High-performance aluminium alloy cable for building

An aluminum alloy, high-performance technology, applied in the direction of insulated cables, power cables, metal/alloy conductors, etc., can solve the problems of unmatched building design service life, manpower and material resource consumption, high replacement costs, etc., to ensure electrical performance, Elimination of bridge costs and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

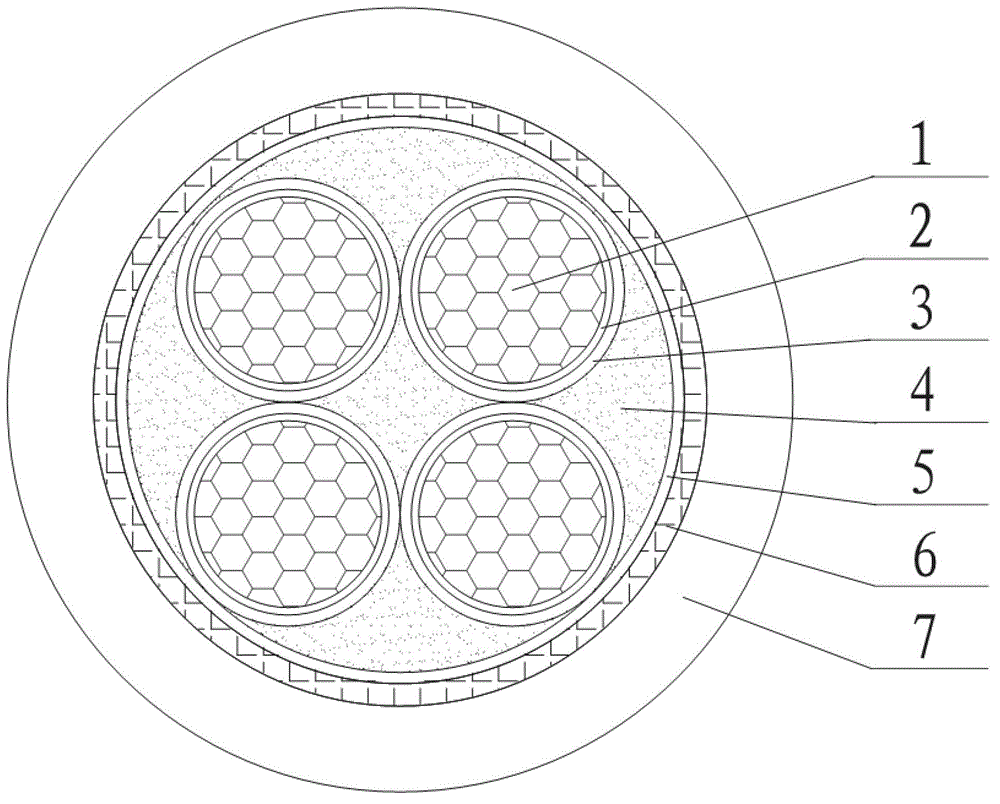

[0022] figure 1 Among them, the cable core includes four core conductors 1 made of aluminum alloy arranged in a low-smoke, halogen-free, flame-retardant filling body 4, which are symmetrically arranged and twisted; Layer insulation 3, wherein the inner layer insulation 2 is an irradiation cross-linked polyethylene insulation layer; the outer layer insulation 3 is a low-smoke, halogen-free, flame-retardant irradiation cross-linked polyolefin insulation layer. The outer wall of the filling body 4 wraps the cable tape layer 5 , the cable armor layer 6 and the cable outer sheath layer 7 sequentially from the inside to the outside.

[0023] The cable tape layer 5 is a flame-retardant glued glass cloth tape, which makes the flame-retardant performance more reliable; the cable armor layer is an aluminum alloy belt interlocking armor layer 6, and the cable out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com