源液压件有限公司

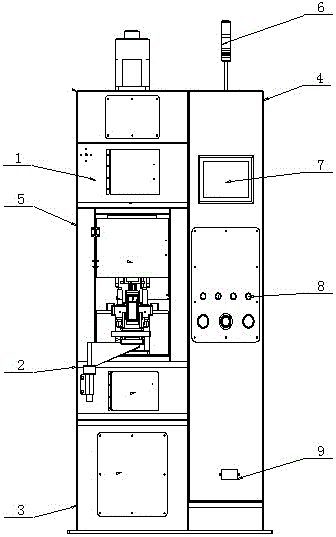

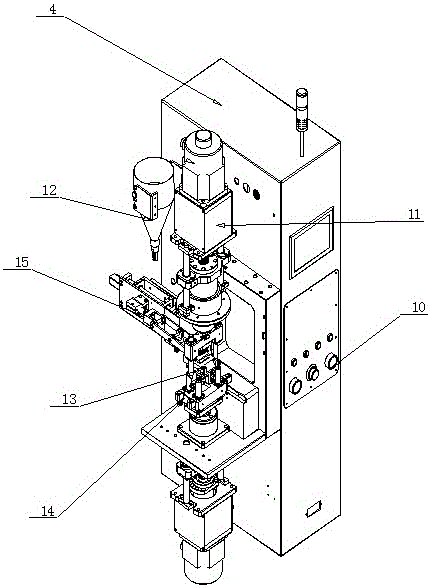

High-precision powder forming machine

The invention discloses a high-precision powder forming machine and relates to the technical field of powder forming machines. A cabinet is arranged at the left half part of the front side of a power forming machine, an electric cabinet is arranged at the right half part of the front side of the powder forming machine, the cabinet is connected with the side edge of the electric cabinet to form the powder forming machine, a side support plate is mounted on the side surface of the cabinet, an overshooting motor and an upper servo motor are mounted in a rack I, a powder flow distributing device is mounted on the side edge of the overshooting motor and located behind the electric cabinet, a vertical linear pressing device is mounted in a rack II, a feeding device is transversely mounted at the side edge of the vertical linear pressing device, an undershooting motor and a lower servo motor are mounted in a rack III. The high-precision powder forming machine has the following benefits: die filling is convenient and quick; the pressure is stable and data display is realized; ultraminiature and irregularly-shaped products can be produced by pressing; adopted operating parts are fully-enclosed, so that potential safety hazards caused during operation are eliminated; the rotational speed is high, the one-outlet multi-mode purpose is achieved, the operation ratio is high, produced dies are low in loss, and products are burr-free; the high-precision powder forming machine can work in a natural environment; the energy consumption is low; oil and material leakage is prevented and no noise is generated.

Owner:GUANGZHOU JINGCHENGDA PRECISION MACHINERY CO LTD

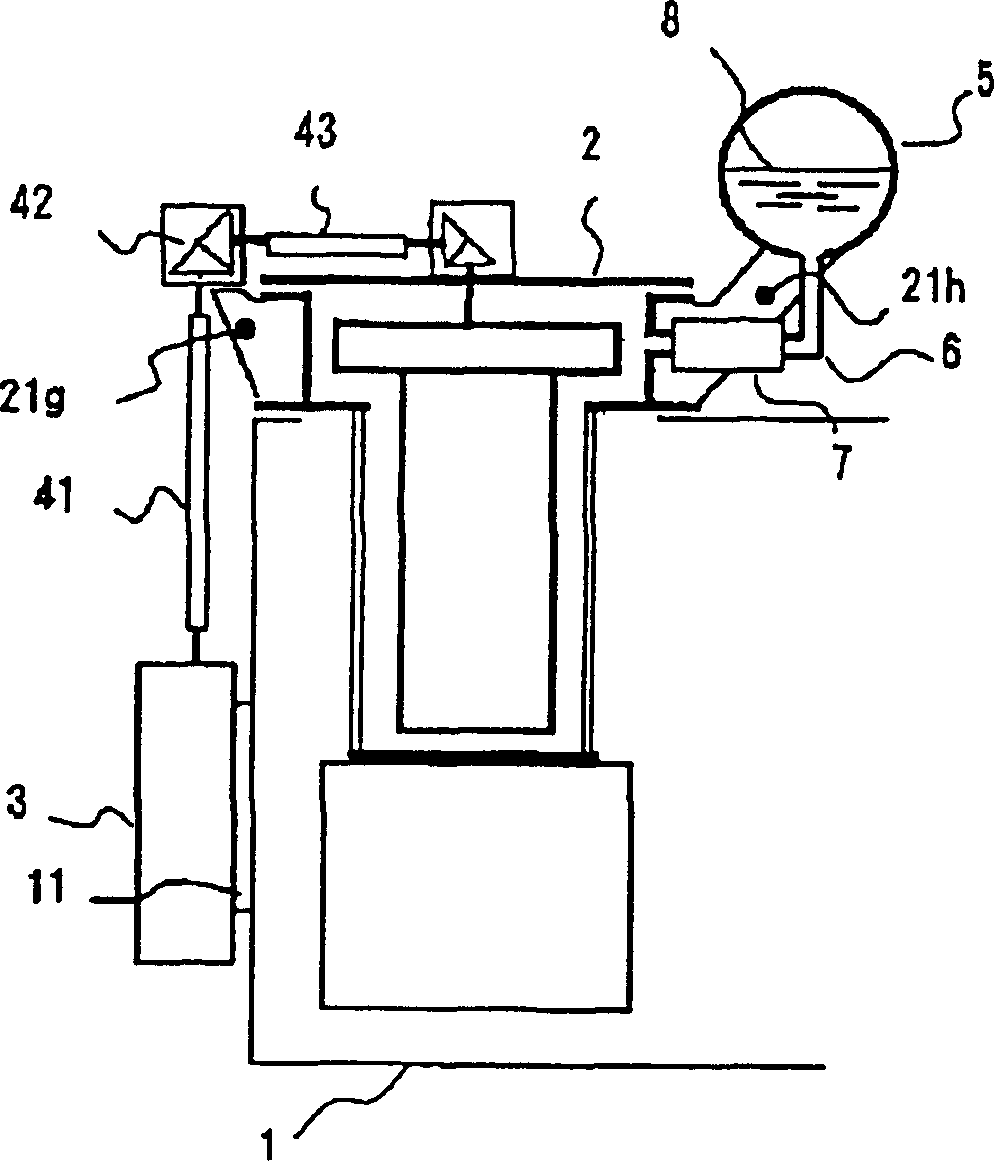

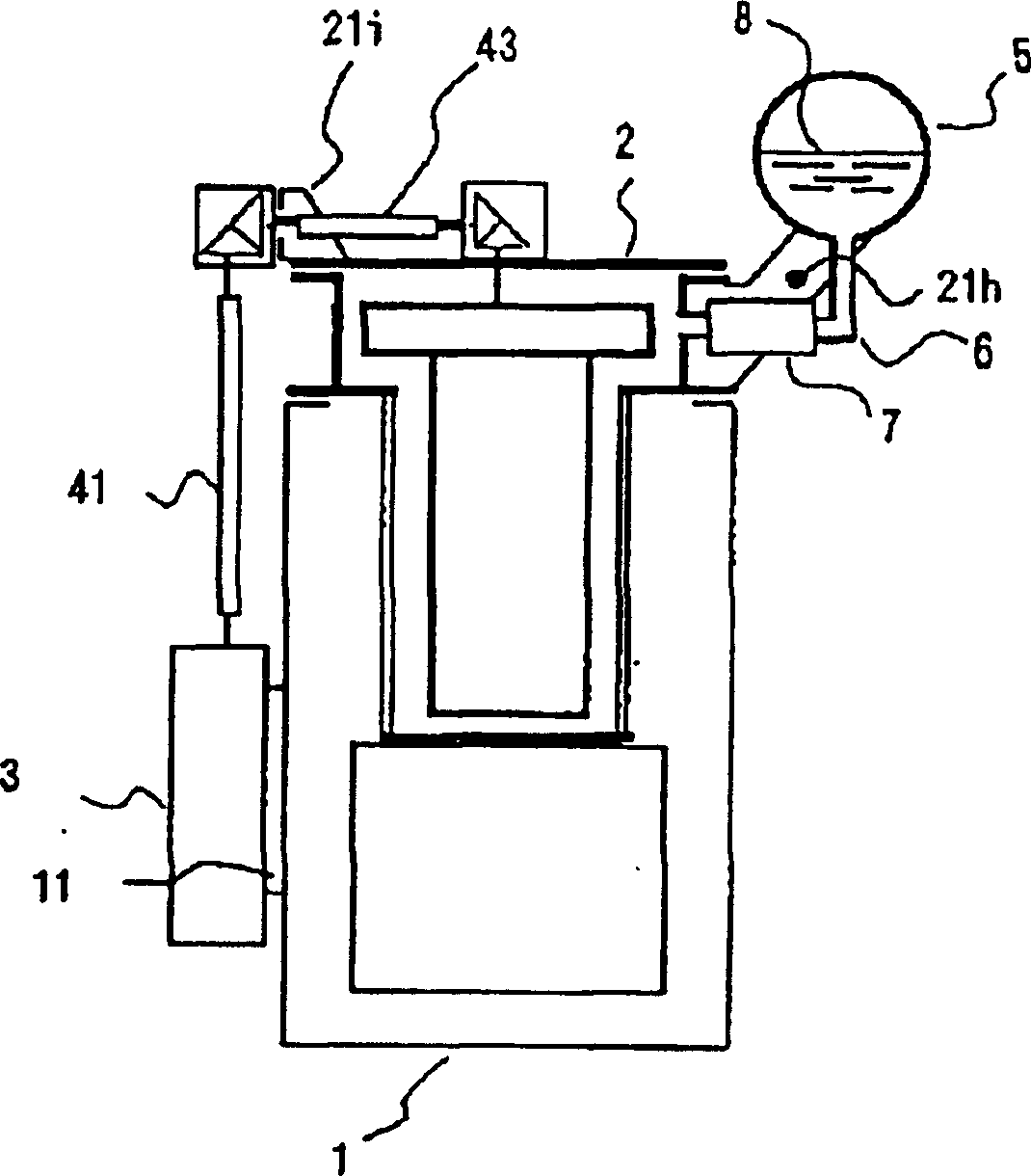

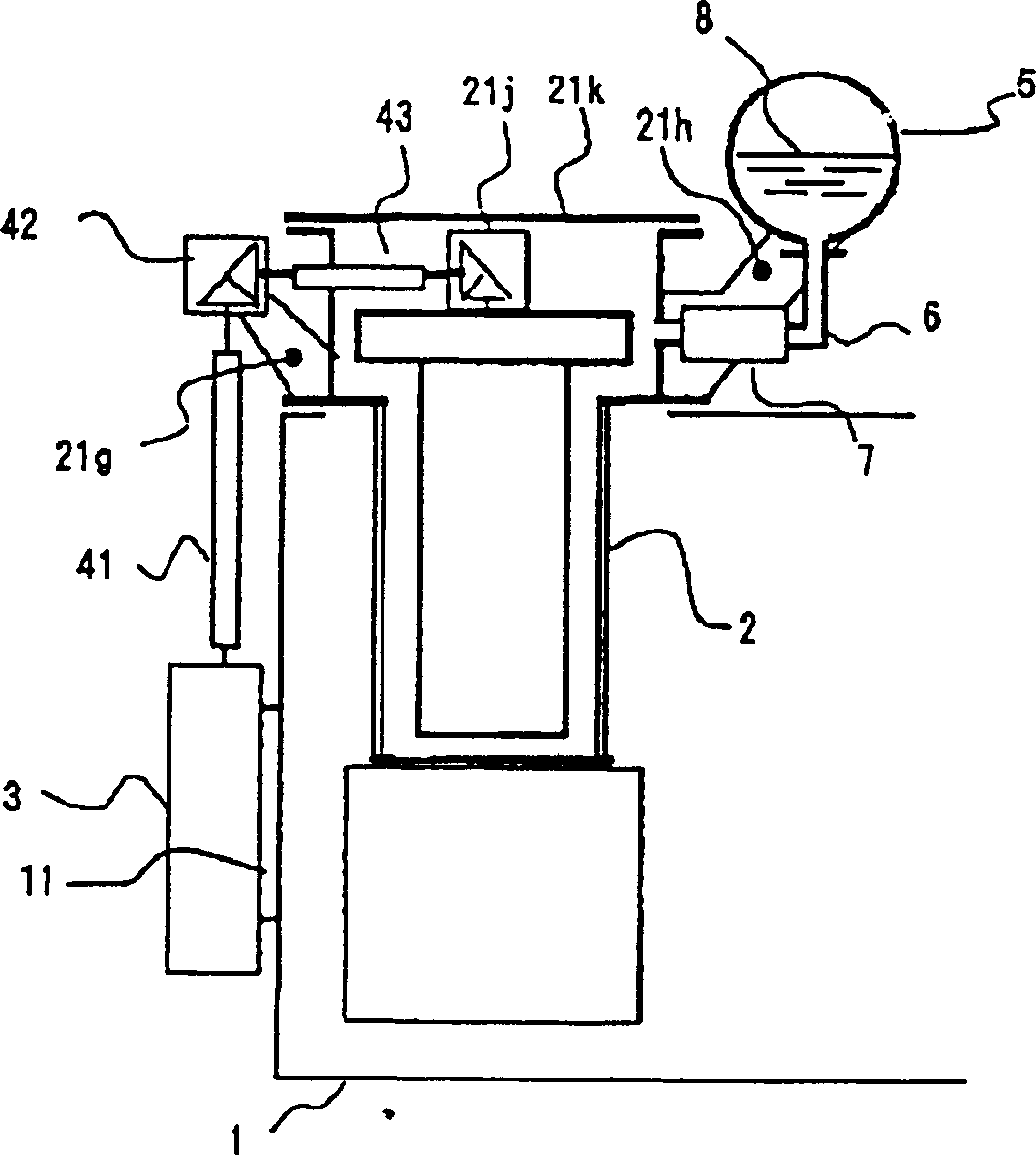

Tap converter

InactiveCN1183559CSave assembly timeNo oil spillTransformers/inductances coolingTransformers/inductances casingsTap changerElectrical and Electronics engineering

To provide a tap changing device which can shorten the assembling time of the device itself and a transformer and can stably obtain a driving force even when many or few errors occur in the attaching positions of an operating mechanism, a tap changer, and a conservator and in which the direction changing device and conservator of the device can be attached to the transformer almost effortless even when the size of the transformer is relatively small and no oil leakage occurs from an oil pipeline. The first direction changing device 42 and conservator 5 of this tap changing device are attached to the head case 21a of the tap changer respectively through fittings 21g and 21h installed to the case 21a.

Owner:MITSUBISHI ELECTRIC CORP

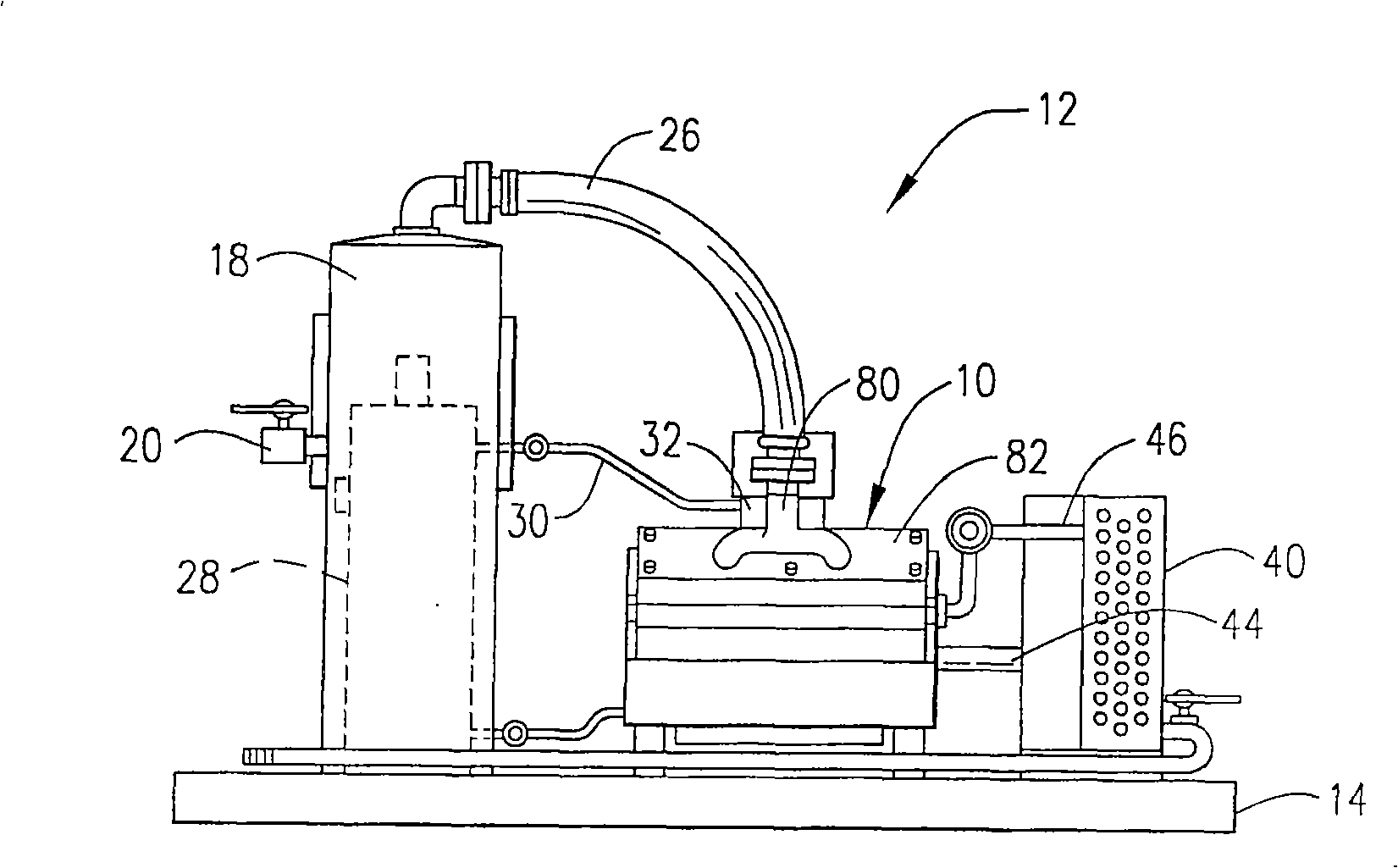

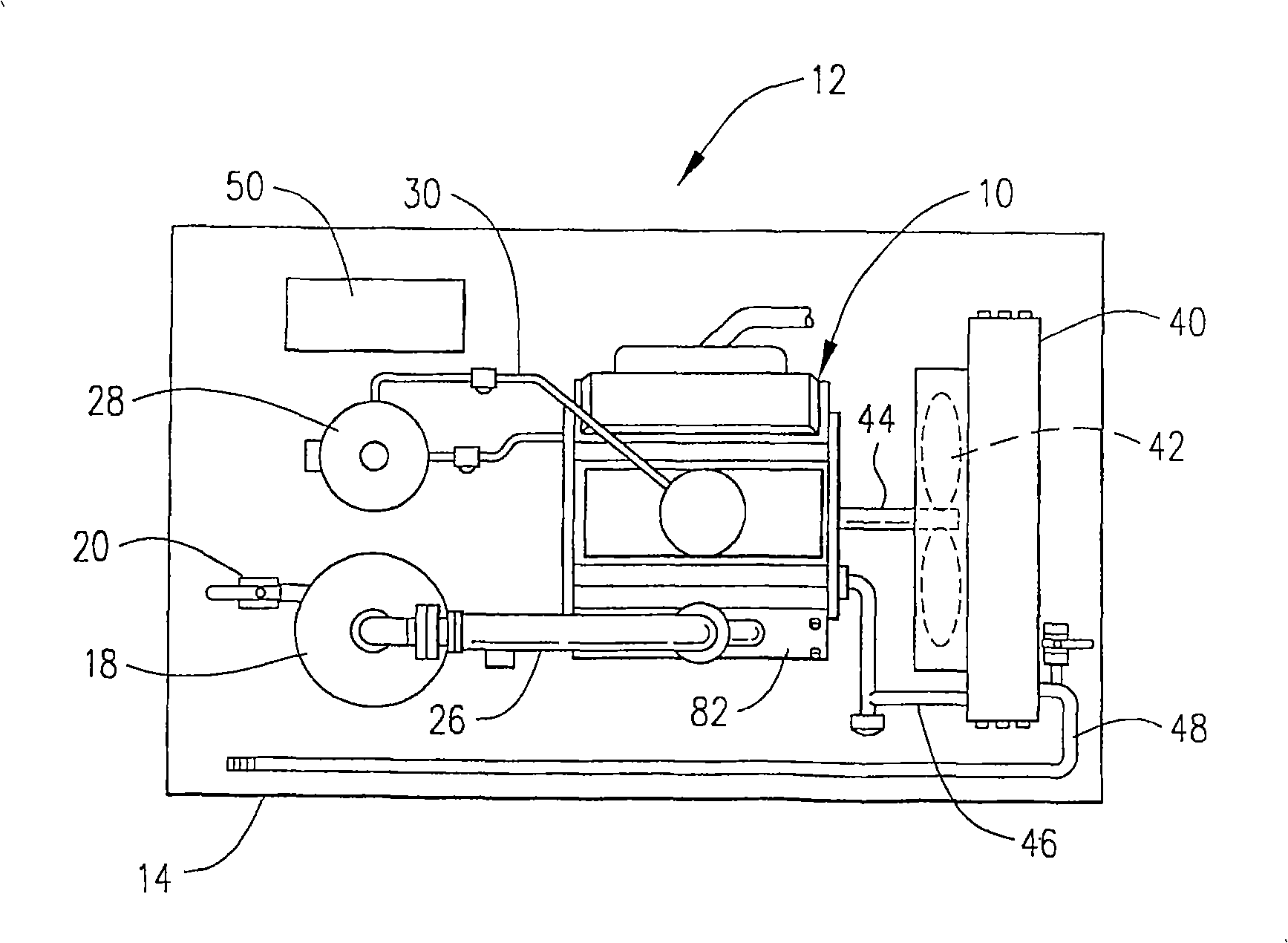

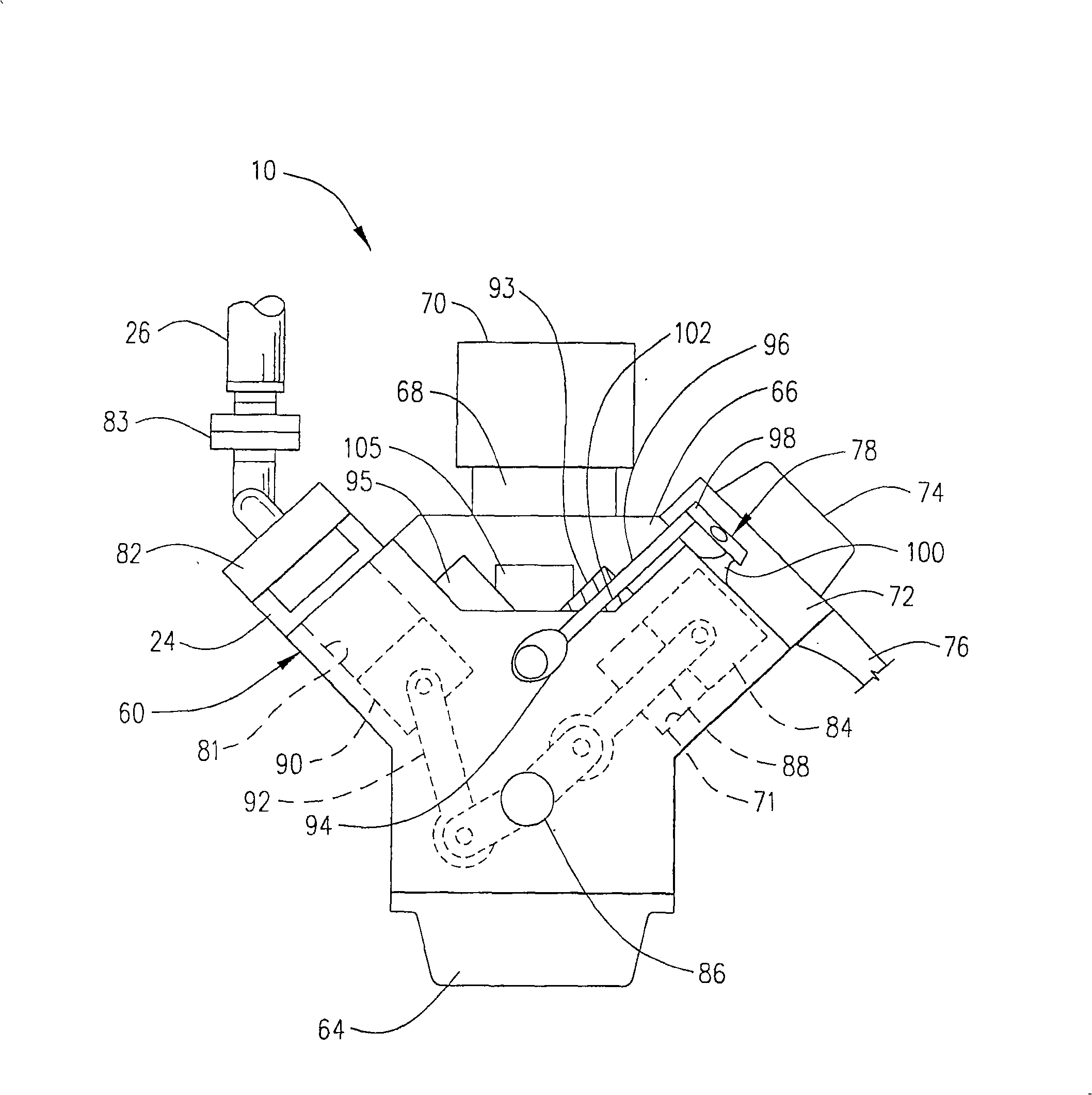

Cylinder block for integral gas compressor and internal combustion engine

InactiveCN101287907ANo cost of cloggingNo oil spillCasingsCombustion enginesGas compressorExternal combustion engine

Owner:COMPRESSCO INC

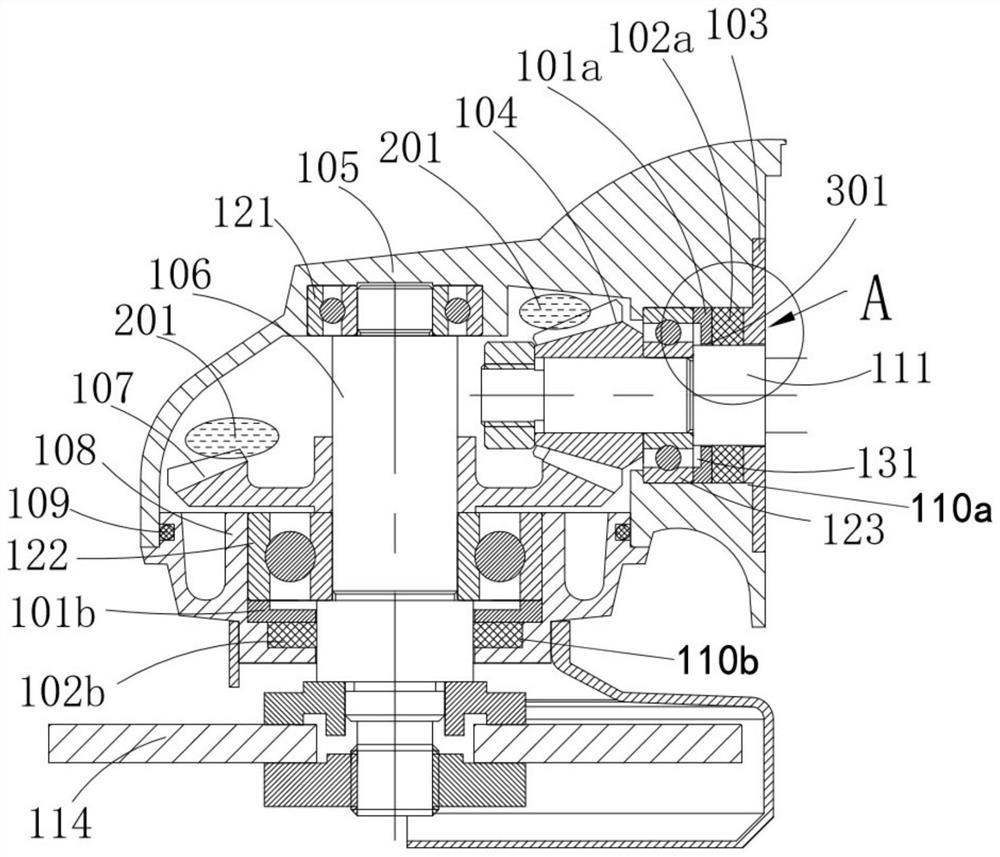

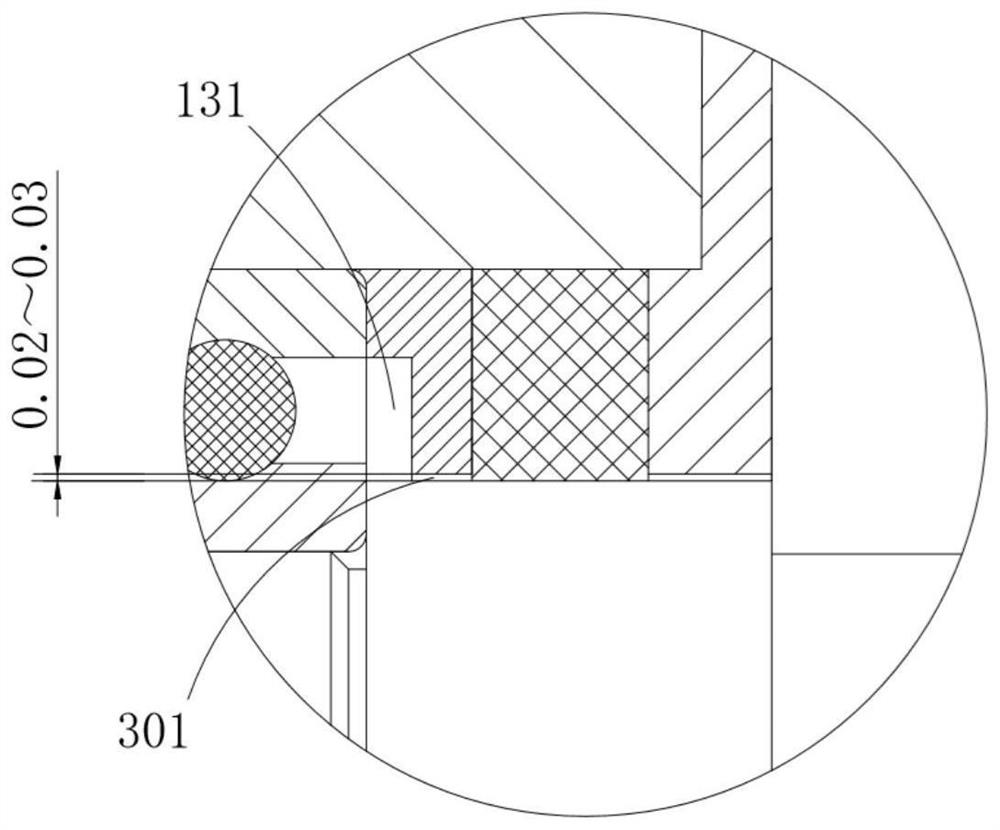

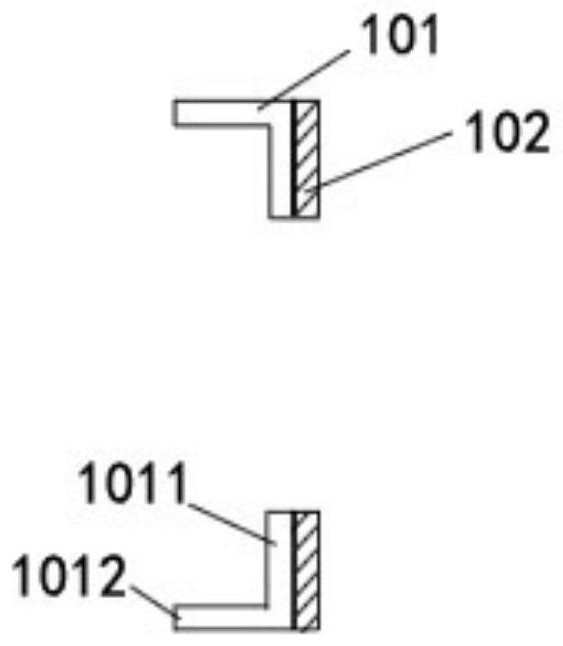

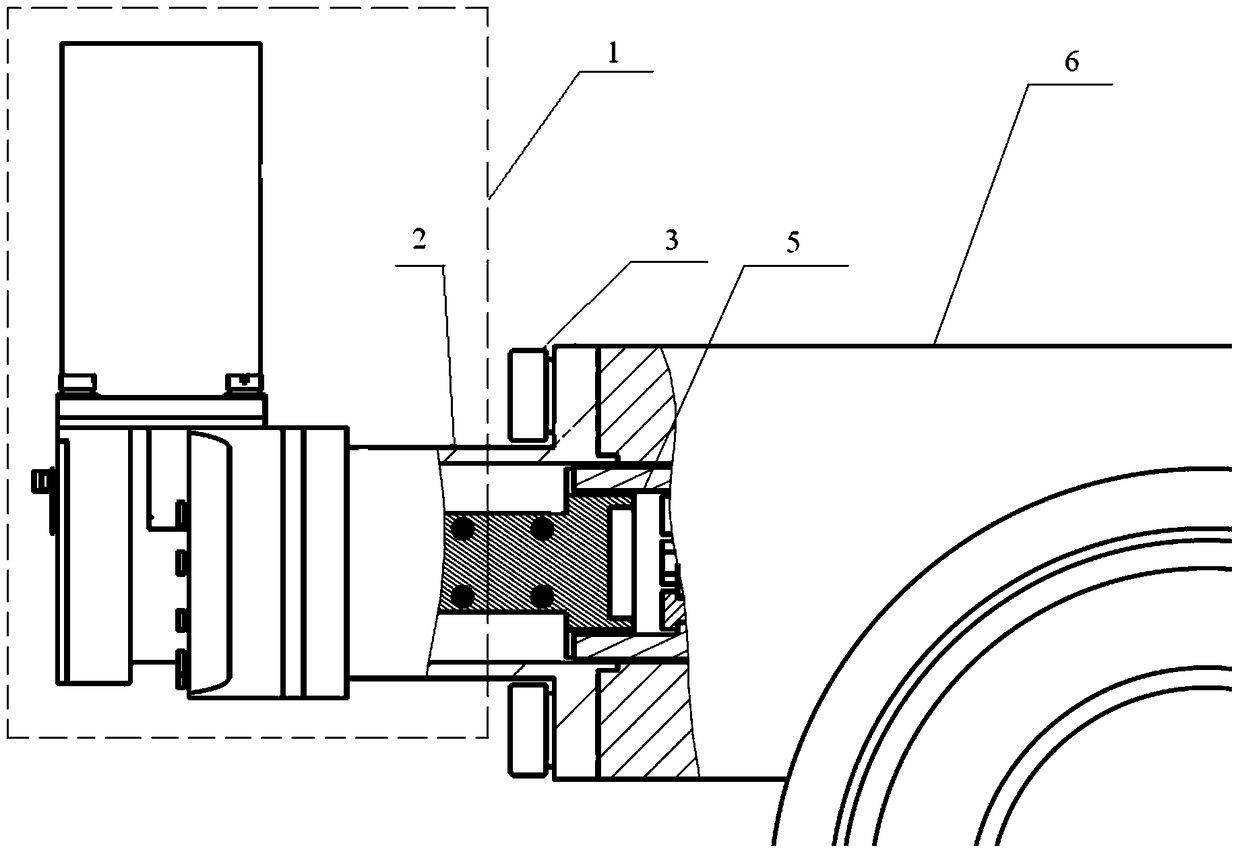

Sealing structure of angle grinder gear box lubricated by lubricating oil and angle grinder

The invention discloses a sealing structure of an angle grinder gear box lubricated by lubricating oil and an angle grinder. The sealing structure of the angle grinder gear box lubricated by the lubricating oil comprises a shell, a transmission mechanism, a sealing assembly and liquid lubricating oil for lubrication. The transmission mechanism comprises a motor shaft, a driving gear, a driven gearand a driving output shaft, and the motor shaft and the driving output shaft are rotatably supported in the shell. The driving gear is assembled at the end of the motor shaft, the driven gear is assembled on the driving output shaft, and the driving gear and the driven gear are meshed and connected to form a rotary gear pair. The sealing assembly comprises an oil separation pressure reduction ring and a sealing ring, gap sealing is formed between the oil separation pressure reduction ring and the shaft, and contact sealing is achieved between the sealing ring and the shaft. The liquid lubricating oil is used in the gear box for the first time, the liquid lubricating oil can completely infiltrate and fully lubricate the meshed rotary gear pair, effective sealing can be achieved in the working state and the static state of the angle grinder, the sealing effect of the sealing assembly is matched, and therefore the service life of the angle grinder can be remarkably prolonged.

Owner:WUYI HENGYOU ELECTROCHEM ZHEJIANG PROV

An anti-explosion fuel tank

InactiveCN103600652BAvoid situations that affect normal workEasy to driveUnderstructuresInternal pressureDepressant

An explosion-suppressing oil tank of the present invention includes a box body, an explosion-suppressing body filled in the box body, and a grid protective cover set outside the oil level sensor, wherein the explosion-suppressing body is set as a porous structure, and the explosion-suppressing body is provided by the bulletin number CN102181756 B is made of the gas station oil tank barrier explosion suppression material aluminum foil; the box body is provided with a grid that divides the box body into two or more chambers, and the explosion suppression body is placed in the chamber; The refueling port of the tank is provided with a refueling shield. Compared with the prior art, the present invention not only can effectively prevent the oil level sensor from being stuck by the explosion suppression body filled in the tank, but also has an oil penetration hole on the surface of the refueling shield so that the oil can smoothly enter the inside of the tank and can effectively prevent The anti-explosion body blocks the filling port, effectively avoiding gun jumping and oil spillage. At the same time, the anti-explosion body effectively controls the gas expansion degree of the fuel tank, so that the pressure in the fuel tank does not change much, and the occurrence of explosion is suppressed.

Owner:茂名市亚泰铝合金抑爆材料有限公司

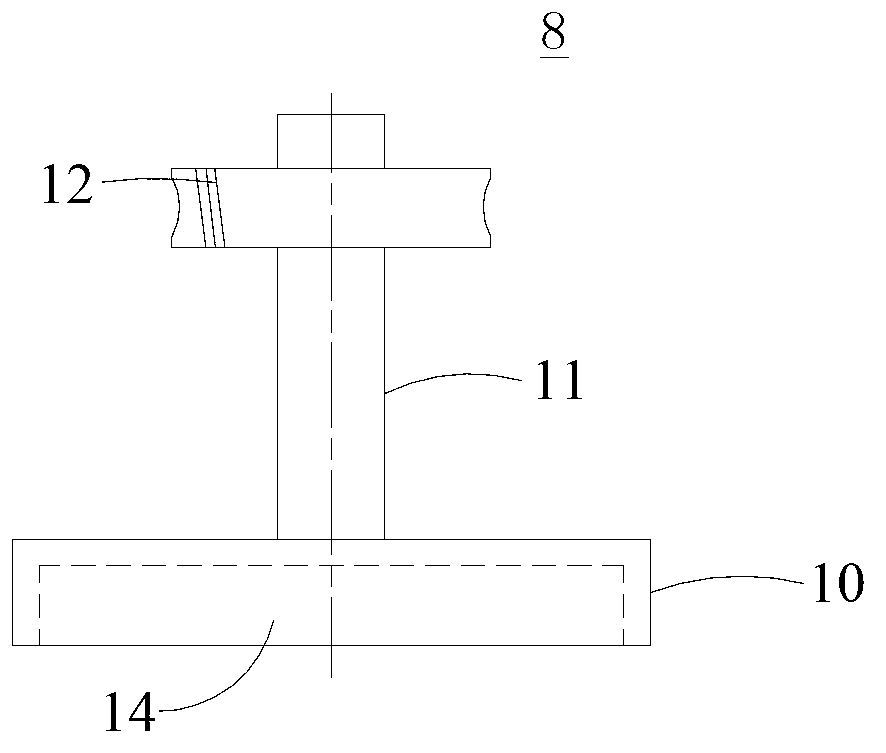

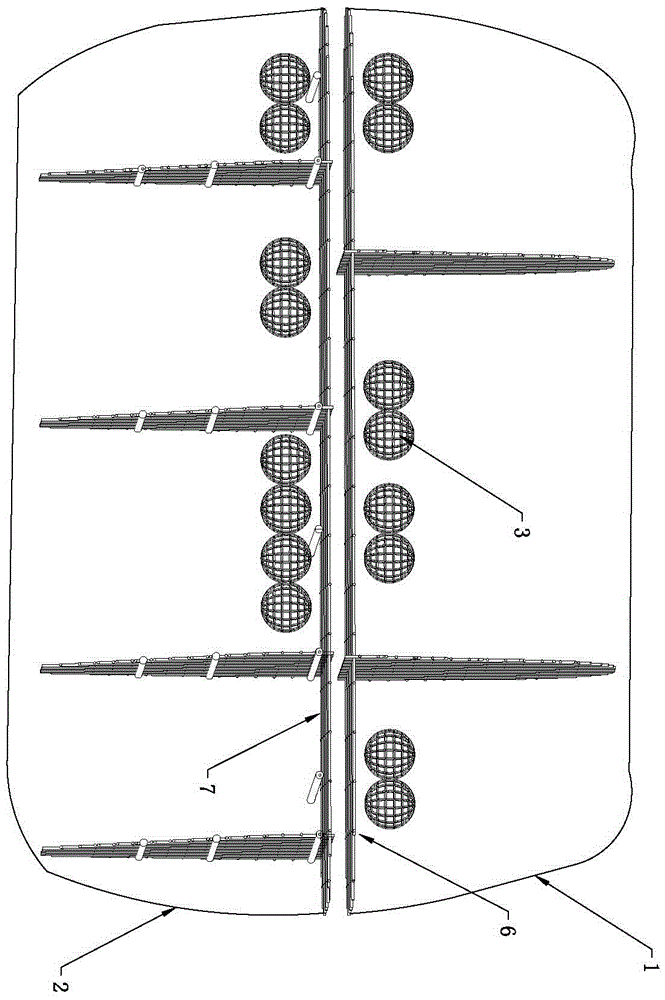

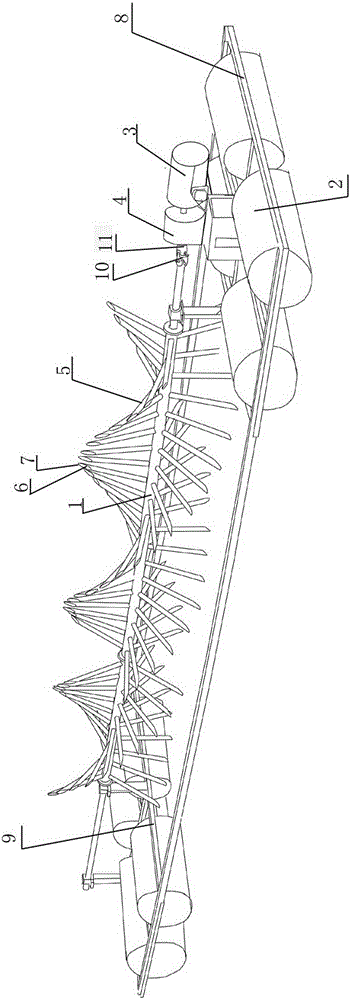

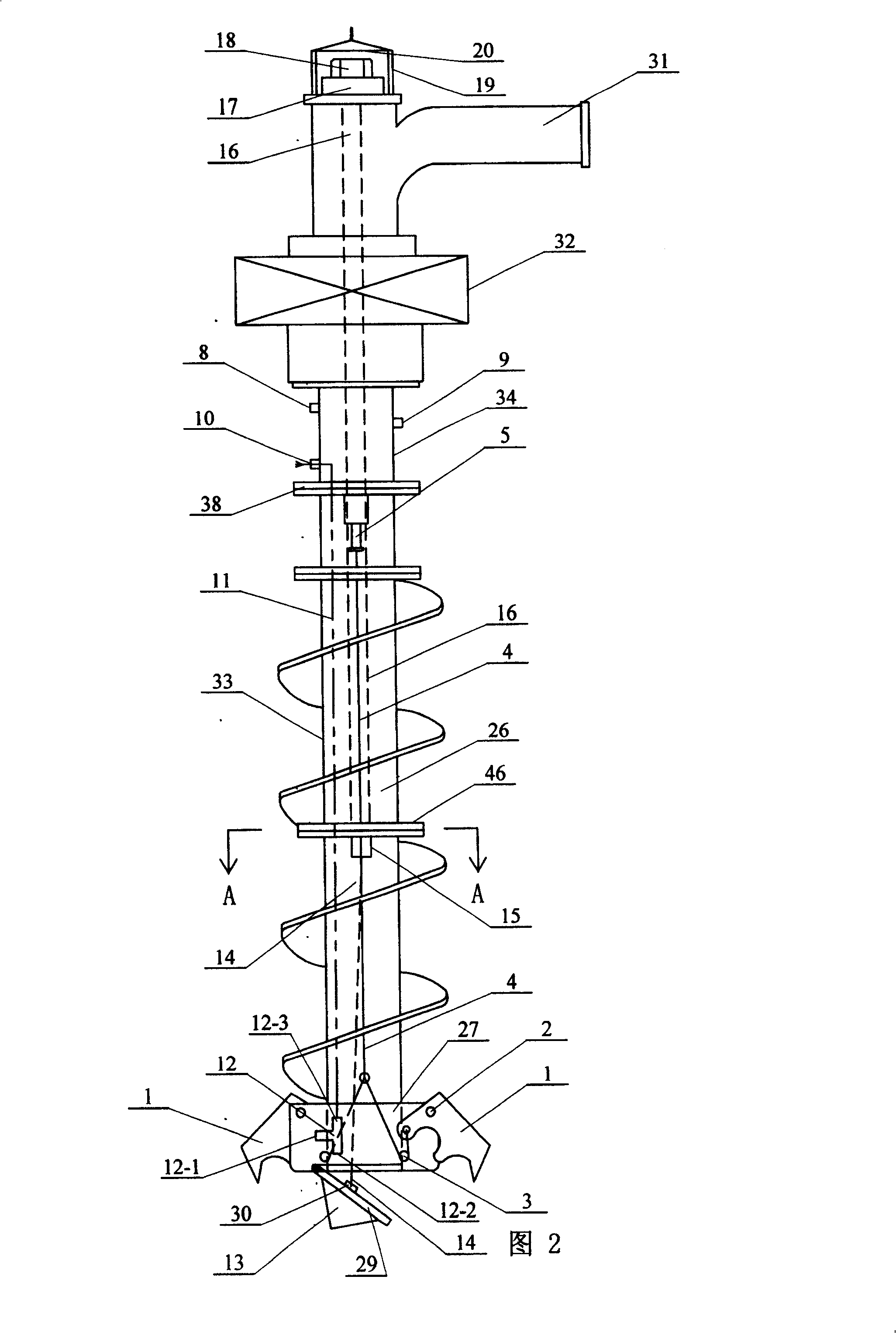

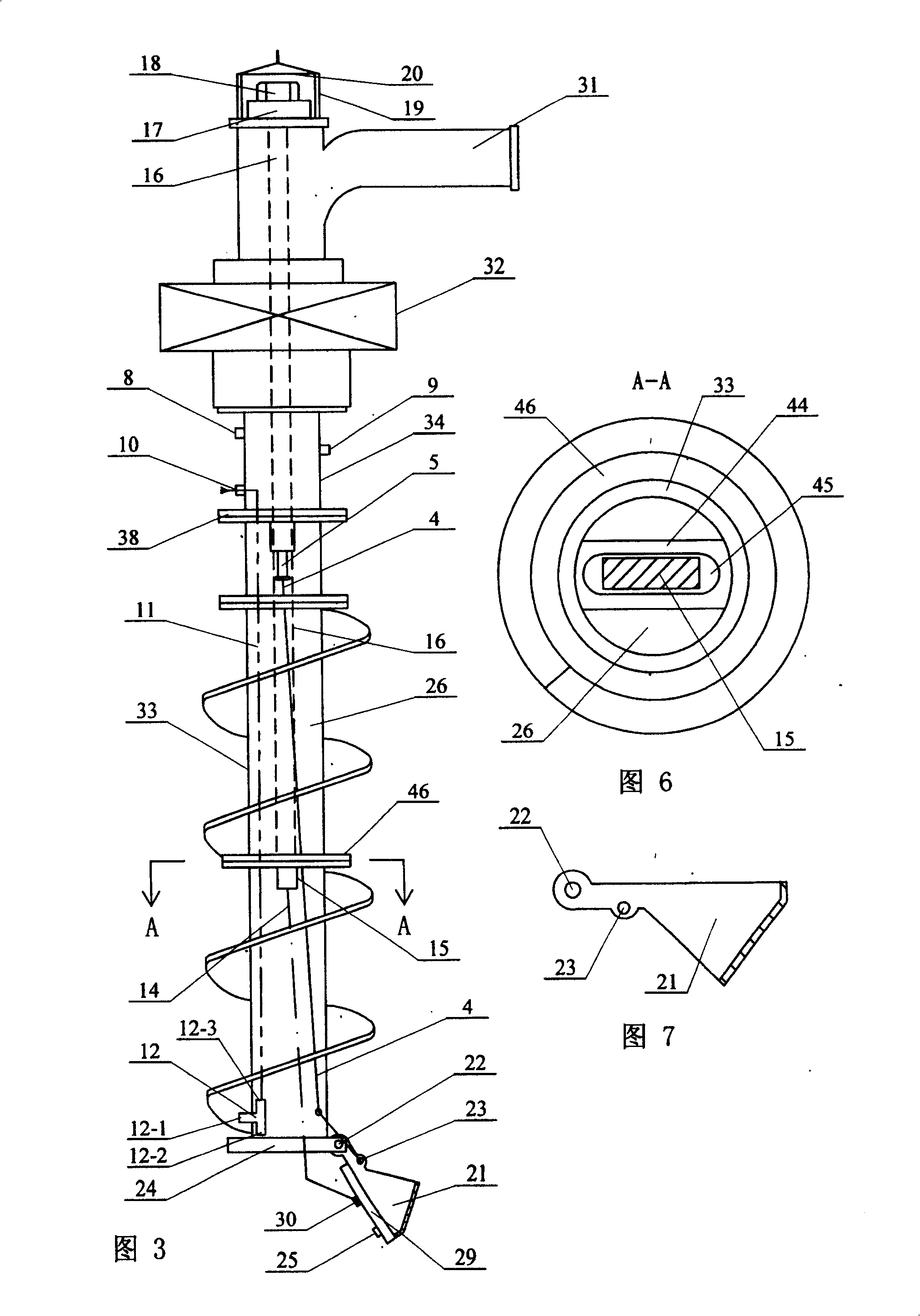

A kind of spiral waterwheel type aerator

InactiveCN102960292BIncrease the lengthImprove water qualityPisciculture and aquariaWater flowEngineering

The invention discloses a spiral waterwheel aerator which mainly comprises a spiral shaft (1) and a power unit. Both sides of the spiral shaft (1) are respectively provided with buoy groups (2); the power unit is positioned at one side of the spiral shaft (1); the power unit comprises a motor (3) and a speed reducer (4); the motor (3) is in drive connection with the speed reducer (4); an output shaft (11) of the speed reducer (4) is in drive connection with the spiral shaft (1); the motor (3) drives the spiral shaft (1) to rotate by the speed reducer (4); a plurality of sections of stirring devices are arranged on the spiral shaft (1); each section of stirring device comprises a plurality of stirring screws (5); and the stirring screws (5) are distributed on the spiral shaft (1) in a diffusing manner and are arranged in a spiral arc umbrella shape. The spiral waterwheel aerator not only generates large water flow in the stirring process and has a high aeration speed, but also can be arranged in a long-distance manner, so that the aeration region is effectively enlarged.

Owner:刘秋林

Method for improving oil spilling of single-sided windowing VIA hole after solder resist development

PendingCN114430623ANo oil spillNo crackNon-metallic protective coating applicationEtchingImage transfer

The invention belongs to the technical field of PCBs, and particularly relates to a method for improving single-side windowing VIA hole oil spilling after solder resist development. Comprising the following steps of cutting, inner layer forming, press fit, drilling, whole board electroplating, image transfer, pattern plating, etching and film stripping, AOI detection, solder resist hole plugging, solder resist surface oil printing, solder resist pre-baking, solder resist pattern transfer, solder resist developing, character printing, post curing, forming and cleaning. According to the method disclosed by the invention, a 1.8-4mil green oil ring is added during preparation aiming at the problem that the VIA hole of a solder-resistant single-side windowing design product is easy to generate an oil-benefiting bad product, so that the phenomenon of bad oil spilling of the VIA hole at the single-side windowing after solder-resistant development is effectively improved.

Owner:HUIZHOU ZHONGJING ELECTRONICS TECH CO LTD

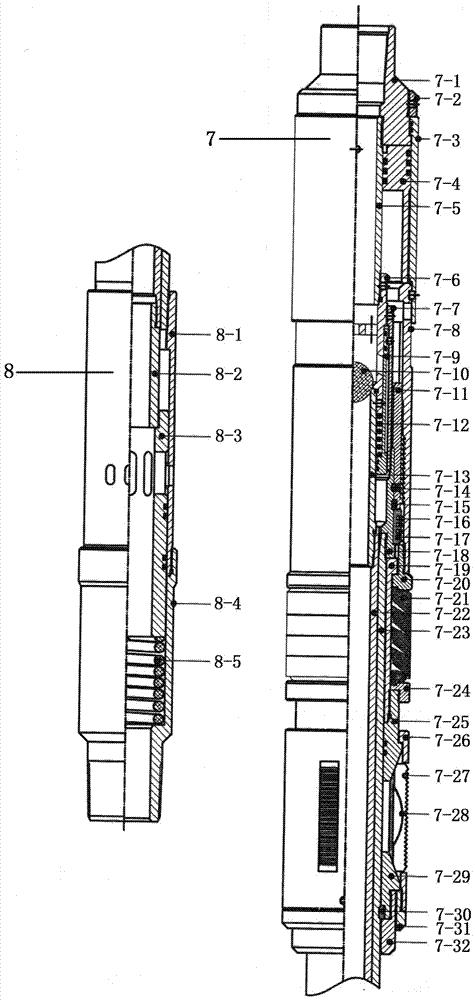

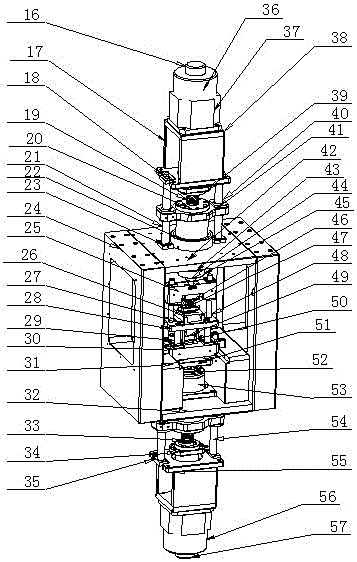

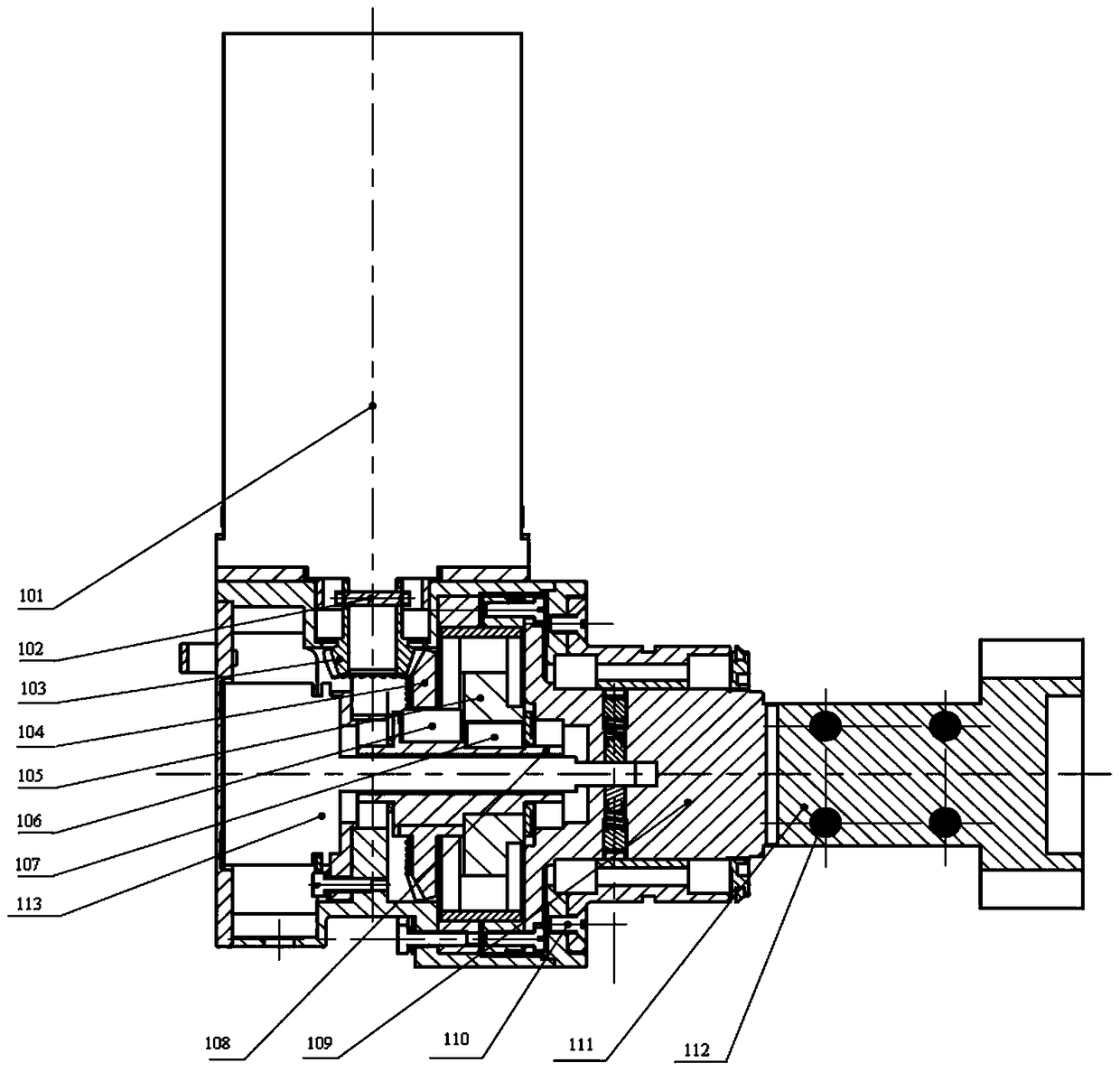

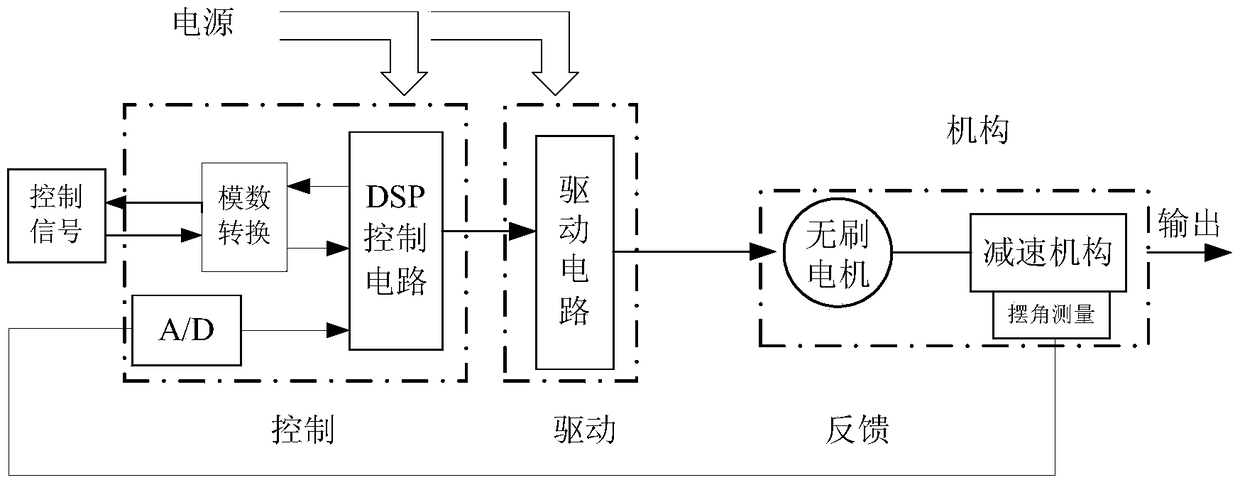

An Electromechanical Servo Mechanism for Variable Thrust Adjustment of Liquid Rocket Engine

ActiveCN105630002BVariable thrust adjustment fastImprove reliabilityControl using feedbackButt jointControl system

The invention belongs to the field of thrust regulation of an engine, and specifically relates to a variable-thrust regulating electromechanical servo mechanism of a liquid rocket engine. The variable-thrust regulating electromechanical servo mechanism comprises an execution mechanism and a control system. The execution mechanism comprises a DC servo motor, a small gear, a large gear, a harmonic reducer, a small shaft, a large shaft, a butt-joint gripper and a potentiometer. The execution mechanism and a regulator are installed. The control system receives a control instruction and a feedback signal, and a gear shaft rotates according to a motion characteristic specified by the instruction. The technical problem that realization of the variable thrust regulation is difficult in the prior art is solved.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

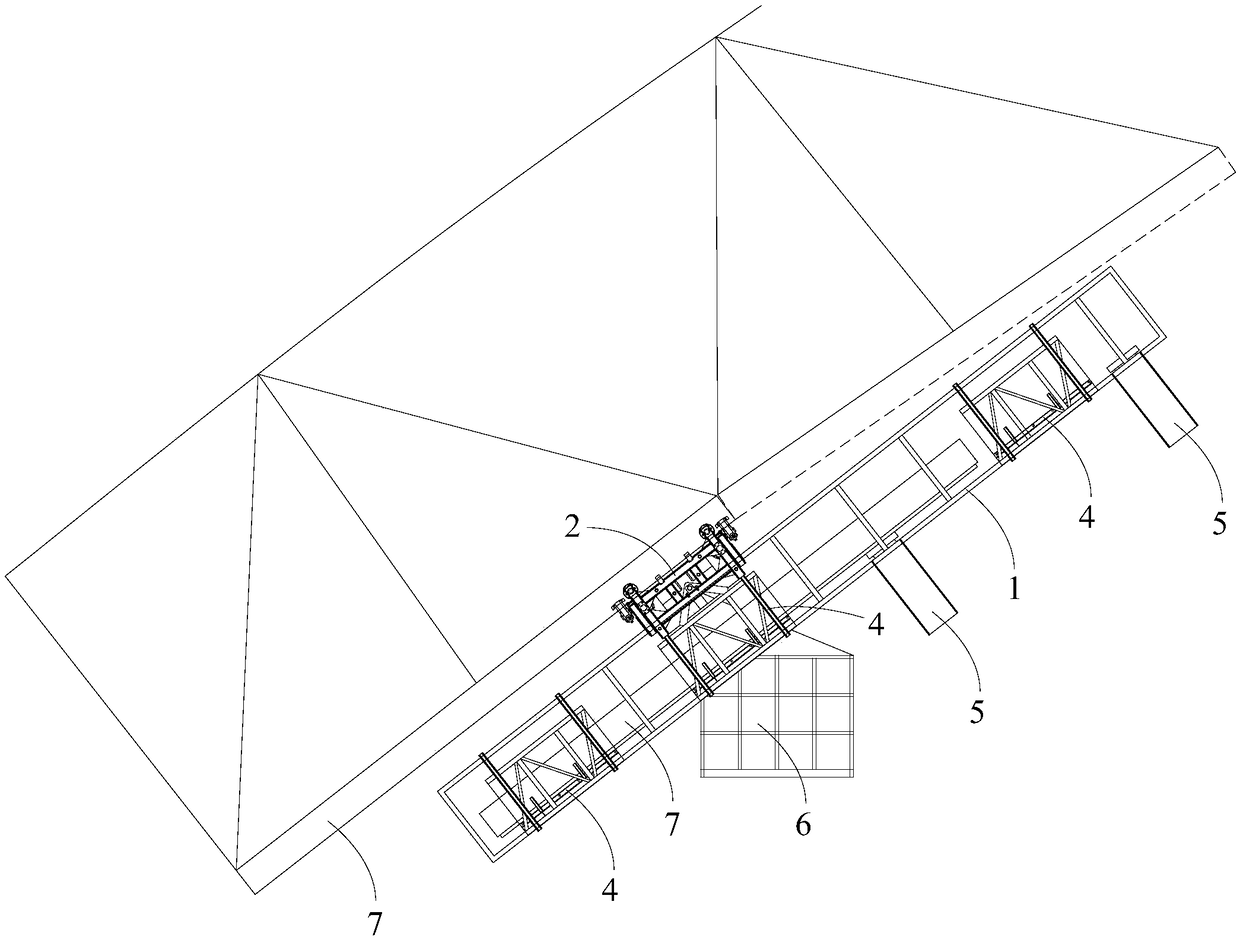

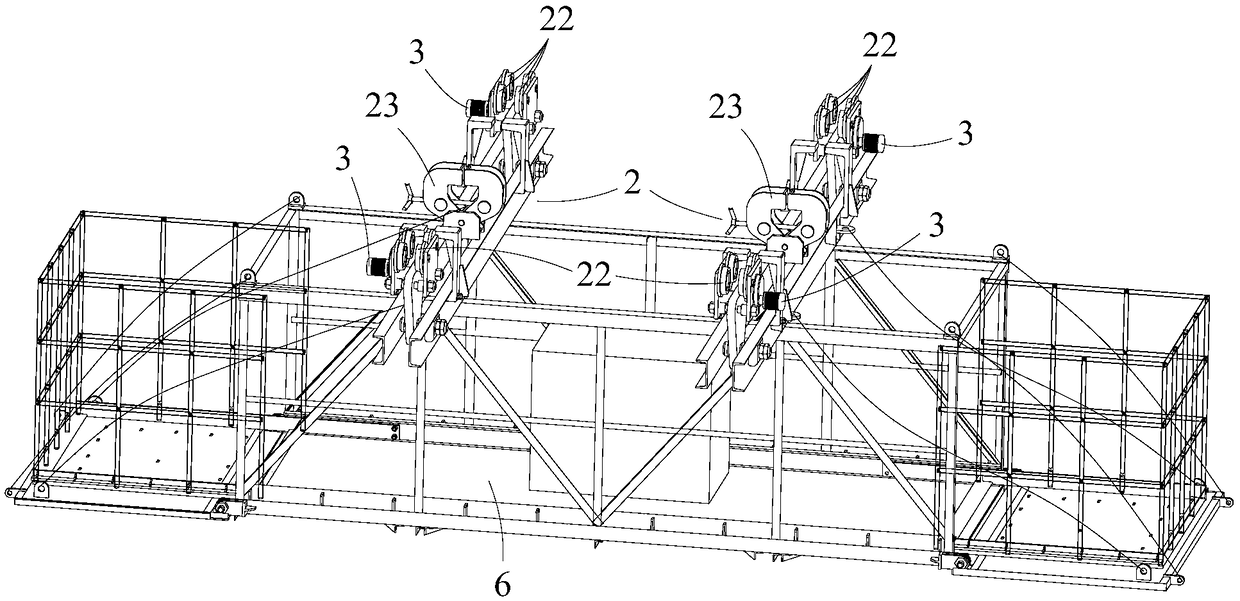

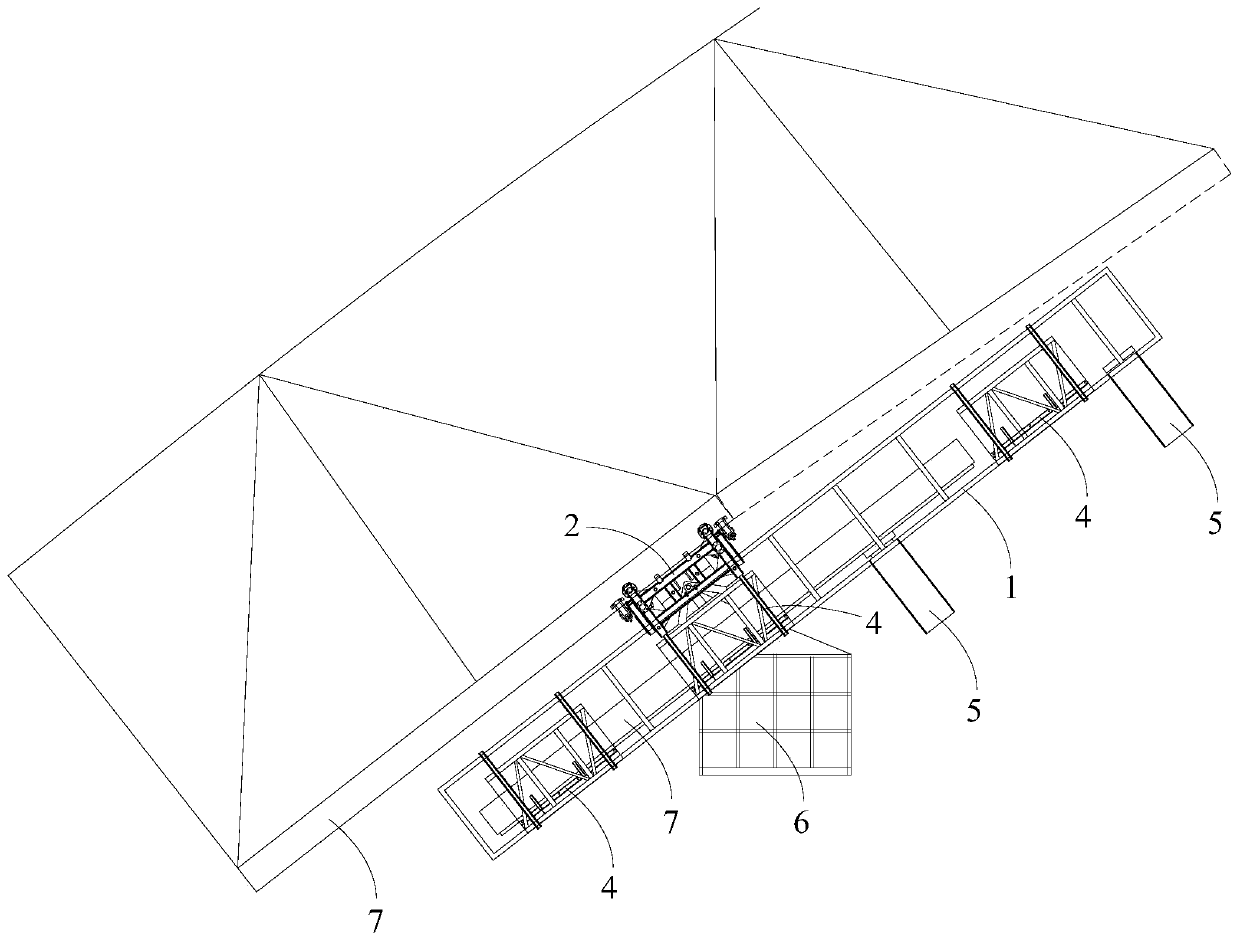

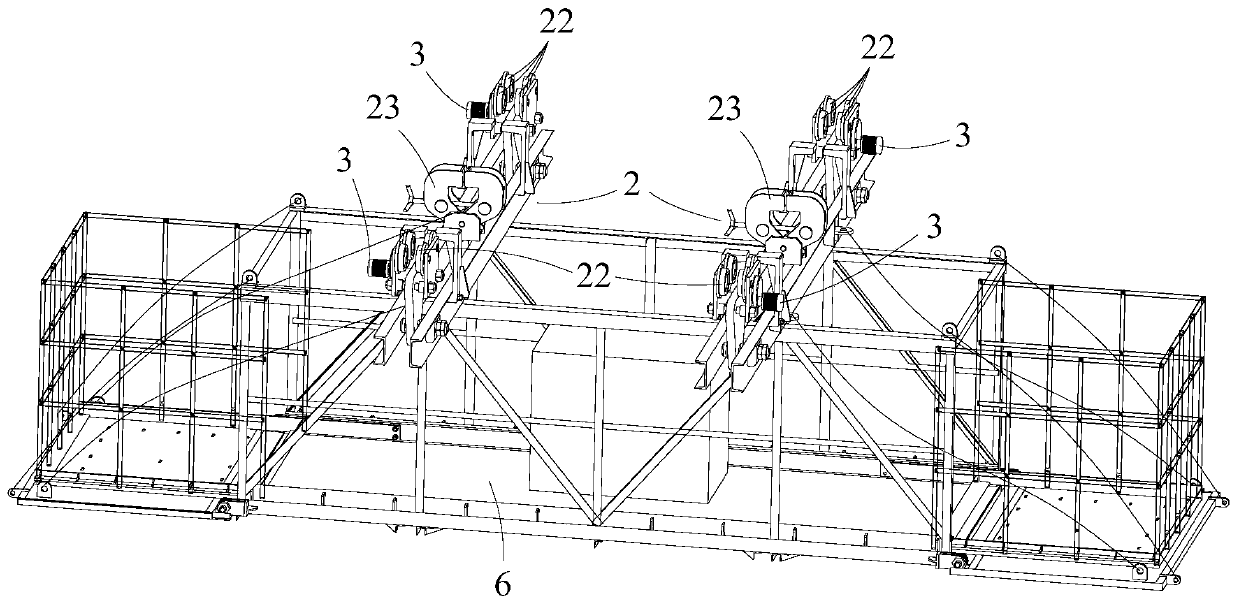

Novel chain track installation method

ActiveCN109083026AAchieve installationReduce investmentBridge structural detailsBridge erection/assemblyControl theory

Owner:CHINA RAILWAY ERJU 5TH ENG +1

Gear box

Owner:许炎章

A method for installing a chain track

ActiveCN109083026BAchieve installationEasy to operate on siteBridge structural detailsBridge erection/assemblyControl theory

Owner:CHINA RAILWAY ERJU 5TH ENG +1

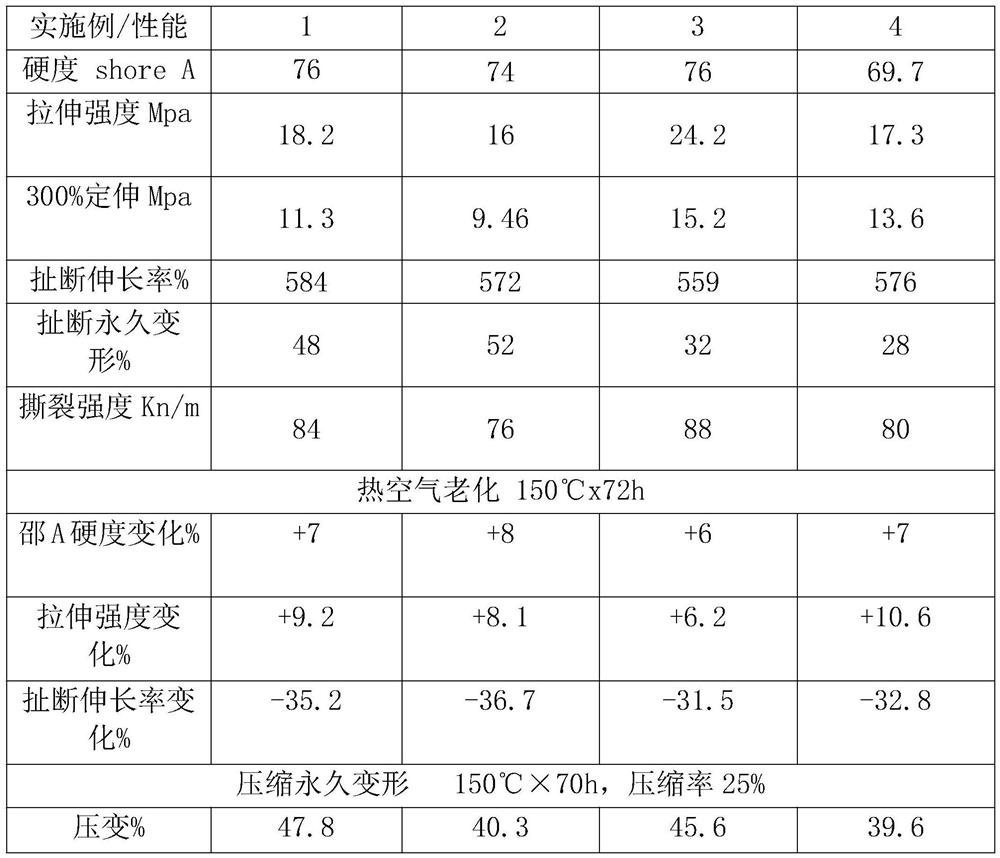

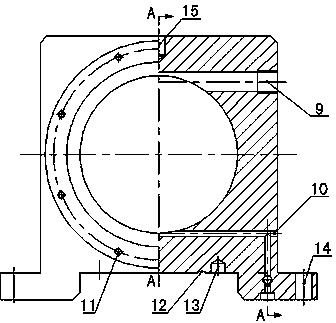

HNBR rubber compound for dynamic diaphragm sealing element of oil pump

The invention relates to an HNBR rubber compound for a dynamic diaphragm sealing element of an oil pump. The HNBR rubber compound comprises the following substances in percentage by weight: 40-55% of hydrogenated nitrile rubber, 1-8% of MPU, 3-10% of a compounding agent, 2-5% of an antioxidant, 25-35% of a reinforcing filler, 3-15% of a softening agent, 1-4% of a vulcanizing agent and 0.1-2% of a vulcanization accelerator. According to the invention, HNBRDN-3418 is adopted as main rubber, and the rubber has good medium resistance and aging resistance, and can ensure basic physical properties required by the rubber material. The most prominent performance of the product is that the oil resistance is excellent under the condition of-20 to 90 DEG C, the volume change rate of Astm standard 901 # oil resistance is within 3% under the condition of 150 DEG C * 70h, and the permanent compression deformation and the dynamic fatigue resistance are very excellent. When the diaphragm is used in methanol diesel for a medium and long term, the small-amplitude dynamic fatigue resistance is excellent, and the service life of the diaphragm seal of the oil pump is prolonged to 181 days from the original 30 days.

Owner:山东道恩特种弹性体材料有限公司 +1

Comprehensive test device of oil film bearing

A comprehensive test device of an oil film bearing belongs to the technical field of the oil film bearing. The structure is as follows: a left bearing, a middle bearing and a right bearing are sequentially arranged from left to right; a shaft connected with a motor through a coupling is arranged inside a bearing hole; an oil path of the left bearing is provided with a dynamic press-in oil hole and a static press-in oil hole at upper and lower top points of a bearing block; oil grooves are arranged inside axle holes at the left end and the right end; the bottom part of each oil groove is communicated with an oil return hole; the dynamic press-in oil hole and a dynamic press-in oil cavity are arranged at the upper part of a vertical center line of a bush; the static press-in oil hole and a static press-in oil cavity are arranged at the lower part; the oil grooves communicated with the oil return hole are arranged on the inner surfaces of the axle holes of a left end cover and a right end cover; the oil path of the middle bearing is respectively provided with the dynamic press-in oil hole at the front and rear top points of the bearing block; the oil grooves are arranged inside the axle holes at the left end and the right end; the bottom part of each oil groove is communicated with the oil return hole; the dynamic press-in oil hole and the dynamic press-in oil cavity are arranged at the front end part and the rear end part of a radial center line of the bush; and the oil grooves communicated with the oil return hole are arranged at the inner surfaces of the axle holes of the left end cover and the right end cover.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com