Flexible display screen and manufacturing method thereof

The technology of a flexible display screen and its manufacturing method, which is applied in the field of display screens, can solve problems such as insufficient stability of glass fixation, no cushioning effect, easy drop and breakage of glass, etc., and achieve the effects of convenient processing, reducing waste, and improving adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

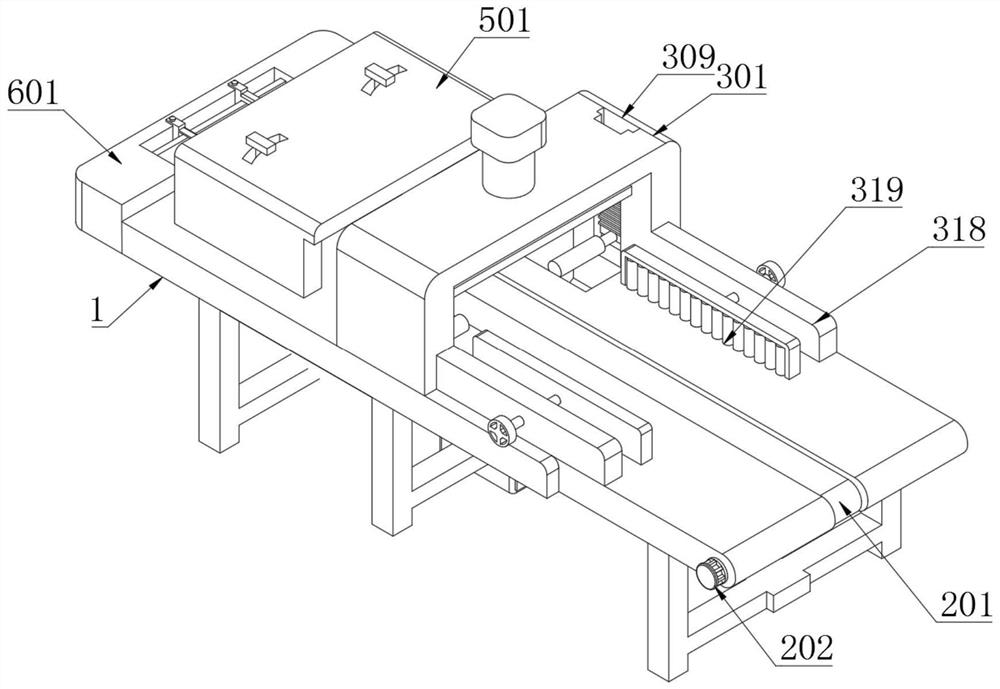

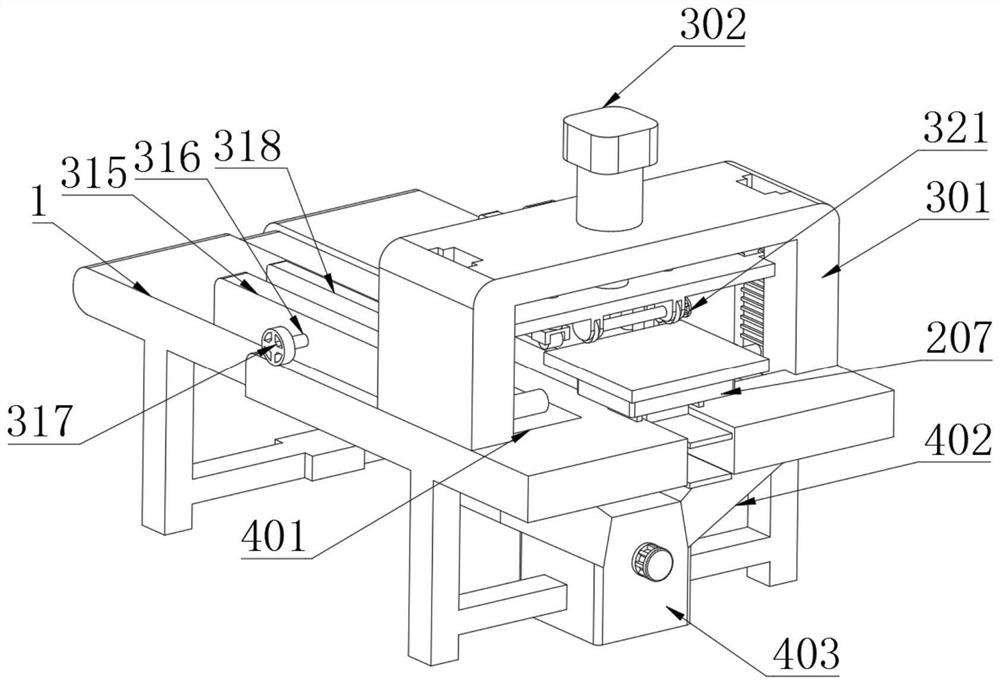

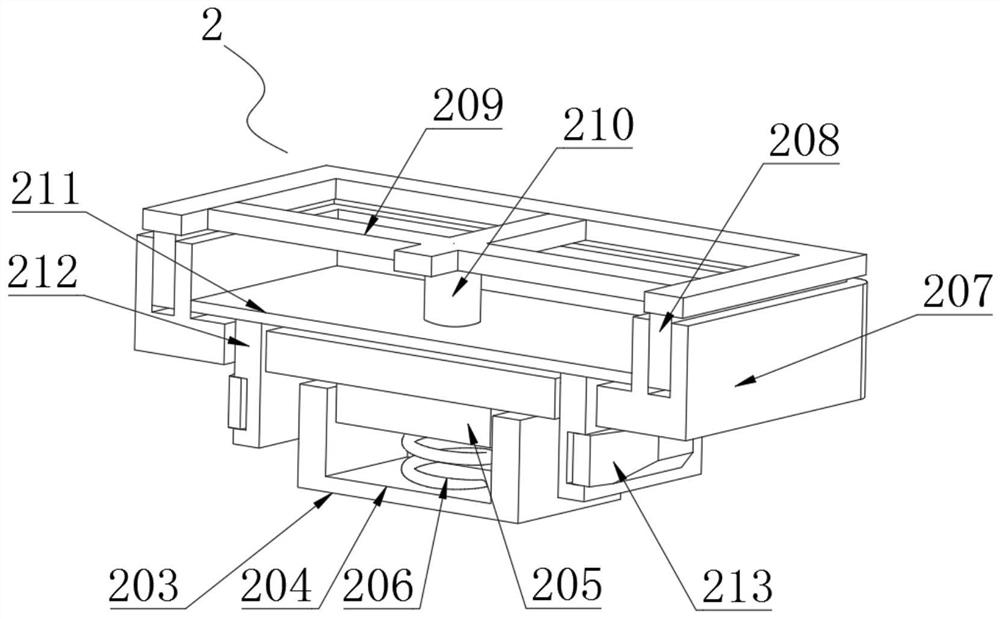

[0049] Example: such as Figure 12 As shown, the present invention provides a method for efficiently manufacturing a flexible display, comprising the following steps:

[0050] S1. Select glass of suitable material, and clean the glass surface to remove impurities on the glass surface;

[0051] S2. Cutting the glass through the positioning and cutting mechanism 3, so that the size of the glass is equal to the size of the display screen to be produced;

[0052] S3, through the power conversion and grinding mechanism 5, the cut glass is polished to increase the smoothness of the cutting surface of the glass;

[0053] S4, clean the glass again, add a cleaning agent to increase the cleaning effect on the glass, and thoroughly remove the remaining debris on the glass;

[0054] S5, smear photoresist evenly on the glass surface, then glass is heated to increase the adhesion between photoresist and glass surface;

[0055] S6, after exposing and etching the glass, removing the remain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com