Patents

Literature

68results about How to "High extension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spray polyurea high-performance waterproof paint and preparation method thereof

InactiveCN101818019AFast curingHigh strengthPolyurea/polyurethane coatingsDiluentUltimate tensile strength

The invention relates to a spray polyurea high-performance waterproof paint which is characterized by comprising component A and component B, wherein the component A comprises semi-prepolymer formed by the reaction between 70-35 parts of polyisocyanate and 30-50 parts of polyether glycol, and 0-15 parts of diluent based on parts by weight; the component B comprises 50-70 parts of amine-terminated polyether, 20-40 parts of amine chain extender and 5-10 parts of filler; and the volume ratio between the component A and the component B is 1:1. Compared with the common spray polyurea high-performance waterproof paint, the spray polyurea high-performance waterproof paint has higher tensile strength, elongation at break, tearing strength and other physical properties, and not only is applicable to waterproof projects of common building projects, basic facilities and the like, but also is especially suitable for high-difficulty waterproof projects of large basic facility construction such as a high speed railway, a subway, a tunnel, water conservancy project and the like.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

Vertical type single-component polyurethane waterproof coating and preparation method thereof

InactiveCN101818022AReduce labor costsTo achieve the purpose of thickeningPolyurea/polyurethane coatingsBenzeneAlcohol

The invention provides a vertical type single-component polyurethane waterproof coating. The coating is prepared from the following components in parts by weight: 15-25 parts of polyether trihydric alcohol, 3-5 parts of toluene di-isocyanate, and 0.3-1.0 part of amine curing agent. The invention also provides a method for preparing the waterproof coating. The waterproof coating has the advantages of high strength, high extension, high adhesion property, no benzene or coal tar, safety, environment protection and the like, can be coated on the vertical surface with the thickness of 0.5-1.0mm each time, has no flowing and dropping, and only needs to coat 2-3 times for the vertical surface to reach the thickness of 2mm.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

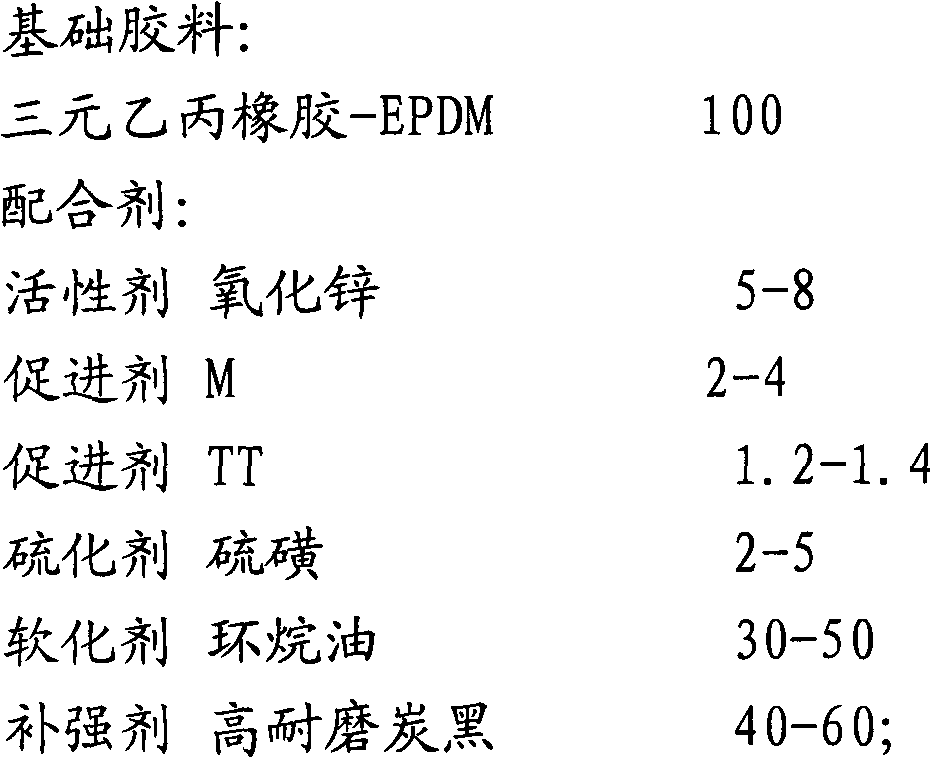

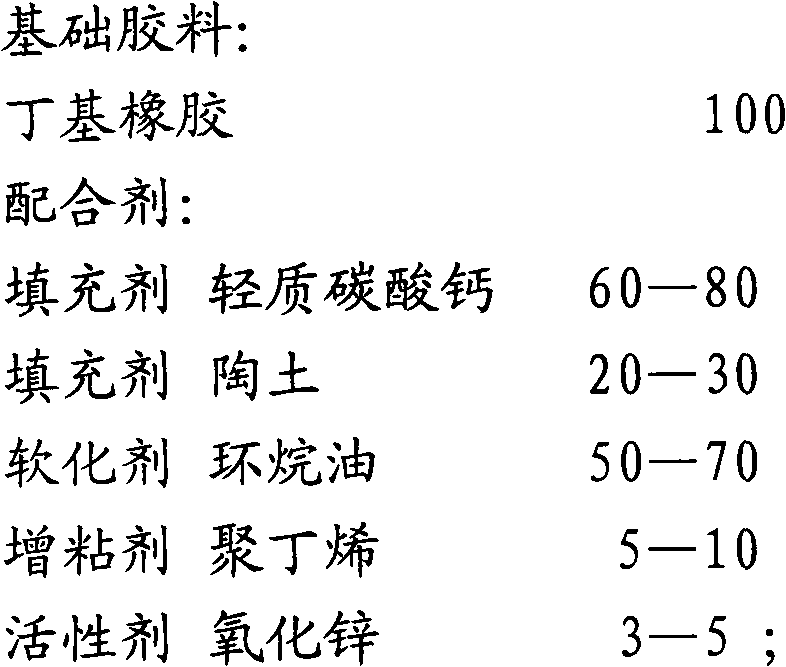

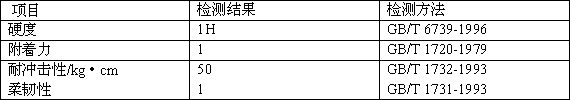

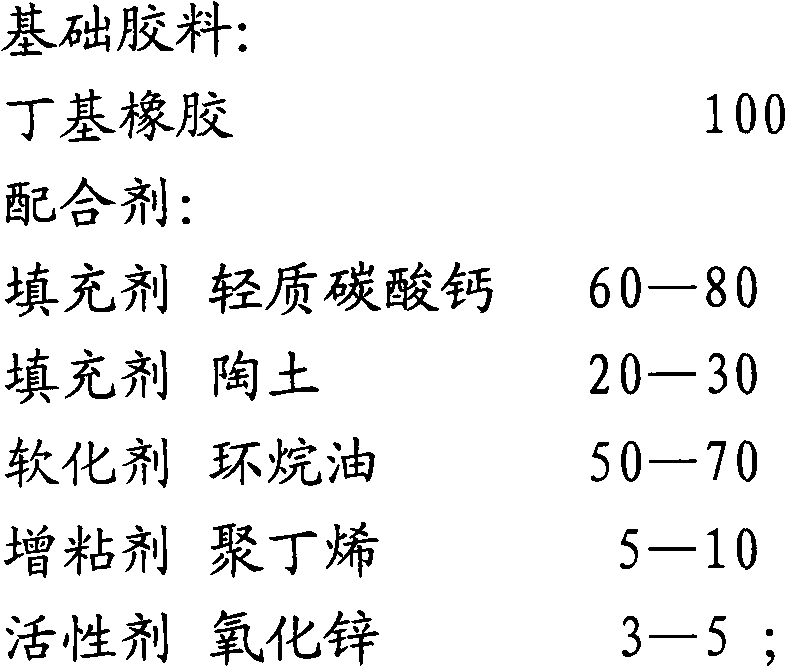

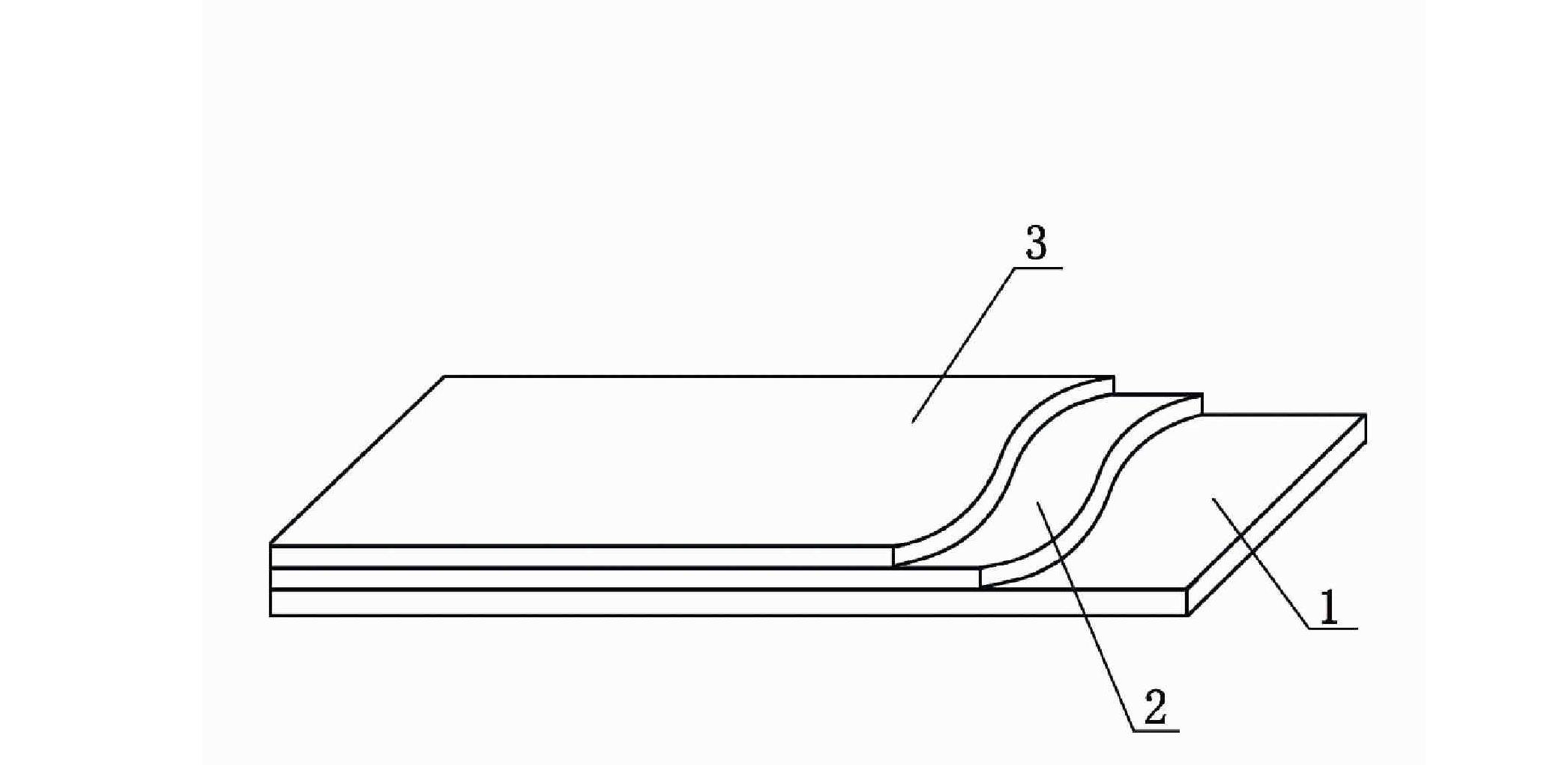

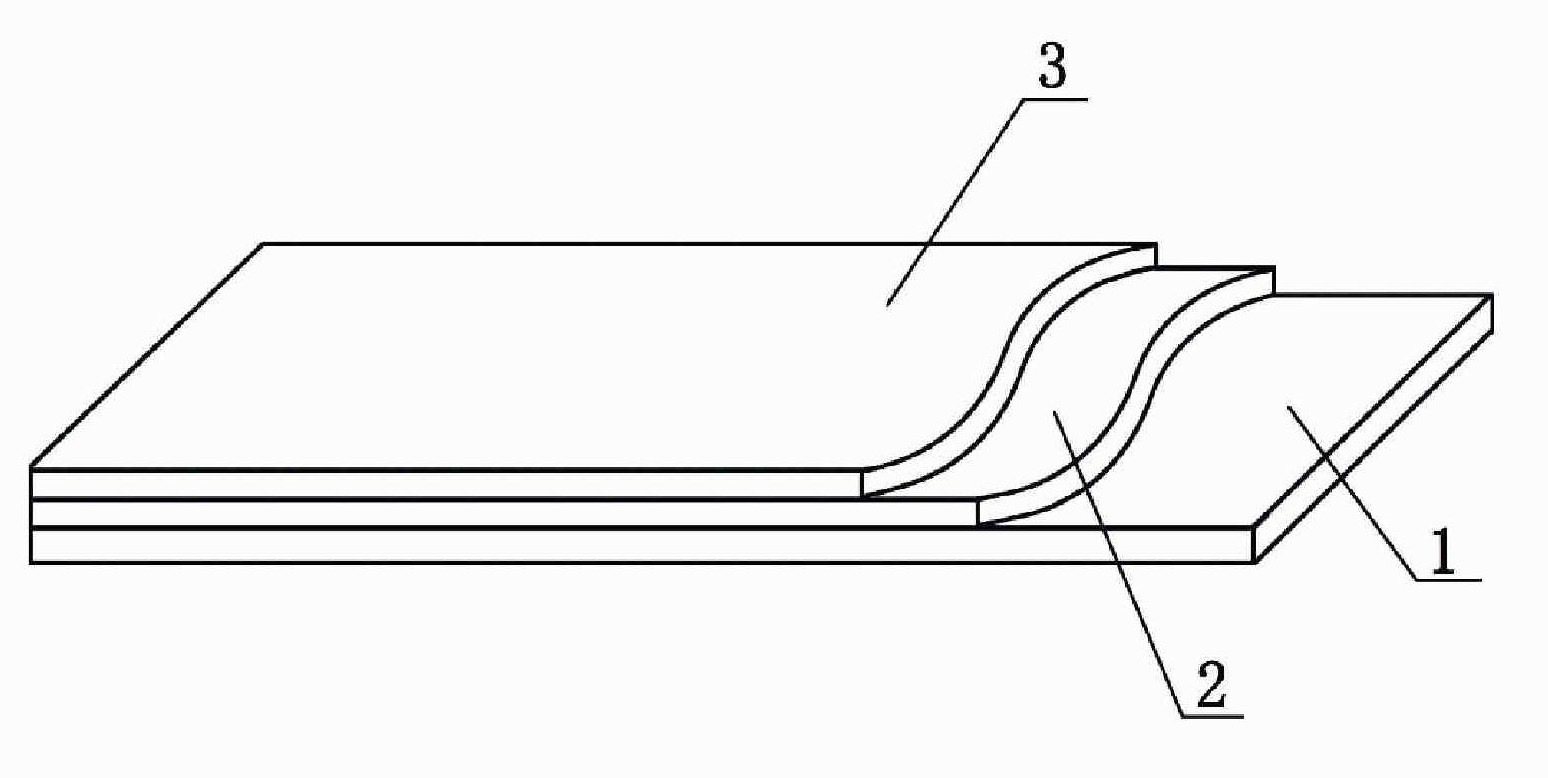

Self-adhering rubber water-proof coiled material and method for preparing same

InactiveCN101545285AUnique "self-locking water" functionSolve the problem of water leakageProtective foundationMarine site engineeringGlass fiberEngineering

A self-adhering rubber water-proof coiled material and a method for preparing the same composed of a rubber water-proof coiled material basal layer, a glue spreading reinforcement layer and a self-adhering rubber waterproof layer on the glue spreading reinforcement layer. The glue spreading reinforcement layer is glue spreaded nonwoven cloth or glue spreaded glass-fiber cloth. The self-adhering rubber waterproof layer is produced by mixing the following materials in proportion by weight: 60-70 portions of ethylene propylene terpolymer (PET); 10-26 portions of butyl rubber; 4-25 portions of chloroprene rubber; 50-70 portions of black carbon; 50-70 portions of fine particle calcium carbonate; 2-7 portions of coumarone; 10-20 portions of naphthenic oil; 5-10 portions of zinc oxide and 0.7-1.2 portions of stearic acid. The construction art is simple and fast. Because the self-adhering base material contains hydrophilic material, the basal layer can be in wet lay up if the basal layer has no water. The method has no glue brushing and glue shining process so as to save time limit for a project and the cost, effectively avoid hollow casing and burst phenomenon and form a whole a complete waterproof sealing system.

Owner:北京立高科技股份有限公司

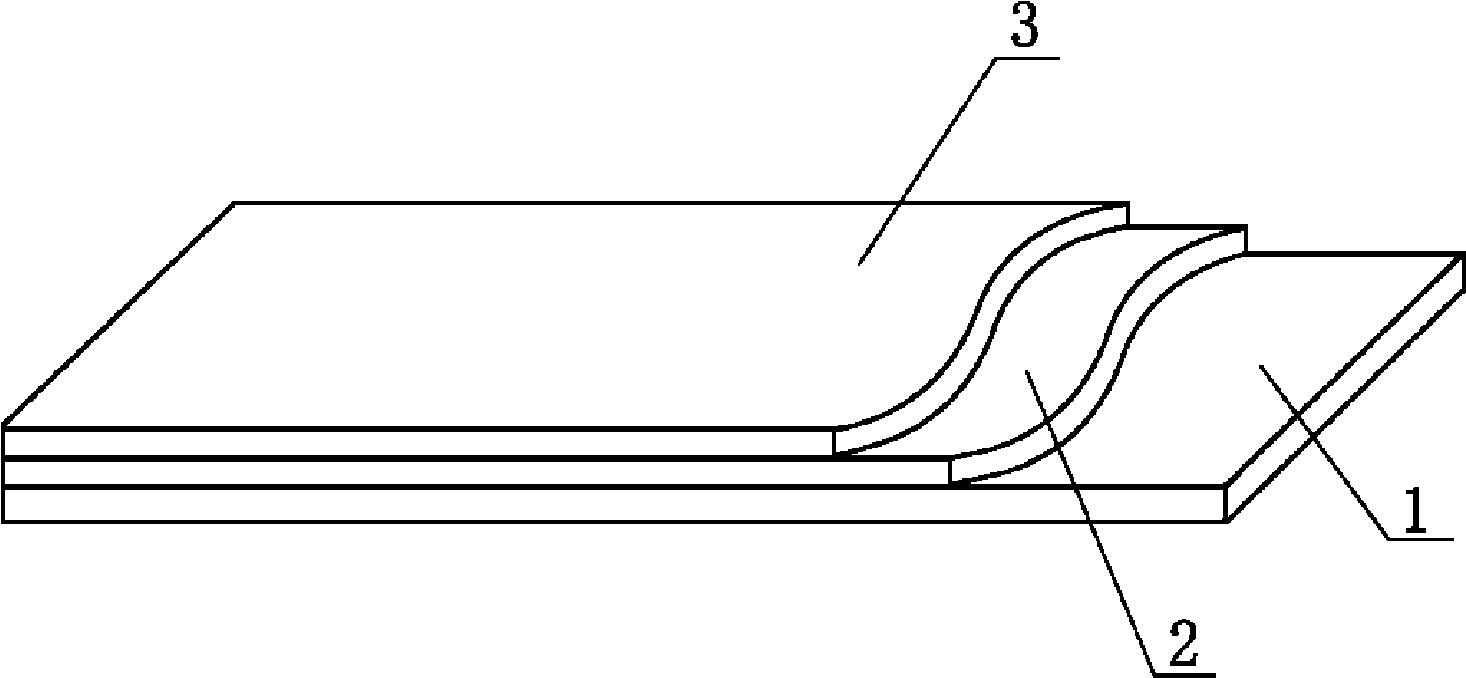

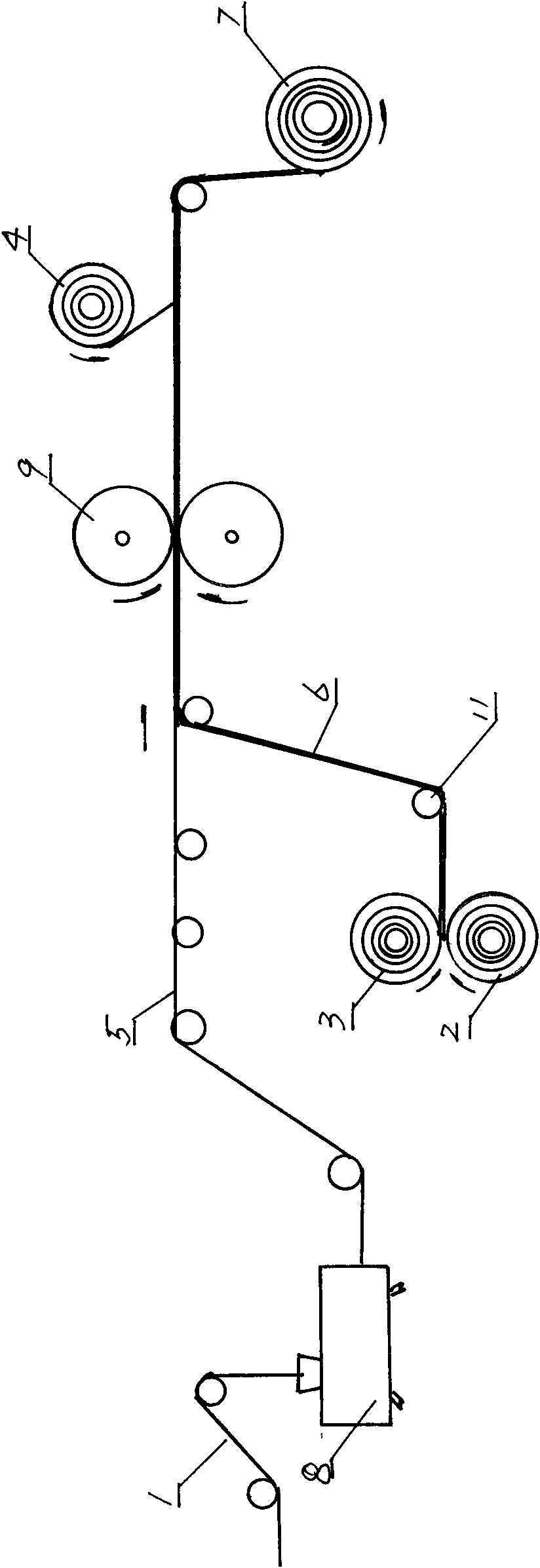

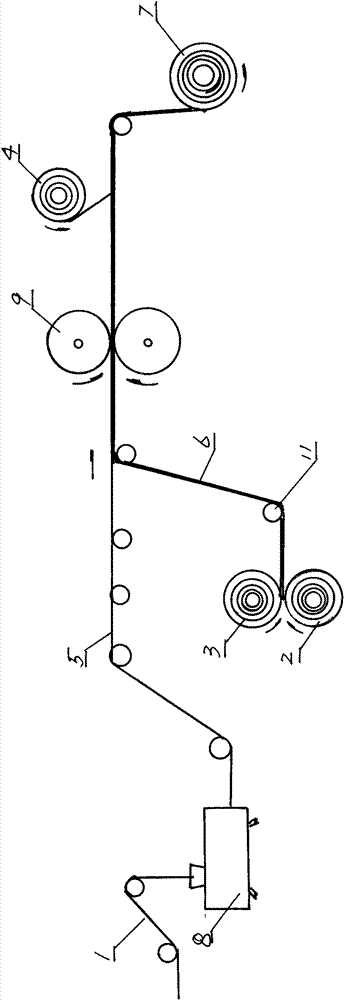

Production method of ethylene propylene diene monomer self-adhesion water-resistant coiled material

ActiveCN104059552ASolve the sticking problemGood value for moneyMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesEthylene-propylene-diene-monomerHot melt

The invention relates to a production method of an ethylene propylene diene monomer self-adhesion water-resistant coiled material. The technical scheme is as follows: the method comprises the following steps: fully coating a composite modified butyl pressure-sensitive self-adhesion adhesive on a ethylene propylene diene monomer vulcanized water-resistant coiled material main body layer by using a hot-melt pressure-sensitive adhesive coating machine to form a composite modified butyl pressure-sensitive self-adhesion layer, coating an anti-adhesion barrier film on the composite modified butyl pressure-sensitive self-adhesion layer, and cutting the side of the anti-adhesion barrier film with a cutting device to arrange intermittent tear slots, thereby preparing the coiled material product. By arranging the ethylene propylene diene monomer vulcanized coiled material main body layer and the composite modified butyl pressure-sensitive self-adhesion layer, the product has dual water-resistant characteristic, and thus, has obviously higher water resistance; the product has the water-resistant function of full skin adhesion, implements the effective fusion and maximum permanent seal between the coiled material and base layer; and besides, the coiled material has high chemical corrosion resistance.

Owner:胜利油田大明新型建筑防水材料有限责任公司

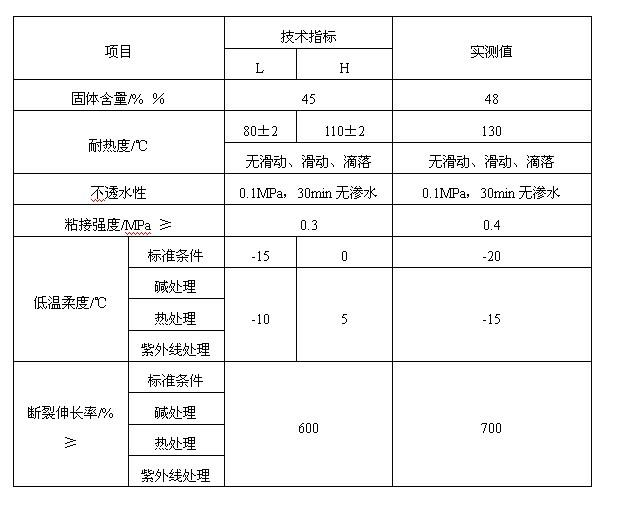

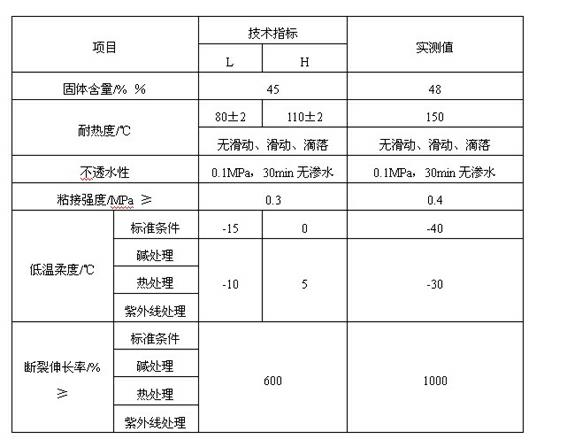

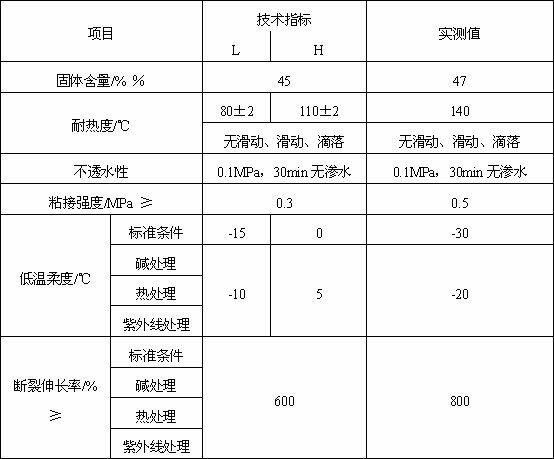

Low temperature resisting polymer modified emulsified asphalt waterproof coating

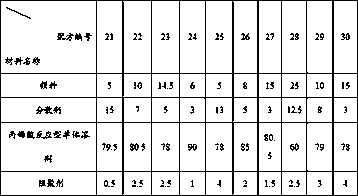

InactiveCN102690601AHigh strengthHigh extensionConjugated diene hydrocarbon coatingsChloropene polymer coatingsBituminous waterproofingPolymer modified

The invention relates to a modified emulsified asphalt waterproof coating, and in particular relates to a low temperature resisting polymer modified emulsified asphalt waterproof coating which is waterproof, moisture-proof and corrosion-proof and is used in the fields of house roofs, undergrounds, indoors, roads and bridges and the like. The coating comprises the following ingredients in parts by weight: 20-40 parts of asphalt A, 1-10 parts of asphalt B, 10-30 parts of polymer emulsion, 0.5-3.0 parts of emulsifying agent, 20-40 parts of water, 10-30 parts of antifreeze agent, 0.1-0.6 part of drier and 0-1 part of thickening agent. The coating is large in film forming strength, high in extension, good in rebound resilience and good in low temperature performance; the formed film can be bent at the temperature of minus 40 DEG C repeatedly without crack and can be stored, transported and adopted for construction application in cold winter; and the coating is fast in film formation, short in drying time in winter construction and free from health damage on construction working personnel.

Owner:TANGSHAN DESHENG WATERPROOF

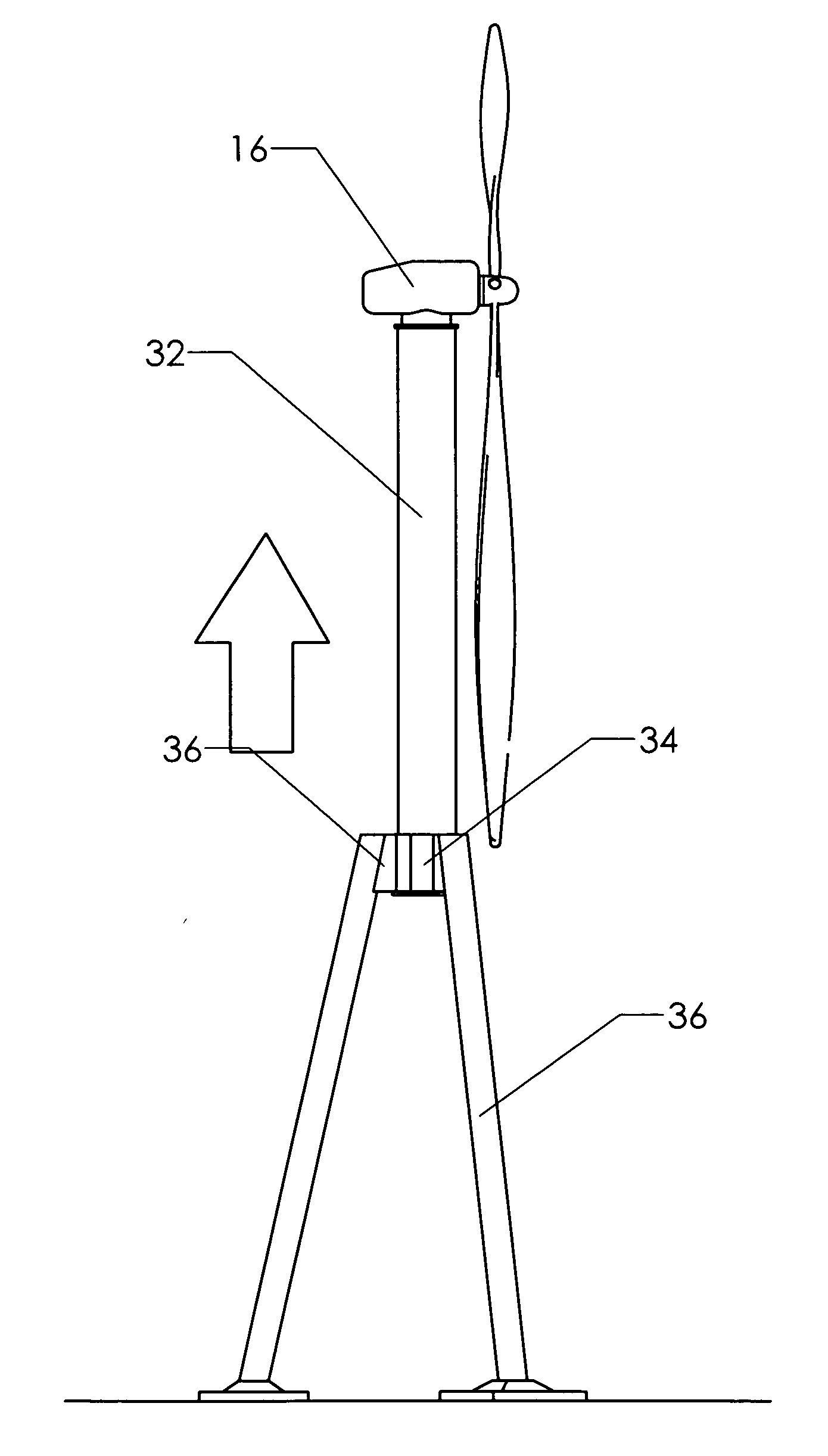

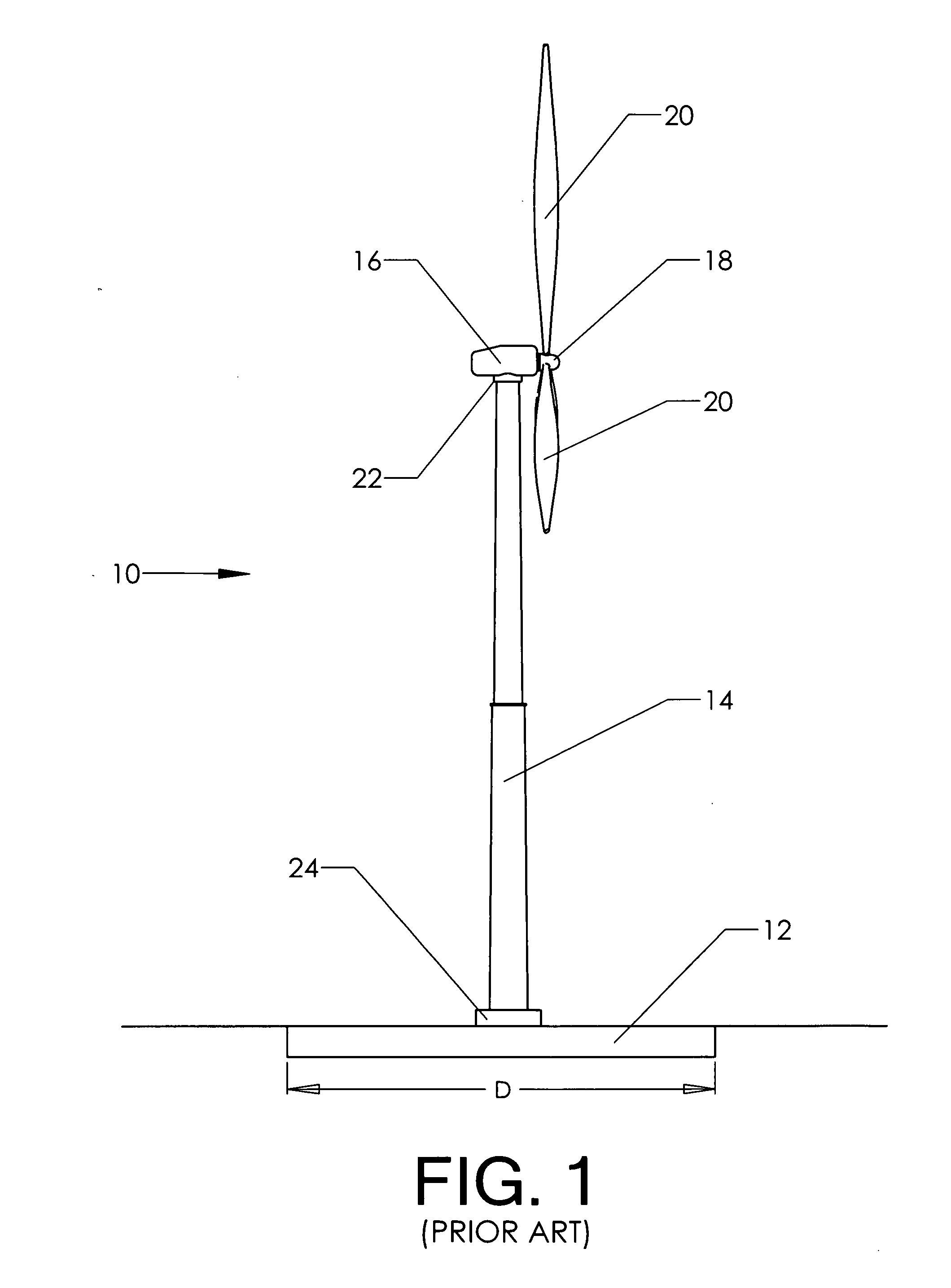

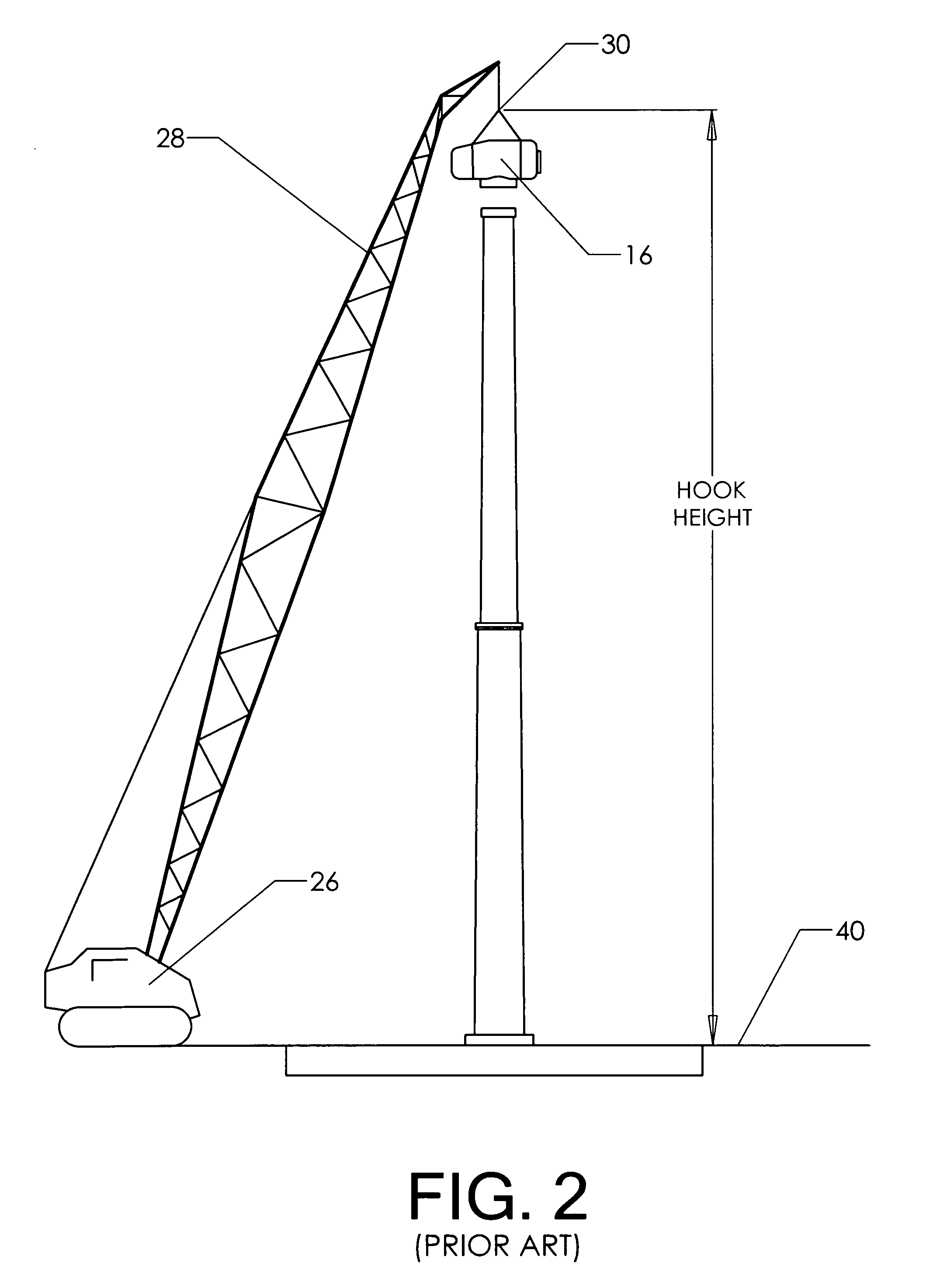

Partially self-erecting wind turbine tower

A partially self-erecting wind turbine tower and a method for carrying out the assembly thereof. A central telescoping pylon is provided. This is placed in an upright position, with its base on a temporary foundation. A plurality of legs is then attached to the telescoping pylon. The upper extreme of each of the plurality of legs is temporarily attached to the upper extreme of the telescoping pylon. With the pylon and legs thus secured, a nacelle is attached to the upper extreme of the telescoping pylon. A hub with attached blades is then affixed to the nacelle. The telescoping pylon is then forced upward through the collar to extend the height of the assembly.

Owner:GEE ANTHONY F

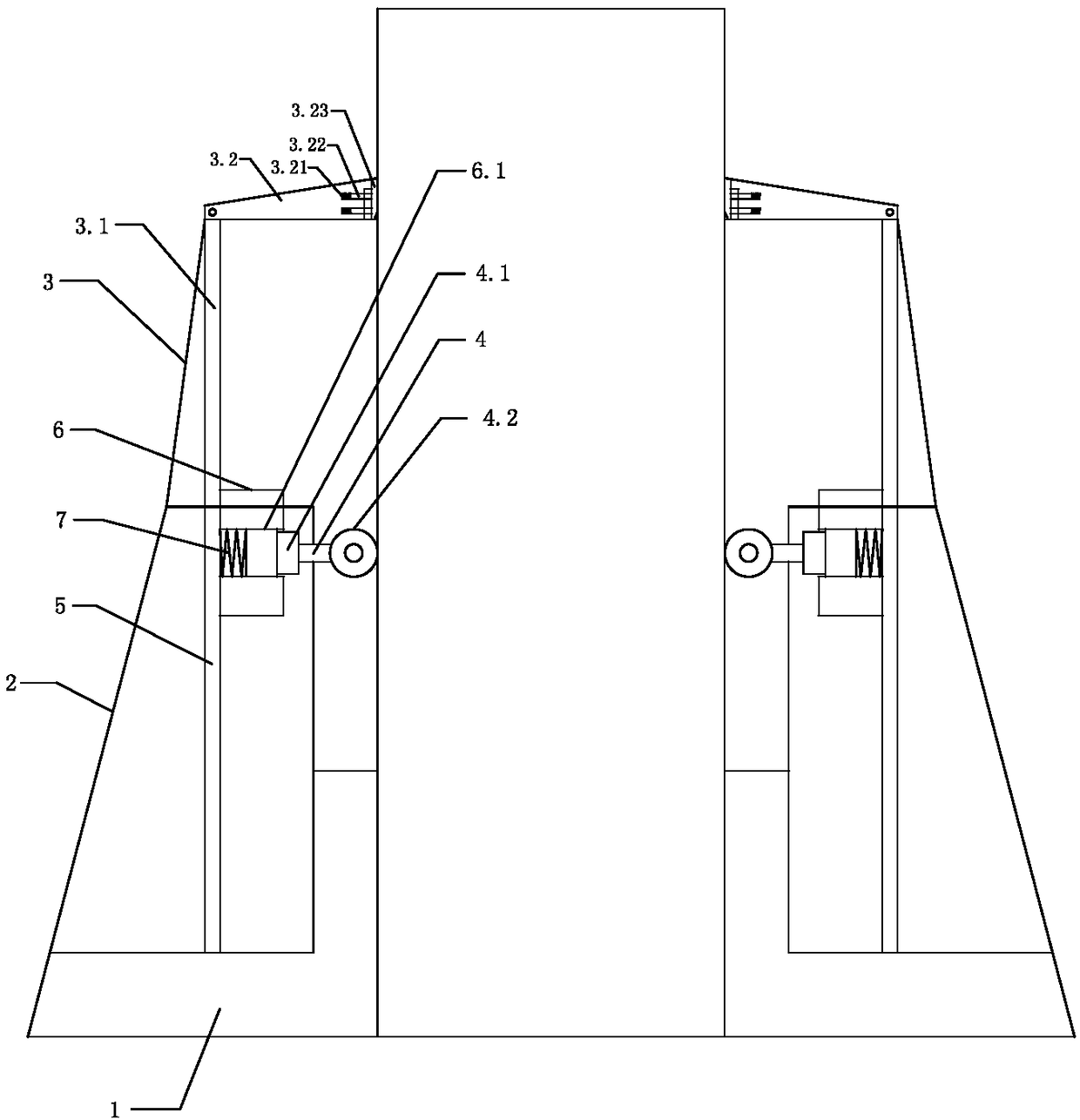

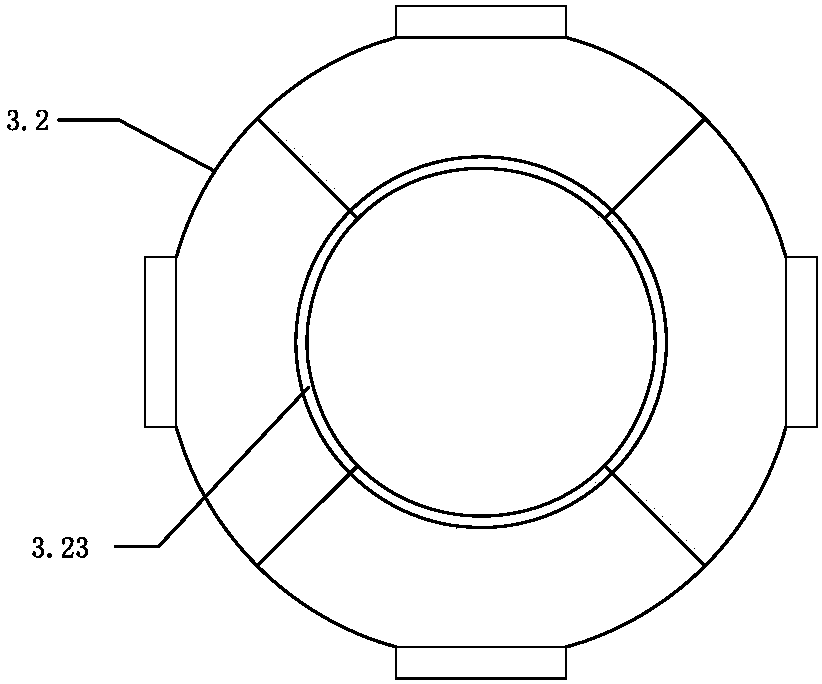

Waterproof aligning pre-tightening seat for cement column body

InactiveCN108204137AExtended slide positionHigh extensionBuilding material handlingEngineeringHinge joint

The invention discloses a waterproof aligning pre-tightening seat for a cement column body. The waterproof aligning pre-tightening seat comprises a base, four pre-tightening piles, extending sectionsand pre-tightening pressure rods; the base is arranged outside the bottom end of the cement column body, and the pre-tightening piles are fixed to the upper end face of the base; the mounting positions of the pre-tightening piles are positions averagely dividing the end face of the annulus of the upper end of the base, and gaps are formed between the pre-tightening piles and the outer wall of thecement column body; slideways are formed in the end faces of the inner walls of the pre-tightening piles, and sliding blocks slidably matched with the slideways are arranged on the slideways; columnargrooves with one ends being open are formed in the sliding blocks, and the center lines of the columnar grooves are perpendicular to those of the pre-tightening piles; openings of the columnar grooves face the cement column body; embedded blocks are fixed to one ends of the pre-tightening pressure rods, and pressing wheels are rotatably assembled to the other ends of the pre-tightening pressure rods; and the extending sections are fixed to the top ends of the pre-tightening piles, and waterproof cover plates are arranged at the top ends of the extending sections in a hinged mode. According tothe waterproof aligning pre-tightening seat, linear pre-tightening is achieved through the pre-tightening pressure rods, and annular gaps between the cement column body and the extending sections areclosed through splicing and hinge joint of the waterproof cover plates capable of being opened and closed to achieve water resistance.

Owner:DALIAN UNIV OF TECH

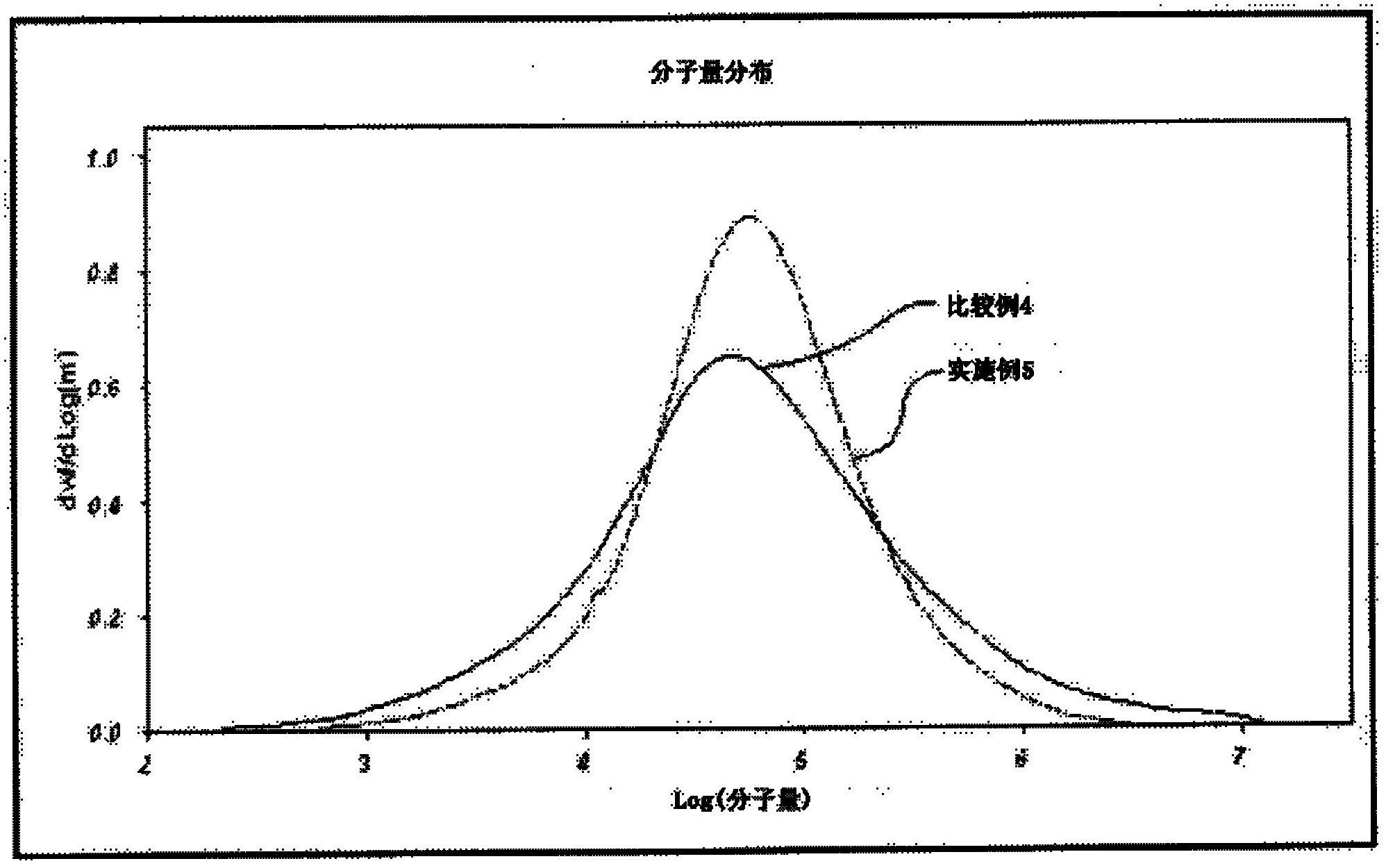

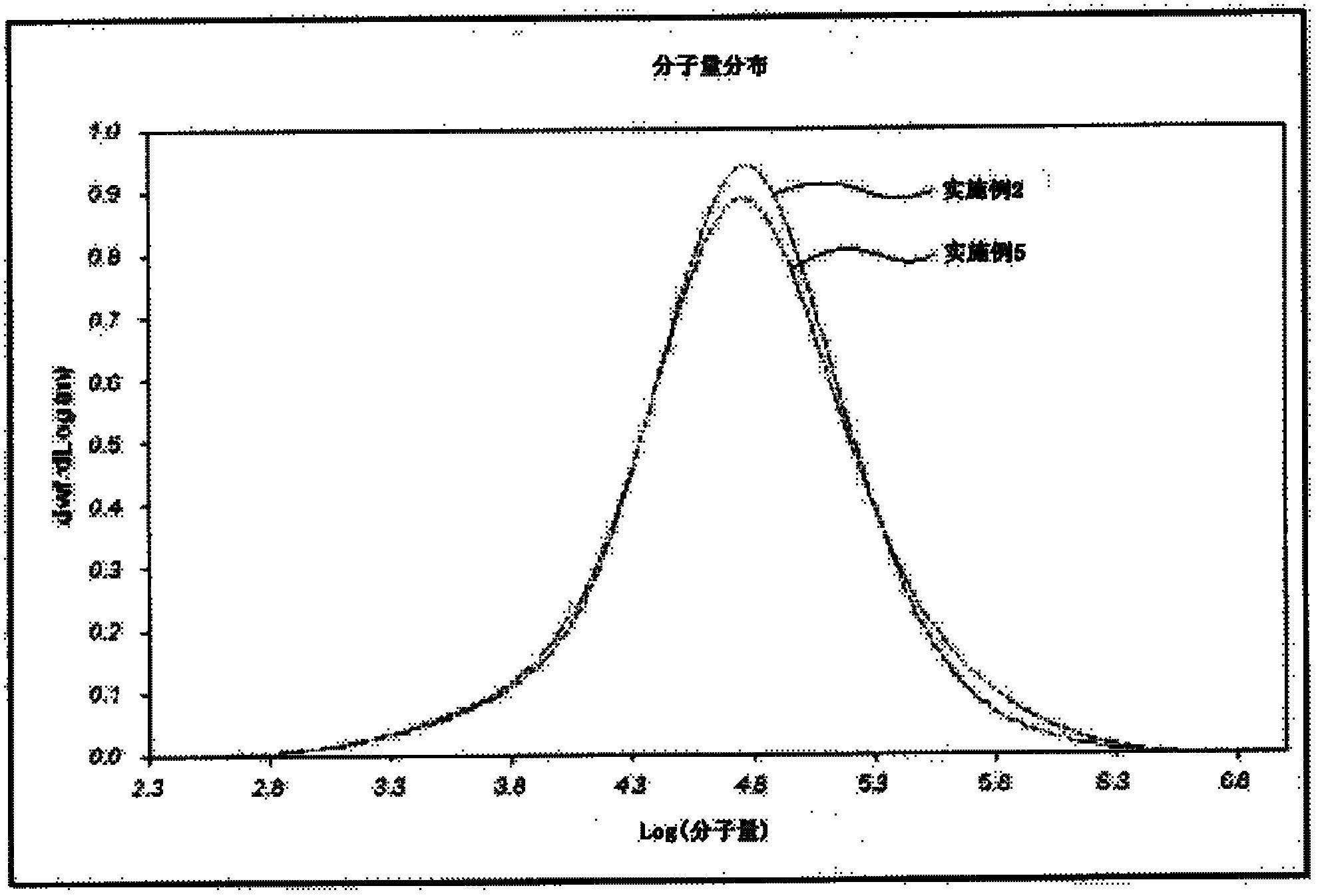

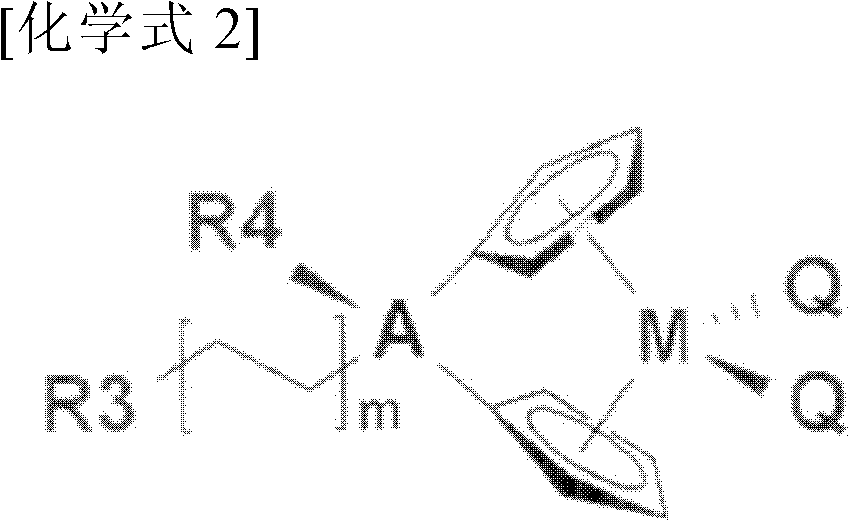

Olefin polymer and fiber including same

ActiveCN102421808AHigh extensionHigh strength propertiesMonocomponent polyolefin artificial filamentFiberPolymer science

The present invention relates to an olefin polymer and to a fiber including same. More specifically, an olefin polymer according to the present invention is characterized by: 1) a density of 0.94 to 0.96 g / cm3; 2) a melt index (MI: 190 DEG C, 2.16 kg) of 0.1 to 1.5 g / 10 min; and 3) a molecular weight distribution (PDI; Mw / Mn) of 2 to 7; and in that the olefin polymer can be prepared by using a supported metallocene catalyst. A fiber which exhibits properties such as high elongation, high tenacity, etc., can be prepared from the olefin polymer according to the present invention.

Owner:LG CHEM LTD

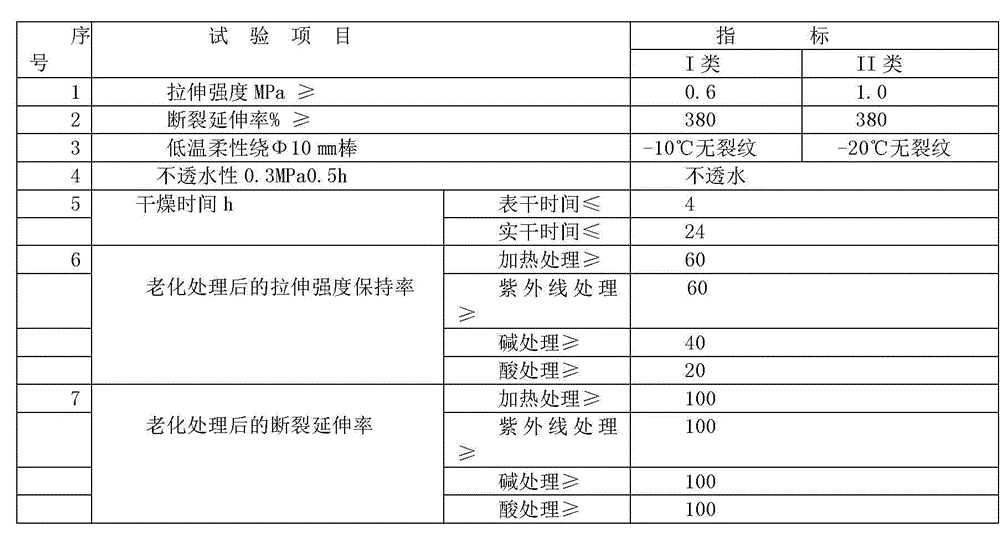

Pure acrylic-acid elastic environment-friendly waterproof paint

InactiveCN102977716ATo achieve a comfortable visual effectImprove adhesionCoatingsExtensibilityUltraviolet

The invention relates to an acrylic-acid paint, particularly a pure acrylic-acid elastic environment-friendly waterproof paint which is prepared by blending the following components in parts by weight: 85-108 parts of acrylic acid emulsion, 4.5-23 parts of thickening agent, 0.017-0.04 part of activating agent, 0.23-1.7 parts of coupling agent and 0.09-0.23 part of defoaming agent. The waterproof paint has the characteristics of high elasticity, high strength, high extensibility and the like in rubber, has excellent functions of weather resistance and ultraviolet resistance, has wide climate application range (-20+ / -80 DEG C), and can be used for construction on a moist basal plane. Since the extensibility is up to higher than 380%, the waterproof paint does not deform or run when being used for sealing cracks of more than 10-30mm. The waterproof paint can be used for crack leakage maintenance of mosaic, ceramic tiles, glass curtain walls, external walls and concrete walls, and peripheral joint filling and integral painting of color steel tile roofing and door / window partitions.

Owner:SHANGHAI QIDONGXIN WATERPROOFING ENG CO LTD

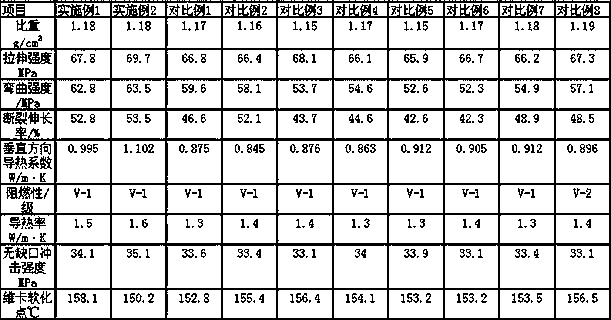

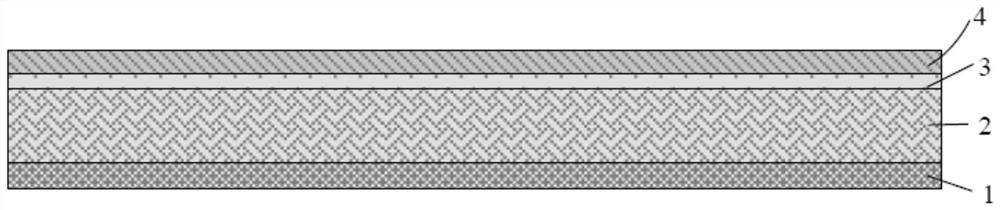

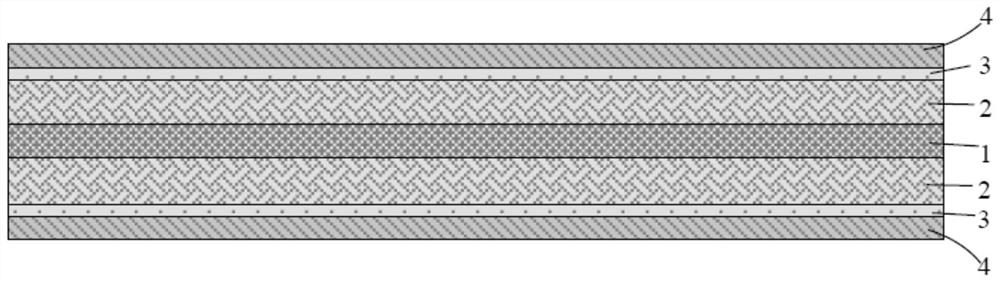

Method for preparing rubber-metal composite waterproof sheet

InactiveCN102127267AHigh strengthHigh extensionFlat articlesMetal layered productsPolymer scienceAdhesive

The invention discloses a method for preparing a rubber-metal composite waterproof sheet, and relates to a method for preparing a rubber composite waterproof sheet. The method has a simple manufacturing process; and the prepared product has high strength, self-healing property and high plasticity, and the construction process is simple without adhesive. The method is characterized by comprising the following steps of: laminating and gluing a 2-8-mesh aluminum mesh and a vulcanized rubber sheet to obtain a laminated sheet of the 2-8-mesh aluminum mesh and the vulcanized rubber sheet; laminating a non-vulcanized rubber sheet with the laminated sheet, and compounding into a composite sheet of the non-vulcanized rubber sheet, the 2-8-mesh aluminum mesh and the vulcanized rubber sheet through a press roll; and compounding an isolating membrane on the composite sheet, laminating and gluing, and winding into a reel on a winding roller to obtain the rubber-metal composite waterproof sheet integrating the vulcanized rubber sheet, the aluminum mesh, the non-vulcanized rubber sheet, and the isolating membrane. The method is used for waterproof sheets in constructional engineering.

Owner:TIANJIN YATENGDA RUBBER & PLASTIC PRODS DEV

Preparation method of high-solid-content low-viscosity acrylate emulsion for sealing gum

InactiveCN103232566AMake up for the shortcomings of aggregationHigh solid contentOther chemical processesEster polymer adhesivesEmulsionChemistry

The invention relates to a preparation method of a high-solid-content low-viscosity acrylate emulsion for sealing gum. The preparation method is characterized by comprising the following steps of: in the presence of nitrogen, adding acrylate, a reactive emulsifier monomer, a latex protective agent and water to a vessel in a certain proportion, and uniformly stirring at room temperature to obtain a mixture liquid; and carrying out vacuumization and nitrogen introduction on a reactor repeatedly for three times, heating to 70-90 DEG C, adding an initiator aqueous solution which accounts for 0.1-0.8wt% of the monomer, dropwise adding 40 percent of the mixture liquid to the reactor, reacting for 15-30 minutes, adding a certain mass of anionic and non-ionic emulsifiers to the rest 60 percent of the mixture liquid to prepare a pre-emulsion, simultaneously dropwise adding the pre-emulsion and the initiator aqueous solution to the reactor, and keeping the constant temperature for 50 minutes after dropwise adding to prepare the acrylate emulsion. The preparation method has the advantages that the emulsion is high in solid content (70-82 percent), low in viscosity (300-600 mpa.s) and good in stability. The preparation method is used for preparing the acrylate-series sealing gum which is high in drying speed and small in shrinkage rate by adding the emulsion to filling and pigment paste.

Owner:LUDONG UNIVERSITY

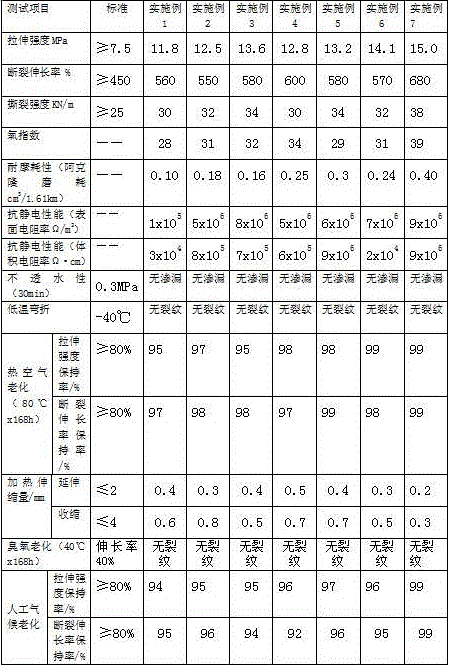

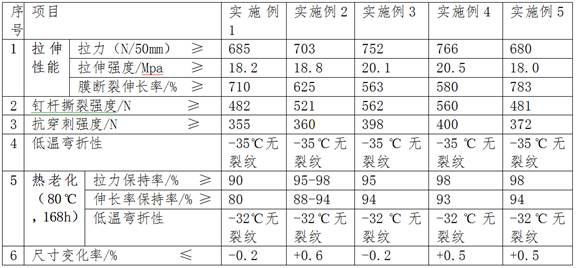

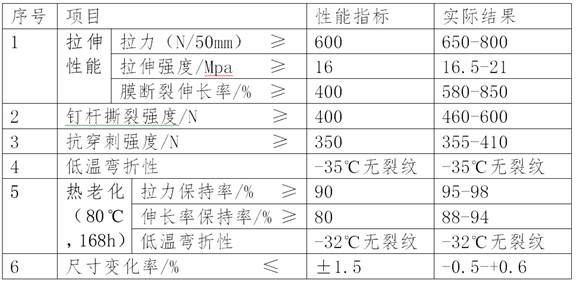

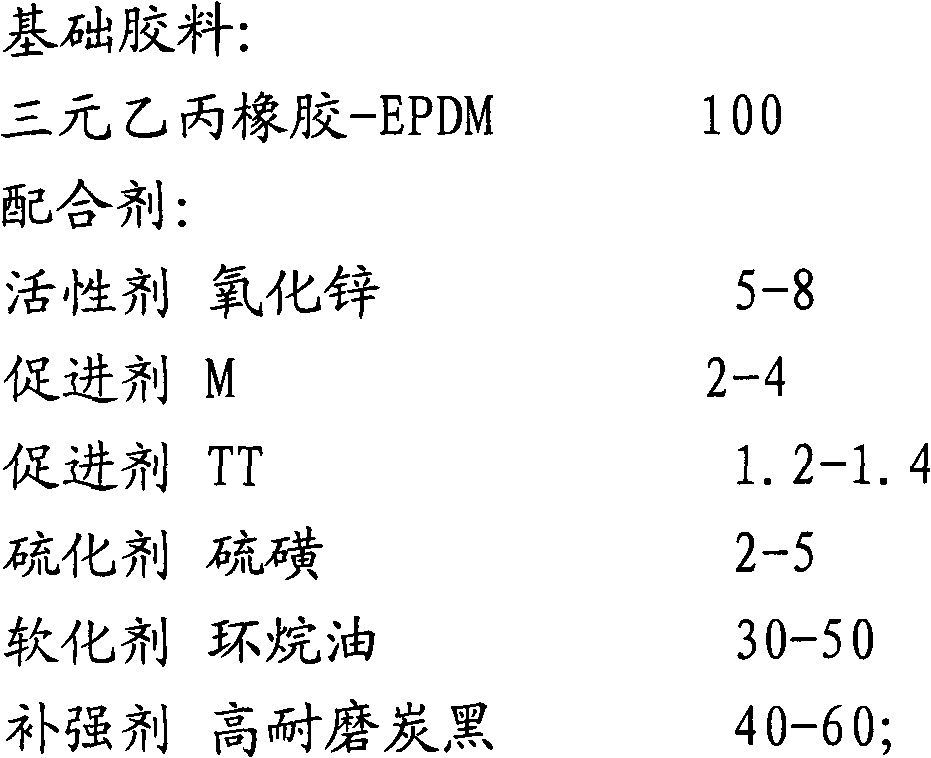

Highly-wear-resistant and antistatic type EPDM waterproof coil material and preparation method thereof

InactiveCN106243525AImprove wear resistanceImprove antistatic performanceFlat articlesBuilding insulationsWear resistantPlasticizer

The invention provides a highly-wear-resistant and antistatic type EPDM waterproof coil material, which comprises EPDM rubber, a composite wear-resistant rubber, a softening plasticizer, and a reinforcing agent. The invention further provides a preparation method of the highly-wear-resistant and antistatic type EPDM waterproof coil material. According to the present invention, the waterproof coil material has excellent wear resistance, has an Akron abrasion index is 0.1-0.3 cm<3> / 1.61 km, has strong static electricity resistance in a complicated harsh environment, has characteristics of long service life, high flame retardancy, good water resistance and good viscosity, has an oxygen index of more than or equal to 28, improves the effect of the adhesion with the bottom paving glue and the edge overlapping glue, is not easily shed from the glue after the long-term use, and has high strength and high extension; in the field of artificial weather aging, the tensile strength retention rate is more than 95%, and the elongation at break retention rate is more than 92%; and the preparation method of the present invention has characteristics of simpleness, low energy consumption, and environment protection.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL

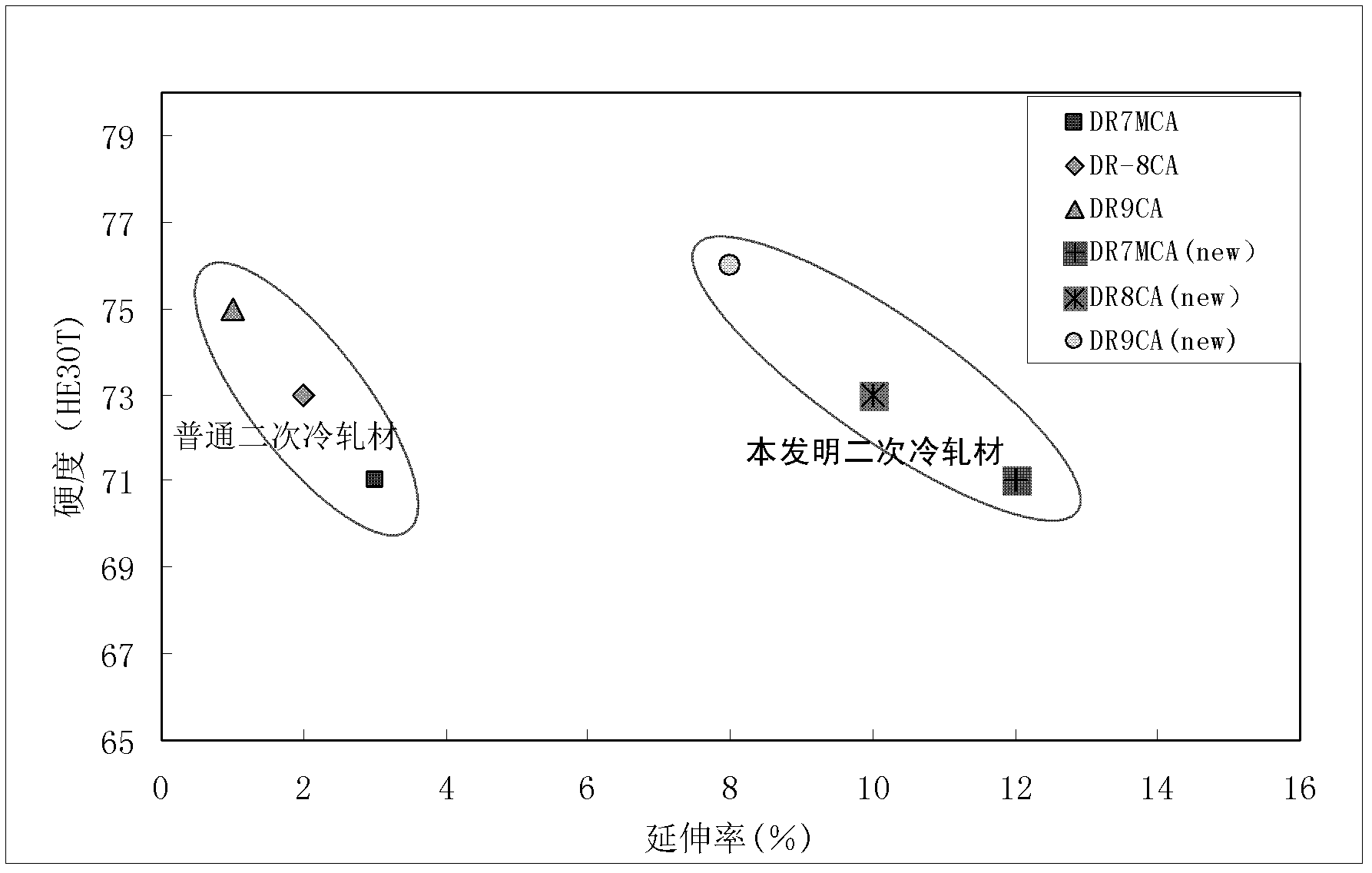

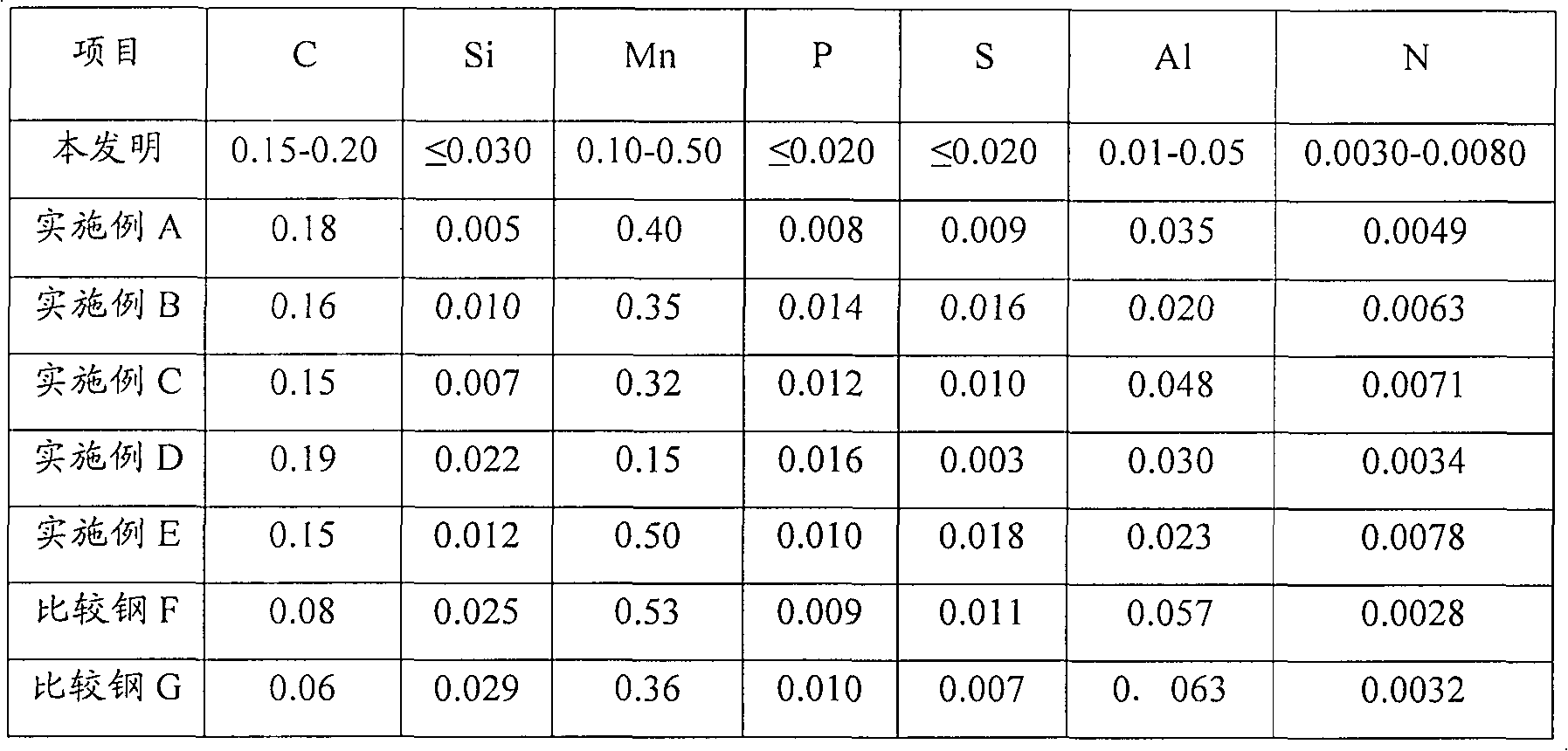

High extended secondary cold-rolled plate and production method thereof

The invention relates to a high extended cold-rolled plate, which comprises the following chemical components in percentage by weight: 0.15-0.20% of C, less than or equal to 0.030% of Si, 0.10-0.50% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, 0.01-0.05% of Al, 0.0030-0.0080% of N, and the balance of iron and inevitable impurity. The production method comprises the following steps: carrying out iron pretreatment, converter melting, refining after the furnace, hot rolling, scouring, cold rolling, continuous annealing, secondary cold rolling, finishing to obtain the finished product roll, wherein in the process of the hot rolling, the controlled heating temperature is 1150-1270 DEG C, the finish rolling temperature is more than Ar3, the coiling temperature is less than or equal to 600 DEG C, the cold rolling deflection is more than or equal to 60%, the continuous annealing temperature is 600-700 DEG C, the annealing time is 40-100 seconds, the secondary cold rolling ratio is 5-15%, the hardness of the obtained secondary cold-rolled plate is HR30T66-80, and the tensile extension is more than or equal to 5%.

Owner:BAOSHAN IRON & STEEL CO LTD

High-adhesion LED-UV piezoelectric spray printing ink and preparation method thereof

The invention relates to high-adhesion LED-UV piezoelectric spray printing ink and a preparation method thereof. In order to solve problems in the prior art, a technical scheme of the high-adhesion LED-UV piezoelectric spray printing ink is as follows: a polyurethane-acrylate resin system is adopted; the ink is prepared from the following components in percentage by weight: 8%-30% of pigment typepaste, 5%-20% of polyurethane-acrylate resin, 5%-16% of a photoinitiator, 30%-50% of an acrylic acid reactive monomer solvent or oligomer, 0.5%-4% of a polymerization inhibitor and 0.5%-2% of a surfactant, wherein the pigment type paste contains sub-micron pigment. The ink is adaptable to various industrial-grade nozzles, and has high adhesion, high extensibility and high bending performance whensprayed on the surfaces of various soft and hard materials.

Owner:TRENDVISION TECH(ZHUHAI) CO LTD

Aluminum electrolysis waste carbon-based porous carbon preparation method

The invention relates to the field of new materials, and discloses an aluminum electrolysis waste carbon-based porous carbon preparation method, which comprises: uniformly mixing an aluminum electrolysis waste carbon material and an activating component according to a mass ratio of 10:(0-100), carrying out a high-temperature reaction under a specific atmosphere condition, cooling to a room temperature, and washing to achieve the pH value of 5-9 so as to obtain the structure-controllable porous carbon material, wherein a mass ratio of the main component to the auxiliary component in the activating component is (10-0):(50-0). According to the present invention, the porous carbon material with the controlled pore parameters is obtained by using the solid waste carbon produced in the aluminum electrolysis process as the raw material through the high temperature activation treatment, such that the high value resource of the aluminum electrolysis waste carbon material is achieved; and by adjusting the type and the consumption of the activating agent and the process conditions, the structure parameters of the porous carbon can be precisely controlled, such that the method is the simple porous carbon preparation method capable of achieving scalability and high value utilization of waste.

Owner:绿业中试低碳科技(镇江)有限公司

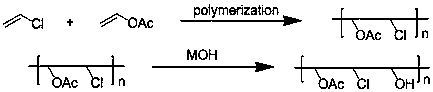

LED-UV piezoelectric type spray printing ink with high adhesion and preparation method thereof

The invention relates to LED-UV piezoelectric type spray printing ink with high adhesion and a preparation method thereof. For solving the problems of the prior art, the technical scheme of the LED-UVpiezoelectric type spray printing ink with high adhesion is as follows: the ink adopts a polyvinyl chloride-vinyl acetate resin system; raw materials of the ink comprise the following components in percentage by weight: 5-35% of pigment type color paste, 2-10% of vinyl chloride-vinyl acetate resin, 5-15% of a photoinitiator, 40-70% of a reaction type monomer solvent or oligomer, 0.2-2% of a surface active agent and 0.5-4% of a polymerization inhibitor, wherein the pigment type color paste comprises sub-micron sized pigments. The ink provided by the invention can adapt to all kinds of industrial-grade sprayers and respectively has high adhesion, high extensibility and high bending property after being sprayed and printed on the surfaces of various soft and hard materials.

Owner:TRENDVISION TECH(ZHUHAI) CO LTD

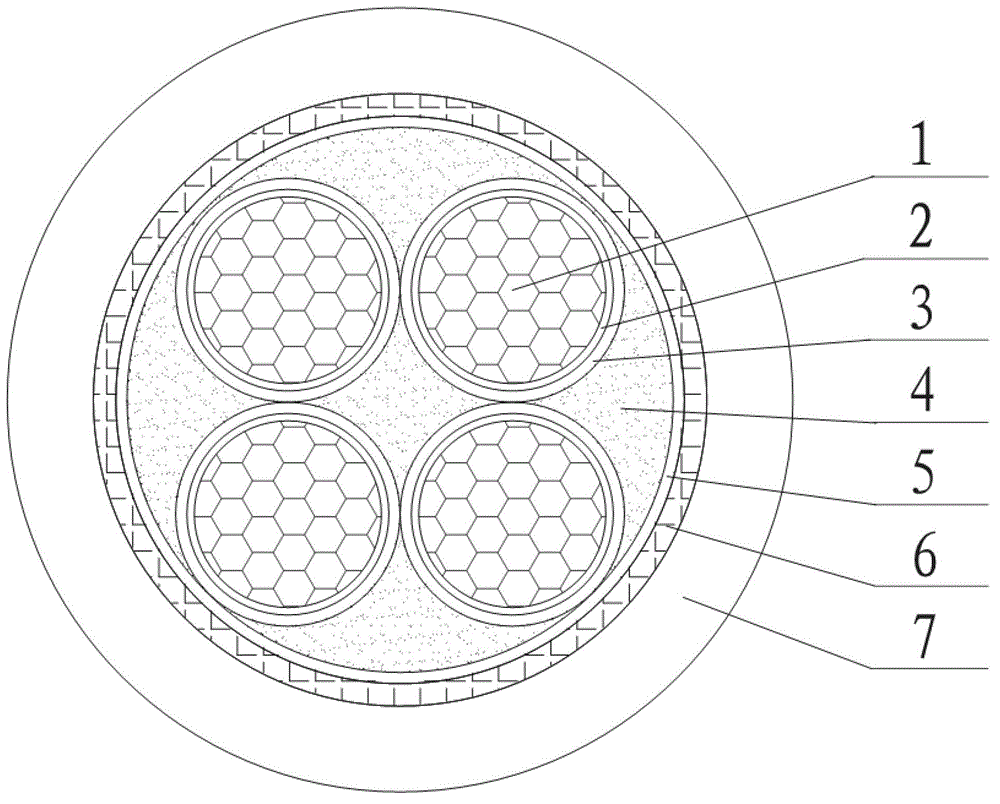

High-performance aluminium alloy cable for building

InactiveCN103337290AExtended durationHas flame retardant propertiesInsulated cablesPower cablesElectricityInsulation layer

The invention discloses a high-performance aluminium alloy cable for buildings, which solves the problems that the conventional power cables for buildings consume more copper resources, are worse in bending performance, and have short service life and the like, and has the advantages of light weight, the capability of corrosion-resistance and halogen-free flame retardant, small bending radius, excellent electrical property, long service life and the like. The high-performance aluminium alloy cable structurally comprises a cable core, wherein the cable core is formed by a plurality of wire core conductors arranged inside a filler and made of aluminium alloy; a conductor double-layer insulation layer is arranged on the outer wall of each wire core conductor; the plurality of wire core conductors are intertwisted in a symmetric arrangement manner; the outer wall of the filler is wrapped with a cable belting layer, a cable armored layer and a cable shield layer sequentially from the inside out.

Owner:SHANGDONG HUALING CABLE

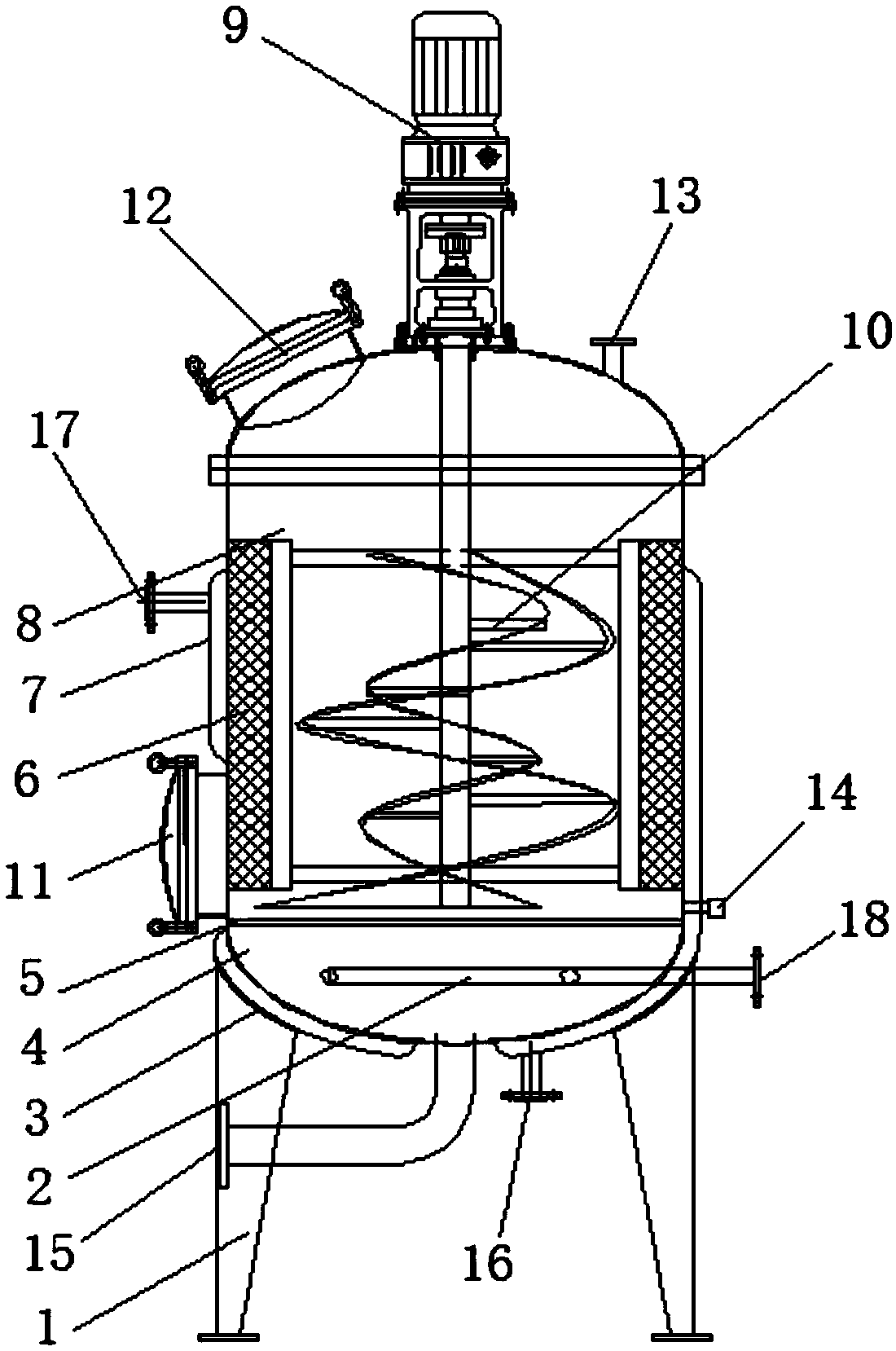

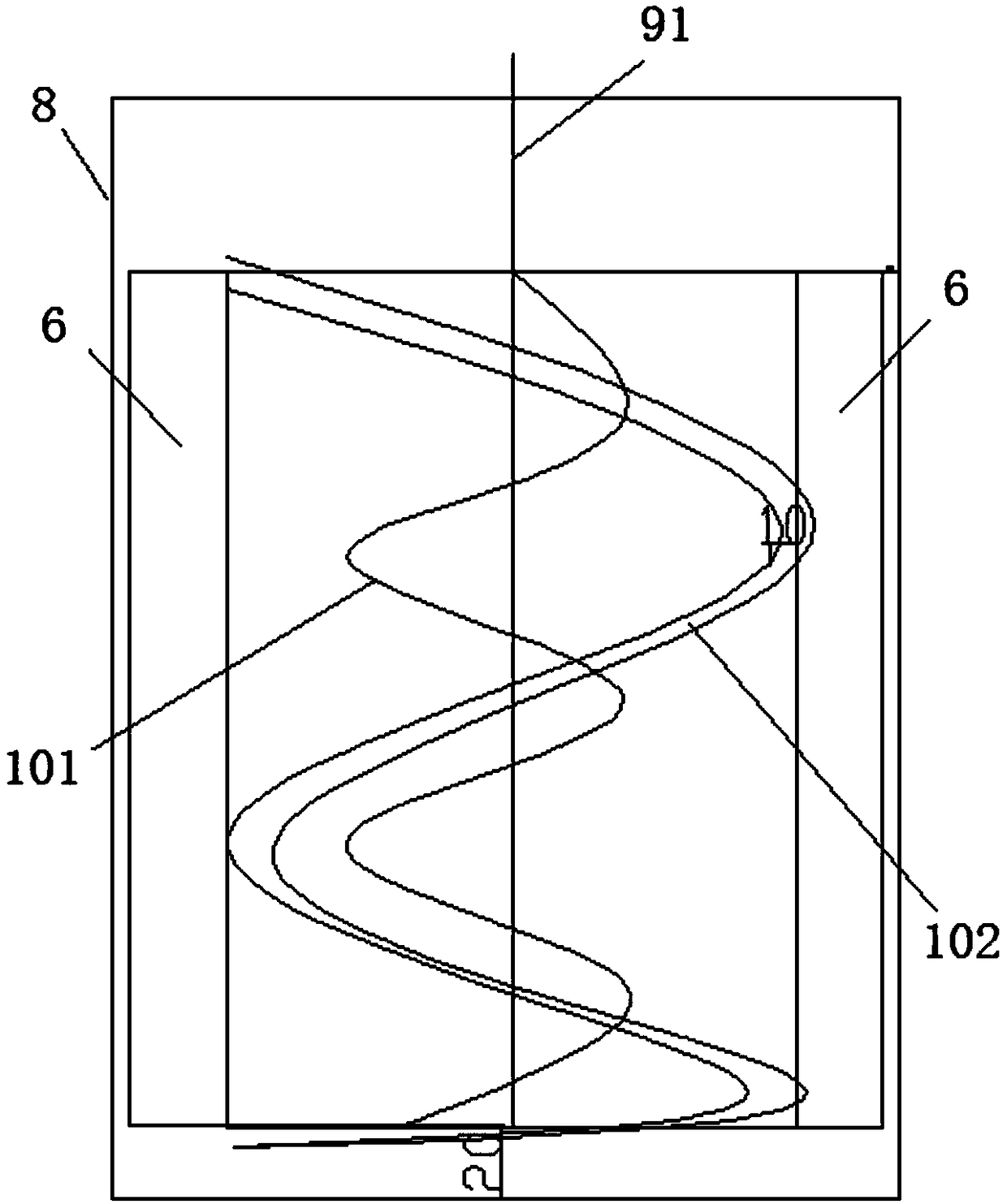

Differential double-spiral stirring type integrated solid fermenting device

ActiveCN108220139AEasy to integrateNot easy to polluteBioreactor/fermenter combinationsBiological substance pretreatmentsSlagPulp and paper industry

The invention provides a differential double-spiral stirring type integrated solid fermenting device. The differential double-spiral stirring type integrated solid fermenting device comprises a cylinder body, wherein a double-spiral agitator blade is arranged in the cylinder body; a 40 to 100-mesh filtering screen hole bottom plate is arranged at the bottom part of the cylinder body; the side wallof the lower part of the cylinder body is provided with a slag outlet. The differential double-spiral stirring type integrated solid fermenting device has the advantages that by arranging the 40 to 100-mesh filtering screen hole bottom plate at the bottom part of the cylinder body, the integration effect of solid enzyme water dissolving and extracting is realized, the sealed type operation is performed at the whole surface, and the easiness in pollution is avoided; by adopting the double-spiral agitator blade, a large spiral stirring blade and a small spiral stirring blade are staggered with90 degrees, the looseness degree of solid koji is improved by positive and reverse stirring, and the extending and heat radiating effects of hyphae are accelerated; by arranging the slag outlet to discharge slag, the filtering, slag discharging and maintenance can be conveniently performed.

Owner:YUNNAN NORMAL UNIV

Waterproof and antibacterial PVC (polyvinyl chloride) cable material formula

InactiveCN107033486AHigh strengthImprove corrosion resistancePlastic/resin/waxes insulatorsAntioxidantCarbon nanotube

The invention discloses a waterproof and antibacterial PVC (polyvinyl chloride) cable material formula. The formula comprises raw materials in parts by weight as follows: 30-40 parts of PVC resin, 10-15 parts of EPDM (ethylene-propylene-diene monomer) rubber, 5-10 parts of chloroprene rubber, 2-5 parts of nano barium sulfate, 1-5 parts of nano titanium dioxide, 2-6 parts of carbon nanotubes, 5-10 parts of expanded perlite, 3-8 parts of inorganic silver-ion-containing silicate, 2-3 parts of an antioxidant, 1-4 parts of sodium hexametaphosphate, 2-5 parts of microcrystalline cellulose, 1-2 parts of silver-loaded zeolite, 2-5 parts of elastic fiber, 4-10 parts of aluminum oxide, 5-10 parts of magnesium hydroxide, 1-3 parts of an anti-aging agent, 3-6 parts of paraffin, 3-5 parts of a silane coupling agent and 1-4 parts of a plasticizer. PVC resin, EPDM rubber and chloroprene rubber are subjected to blending crosslinking modification, so that the cable material has characteristics of plastic and rubber, has high strength, high elongation, long service life, light weight, good bonding property and excellent waterproof performance, has aging resistance and flame retardance and is convenient to construct and maintain. Raw materials are non-toxic and harmless, environment-friendly and harmless to body health.

Owner:ANHUI YILI CABLE

Aqueous reaction type rubber asphalt waterproof paint and production method thereof

ActiveCN103013335AGood anti-sagImprove permeabilityChloropene polymer coatingsBituminous coatingsEmulsionAsphalt

The invention discloses aqueous reaction type rubber asphalt waterproof paint and a production method thereof. The paint is prepared by mixing the following substances as raw materials in parts by weight: 8.1 to 14.5 parts of cationic styrene acrylic emulsion, 30.4 to 35.9 parts of cationic emulsified asphalt, 18.2 to 22.3 parts of cationic chloroprene emulsion, 0.4 to 0.7 part of non-ionic emulsifier, 0.2 to 0.4 part of cationic emulsifier, 0.3 to 0.6 part of defoaming agent, 29.5 to 33.5 parts of superfine talcum powder, and 0.4 to 0.6 part of cationic thickening agent. The paint has a function of water channeling prevention function and sagging resistant performance, and has the advantages of excellent physical and mechanical properties, convenience in construction and high cost performance.

Owner:KESHUN WATERPROOF TECH CO LTD

Low-earing and low-hardness capacitor shell and preparation method thereof

InactiveCN112126823AReduce intensityStrength 75-85Mpa, low elongationMetal rolling arrangementsUltimate tensile strengthCapacitor

The invention belongs to the technical field of aluminum strip calendering manufacturing, and discloses a low-earing and low-hardness capacitor shell and a preparation method thereof. The low-earing and low-hardness capacitor shell comprises the following components in percentage by mass: 0.1% of Si, 0.18-0.28% of Fe, not greater than 0.03% of Cu, not greater than 0.01% of Mn, not greater than 0.03% of Zn, not greater than 0.03% of Ti, and the balance Al. The process flow comprises such steps as smelting, cast rolling, rough rolling, edge cutting, finish rolling and finished product annealing;and the prepared capacitor shell is 75-85Mpa in tensile strength, can reach the elongation above 30%, is excellent in machining performance, low in strength, excellent in plasticity, high in elongation and low in earing rate, and greatly improves the machining efficiency.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Rubber waterproof material

The invention discloses a rubber waterproof material. The rubber waterproof material is prepared from the following raw materials in parts by weight: 20-30 parts of ethylene propylene diene monomer, 10-15 parts of chloroprene rubber, 10-15 parts of butyl rubber, 5-10 parts of chlorinated polyethylene resin, 5-12 parts of sodium bentonite, 5-10 parts of modified sodium silicate, 3-5 parts of polypropylene fiber, 40-50 parts of deionized water, 1-3 parts of a preservative, 0.1-0.2 part of polyvinylpyrrolidone, 1-2 parts of a wetting agent, 1-5 parts of a dispersing agent, 2-6 parts of a thickening agent, 0.5-4.5 parts of a defoaming agent, 5-8 parts of hexamethylphosphoramide and 1-2 parts of rosin. The rubber waterproof material is a waterproof material utilizing a blended material of the ethylene propylene diene monomer, the chloroprene rubber, the butyl rubber and the chlorinated polyethylene resin as a main body material. The rubber waterproof material has the characteristics of plastic and rubber, such as high strength and ductility, long service life, lightness, good bonding property and the like. The rubber waterproof material has excellent weather ageing resistance, flame retardance, water resistance, ageing resistance, corrosion resistance and high-low temperature resistances.

Owner:安庆越球建筑防水材料有限公司

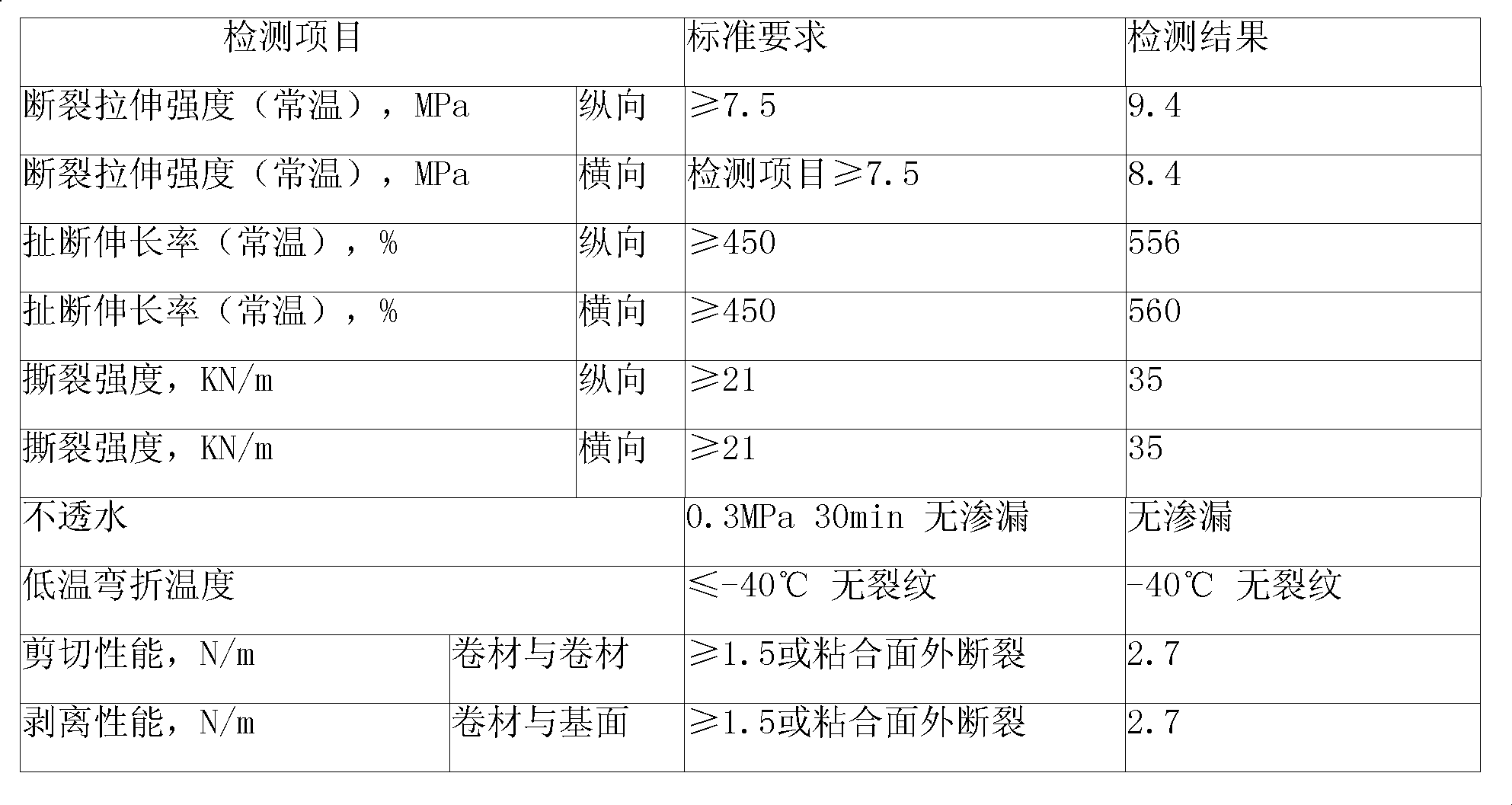

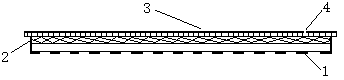

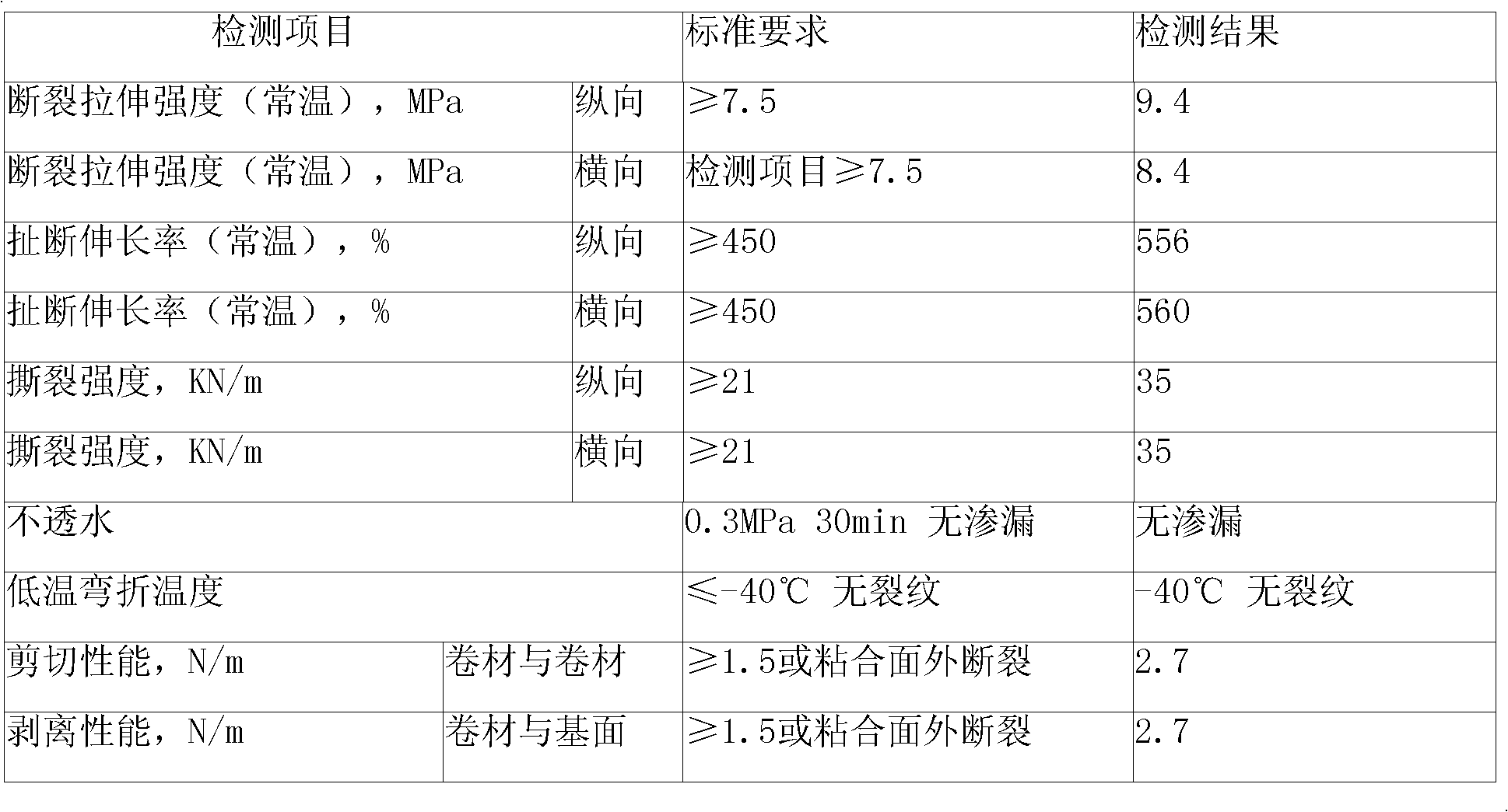

Low-bending-modulus high-molecular pre-laid waterproof coiled material and preparation method thereof

ActiveCN113930010AHigh extensionHigh strengthRoof covering using flexible materialsProtective foundationLinear low-density polyethyleneLow-density polyethylene

The invention discloses a low-bending-modulus high-molecular pre-paving waterproof coiled material, which is a multi-layer composite waterproof material with excellent performance and is researched and developed specially for engineering parts needing to be constructed by a pre-paving method in underground engineering. A main body sheet of the coiled material mainly comprises the following components in parts by mass: 40 to 65 parts of linear low-density polyethylene, 15 to 30 parts of polypropylene, 10 to 20 parts of a compatibilizer and 10 to 20 parts of a calcium carbonate master batch. During preparation, the components are fully dried and mixed, melted at high temperature, extruded and molded, and glue and sand are coated to prepare the low-bending-modulus high-molecular pre-paved waterproof coiled material. The method is simple in production process and low in cost; the extension performance, aging resistance and stability are excellent, and the coiled material is soft and easy to install; the material is also environment-friendly; and the material with excellent performance is suitable for construction of underground engineering needing a pre-paving method.

Owner:河南华瑞兴业防水科技有限公司

Method for preparing rubber-metal composite waterproof sheet

InactiveCN102127267BHigh strengthHigh extensionFlat articlesMetal layered productsPolymer scienceAdhesive

Owner:TIANJIN YATENGDA RUBBER & PLASTIC PRODS DEV

Novel thermal conductive insulating plastic

InactiveCN110387089AHigh thermal conductivityLow costHeat-exchange elementsPolyvinyl alcoholAntioxidant

The invention discloses novel thermal conductive insulating plastic. The novel thermal conductive insulating plastic is prepared from the following raw materials: styrene monomer, dibenzoyl peroxide,deionized water, polyvinyl alcohol, sodium polystyrene sulfonate, aniline, 3,4-ethylene dioxythiophene, a catalyst, actinolite powder, a regulator, a stabilizer, polyphosphazene, a fullerene loading agent, polyphenylene ether resin, acicular alpha-alumina, nano silica, an antioxidant, a lubricant and a flame retardant. The heat conductive plastic is light in weight, good in insulating performance,low in production cost and good in heat dissipation performance, a one-step method is used for preparing heat conductive polystyrene particles, and further blending modification is carried out to improve thermal conductivity, the novel thermal conductive insulating plastic has the characteristics of high mechanical properties, corrosion resistance, high heat transfer coefficient and impact resistance and can be subjected to secondary blending modification processing, and the defects of high filling rate, poor mechanical properties and high cost of existing thermal conductive plastic are overcome.

Owner:蚌埠创特新材料科技有限公司

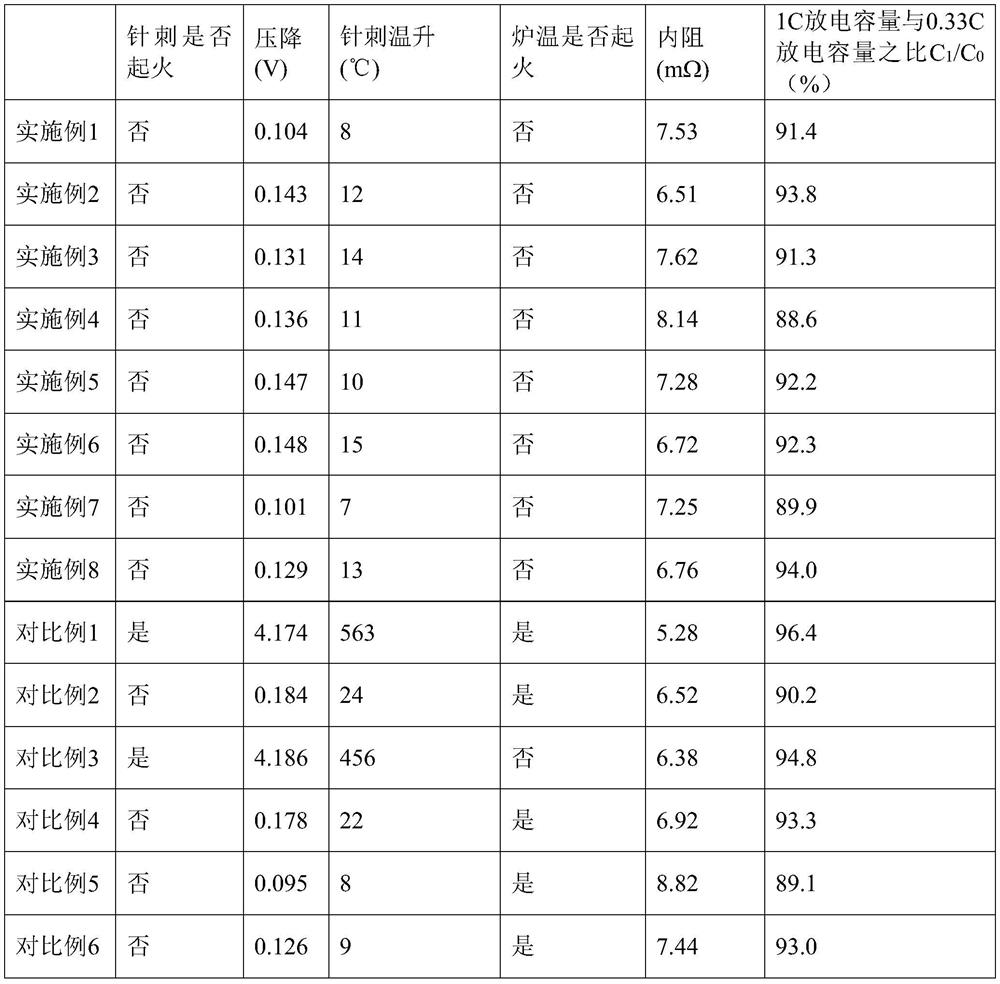

Electrode plate and lithium ion battery comprising same

PendingCN114094039AHigh extensionArea to avoidNon-aqueous electrolyte accumulator electrodesCell component detailsComposite materialLithium electrode

The invention provides an electrode plate and a lithium ion battery comprising the same. The electrode plate comprises a current collector, an active substance layer, an electrolyte and a functional coating; the current collector is provided with two opposite surfaces; the active substance layer is arranged on at least one surface of the current collector; the electrolyte is arranged inside and / or on the surface of the active substance layer; the functional coating layer is disposed on an active material layer including an electrolyte. By constructing the in-situ curing electrolyte and the functional coating, the influence of a single functional coating mode on the increase of the internal resistance of the battery can be reduced while the needling and heating safety of the battery is improved, and the electrical property of the battery is ensured.

Owner:ZHUHAI COSMX BATTERY CO LTD

Degreased tire bead wire processing method

The invention discloses a degreased tire bead wire processing method. The method comprises the following steps of (1) paying-off; (2) straightening; (3) mixed degreasing; (4) tempering; (5) water washing; (6) surface treatment; (7) water washing; (8) alloy combination; (9) water washing; (10) neutralizing; (11) water washing; (12) hot water washing; (13) drying; (14) oil coating; (15) wind-up; and (16) cooling. By means of the method, the strict requirements of foreign customers for high torsion, high elongation and high strength of tire bead wires of high-performance radial tires are met; the international competitiveness of domestic products is improved; the progress of the industry is led to and promoted; and the transformation, upgrading and scientific and technological innovation of the industry are promoted.

Owner:李文军

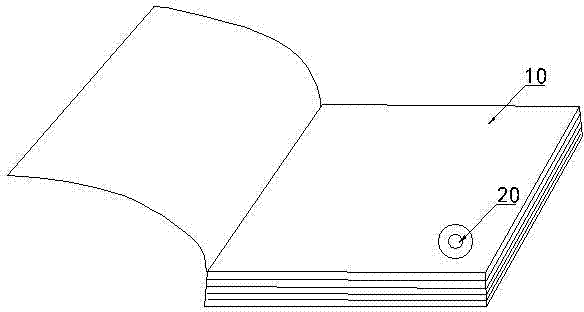

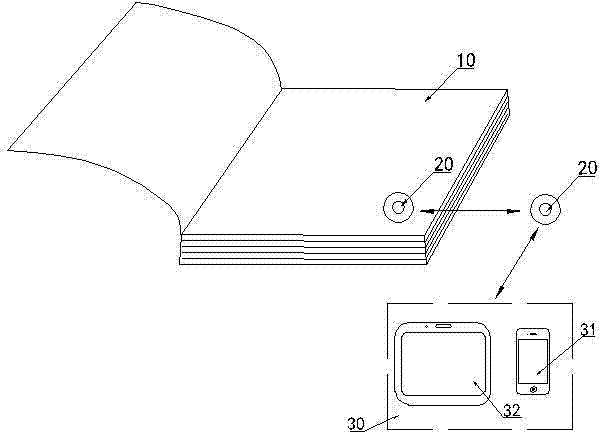

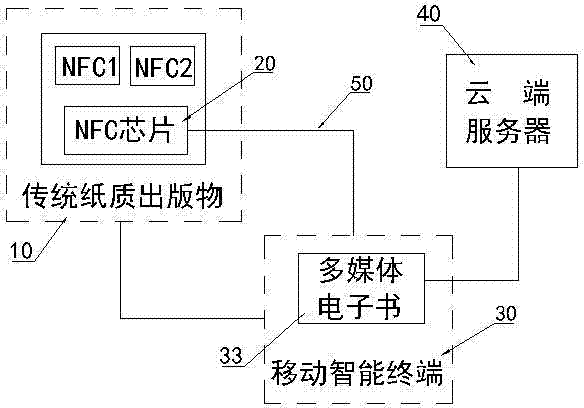

New media interactive picture book and interactive application system and use method thereof

InactiveCN104504432AImprove and expandHigh extensionSensing record carriersRecord carriers used with machinesMediaFLOEngineering

The invention discloses a new media interactive picture book, and an interactive application system and a use method thereof. The new media interactive picture book comprises a traditional paper publication, wherein an NFC (Near Field Communication) chip which is integrated with the inner page of the traditional paper publication is embedded into the inner page of the traditional paper publication. The interactive application system comprises a cloud server, an intelligent mobile terminal having an NFC function, and the new media interactive picture book, wherein a multimedia electronic book is stored in the cloud server; and the intelligent mobile terminal having the NFC function is used for acquiring data information link of the NFC chip in the new media interactive picture book through a near distance connection protocol, performing verification, and downloading and acquiring the multimedia electronic book in the cloud server. The troubles of traditional publications are effectively eliminated, and the target of stabilizing the consumption market is reached. Each publication has a unique identity code, and a customer can detect whether purchased books and magazines are genuine or not through intelligent mobile terminals such as mobile phones while purchasing, so that the possibility of piracy of the traditional publications and electronic readings is better avoided.

Owner:宁波一坤数码科技有限公司

Self-adhering rubber water-proof coiled material and method for preparing same

InactiveCN101545285BUnique "self-locking water" functionSolve the problem of water leakageProtective foundationMarine site engineeringGlass fiberEngineering

A self-adhering rubber water-proof coiled material and a method for preparing the same composed of a rubber water-proof coiled material basal layer, a glue spreading reinforcement layer and a self-adhering rubber waterproof layer on the glue spreading reinforcement layer. The glue spreading reinforcement layer is glue spreaded nonwoven cloth or glue spreaded glass-fiber cloth. The self-adhering rubber waterproof layer is produced by mixing the following materials in proportion by weight: 60-70 portions of ethylene propylene terpolymer (PET); 10-26 portions of butyl rubber; 4-25 portions of chloroprene rubber; 50-70 portions of black carbon; 50-70 portions of fine particle calcium carbonate; 2-7 portions of coumarone; 10-20 portions of naphthenic oil; 5-10 portions of zinc oxide and 0.7-1.2 portions of stearic acid. The construction art is simple and fast. Because the self-adhering base material contains hydrophilic material, the basal layer can be in wet lay up if the basal layer has no water. The method has no glue brushing and glue shining process so as to save time limit for a project and the cost, effectively avoid hollow casing and burst phenomenon and form a whole a completewaterproof sealing system.

Owner:北京立高科技股份有限公司

Grafting cultivation method for camellia oleifera

InactiveCN108739028AGood moisturizing effectAvoid infectionGraftingGrowth substratesSaccharumSucrose

The invention discloses a grafting cultivation method for camellia oleifera. The grafting cultivation method includes: preparing a seedling bed, processing scions, processing stocks, grafting, and performing management after grafting. The method has the advantages that aloe extract in a healing agent used in the method has antibacterial active components and can prevent infection and rot of grafting wounds, the colloidal aloe extract has a good moisturizing effect and can keep the grafting wounds moist to prevent withering, and accordingly survival rate is increased; the joint effect of naphthylacetic acid, indolebutyric acid, brassinolide and sucrose accelerate callus differentiation and formation, the connection and extension of the stocks and scion calluses are promoted, and wound healing is accelerated; nutrient soil comprises sandy loam, turfy soil and compound fertilizer, the soil is loose and fertile and good in water retaining performance and breathability, and grafting seedling growth is promoted while diseases and pests are reduced; a nutrient solution is reasonably applied during the management after grafting, and the nutritional requirements of the grafting seedlings are satisfied; the method is scientific, simple, high in survival rate, easy to operate, and capable of increasing the yield and quality of camellia oleifera fruits.

Owner:邓建军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com