Cylinder block for integral gas compressor and internal combustion engine

A technology of gas compressors and cylinder blocks, which is applied in the direction of liquid variable displacement machinery, machines/engines, mechanical equipment, etc., and can solve the problems of increasing the cost of compressors, oil leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

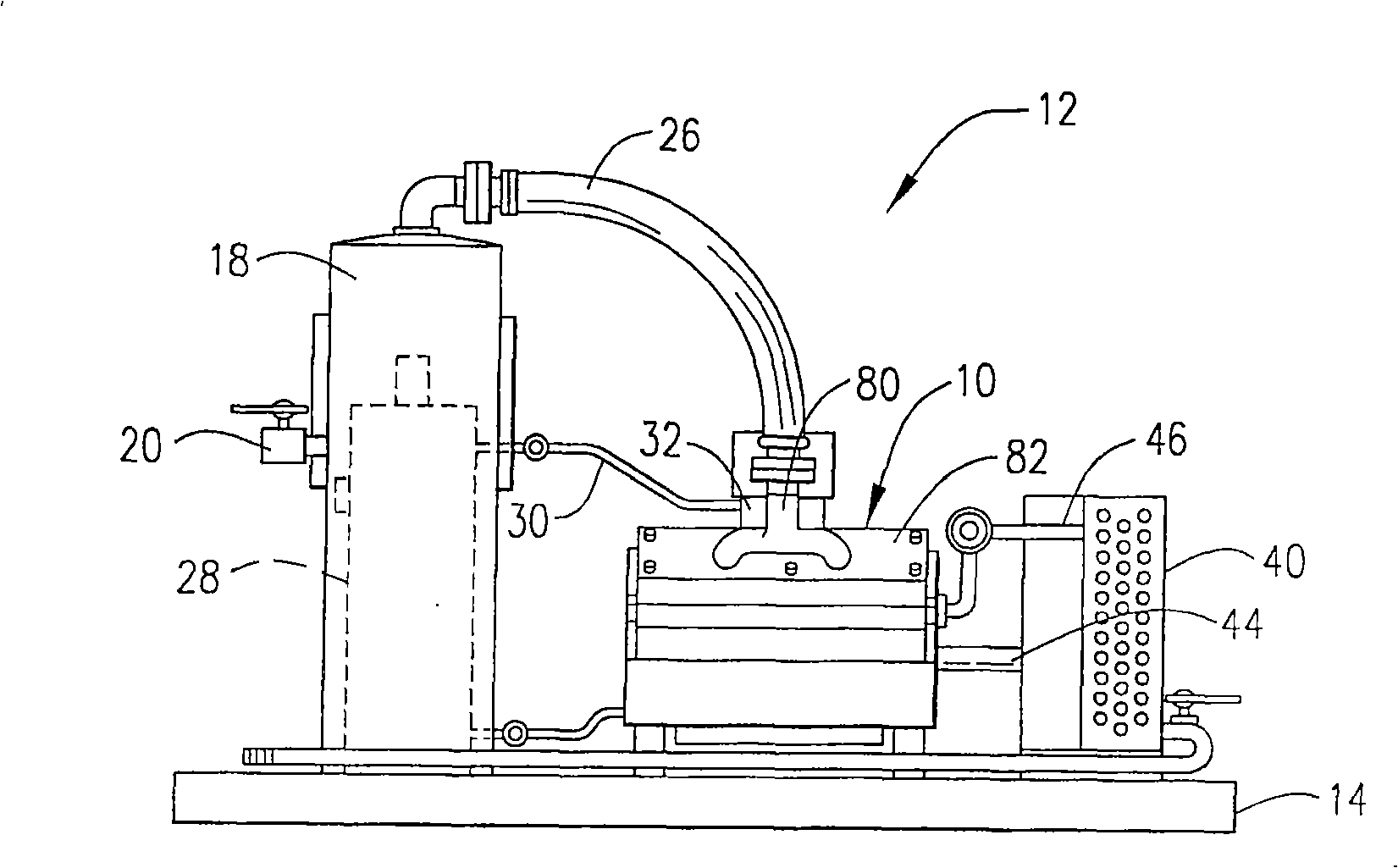

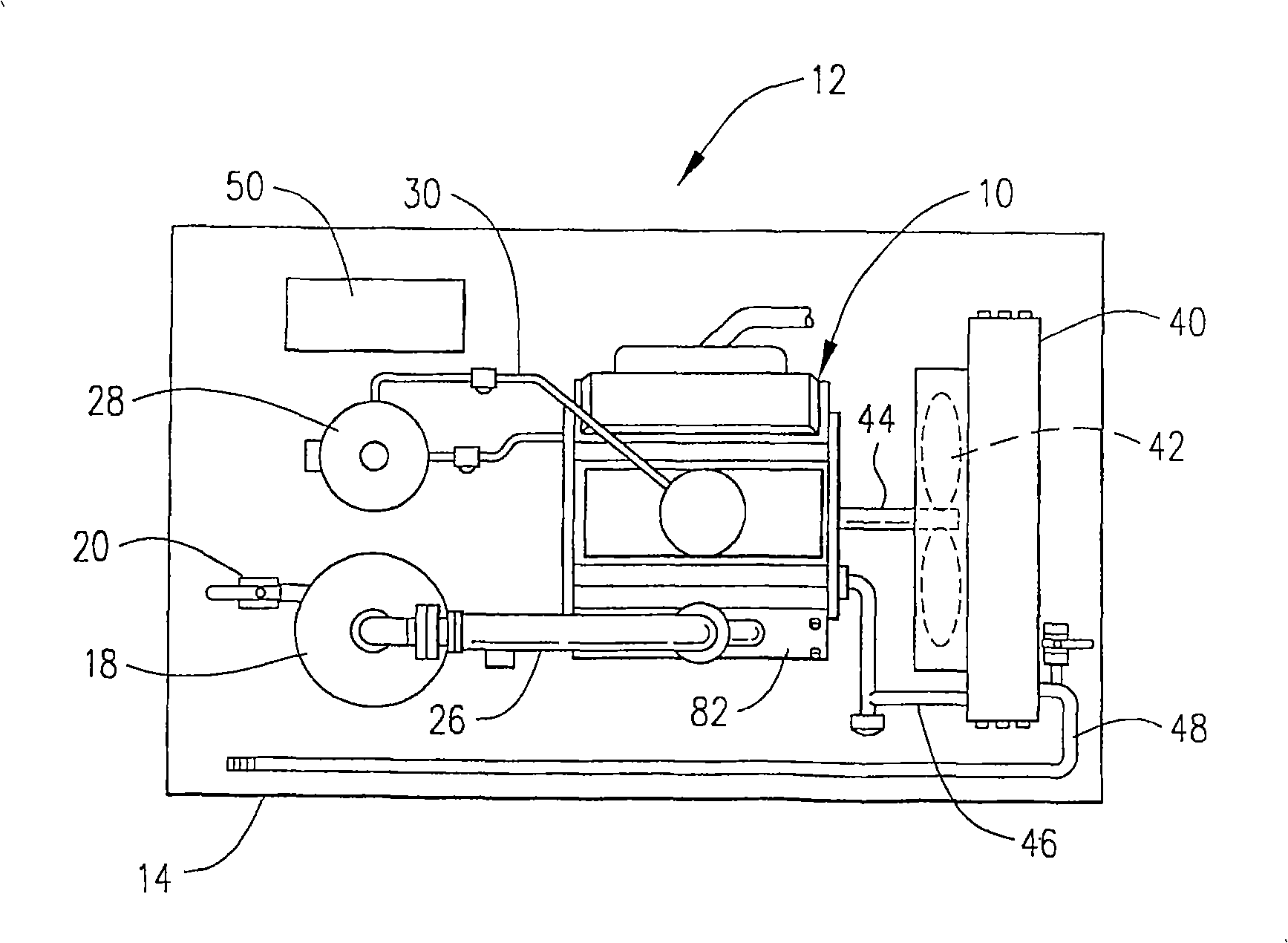

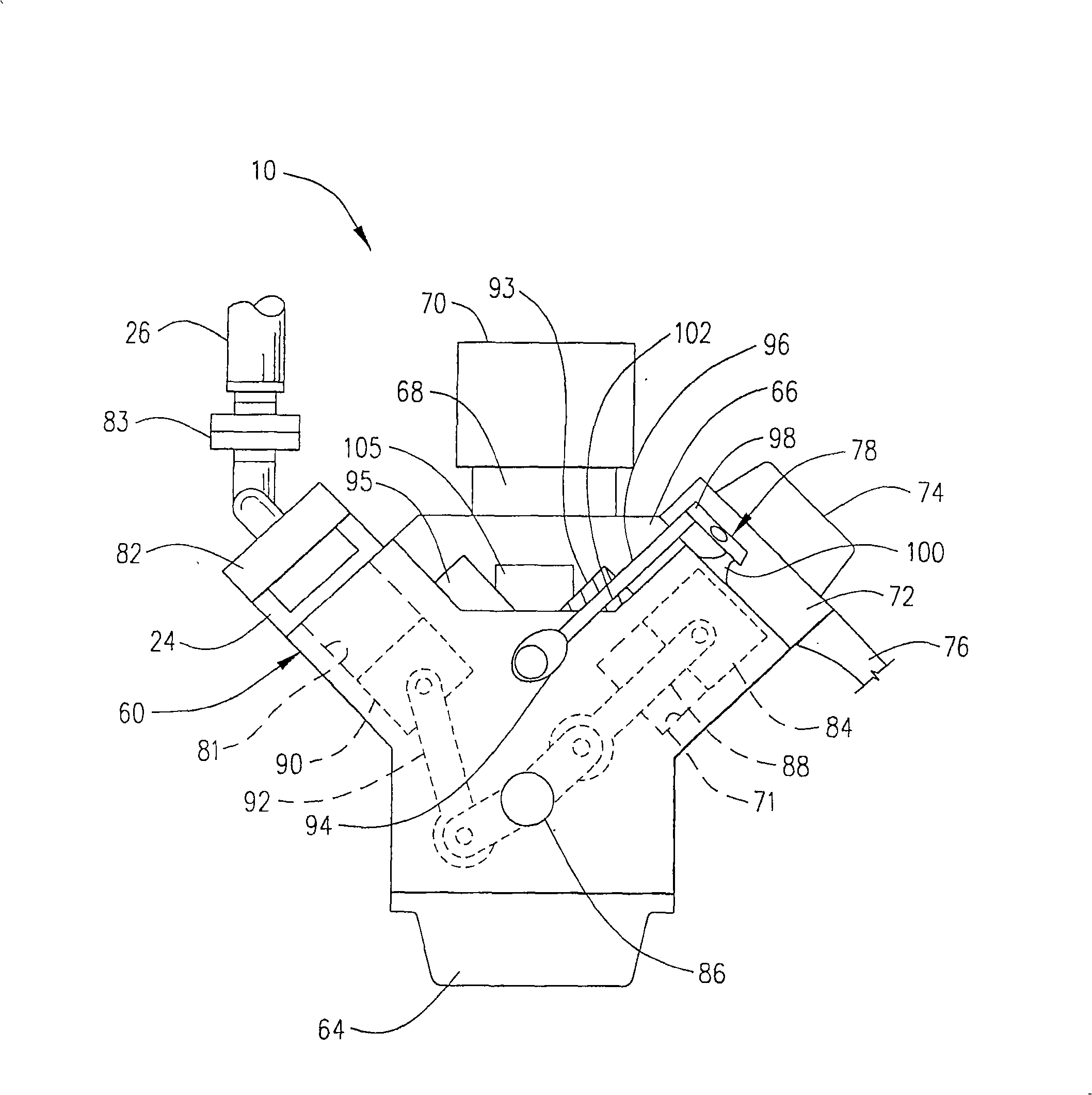

[0020] Referring now to the accompanying drawings, and in particular to figure 1 , designates an integrated gas compressor and internal combustion engine incorporating the cylinder block of the present invention, and is generally designated by the numeral 10. Compressor 10 is shown as part of compressor package 12 . The integrated gas compressor and internal combustion engine 10 is also referred to here simply as compressor 10 .

[0021] Compressor assembly 12, as shown, is of a type particularly suitable for recovering natural gas from a well, but may also be used for other combustible gases or gases with elevated inlet pressure. The present invention is not intended to be limited to the illustrated compressor package 12 . figure 1 and 2 It has been greatly simplified to remove the bulk of the tubing and wiring associated with the kit 12 . Omitted terms are known in the art and are not necessary for an understanding of the present invention.

[0022] In a typical suite 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com