A kind of spiral waterwheel type aerator

A waterwheel type aerator and spiral technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of limited oxygen supply length, limited oxygen increasing area, heavy impeller self-weight, etc., and achieve light weight and enlarged stirring area, speed-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

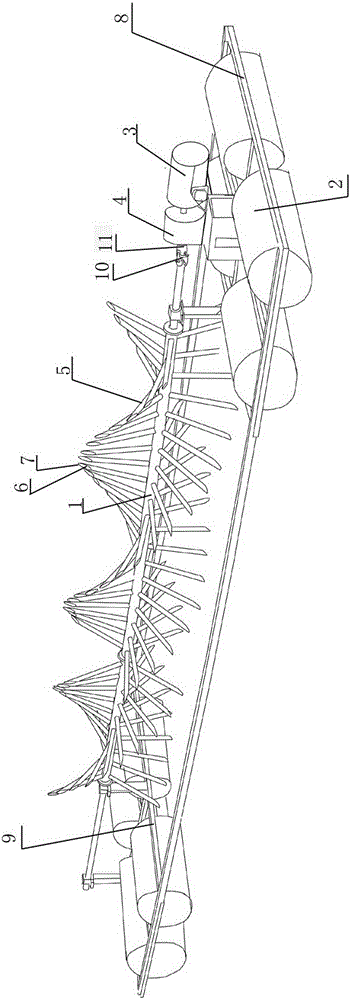

[0008] Implement one, in figure 1 Among them, the present invention provides a spiral waterwheel type aerator, which mainly includes a screw shaft 1 and a power unit, on both sides of the screw shaft 1 there are respectively buoy sets 2, and the power unit is located on one side of the screw shaft 1, Both sides of the screw shaft 1 are also provided with bracket I9 and bracket II8. The two buoy groups 2 are located on the bracket I9 and bracket II8 respectively, and the power unit is located on the bracket 8 on one side. 3 and the reducer 4 are in transmission connection, the output shaft 11 of the reducer 4 is in transmission connection with the screw shaft 1, the output shaft 11 of the reducer 4 is in transmission connection with the screw shaft 1 through the universal joint 10, and the motor 3 is connected with the screw shaft 1 through the reducer 4 The screw shaft 1 is driven to rotate, and several sections of stirring devices are arranged on the screw shaft 1. Each secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com