Patents

Literature

231results about How to "No break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

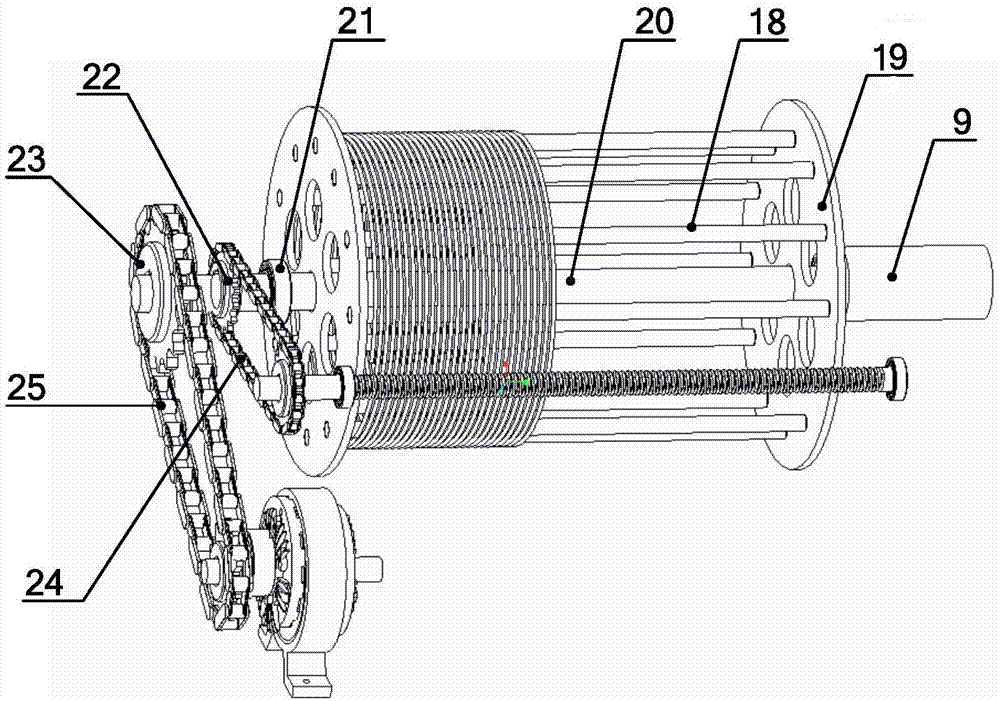

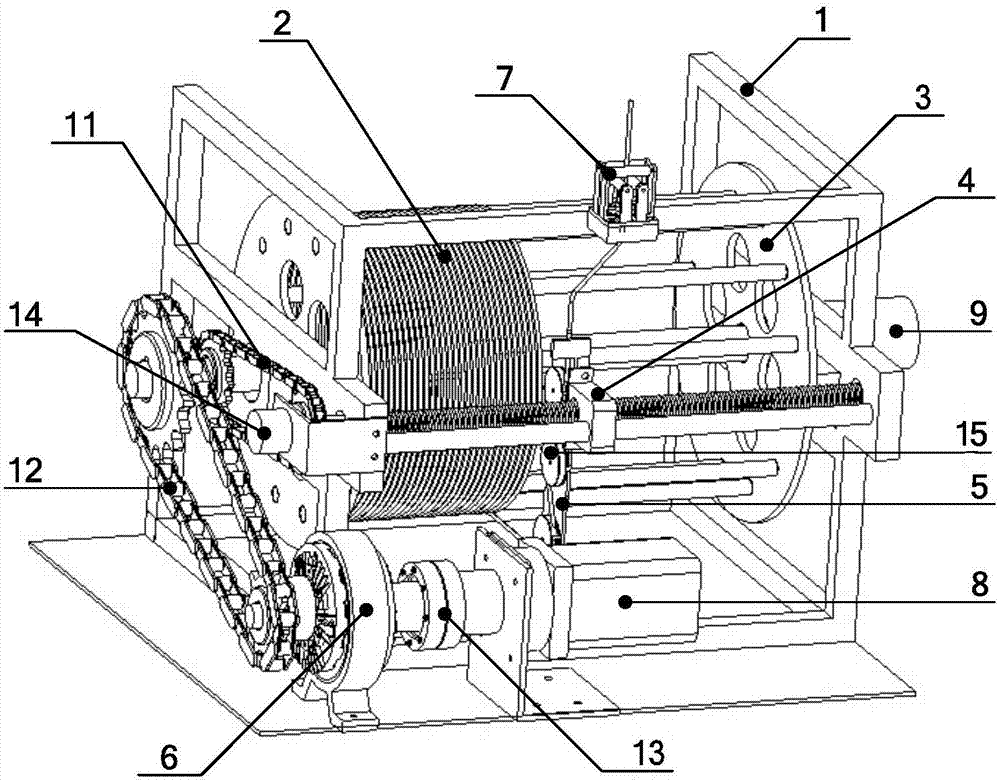

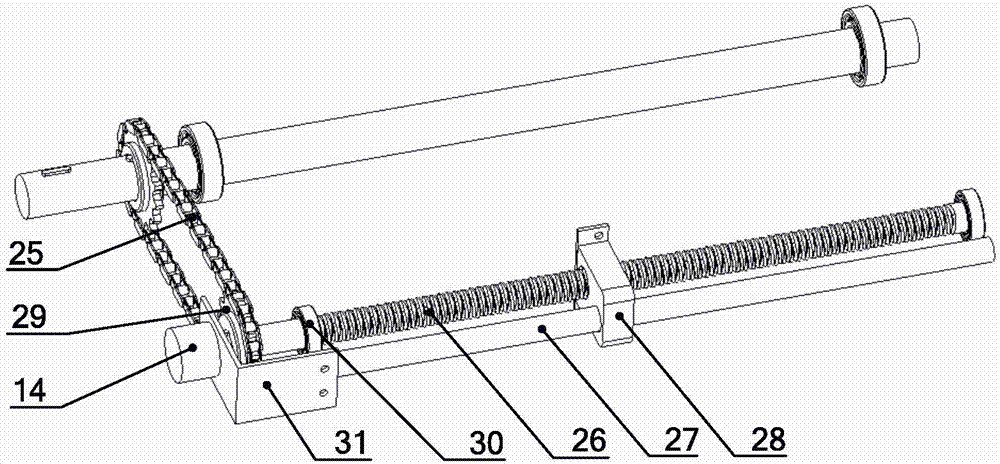

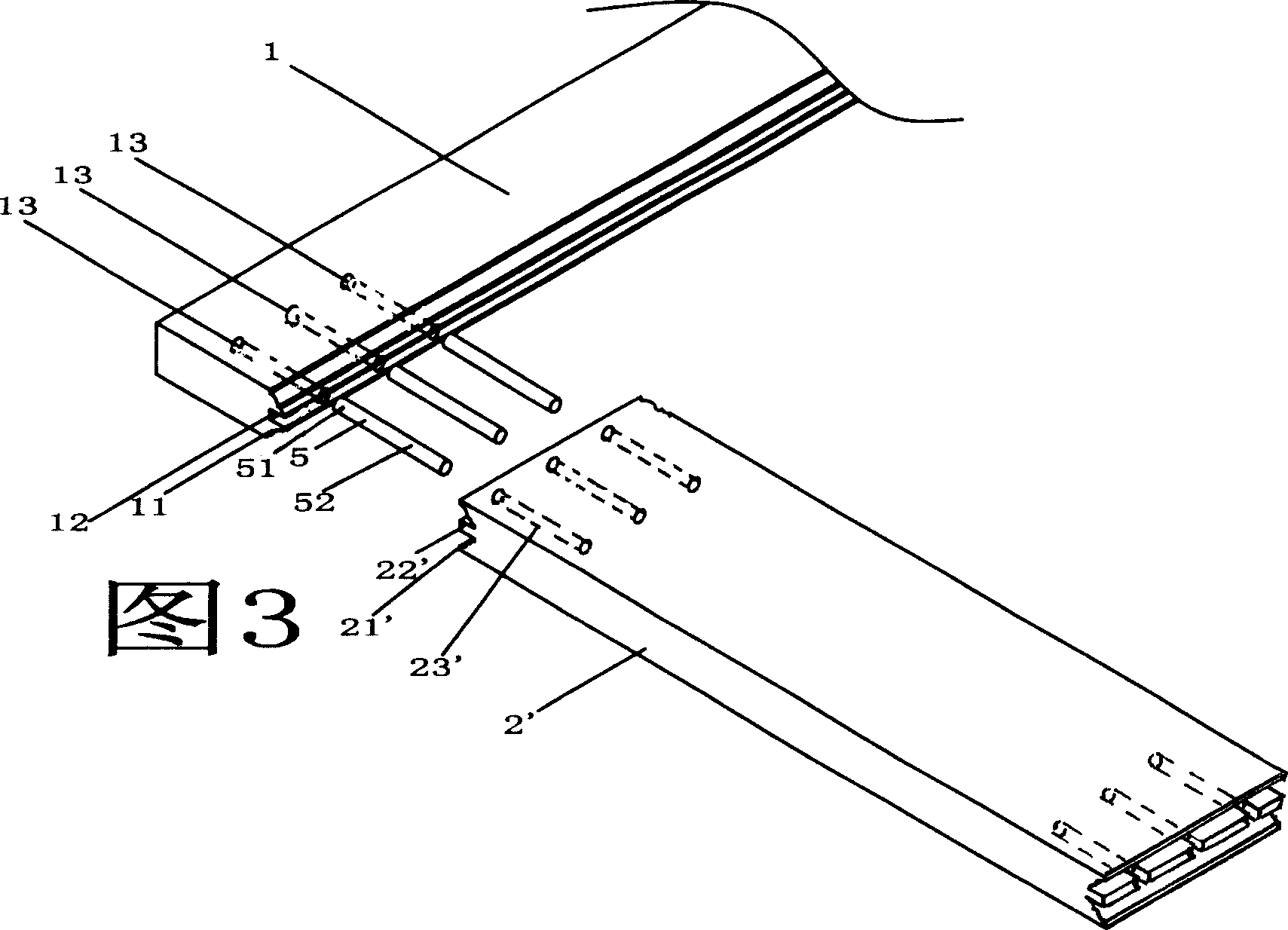

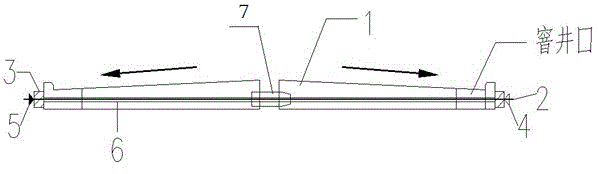

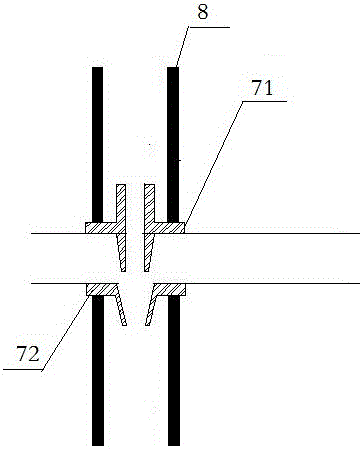

Cable tension self-adjustment winch and control method thereof

ActiveCN106946097AImprove Motion Control AccuracyOvercoming Low Intensity ProblemsFilament handlingMaximum torqueAutomatic control

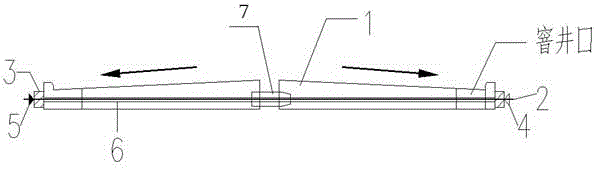

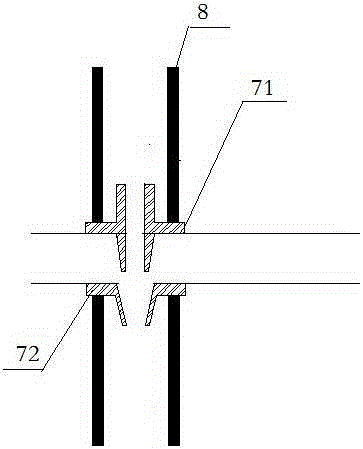

The invention discloses a cable tension self-adjustment winch and a control method thereof, and belongs to the field of automatic control. The cable tension self-adjustment winch comprises a winding drum and a driving device driving the winding drum to rotate; the driving device is electrically connected with a control device; a winding displacement device parallel to the axial direction of the winding drum is arranged on the outer side of the winding drum; the winding drum is linked with the winding displacement device; a tension detection device is arranged on the winding displacement device, is located between the winding displacement device and the winding drum, and is electrically connected with the control device; and a tension protection device is connected with between the driving device and the winding drum, limits maximum torque output by the driving device and is connected with the control device. Through the measurement on winding and unwinding stressed states and winding and unwinding movement states of a cable and a clutch state of the tension protection device, self-adaption control is carried out on a rotating speed and torque of the winding drum, so that winding and unwinding movement of the cable is coordinated with active movement of a high-speed mobile object, and cable breakage is avoided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

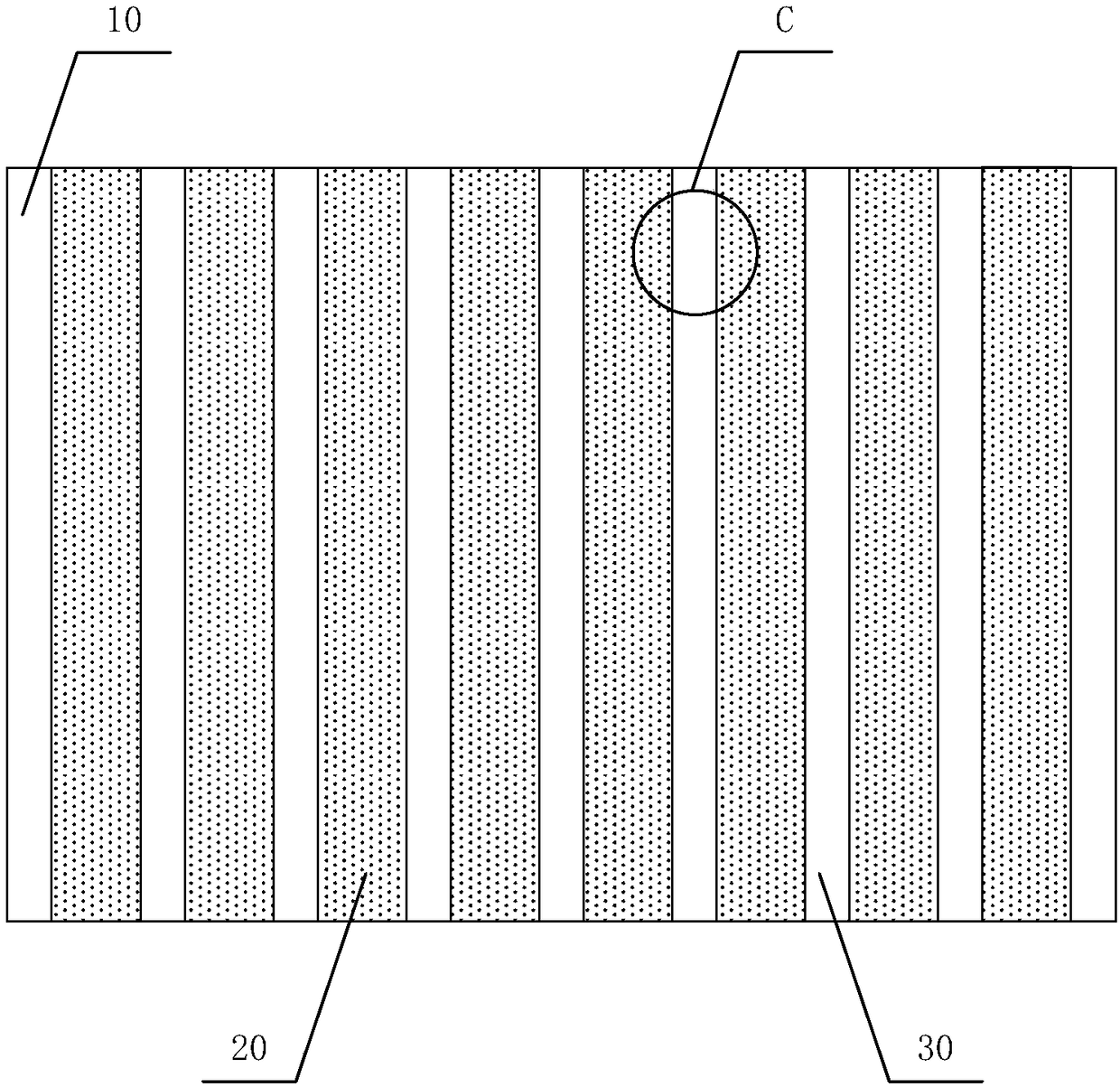

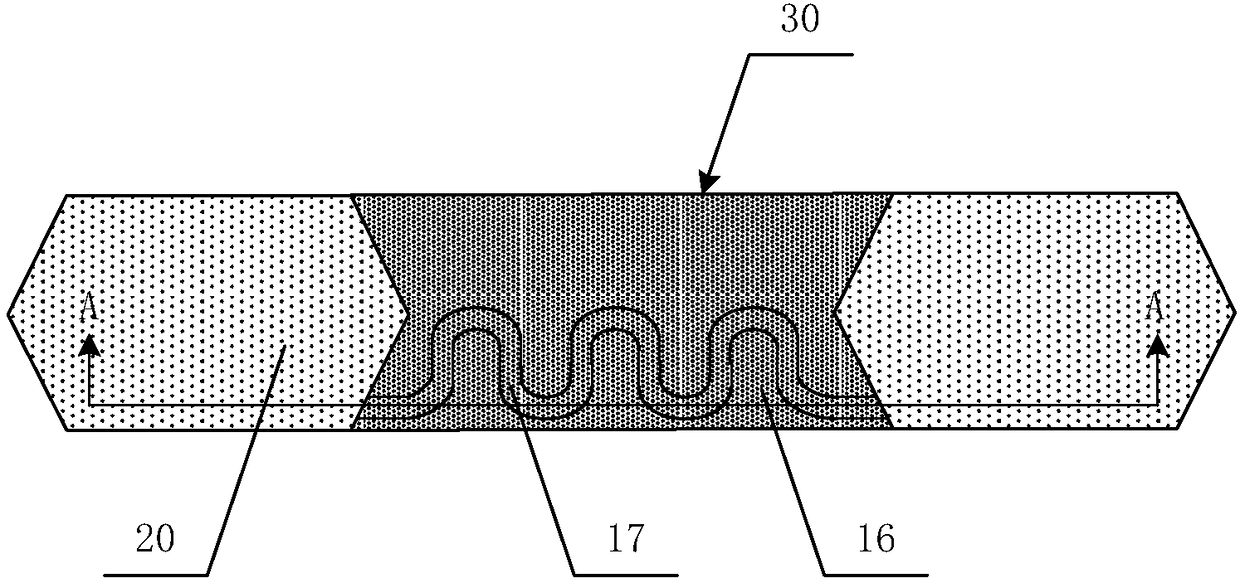

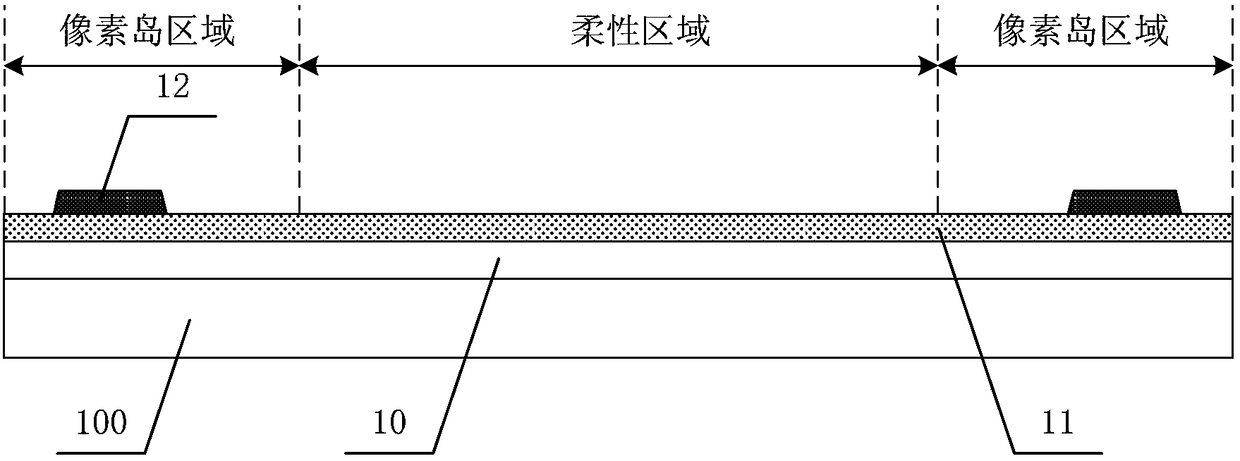

Flexible array substrate and preparation method thereof and flexible display panel

ActiveCN108461531AGood stretchImprove bendabilityFinal product manufactureSolid-state devicesFlexible displayComputer science

The invention relates to the technical field of display and discloses a flexible array substrate and a preparation method thereof and a flexible display panel. The flexible array substrate comprises aplurality of pixel island regions which are sequentially arranged; flexible areas are arranged between the adjacent pixel island regions; each pixel island region comprises a gate electrode; each flexible area comprises a first elastic layer; each first elastic layer is provided with a first connection line; each first connection line is provided with a second elastic layer; each second elastic layer is provided with a second connection line; a plurality of interlayer through holes are formed in each second elastic layer; an elastic conductive column is arranged in each interlayer through hole; the elastic conductive columns are electrically connected with the first connection lines and the second connection lines separately; and the first connection lines and / or the second connection lines are connected with the gate electrodes of the adjacent pixel island regions. Through the arrangement of the elastic conductive columns and a dual-layer connection electric structure, the flexible array substrate has relatively excellent tensile property in the direction vertical to the flexible array substrate, and good tensile property and bendability of the flexible array substrate are achieved.

Owner:BOE TECH GRP CO LTD

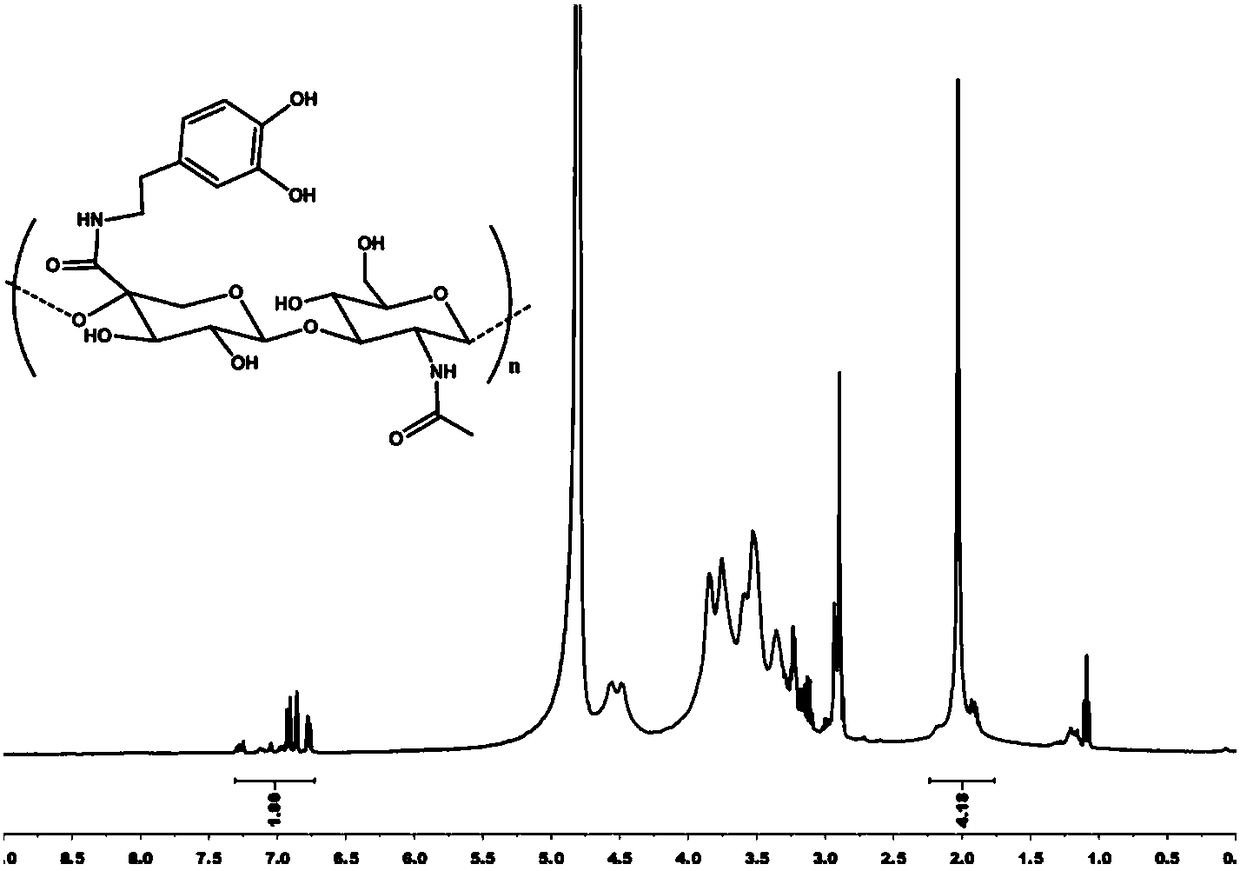

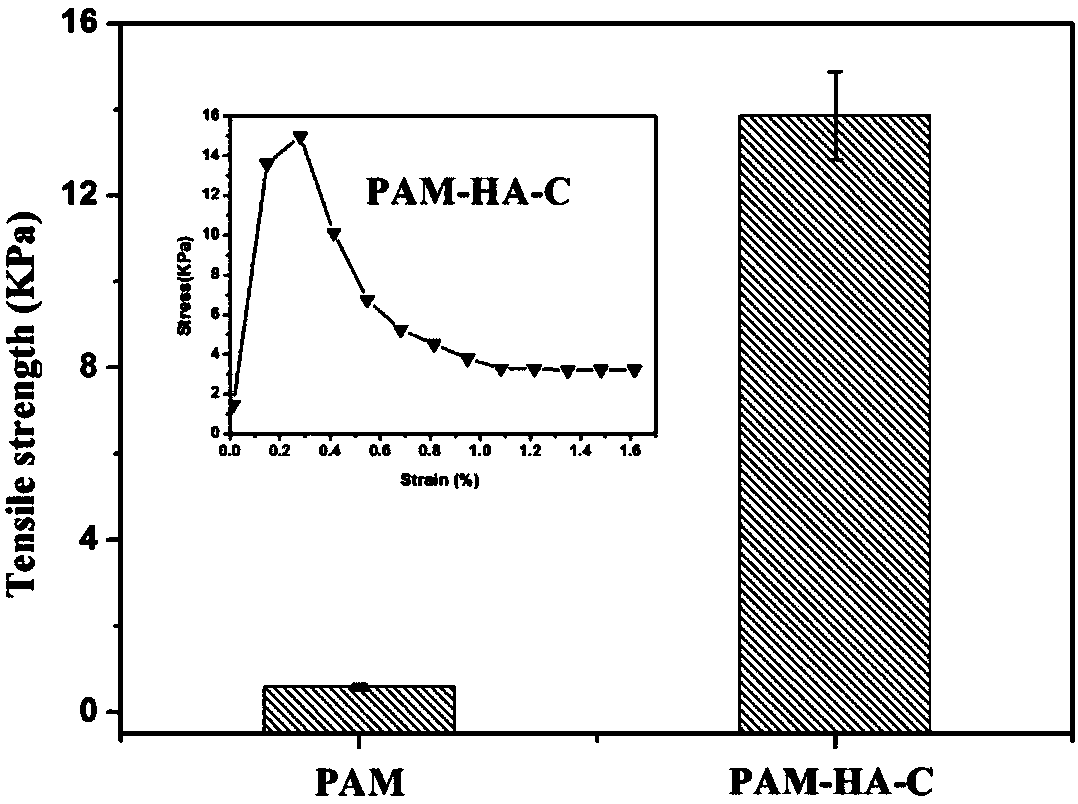

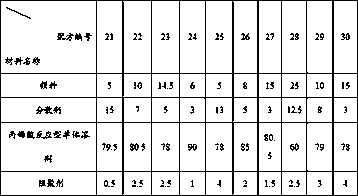

Preparation method of self-adhering super strong hydrogel

The invention discloses a preparation method of a self-adhering super strong hydrogel, and is characterized in that the preparation method comprises the steps: adding dopamine grafted modified hyaluronic acid into an acrylamide aqueous solution, adding N,N-methylene bisacrylamide and ammonium persulfate, fully stirring evenly, and carrying out sealed vacuumization for 10-15 min; in an ice water bath and under a stirring condition, adding tetramethylethylenediamine, placing at the temperature of 0-4 DEG C, and crosslinking for 12-16 h, to obtain the self-adhering super strong polyacrylamide hydrogel. The prepared self-adhering super strong hydrogel has the following advantages: 1, the adhesion strength is large, is up to 12.3 kPa and is 3-4 times that of a pure polyacrylamide gel; and during use, an auxiliary adhesive or adhesive tape and the like does not need, and the self-adhering super strong hydrogel can adhere onto the surface of any material; and 2, the self-adhering super stronghydrogel has self-healing and self-repairing properties and can be self-healed in 20-30 min.

Owner:JIANGHAN UNIVERSITY

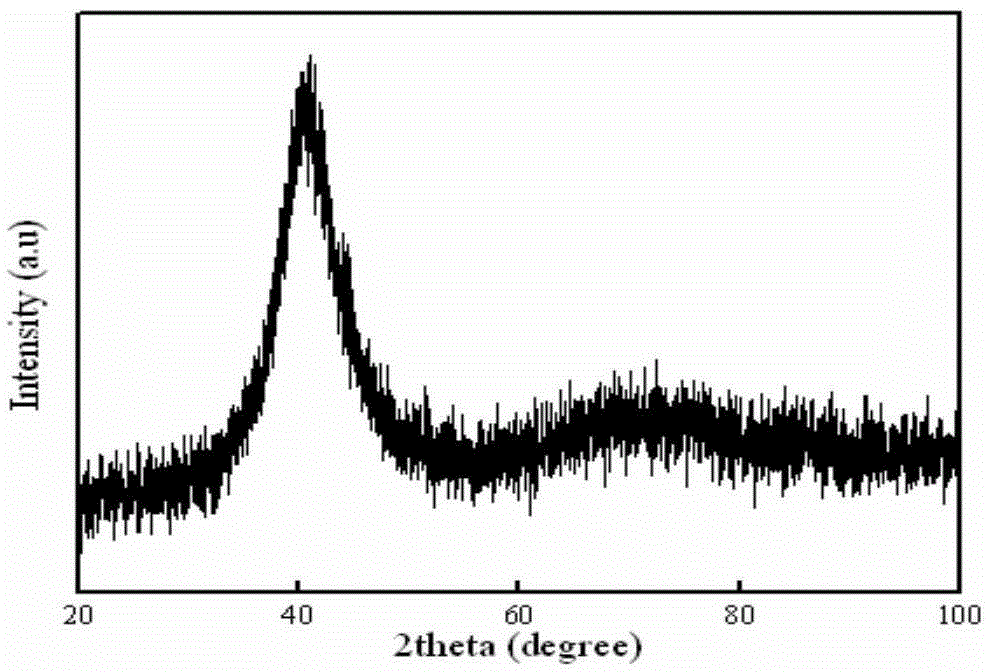

High-tap density micro aluminum powder and method for producing the same

The invention discloses minute silver powder with high tap density and a method for producing the same. The silver powder has the following properties: the average particle diameter of the silver powder is between 0.3 and 1.5 mu m; the tap density of the silver powder is not less than 4.5g / cm<3>; and the contraction rate of the silver powder is less than or equal to 19 percent after the silver powder is sintered at the temperature of less than or equal to 900 DEG C. The production method comprises: (1) preparing a solution containing silver ions for standby; (2) preparing a reducer aqueous solution containing a dispersant for standby; (3) preparing a treatment solution containing a treating agent for standby; (4) mixing and reacting the solution containing the silver ions and the reducer solution containing the dispersant for reducing the silver ions to silver particles; (5) filtering out a reaction solution, and cleaning the silver particles by deionized water; (6) pumping and leaching the cleaned silver powder, putting the cleaned silver powder into the treatment solution for treatment; and subsequently, filtering out the treatment solution; and (7) drying the silver powder in a vacuum oven; and pulverizing the dried silver powder to obtain the minute silver powder with high tap density. Silver slurry prepared from the silver powder is printed on a magnet body or a substrate, is sintered at temperature of less than or equal to 900 DEG C and has good matching property with the magnet body or the substrate. The minute silver powder is suitable for a manufacturer for producing an electronic element.

Owner:贵阳晶华电子材料有限公司

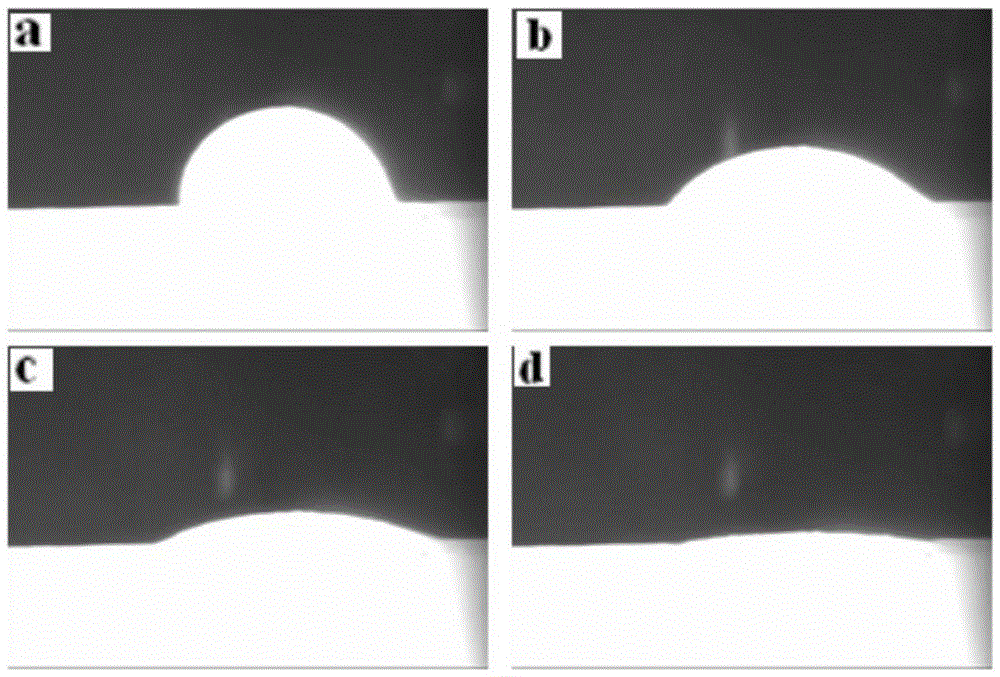

Active amorphous brazing filler metal for brazing ZrB2-SiC ceramic materials, preparation method for active amorphous brazing filler metal and brazing process

InactiveCN105252169AImprove wettabilityImprove toughnessWelding/cutting media/materialsSoldering mediaUltra-high-temperature ceramicsRoom temperature

The invention discloses active amorphous brazing filler metal for brazing ZrB2-SiC ceramic materials, a preparation method for the active amorphous brazing filler metal and a brazing process, particularly relates to Cu-Ti-Ni-Zr high-temperature active amorphous brazing filler metal for brazing ZrB2-SiC ultra-high-temperature ceramic materials, a preparation method for the Cu-Ti-Ni-Zr high-temperature active amorphous brazing filler metal and a brazing process, and belongs to brazing filler metal in the amorphous and metallurgy fields. The components of the brazing filler metal comprise, by atomic percentage, 36.0-42.0% of Cu, 30.0-35.0% of Ti, 16.0-23.0% of Zr and the balance Ni. The melting temperature of the active amorphous brazing filler metal is 1110-1150 K, and the brazing temperature is 1183-1273 K. The Cu-Ti-Ni-Zr high-temperature active amorphous brazing filler metal obtained through the rapid condensation technology has good wettability. The room temperature shearing strength of the ZrB2-SiC ultra-high-temperature ceramic materials brazed through the amorphous brazing filler metal in a vacuum brazing mode can be as high as 160 MPa and much higher than that of Cu-based and Ag-based brazing filler metal.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Fluorine rubber seal element and preparing method thereof

ActiveCN101168656AExtended service lifeGood process performanceOther chemical processesCarbon blackCalcium hydroxide

The invention provides a fluorinated rubber sealing element; the invention is characterized in that the sealing element is produced by the raw material with the following quality parts: binary fluorinated elastomer of 60 to 80 parts, tetrafluoroethlene propylene rubber of 20 to 40 parts, carbon black of 20 to 40 parts, calcium hydroxide of 3 to 5 parts, metal oxide of 3 to 6 parts, hexafluoride sonitroso propyl diphenol of 1.5 to 2 parts, benzyl triphenyl phosphorus chloride of 0.3 to 0.5 part, processing aid of 0.5 to 2 part, dicumyl peroxide of 0.5 to 1.2 parts, and triene propyl isocyan urate of 0.5 to 1.2 parts. The invention has the preparation method that sulphation for 8 to 12 minutes is molded on a compression machine under 165 to 180 DEG C through being extruded and formed after the raw material with the quality parts are added in mixing equipment to be mixed uniformly under 60 to 80 DEG C, and then the sealing element is produced after performing secondary cure for 8 to 24 hours in hot air of 200 to 250 DEG C. The fluorinated rubber sealing element produced has long service life and can be high temperature water vapor resistant and high and low impact resistant.

Owner:广州国机智能橡塑密封科技有限公司

Preparation method of novel smokeless mosquito-repellent incense

InactiveCN105685114AConducive to environmental protectionSmooth appearanceBiocidePest repellentsIgnition pointFire retardant

The invention discloses a preparation method of novel smokeless mosquito-repellent incense, belonging to the technical field of preparation of the mosquito-repellent incense. The novel smokeless mosquito-repellent incense is prepared by the steps of preparing sludge carbon powder, preparing paste, molding the paste, drying the molded paste, spraying chemicals onto a dry mosquito-repellent incense blank, and the like. According to the preparation method, sludge carbon is taken as an incendiary agent, and an inorganic substance in the sludge carbon is taken as a flame retardant, so that not only is a new way provided for the resource utilization of the sludge carbon, but mass disafforestation caused by the mosquito-repellent incense industry is also avoided, and the preparation method of the novel smokeless mosquito-repellent incense is beneficial to environmental protection. The novel smokeless mosquito-repellent incense is non-toxic and harmless and can meet the requirement of environmental protection for the product; after the novel smokeless mosquito-repellent incense is burnt and absorbed by the human body, asthma, nerve poisoning and cancers are not caused; the novel smokeless mosquito-repellent incense has a smooth appearance, is free from fracture and mildew spots, and has the breaking-resistant strength of 425-456g and the ignition point time of 8.61-9.01h; in the burning process, smoke is not generated; the novel smokeless mosquito-repellent incense avoids a phenomenon of broken-end flameout when being burnt to an iron-tooth disk.

Owner:庞用

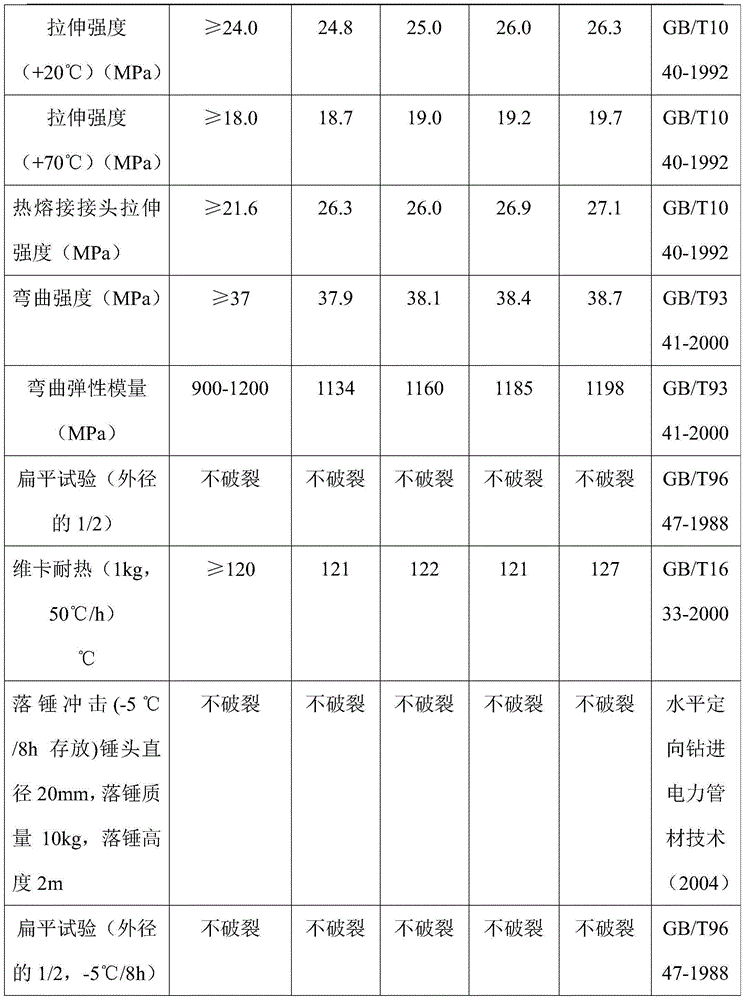

Anti-impact MPP (molypermalloy powder core) electric protection tube

The invention discloses an anti-impact MPP (molypermalloy powder core) electric protection tube. The anti-impact MPP electric protection tube is prepared from the following raw materials in parts by weight: 90-110 parts of polypropylene, 5-15 parts of ethylene-propylene-diene monomer, 10-25 parts of talcum powder, 3-10 parts of brucite powder, 5-12 parts of modified micro silicon powder, 0.8-2 parts of colouring agent, 5-15 parts of nano mica, 0.5-2 parts of antioxidant, 0.5-2 parts of polytetrafluoroethylene, 10-25 parts of modified shell powder, 5-15 parts of modified hectorite, 5-25 parts of novel organic montmorillonite, 5-18 parts of melamine cyanurate, 10-25 parts of modified crystal whisker, 15-30 parts of long glass fiber, 3-8 parts of expandable graphite and 5-20 parts of intumescent flame retardants. The anti-impact MPP electric protection tube has excellent impact resistance, flame retardance, ageing resistance, cold resistance and heat resistance.

Owner:安徽宁国市高新管业有限公司

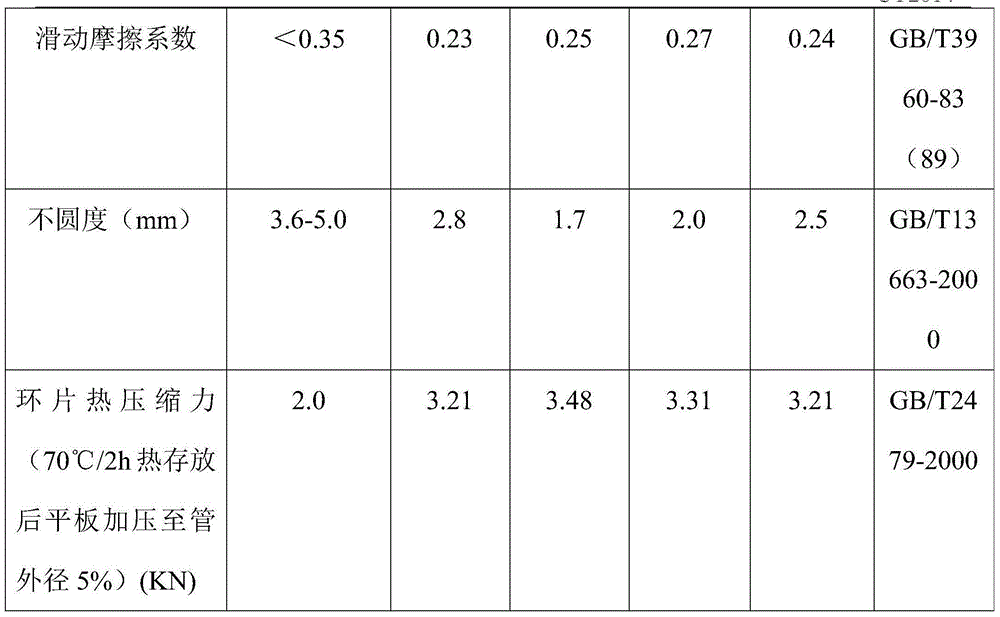

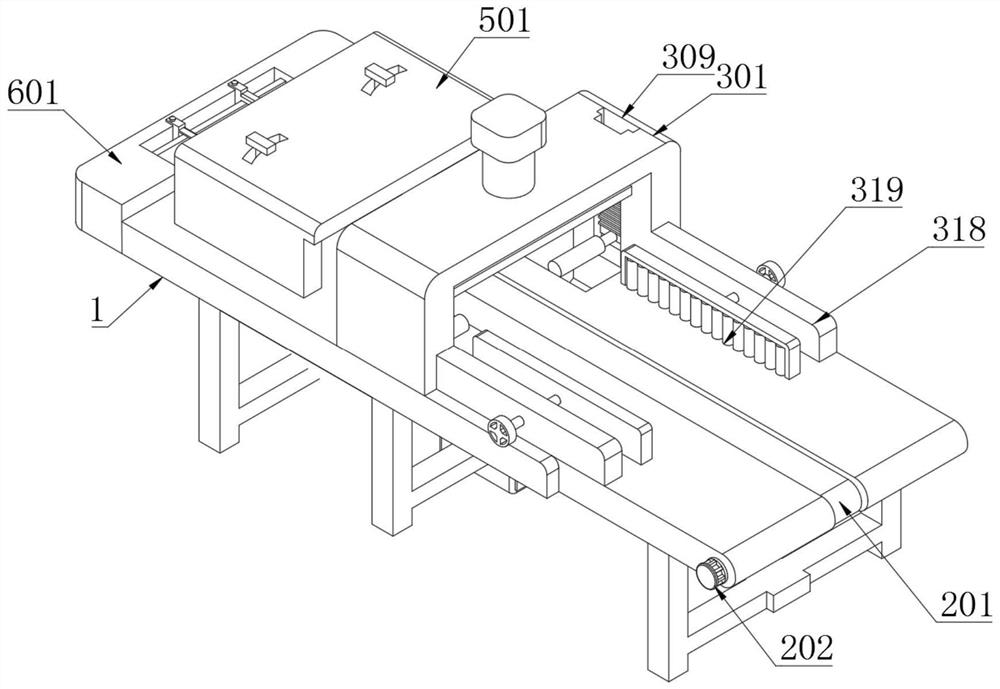

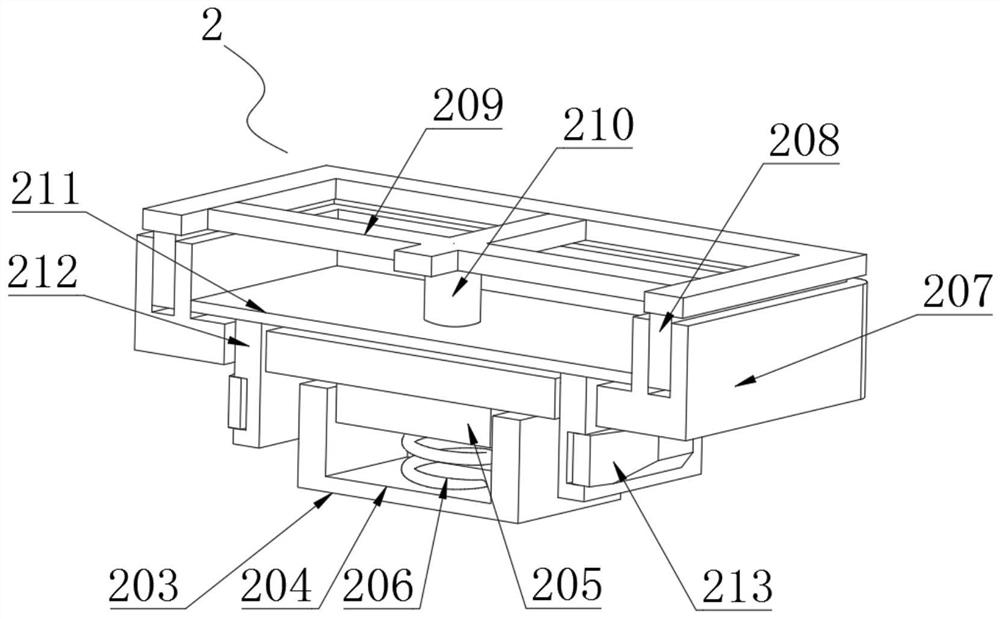

Flexible display screen and manufacturing method thereof

ActiveCN111882991AScientific and reasonable structureEasy to useEdge grinding machinesGrinding carriagesElectric machineryDrive motor

The invention discloses a flexible display screen and a manufacturing method thereof. The middle of the top end of a machine base is fixedly connected with a positioning cutting mechanism, the other side of the top end of the machine base is fixedly connected with a power conversion and grinding mechanism, and the middle of the machine base is rotationally connected with an adsorption fixing and moving mechanism; The adsorption fixing and moving mechanism comprises a conveying belt, a driving motor, a mounting base, an embedding groove, a movable plate, a supporting spring, a suction cup and arubber plate. The flexible display screen is scientific and reasonable in structure and safe and convenient to use, the adsorption fixing and moving mechanism is arranged, glass is adsorbed and fixedthrough the suction cups, the stability of the glass is improved, loss caused by falling of glass in moving machining process is avoided. The movable plug plate is driven to slide in the suction cupthrough cooperation of the rubber plate and the connecting rod in the glass adsorption process, and meanwhile the movable plug plate extrudes air pressure in the suction cup due to the fact that the movable plug plate is attached to the interior of the suction cup.

Owner:SHENZHEN RUGIN ELECTRONICS

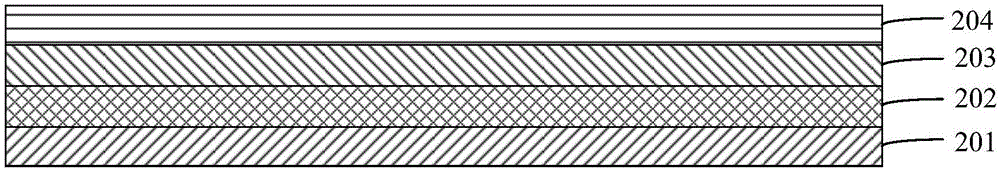

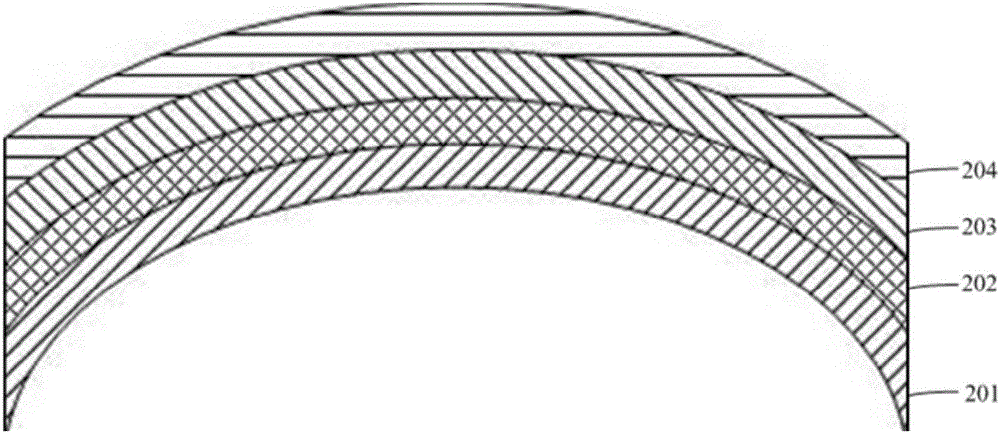

Organic light emitting display panel and manufacturing method therefor, and display apparatus

ActiveCN106653815AReduced risk of breakageQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsSurface plate

Embodiments of the invention disclose an organic light emitting display panel and a manufacturing method therefor, and a display apparatus. The organic light emitting display panel comprises a display region and a non-display region which is arranged around the display region, and also comprises a flexible substrate; the non-display region also comprises a first inorganic layer, a metal lead layer, a first organic layer and a second inorganic layer, wherein the first inorganic layer is positioned on the flexible substrate; the metal lead layer is positioned on one side, far from the flexible substrate, of the first inorganic layer; the metal lead layer comprises multiple separately-arranged metal leads; the first organic layer is positioned on the surface on one side, far from the first inorganic layer, of the metal lead layer; the metal leads are coated with the first organic layer; and the second inorganic layer is positioned on one side, far from the metal lead layer, of the first organic layer. By adoption of the technical scheme, cracking of the metal leads can be avoided.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

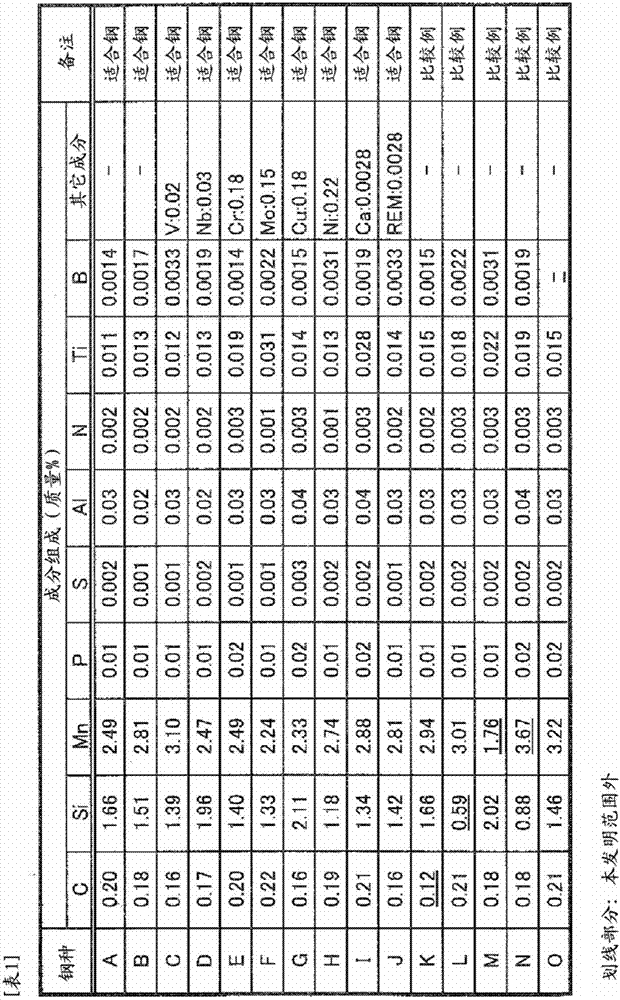

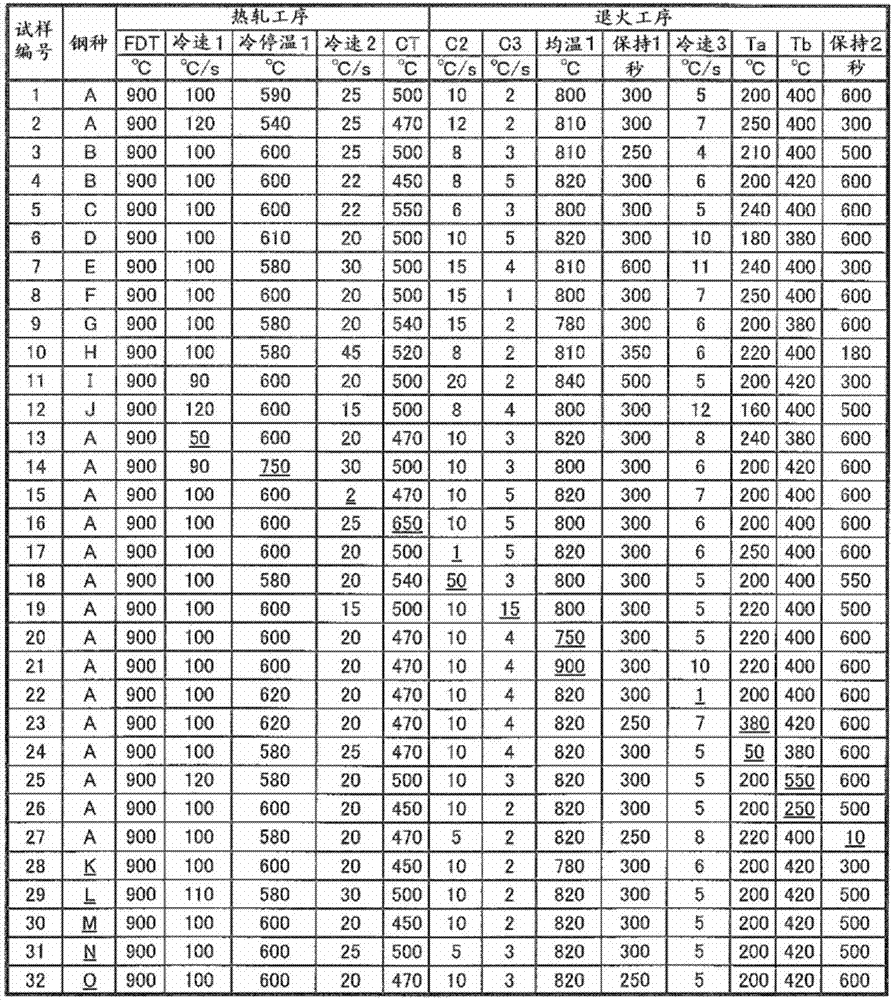

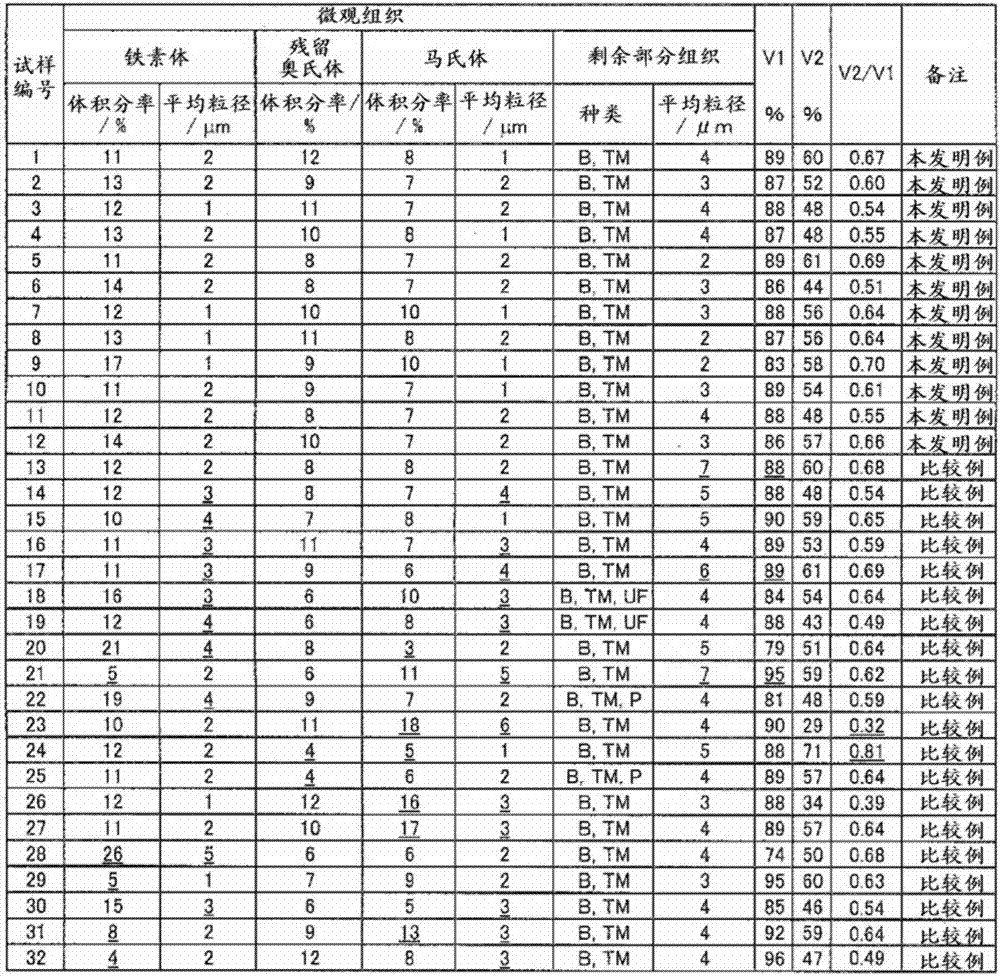

High-strength cold-rolled steel sheet and method for producing same

ActiveCN107002198AHigh tensile strengthHigh yield ratioFurnace typesHeat treatment furnacesSheet steelHigh intensity

Provided are: a high-strength cold-rolled steel sheet which solves problems of prior art and has a good balance among a plurality of characteristics (yield ratio, strength, elongation, bore expanding properties and delayed fracture resistance); and a method for producing this high-strength cold-rolled steel sheet. A high-strength cold-rolled steel sheet which is characterized by having a specific component composition and by having a microstructure that is a composite structure which contains 10-25% by volume of ferrite having an average crystal grain size of 2 [mu]m or less, 5-20% by volume of residual austenite, and 5-15% by volume of martensite having an average crystal grain size of 2 [mu]m or less, with the balance made up of tempered martensite and bainite having an average crystal grain size of 5 [mu]m or less, in said microstructure the volume fraction (V1) of hard phases other than ferrite and the volume fraction (V2) of the tempered martensite satisfying the condition of formula (1) which is 0.35<=V2 / V1<=0.75 Formula (1).

Owner:JFE STEEL CORP

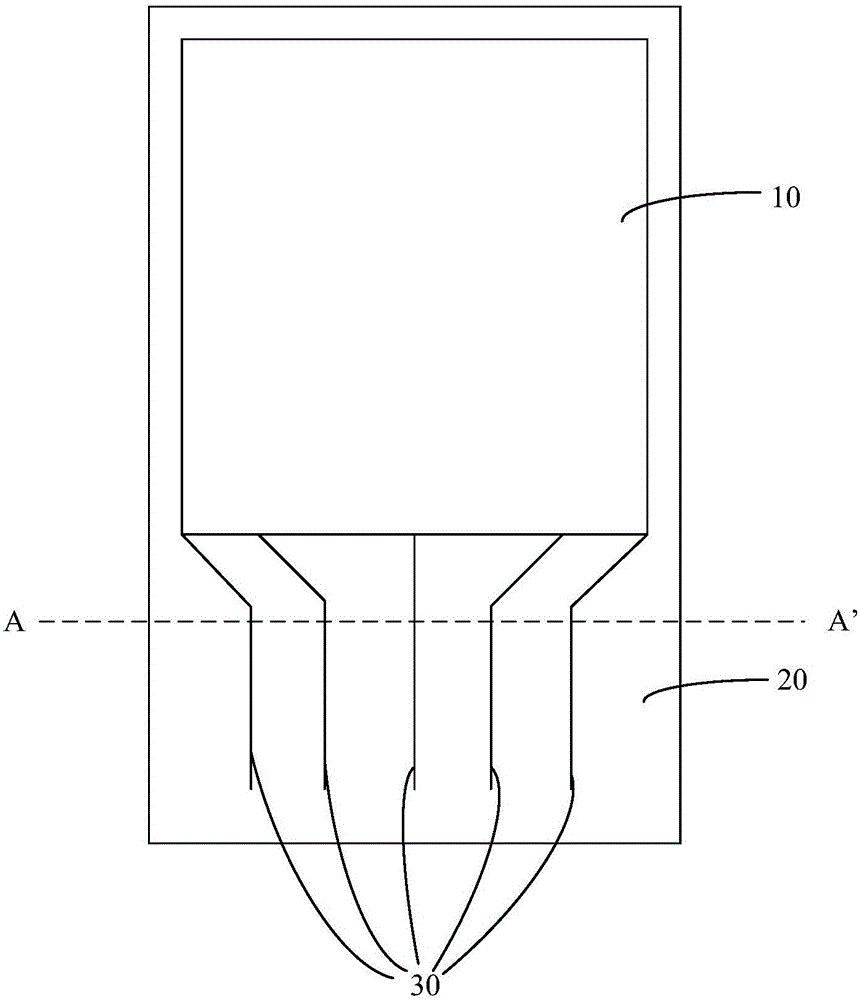

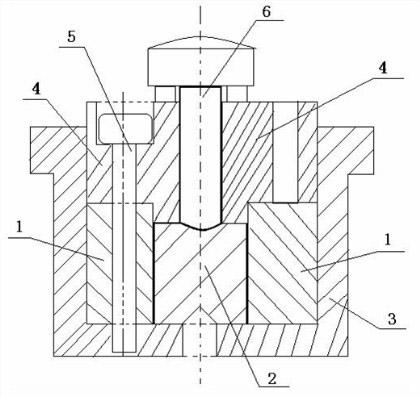

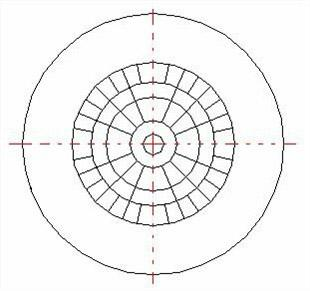

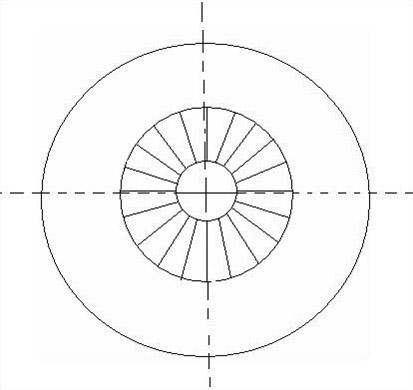

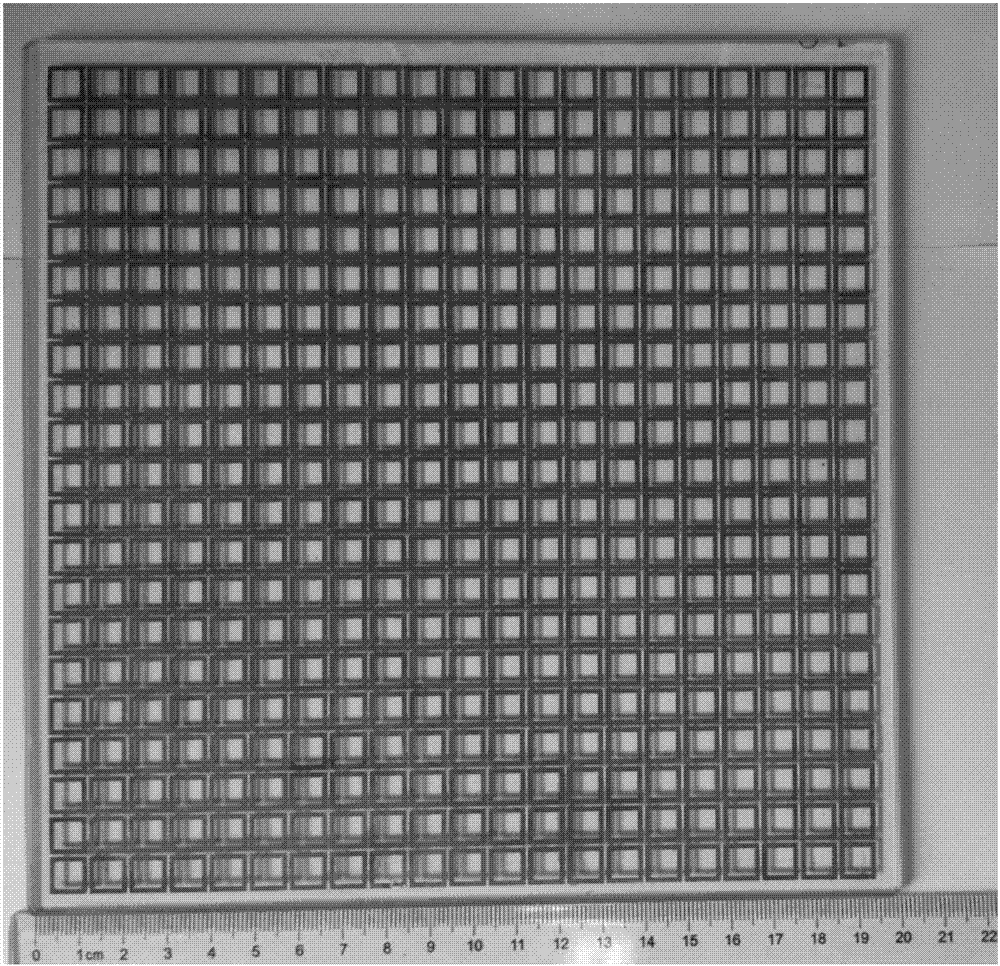

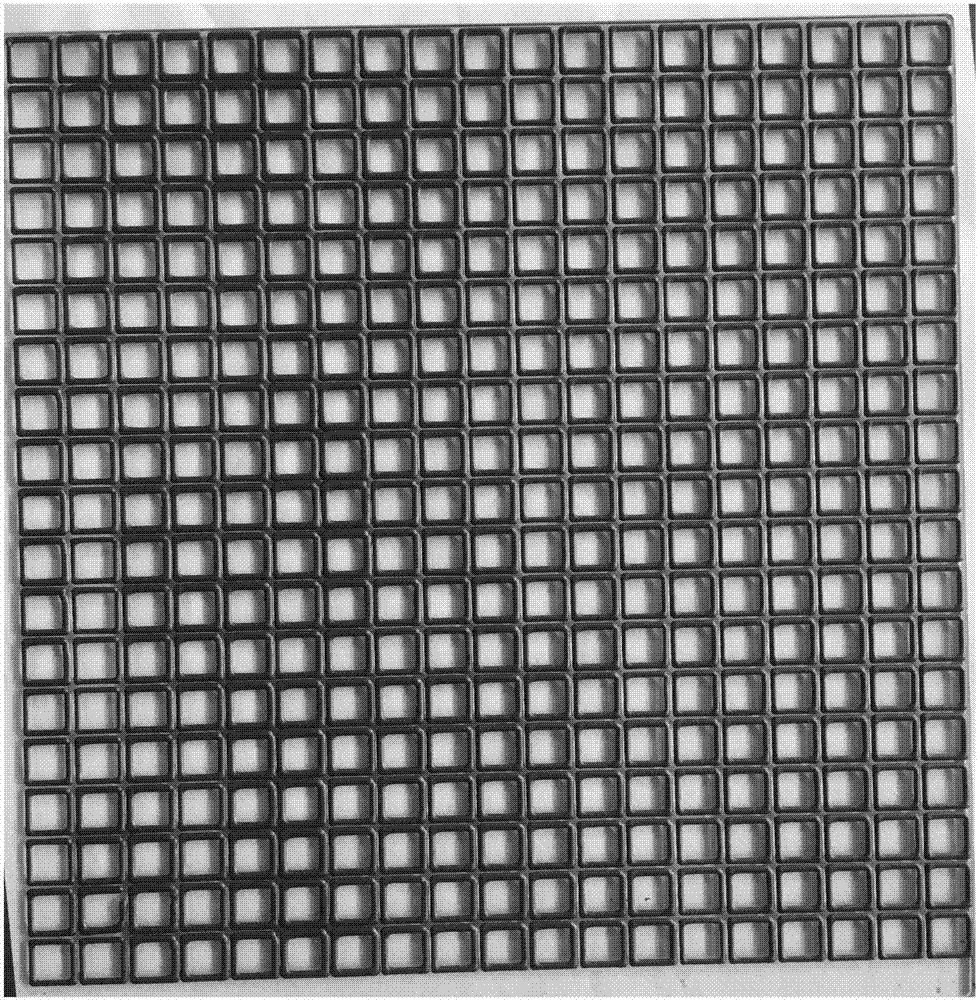

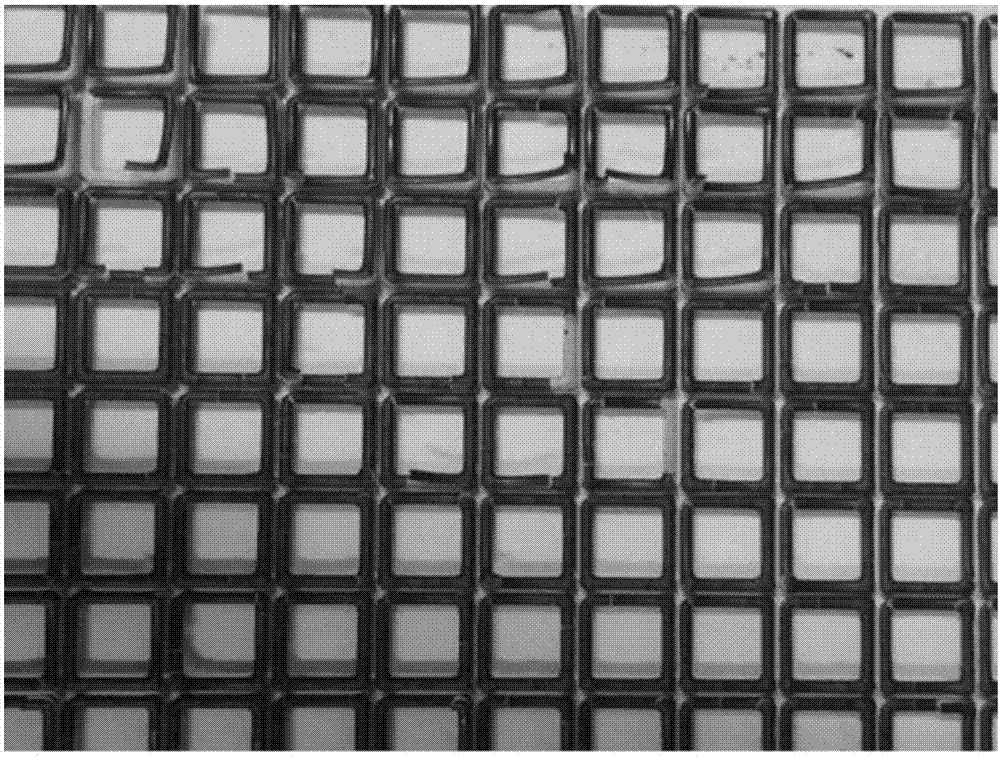

Method for manufacturing grid of millimeter-wave traveling wave tube

InactiveCN102184821AImprove performanceReduce the chance of sparkingPhotomechanical apparatusNon-emitting electrodes manufactureManufacturing gridWave tube

The invention discloses a method for manufacturing a grid of a millimeter-wave traveling wave tube. The method comprises the following steps of: firstly etching to obtain a planar grid with a required shape on a grid substrate by applying a photoetching technology, then, processing and forming the planar grid by a special spherical forming mold to obtain a spherical-crown-shaped grid, finally polishing the grid to obtain the grid of the millimeter-wave traveling wave tube. The method for manufacturing the grid of the millimeter-wave traveling wave tube, provided by the invention, has the advantages of strong maneuverability and reasonable technical design, and can be used for processing and manufacturing small-size, thin and complexly-shaped spherical grids with special size requirement; the grid manufactured with the method disclosed by the invention has the advantages of no burrs on the surface, low fire striking probability, high qualification rate, stable performances and very important application value.

Owner:NANJING SANLE ELECTRONICS INFORMATION IND GRP

Tap hole clay for recycled material high blast furnace and preparation method thereof

The invention belongs to the field of blast furnace iron making and particularly relates to tap hole clay for a blast furnace which replaces the conventional dense raw materials and coke powder by recycled materials and a preparation method thereof. The formula of the tap hole clay comprises the following components in percentage by weight: 55 to 70 percent of recycled material, 14 to 23 percent of clay, 2 to 5 percent of asphalt, 2 to 5 percent of sericite and 12 to 16 percent of binding agent. The dense raw materials such as dense corundum, high-alumina aggregate, an SiC raw material and the like and the coke powder are replaced by the recycled materials, so that mineral resources are saved, a large amount of energy is saved, waste discharge can be reduced effectively, the production cost of the tap hole clay is lowered and remarkable economic and social benefits are achieved.

Owner:通化耐博新材料股份有限公司

Aluminum alloy material for special-type high pressure oil pump cases and preparation method thereof

The invention relates to an aluminum alloy material for special-type high pressure oil pump cases, which contains the following chemical components in percentage by mass: 1.8-2.1% of silicon, 0.5-0.7% of copper, 5.8-6.1% of magnesium, 3.2-3.4% of manganese, 2.6-2.8% of titanium, 0.9-1.2% of iron, 0.3-0.4% of Li, 0.03-0.05% of Ba, 0.3-0.6% of bismuth and the balance of aluminum. By adding the magnesium, the alloy has excellent thermal conductivity, high temperature resistance and favorable corrosion resistance. By adding the titanium, copper and iron, the aluminum alloy material has the characteristics of high die casting yield, compact casting, high finished product strength, no crack, high flexibility and favorable air tightness. By adding the silicon, the aluminum alloy material has favorable wear resistance. The aluminum alloy is suitable for special-type high pressure oil pump cases, and has long service life. When the refining agent is used for casting production, the porosity in the casting is lowered by 1-2 degrees, the oxide inclusion content is lowered by 2 levels or so, and the yield is obviously enhanced.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

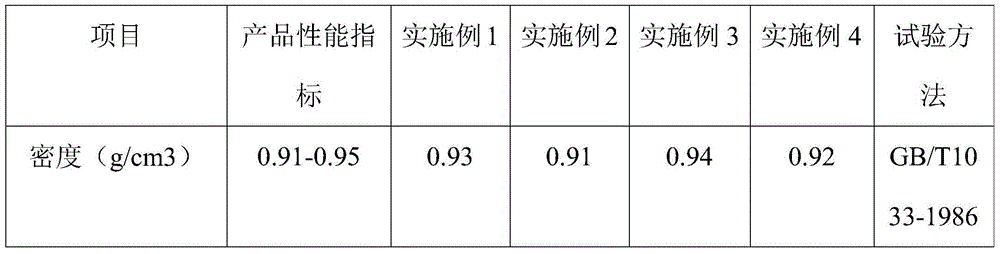

Sectional material manufacturing technique for regenerative plastic doors and windows

The invention relates to a sectional material manufacturing technique for regenerative plastic doors and windows, which has the innovative points that the sectional material manufacturing technique adopts the technical steps as follows: regenerative plastics that adopt polyolefin thermoplastic plastics as main components are taken as main material; a sectional material is prepared through the procedures such as cleaning crushing, granulation, injection mold extrusion formation, stress elimination, planing milling processing, surface coating, and co-extrusion sealing; and the sectional material can be used for manufacturing high-quality doors and windows. The sectional material mainly takes the regenerative plastics made of recovered plastic garbage as the main material, so that the utilization ratio of resources is improved, and environmental protection can be achieved; the sectional material adopts a solid structure that is processed through extrusion moulding, and no shedding, no fracture and no deformation are caused in a cool drop hammer impact test; in addition, aluminum foil layers are arranged on the surface of the sectional material, so that ultraviolet ray resistance, ageing resistance, no fading, no shedding and strong weatherability can be achieved. A non-decorative surface of the sectional material is coated with a high density polyethylene layer, and decorative surfaces of the sectional material are coated with the aluminum foil layers through bonding agents, so that the high density polyethylene layer is formed between the aluminum foil layers of a front decorative surface and a rear decorative surface and is used as a heat blocking layer, and the thermal conductivity coefficient is low.

Owner:南通美特美节能门窗有限公司

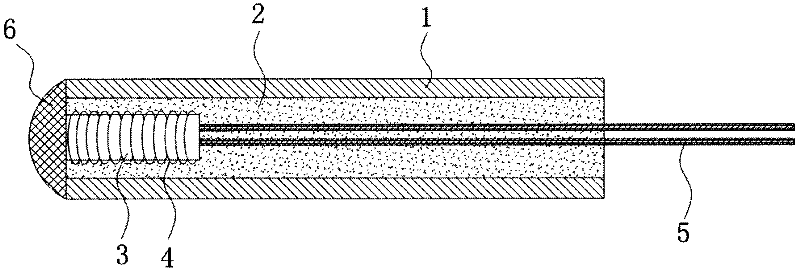

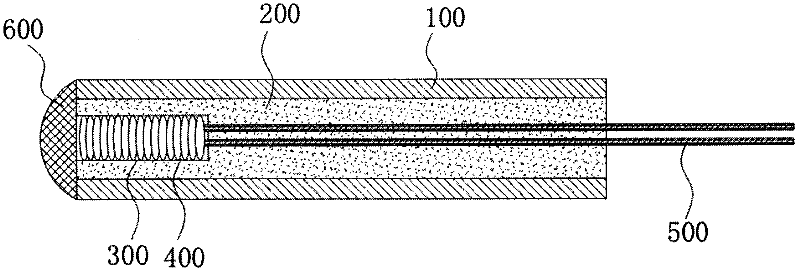

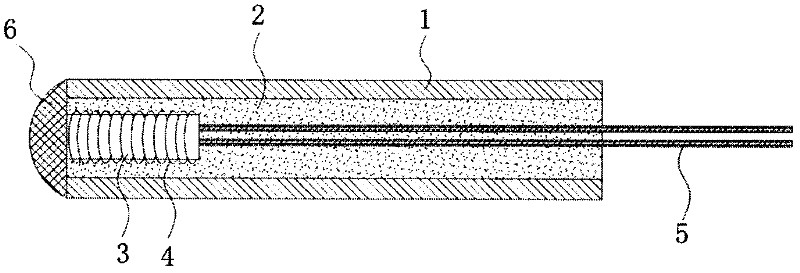

Electro-thermal push bar for electronic thermostat of engine

InactiveCN102536418AExtended service lifeSimple structureCoolant flow controlMachines/enginesElectricityControl power

The invention discloses an electro-thermal push bar for an electronic thermostat of an engine, which comprises a push bar body. A heating element is disposed inside the push bar body and comprises a magnesium oxide stick, an electric heating wire and a high-temperature wire, wherein the electric heating wire is wound on the magnesium oxide stick, two ends of the electric heating wire are connected through the high-temperature wire, and the high-temperature wire extends out of the push bar body to be connected with a control power source. The heating element and the push bar inside the electronic thermostat are integrated, so that deformation and even breakage of the heating element under the action of external force is avoided, the service life of the heating element of the electronic thermostat is prolonged, and the engine is guaranteed to operate within a proper temperature range for long. In addition, a conventional sheet heater for the electronic thermostat is changed into a stick heater, and the stick heater compared with the sheet heater has the advantages of no crisping, no deformation and no breakage, is longer in service life and further is simple in structure. Therefore, the internal structure of the electronic thermostat is simpler, and manufacturing cost and difficulty can be reduced.

Owner:乐清市海狮电热电器制造有限公司

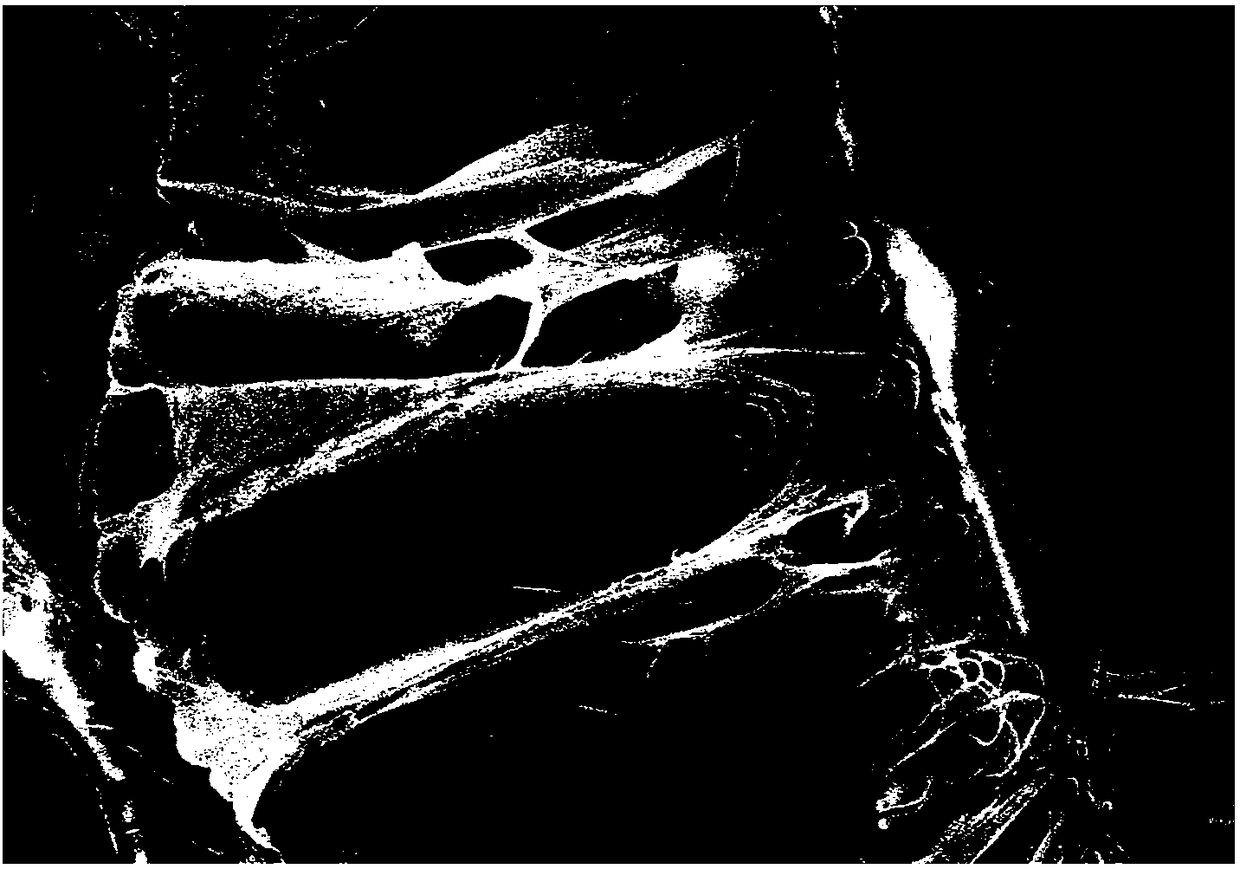

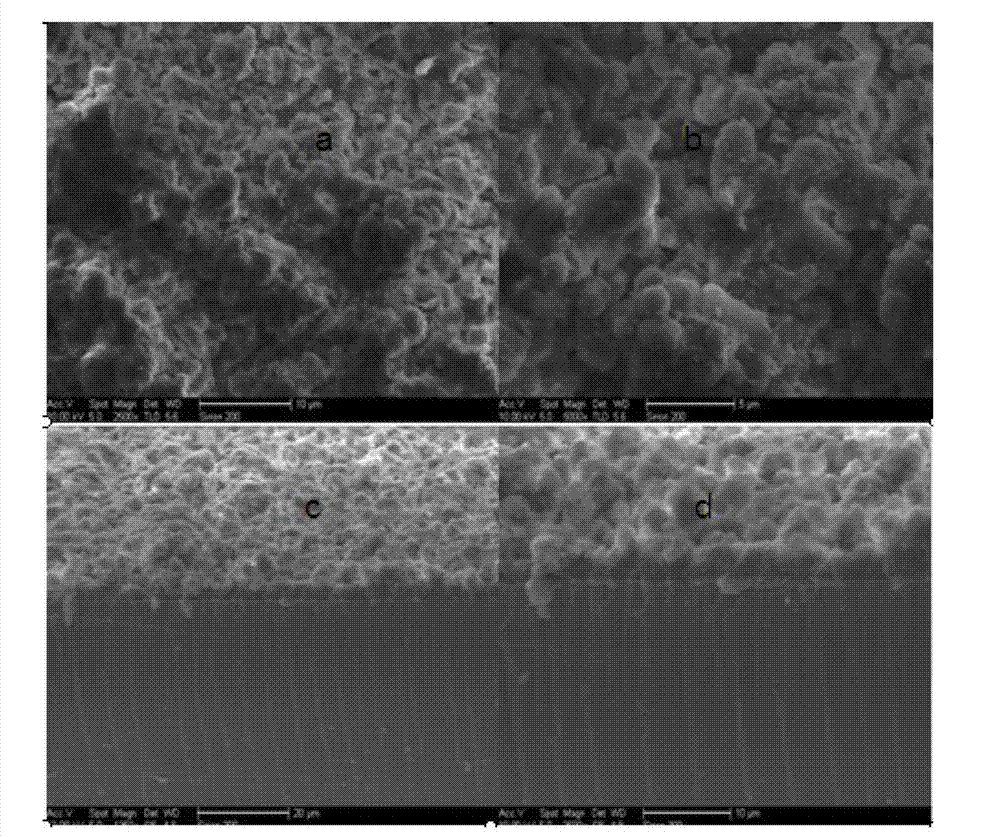

Hollow fiber composite membrane of ultrathin active layer and preparation method thereof

InactiveCN107789988AControllable ultra-thin thicknessEasy to makeSemi-permeable membranesMembranesFiberHollow fibre

The invention belongs to the field of functional polymer materials, and concretely relates to a hollow fiber composite membrane of an ultrathin active layer and a preparation method thereof. The hollow fiber composite membrane employs a polymer porous membrane whose internal surface and / or external surface is provided with a compact skin as a base membrane, and a hydrophilic material with selecting function is loaded on an external wall of the base membrane as an active separating layer. The thickness of the active separating layer is 0.2-1[mu]m. The invention also provides a preparation method of the composite membrane. The preparation process is simple and easy to operate; the composite membrane has high selectivity; the composite membrane has low preparation cost and is easy to realizeindustrial production. The thickness of the active separating layer on the surface of the composite membrane is ultra thin, usage amount is low, and the method is suitable for industrial production; the active layer of the hollow fiber composite membrane is compact without defects, the preparation method is simple, and the thickness is controllable.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

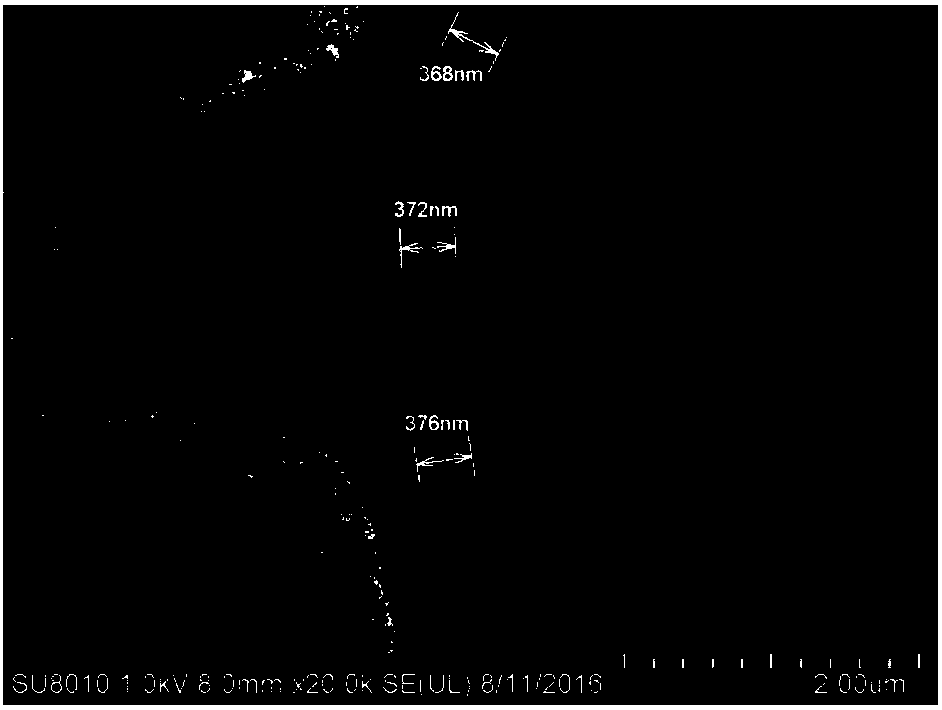

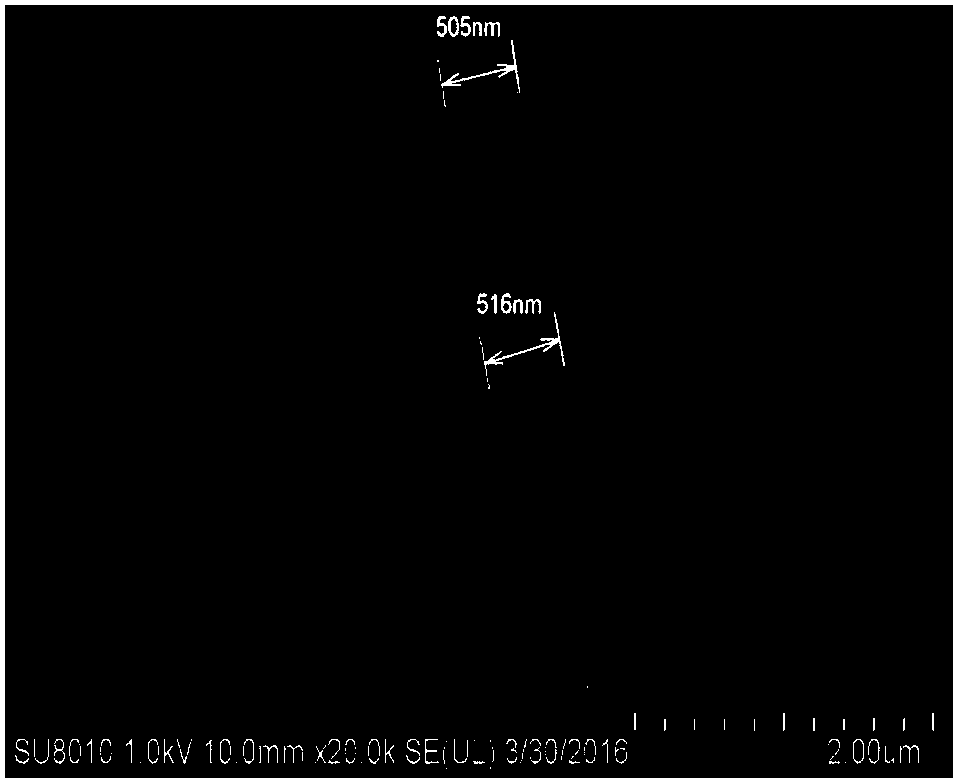

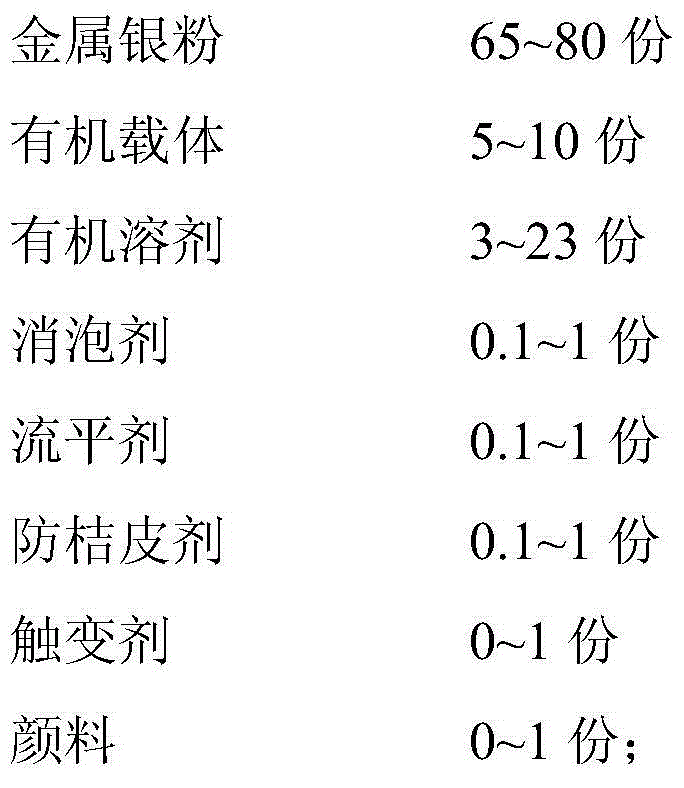

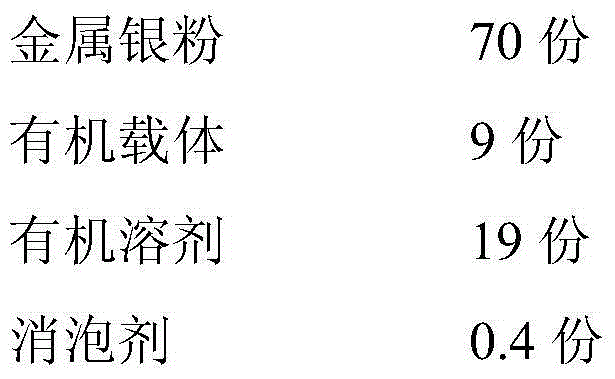

Conductive silver paste for fine line laser etching for capacitive type touch screen

ActiveCN105788701AFlat surfaceImprove yieldNon-conductive material with dispersed conductive materialCable/conductor manufactureSkin agentCorrosion

The invention relates to conductive silver paste for fine line laser etching for a capacitive type touch screen. The conductive silver paste comprises the following components in parts by weight: 65-80 parts of metal silver powder, 5-10 parts of organic carrier, 3-23 parts of organic solvent, 0.1-1 parts of defoaming agent, 0.1-1 parts of leveling agent, 0.1-1 parts of anti-skinning agent, 0-1 parts of thixotropic agent and 0-1 parts of pigment; the preparation method for the conductive silver paste comprises the steps of mixing the organic carrier and the organic solvent to prepare a uniform colloidal solution; then adding the other components in sequence; and enabling the mixture to be mixed through a mixer, grinded through a three-roll mill, filtered, and the like to obtain the conductive silver paste for fine line laser etching for the capacitive type touch screen. Compared with the prior art, the conductive silver paste is simple in preparation process; the prepared conductive silver paste is low in resistance, high in adhesive force, high in surface hardness, corrosion resistance, and oxidization resistance, wherein the adhesive force between the conductive silver paste and a PET substrate can reach 5B level, and the surface hardness can reach greater than 3H; and therefore, the fine lines on the capacitive type touch screen can be manufactured by a laser etching process.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

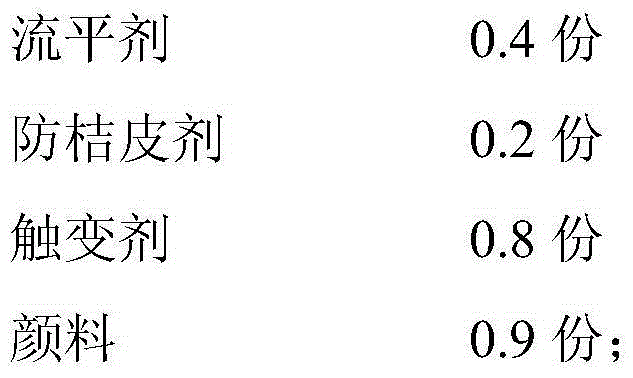

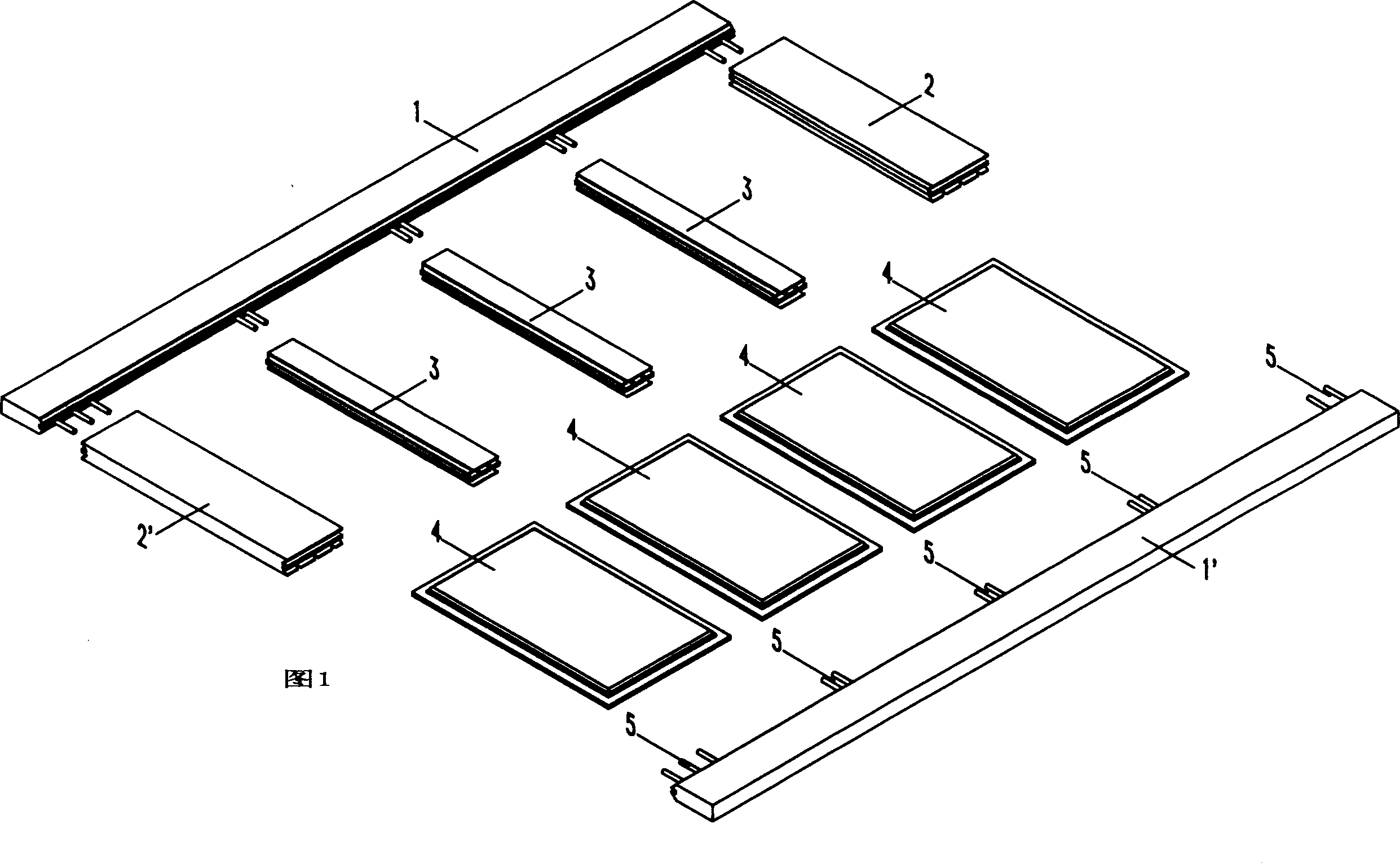

Assembling type wood door leaf

Owner:薛连秀

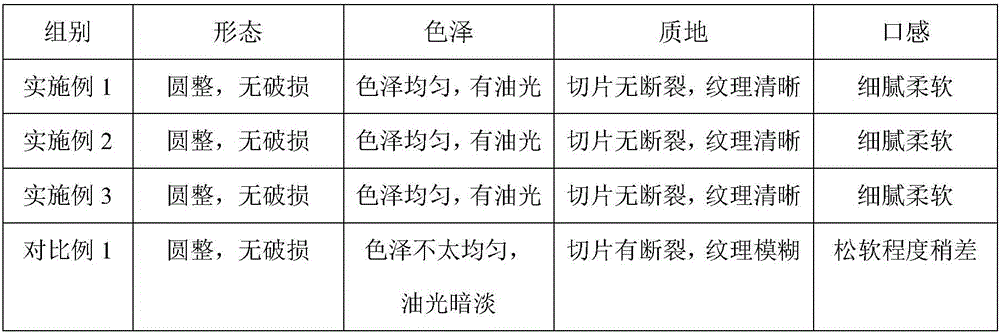

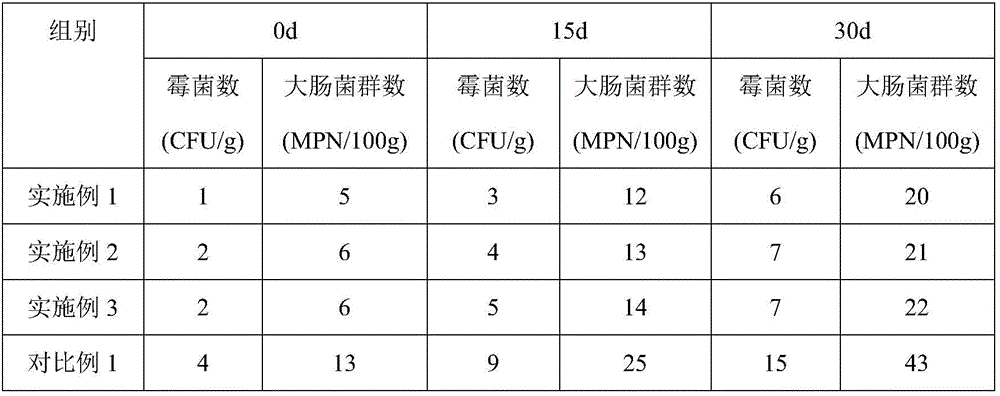

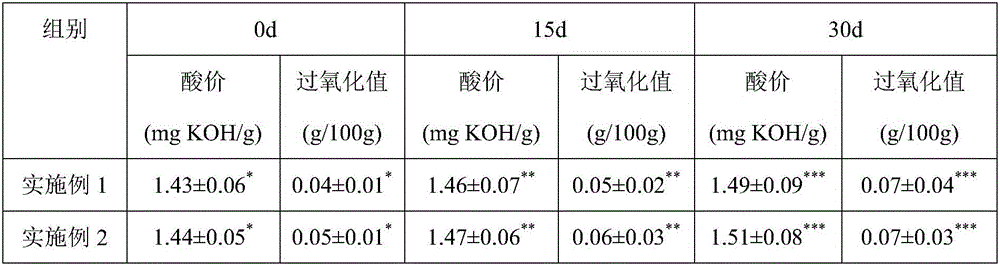

Pericarpium citri reticulatae mooncake and preparation method thereof

InactiveCN106106690ASmall particle sizeImprove thermal stabilityDough treatmentBakery productsSodium bicarbonateRed bean

The invention belongs to the field of food and particularly relates to a pericarpium citri reticulatae mooncake and a preparation method thereof. The pericarpium citri reticulatae mooncake comprises a mooncake wrapper and stuffing. The mooncake wrapper is prepared from wheat flour, arrowroot starch, waxy highland barley starch, syrup, vegetable fat, sodium bicarbonate and egg white. The stuffing is prepared from pericarpium citri reticulatae powder, red bean paste or red bean particles, syrup and vegetable fat. In the preparation process, the pericarpium citri reticulatae mooncake is easy to form, good in figurability, easy to demould after being baked, low in sugar and calorie, mellow in mouthfeel, delicious, capable of tonifying spleen and helping and promoting digestion and beneficial to health, and mooncake oil leaking and cracking phenomena cannot occur in the storing process.

Owner:广东橘香斋大健康产业股份有限公司

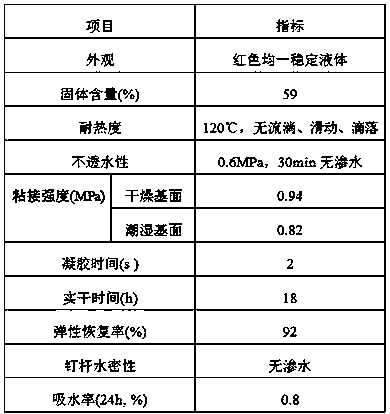

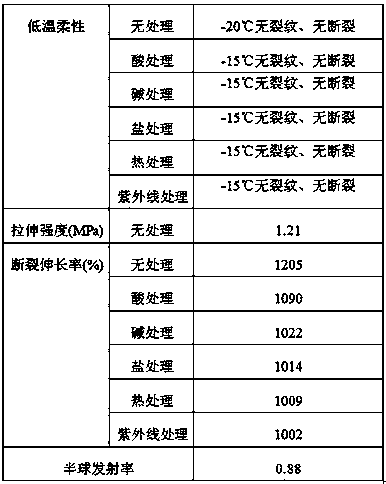

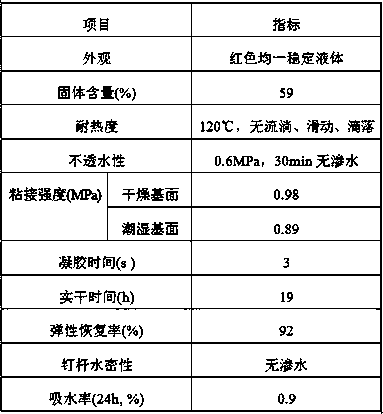

Heat reflection type colored spray-quick-setting rubber-asphalt waterproof coating material and preparation method therefor

ActiveCN109280452AHigh solid contentWater-based environmental protectionRosin coatingsConjugated diene hydrocarbon coatingsNano zinc oxideAsphalt

The invention provides a heat reflection type colored spray-quick-setting rubber-asphalt waterproof coating material. The waterproof coating material is characterized by comprising a component A and acomponent B, wherein the component A comprises the following ingredients: emulsified modified asphalt, fillers, an infrared reflection pigment, nano zinc oxide, a dispersant, latex, a bactericide, water and color paste. The component B is prepared through mixing calcium chloride, sodium chloride and water according to the mass ratio of 7.8: 0.2: 92. The waterproof coating material is aqueous andenvironmentally friendly and is high in adhesion and high in bonding strength.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL +3

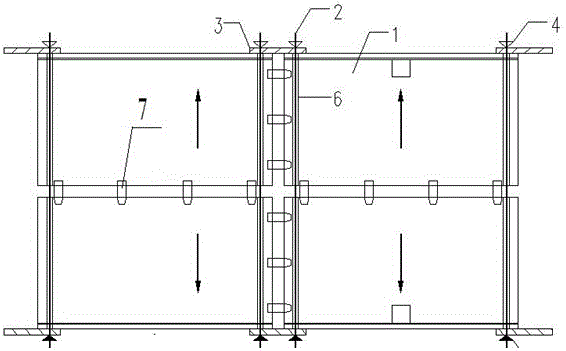

Concrete preassembled road high in rupture strength

InactiveCN105064160AImprove flexural strengthEasy to transportSingle unit pavingsPaving detailsStructural engineeringRoad surface

The invention discloses a concrete preassembled road high in rupture strength. The concrete preassembled road comprises four concrete precast slabs; the two sides of each concrete precast slab are provided with holes used for placing steel strands; adjacent concrete precast slabs are connected via the steel strands; the diameter of the steel strand is 15.50mm; the four sides of each concrete precast slab are provided with the holes used for placing the steel strands, and adjacent concrete precast slabs are connected via the steel strands; one road surface unit is formed from the four concrete precast slabs via the steel strands and steel connecting plates arranged on the outsides of the concrete precast slabs; connecting key structures are arranged between adjacent concrete precast slabs; each connecting key structure comprises a shearing-resistant convex key and a shearing-resistant concave key matching with each other. The concrete preassembled road is convenient for transportation, and rapid and convenient for installation; road slabs can be divided into a plurality of kinds and types according to the ratio of the short edges to the long edges; and the plurality of positioning shearing-resistant connecting keys are arranged on the joint interfaces of the precast slabs so as to ensure that rupture or breakage of the road slabs is not caused under repeated action of overload vehicles.

Owner:郭晓磊 +17

High-adhesion LED-UV piezoelectric spray printing ink and preparation method thereof

The invention relates to high-adhesion LED-UV piezoelectric spray printing ink and a preparation method thereof. In order to solve problems in the prior art, a technical scheme of the high-adhesion LED-UV piezoelectric spray printing ink is as follows: a polyurethane-acrylate resin system is adopted; the ink is prepared from the following components in percentage by weight: 8%-30% of pigment typepaste, 5%-20% of polyurethane-acrylate resin, 5%-16% of a photoinitiator, 30%-50% of an acrylic acid reactive monomer solvent or oligomer, 0.5%-4% of a polymerization inhibitor and 0.5%-2% of a surfactant, wherein the pigment type paste contains sub-micron pigment. The ink is adaptable to various industrial-grade nozzles, and has high adhesion, high extensibility and high bending performance whensprayed on the surfaces of various soft and hard materials.

Owner:TRENDVISION TECH(ZHUHAI) CO LTD

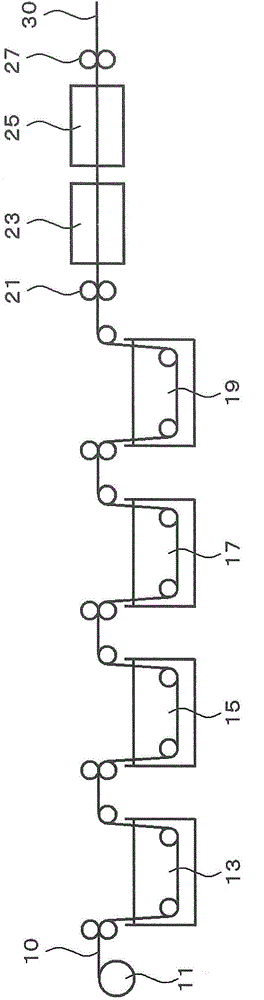

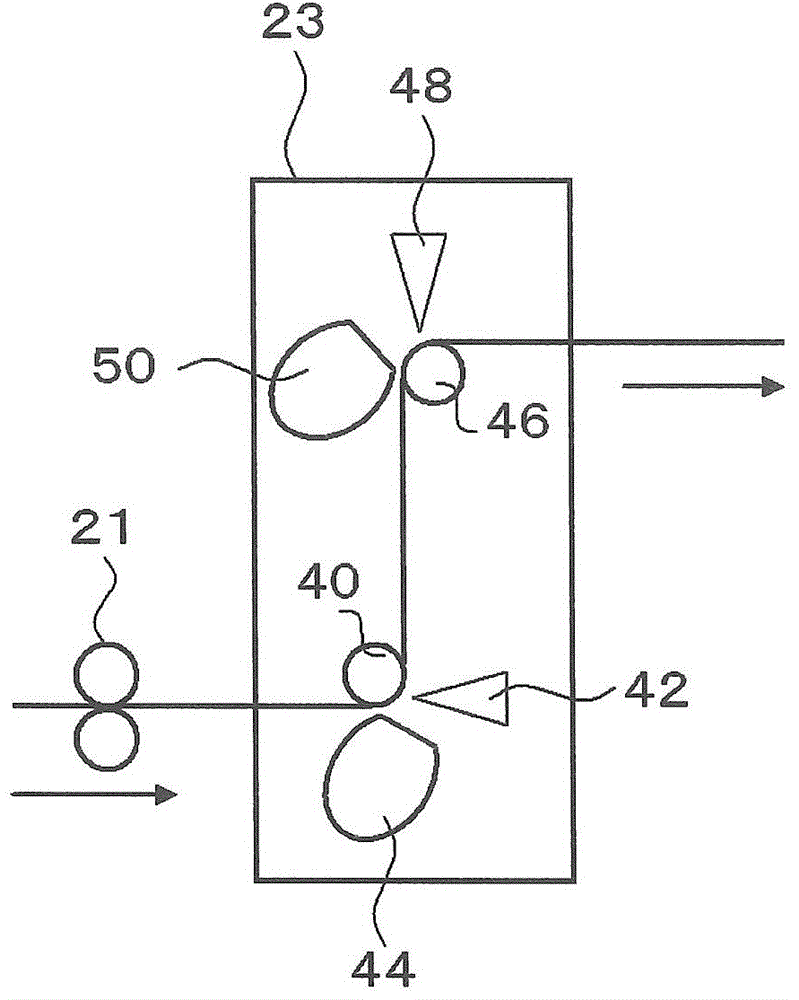

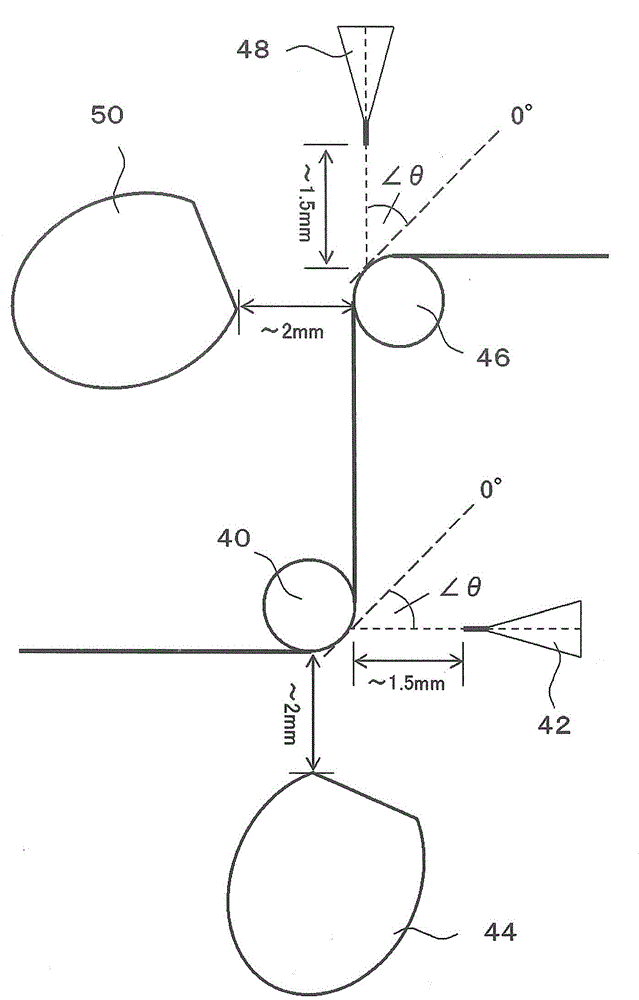

Polarized film, and method for manufacturing polarizer

ActiveCN104823088ANo breakGood lookingSynthetic resin layered productsPolarising elementsPolarizerEngineering

According to the present invention, after a cleaning process, a drying process is performed in which, while tension of 200-1500 N / m is maintained on a polarized film and while the film is wound on a first roll provided on one side of the film, air is blown on the film surface on the opposite side from the first roll to perform drying, and then, while the surface on which air was blown is wound onto a second roll, air is blown on the film surface on the opposite side from the second roll to perform drying, and the water removed by the air is recovered using a first exhaust container and a second exhaust container provided near the corresponding air-blowing positions.

Owner:SUMITOMO CHEM CO LTD

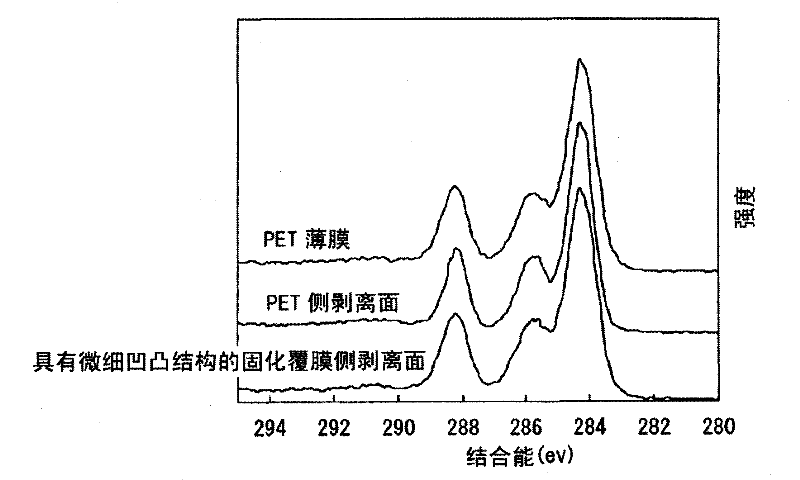

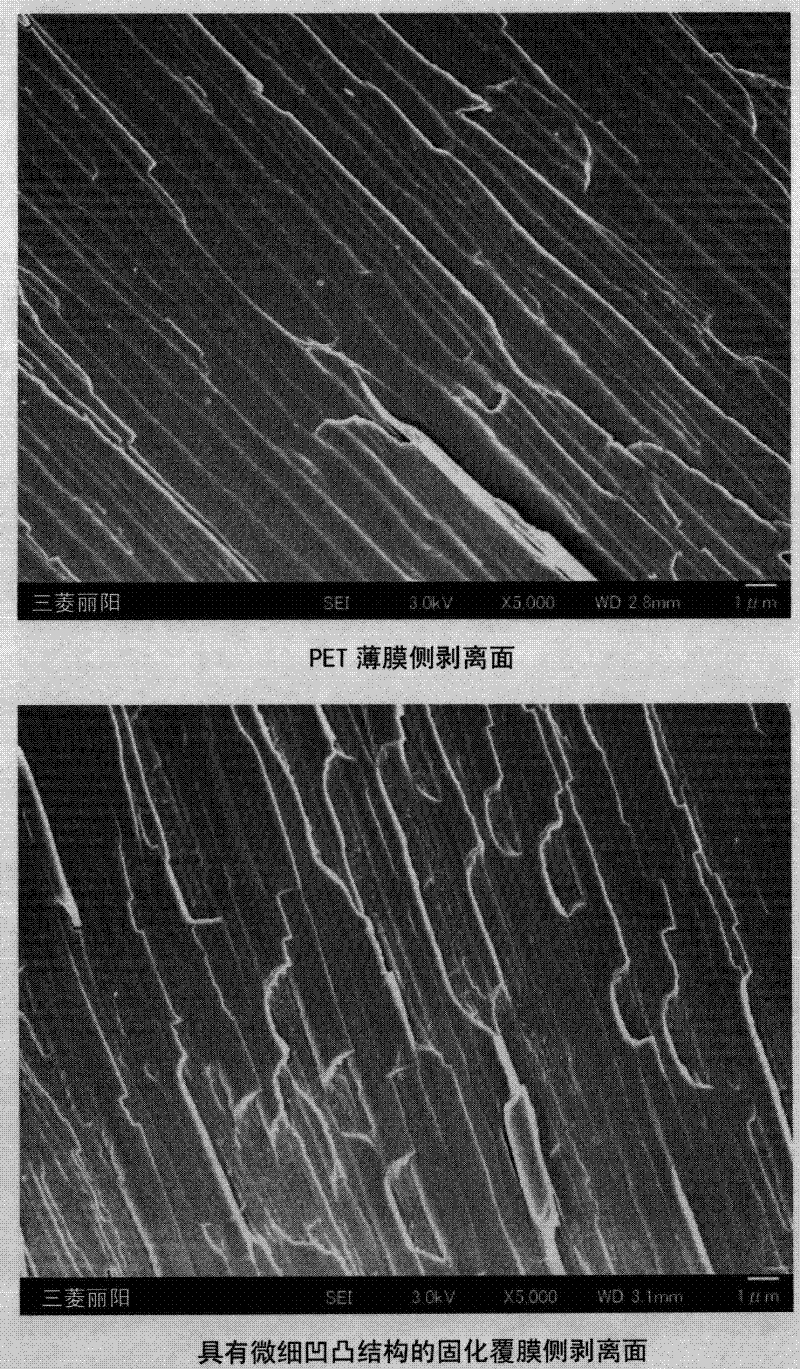

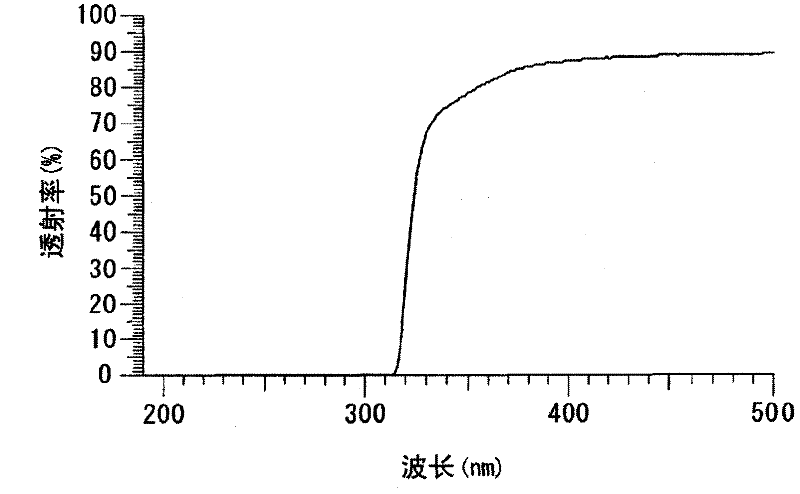

Process for producing film

ActiveCN102341229AStable manufacturingNo breakSynthetic resin layered productsFlat articlesUltravioletOptical transmittance

Owner:MITSUBISHI CHEM CORP

Impacting-resistant and abrasion-resistant concrete prefabricated road

ActiveCN105113352AEasy to transportQuick installationPaving reinforcementsSingle unit pavingsBarium nitrateRoad surface

The invention discloses an impacting-resistant and abrasion-resistant concrete prefabricated road. The impacting-resistant and abrasion-resistant concrete prefabricated road comprises four prefabricated boards. Holes where steel strands are contained are formed in the two sides of the prefabricated boards respectively. The adjacent prefabricated boards are connected through the steel strands. The diameter of the steel strands is 14.50 mm. Or holes where the steel strands are contained are formed in the four sides of the prefabricated boards, and the adjacent prefabricated boards are connected through the steel strands. The four prefabricated boards form a road surface unit through the corresponding steel strands and steel connecting board bands on the outer sides of the prefabricated boards. Connecting key structures are further installed between the adjacent prefabricated boards. Each connecting key structure comprises a shearing-resisting convex key and a shearing-resisting concave key which are matched. The prefabricated boards are made of cement, coal ash, sand, water, nylon fibers, barium nitrate, calcium lignosulphonate, silicon carbide powder, sepiolite powder, alumina silicate fibers and gypsum.

Owner:惠州大亚湾市政基础设施有限公司

Melt spun TPU fibers and process

ActiveCN100390216CExtension of timeNo breakMonocomponent polyurethanes artificial filamentWoven fabricsThermoplasticPolyester

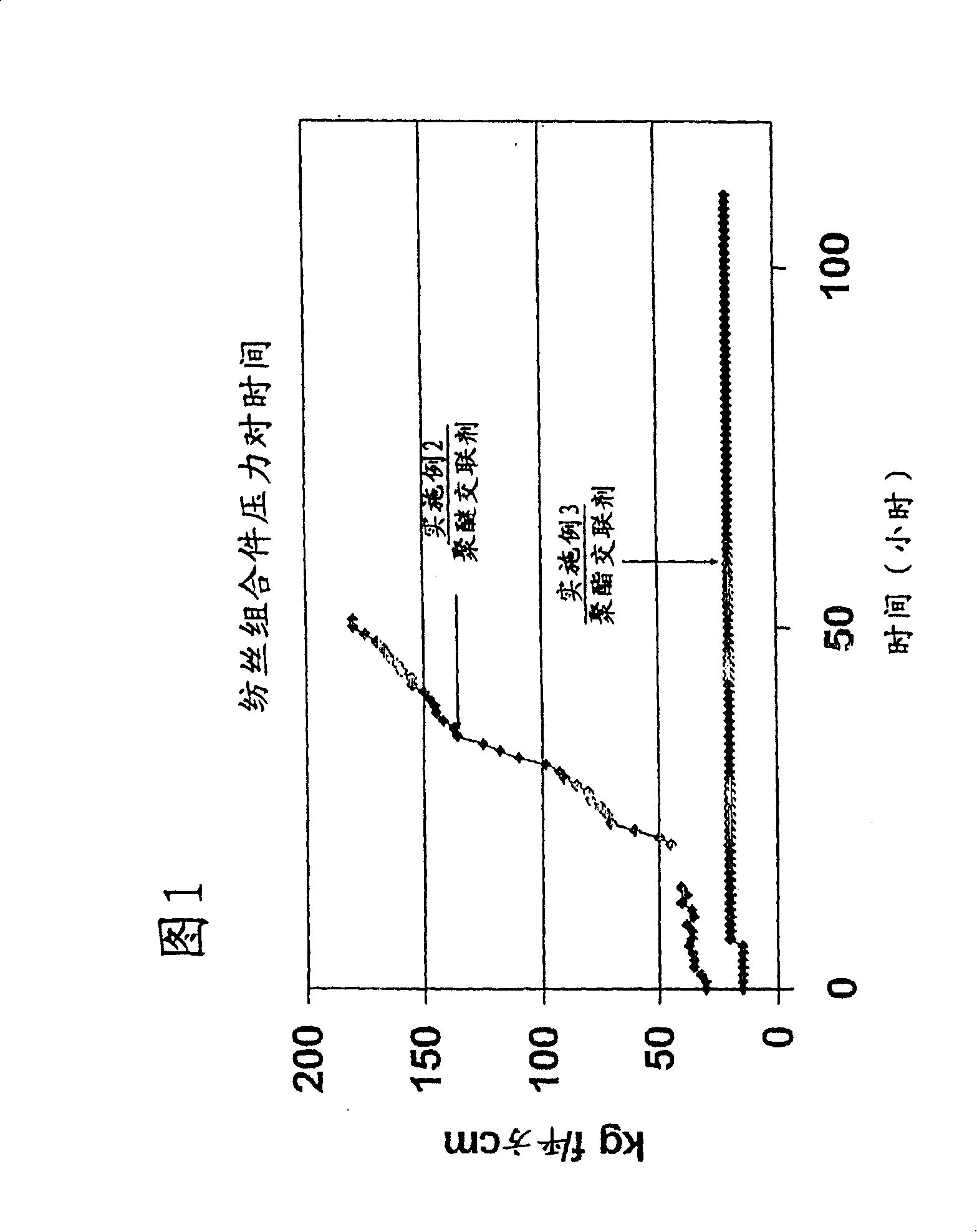

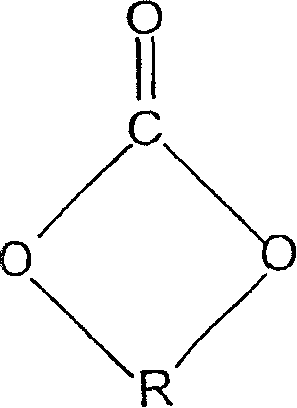

Thermoplastic polyether polyurethane polymers are disclosed which are mixed with a non-polyether crosslinking agent to achieve long run times in a melt spinning process to make elastic fibers. The crosslinking agent is preferably a polyester polyol reacted with a diisocyanate. A melt spinning process is also disclosed using a polyether polyurethane with a polyester crosslinking agent. Long melt spinning run times can be achieved without experiencing excessive pressure buildup in the spinneret and fiber breakage.

Owner:LUBRIZOL ADVANCED MATERIALS INC

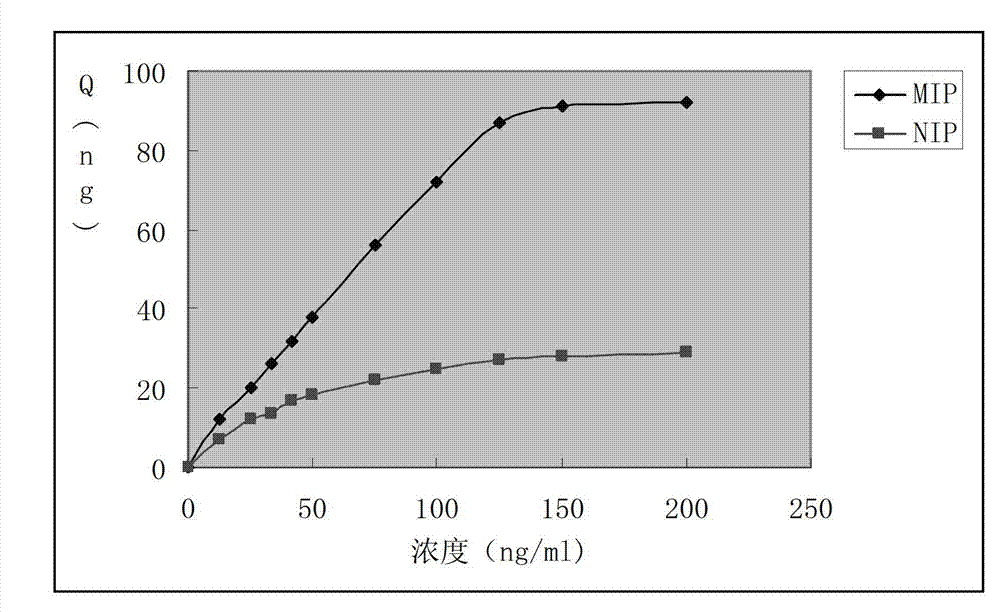

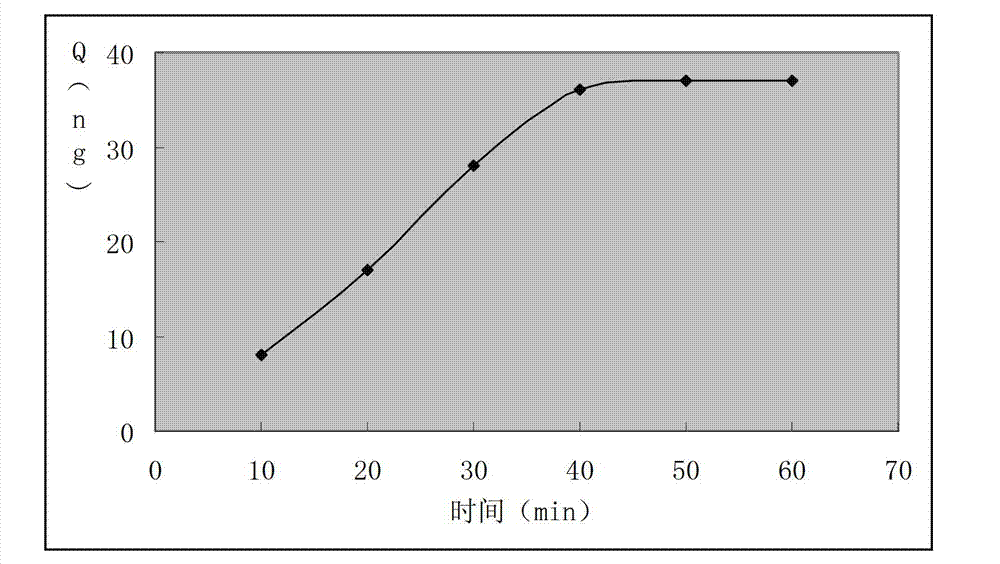

Preparation method of dumbbell-shaped molecular imprinting stirring rod

InactiveCN103111260AImprove thermal stabilityNo sheddingOther chemical processesAlkali metal oxides/hydroxidesCross-linkFunctional monomer

The invention discloses a preparation method of a dumbbell-shaped molecular imprinting stirring rod. The method comprises the following steps of: dipping on the dumbbell-shaped stirring rod in alkali and acid in turn for carrying out activation and silanization reaction; further dipping the dumbbell-shaped stirring rod into a trimethylolpropane tricrylic acid ester solution to carry out grafting reaction; putting a template molecule vardenafil and a functional monomer into a pore-foaming agent for prepolymerization, subsequently adding a cross-linking agent and an initiator and putting into the grafted dumbbell-shaped stirring rod to polymerize; repeating the polymerization reaction of the dumbbell-shaped stirring rod, further aging, and finally washing the template molecules so as to obtain the dumbbell-shaped molecular imprinting stirring rod. The stirring rod prepared by using the preparation method is combined with a chromatograph and can be applied to rapid separation and enrichment of nafil compounds in complex matrixes such as food, medicines and health-care products, so that accurate detection on a sample, with high selectivity and high sensitivity, is achieved.

Owner:NANJING MEDICAL UNIV

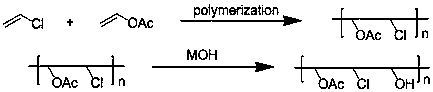

LED-UV piezoelectric type spray printing ink with high adhesion and preparation method thereof

The invention relates to LED-UV piezoelectric type spray printing ink with high adhesion and a preparation method thereof. For solving the problems of the prior art, the technical scheme of the LED-UVpiezoelectric type spray printing ink with high adhesion is as follows: the ink adopts a polyvinyl chloride-vinyl acetate resin system; raw materials of the ink comprise the following components in percentage by weight: 5-35% of pigment type color paste, 2-10% of vinyl chloride-vinyl acetate resin, 5-15% of a photoinitiator, 40-70% of a reaction type monomer solvent or oligomer, 0.2-2% of a surface active agent and 0.5-4% of a polymerization inhibitor, wherein the pigment type color paste comprises sub-micron sized pigments. The ink provided by the invention can adapt to all kinds of industrial-grade sprayers and respectively has high adhesion, high extensibility and high bending property after being sprayed and printed on the surfaces of various soft and hard materials.

Owner:TRENDVISION TECH(ZHUHAI) CO LTD

High-temperature-resistant printing material and application thereof

ActiveCN107311465ANot easy to fall offImprove adhesionAdditive manufacturing apparatusCoatingsPhosphateTitanium nitride

The invention discloses a high-temperature-resistant printing material which is prepared by mixing 10 to 15 mass parts of an inorganic bonding material and 0.5 to 6 mass parts of a conductive material, wherein the inorganic bonding material is one or a mixture of water glass, silica sol, alumina sol, aluminum silicate or aluminium dihydrogen phosphate; the conductive material is one or a mixture of graphite powder, graphene, a carbon nano tube, carbon black, titanium nitride powder or ruthenium dioxide powder. The high-temperature-resistant printing material disclosed by the invention can be applied to a high-temperature condition of 700 DEG C or higher; after being subjected to high-temperature thermal treatment of the inorganic bonding material, an oxide film can be formed on the surface of the conductive material to prevent oxidization of the conductive material; meanwhile, the high-temperature-resistant printing material further has the advantages of small thermal expansion coefficient, high heat stability and high thermal matching performance with a ceramic substrate.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com