Patents

Literature

133results about How to "Has flame retardant properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PBT/ABS alloy material and preparation method thereof

InactiveCN101215409AGood physical and mechanical propertiesSimple preparation processFire retardantHigh intensity

The invention discloses a PBT / ABS alloy material and a process for preparation, which comprises PBT 10-45%, ABS 10-45%, compatibilizer 1-10%, filling reinforcing agent 10-40%, composite flame retardant 20-30%, lubricating agent 0.1-0.6%, and anti-oxidant 0.1-12%. PBT system and ABS system are welded together through choosing appropriate flame retardant and reinforcing agent, and the invention which is prepared has the character of flame resisting, and which is environment friendly and innocuous, and various physical mechanics properties of the invention are excellent when alloy material is guaranteed to have flame-proof function, and the flame-proof alloy material has the advantages of simple preparation technology, stable sizes, high intensity, aesthetic appearance, high flowability, and drug tolerance and the like.

Owner:SHENZHEN KEJU NEW MATERIAL

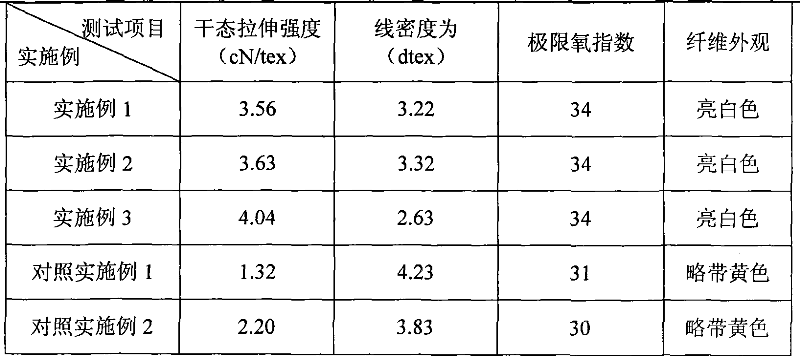

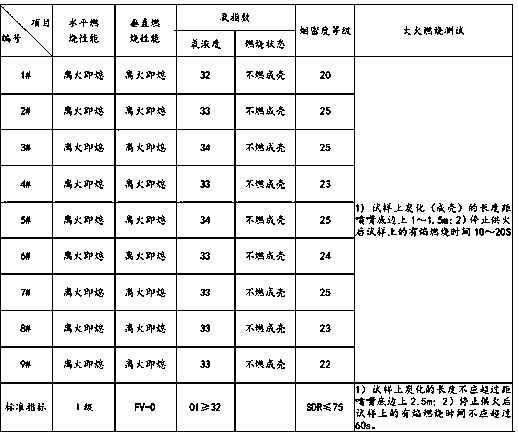

Preparation method of flame-proof sea silk new material

ActiveCN101037814AIntrinsically flame retardantHas flame retardant propertiesAlginate artificial filamentsWet spinning methodsFiberPolymer science

This invention disclosed a method of produce new material of flame retardant alginate fiber: make sure the proportion of G chain segment and M chain segment which in the molecular structure is 1:1 - 1:3, the potassium alginate's weight percent of solute is 4-7% or the mixture of potassium alginate and sodium alginate be fully predissolved and dissolved and after adjustment viscosity, filter and defoamed by sodium hypochlorite or hydrogen peroxide, produce alginate fiber material by solution spinning at room temperature, the draft proportion of fiber is 120-300%. The limited oxygen index of the fiber reaches to 34, the fiber's tensile strength is more than 3.5cN / tex, the linear density is 2.2-3.5 dtex. The fiber produced by this method is flame retardant, high strength of fracture and bio-degradable, and so on, so which can be used to produce flame retardant textiles by pure spinning or blended. This invention disclosed a method of produce a new material of flame retardant alginate fiber: make sure the proportion of G chain segment and M chain segment which in the molecular structure is 1:1 - 1:3, the potassium alginate's weight percent of solute is 4-7% or the mixture of potassium alginate and sodium alginate be fully predissolved and dissolved and after adjustment viscosity, filter and defoamed by sodium hypochlorite or hydrogen peroxide, produce alginate fiber material by solution spinning at room temperature, the draft proportion of fiber is 120-300%. The limited oxygen index of the fiber reached to 34, the fiber's tensile strength is more than 3.5cN / tex, the linear density is 2.2-3.5 dtex. The fiber produced by this method is flame retardant, high strength of fracture and bio-degradable, and so on, so which can be used to produce flame retardant textiles by pure spinning or blending.

Owner:QINGDAO UNIV

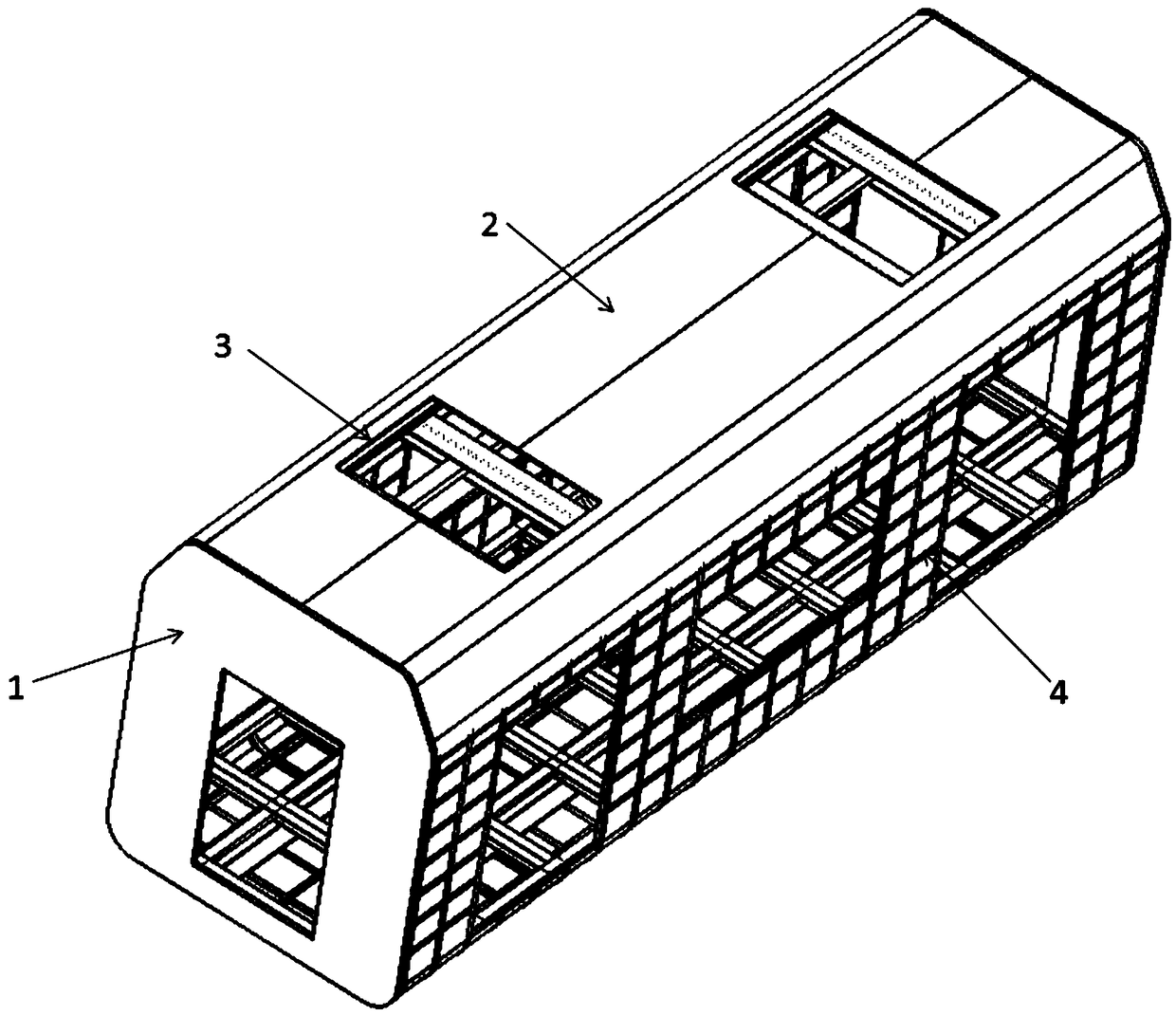

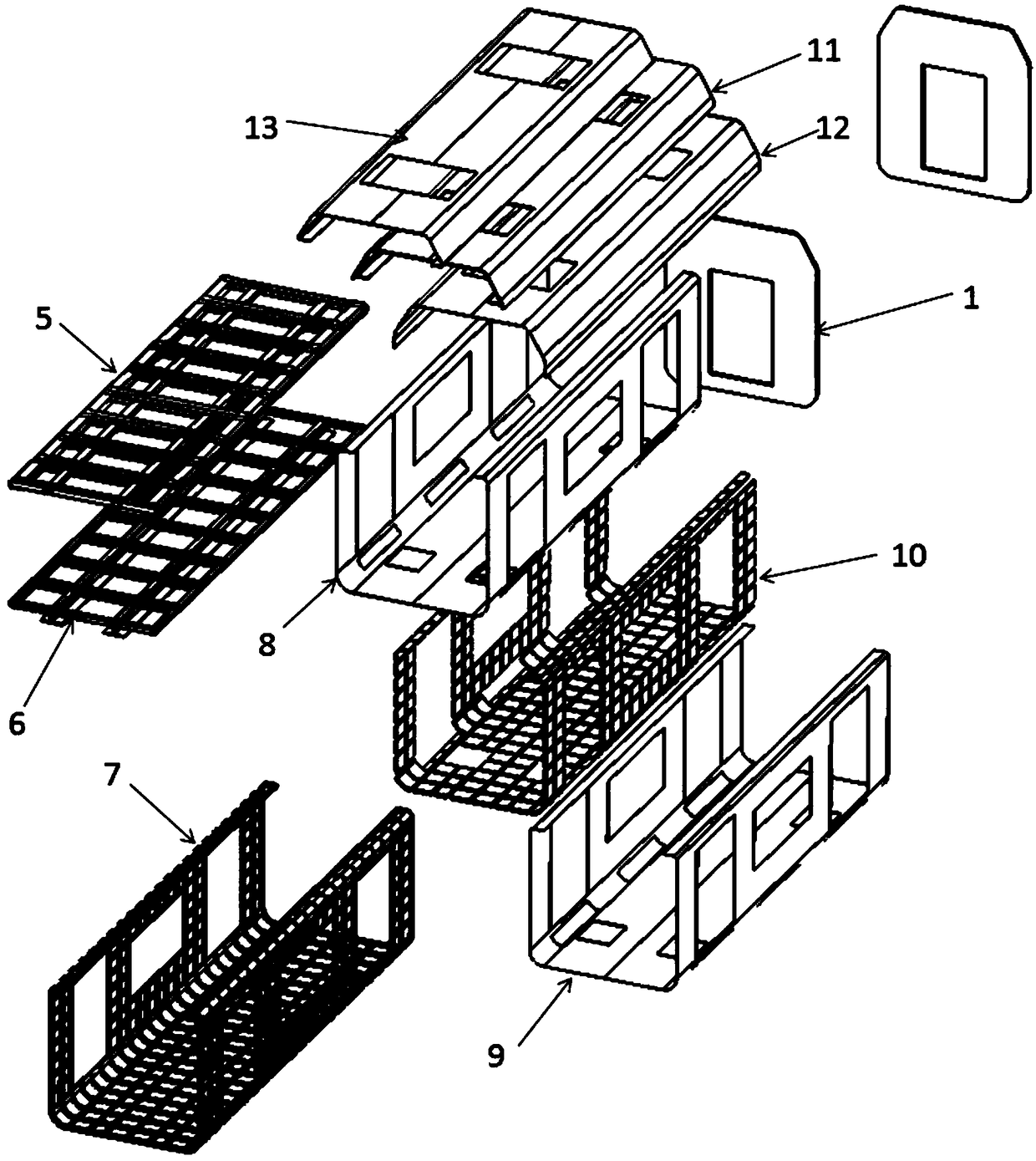

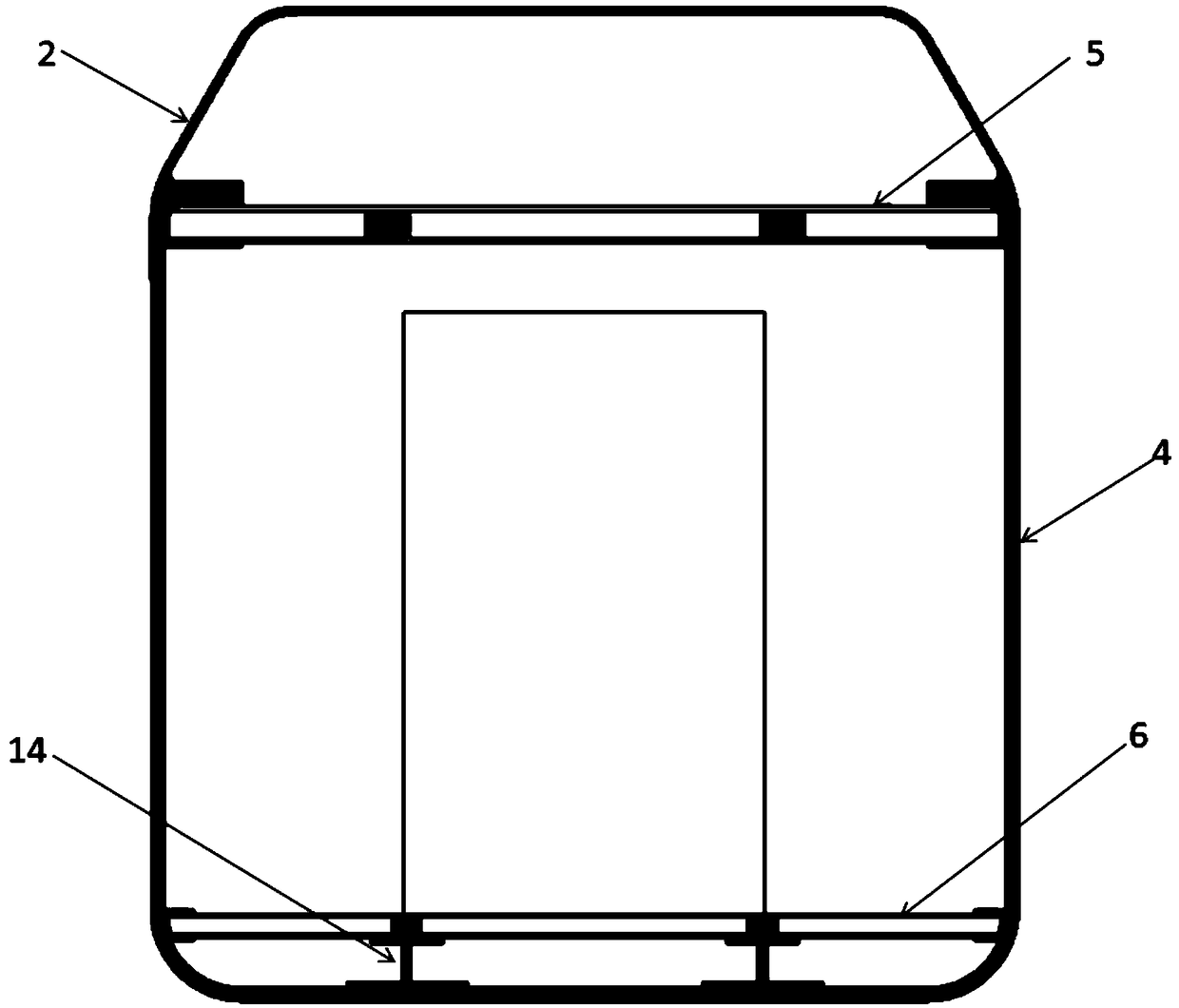

Structure and manufacturing process of low-cost carbon fiber composite material sky railway train body

ActiveCN108622123AAchieve lightweightIncrease stiffnessRailway roofsAxle-box lubricationBogieEngineering

The invention discloses a structure and a manufacturing process of a low-cost carbon fiber composite material sky railway train body, and belongs to the technical field of application of composite materials on rail vehicles. The structure comprises a train body side wall, wherein end walls are assembled and connected to the both ends of the train body side wall; a top frame and a bottom frame arecorrespondingly assembled and connected to the inner top surface and the inner bottom surface of the train body side wall, a ceiling is assembled and connected to the outer top surface of the train body side wall, and a bogie mounting hole is formed in the ceiling; the train body side wall and the end walls both comprise reinforced rib frames, inner skins and outer skins, and grids of the reinforcing rib frames are filled with sandwich foam blocks; the ceiling comprises a sandwich panel, an upper skin and a lower skin, and the top frame, the bottom frame, the reinforcing rib frame, the inner skins, the outer skins, the upper skin and the lower skin are all integrally molded from carbon fiber composite materials; and the inner portions of the reinforcing rib frames are filled with sandwichfoam, and the purpose of satisfying the function and structure of the load bearing mode of a suspension-type train body on the premise of light weight of the train body is achieved.

Owner:SOUTHWEST JIAOTONG UNIV

Antirust paint with rust and preparation method thereof

InactiveCN103059699ALow viscosityStrong penetrationAnti-corrosive paintsEpoxy resin coatingsChemistryEmulsion

The invention relates to an antirust paint and a preparation method thereof. The antirust paint with rust disclosed by the invention comprises the following components in parts by weight: 28-42 parts of silicone acrylic emulsion, 0.1-0.7 parts of sodium hexametaphosphate, 1.4-2.2 parts of alcohol ester 12, 0.9-2.1 parts of triethanolamine, 2.5-4 parts of aluminum dihydrogen triphosphate, 5.6-8.2 parts of titanium dioxide, 5.6-8.2 parts of barium metaborate, 1.8-4.1 parts of silica sol, 1.6-4.3 parts of potassium metasilicate, 0.15-0.35 parts of anti-rust agent, and 20-30 parts of vinyl ester resin. The preparation method comprises the following steps of: firstly, preparing vinyl ester resin, and weighing each component; putting the other components except for the vinyl ester resin into a mixer to mix and stir for 15-40 minutes to obtain mixed material I; grinding the mixed material I until the fineness of the grain size of the mixture is 20-40 microns; adding the vinyl ester resin to stir for 30-50 minutes, and then filtering by 300-350 meshes of filter cloth. The antirust paint with rust provided by the invention has the characteristics of low cost, high thermal resistance, corrosion resistance, flame retardant properties and the like, and can be widely applied to production and construction equipment.

Owner:河北华强科技开发有限公司

Inorganic composite insulation board and preparation method thereof

InactiveCN103265262AImprove heat resistanceLow temperature shrinkageFiberBuilding insulation materials

The invention provides an inorganic composite insulation board and a preparation method thereof, belonging to the technical field of novel building insulation materials. The inorganic composite insulation board is characterized by comprising the following components by weight parts: 40-48 parts of expanded perlite, 5-15 parts of phenolic foam particles, 32-36 parts of an inorganic binder, 2-6 parts of an organic reinforcing agent, 2-3 parts of a waterproof agent, 2-3 parts of inorganic enhance fibers, 1-2 parts of a hardening agent, and 1-2 parts of a fire retardant. The above raw materials are fully stirred, compressed, molded, and dried under a constant temperature to prepare the inorganic composite insulation board, and the board has advantages of good thermal insulation performance, light weight, small thermal conductivity coefficient, good stability, high intensity, convenient construction, etc., and can be widely applied in roofs and walls of various industrial and civil buildings, waterproofing and insulation of cold storages, barns and basements, as well as various cold insulation engineering.

Owner:安徽百穗供应链有限公司

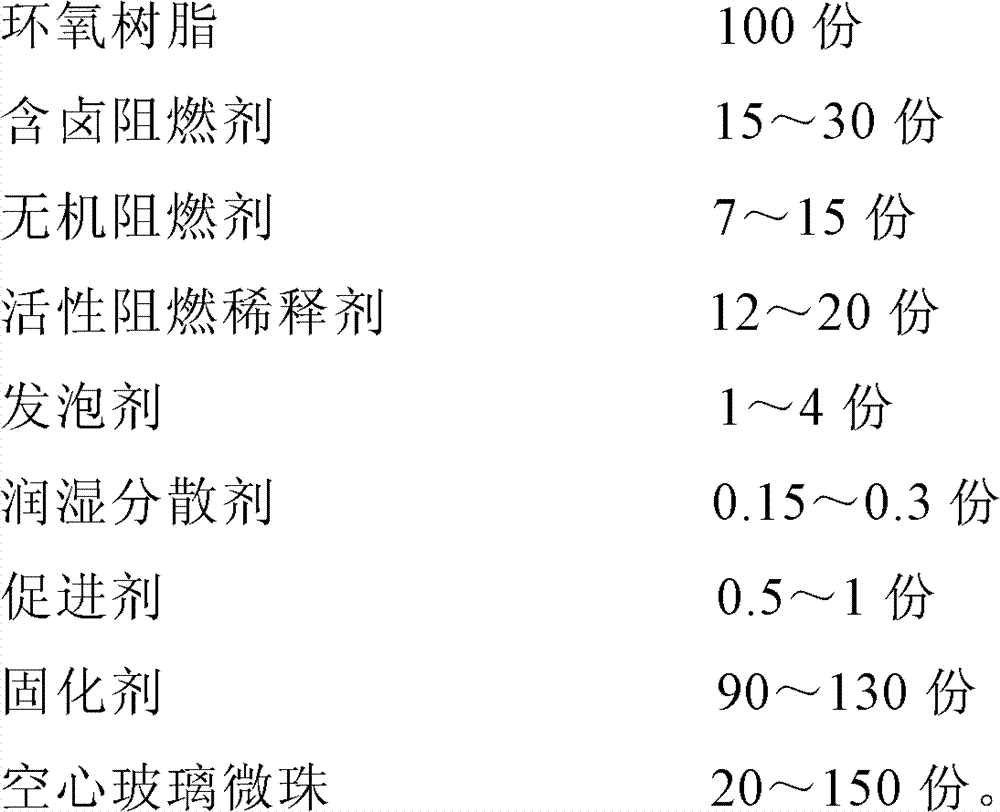

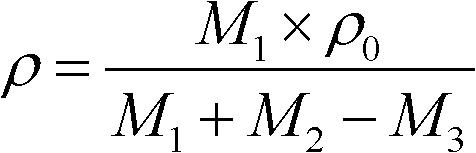

Flame retardant solid buoyancy material and preparation method thereof

ActiveCN102775727AOvercoming Flame Retardancy RequirementsNo loss of net buoyancyHalogenFire retardant

The invention relates to the technical field of a solid buoyancy material used in a marine environment and specifically to a flame retardant solid buoyancy material and a preparation method thereof. The flame retardant solid buoyancy material comprises, by mass, 100 parts of an epoxy resin, 15 to 30 parts of a halogen-containing fire retardant, 7 to 15 parts of an inorganic fire retardant, 12 to 20 parts of an active flame retardant diluent, 1 to 4 parts of a foaming agent, 0.15 to 0.3 part of a wetting dispersant, 0.5 to 1 part of an accelerator, 90 to 130 parts of a curing agent and 20 to 150 parts of hollow glass beads. The flame retardant solid buoyancy material provided in the invention has the characteristic of flame retardation, can be used in deep sea, is free of loss of net buoyancy and is processable.

Owner:MARINE CHEM RES INST

Pure polylactic acid tows as well as preparation method and cigarette filter trip thereof

InactiveCN103088458AAvoid potential hazardsCompensation for pressure dropTobacco smoke filtersArtificial filament washing/dryingPolymer scienceCrotonaldehyde

The invention relates to pure polylactic acid tows and a cigarette filter trip of the pure polylactic acid tows. The pure polylactic acid tows are made of a spinning raw material formed by blending L-polylactic acid and D-polylactic acid (dextrorotation polylactic acid), wherein the L-polylactic acid accounts for 90-98% of the total weight, and the D-polylactic acid accounts for 2-8% of the total weight. The pure polylactic acid tows are spun by a conventional two-step process cigarette polypropylene staple melt spinning technology. The pure polylactic acid tows can be used for producing the cigarette filter trips with different hardness and have the advantages of being capable of effectively inhibiting molds and harmful bacteria in tobacco shreds and on the surfaces of cigarette holders, having compete biodegradability within three months and obvious mechanical affinity on carbonyl compounds in smoke gas and being capable of effectively intercepting harmful matters such as formaldehyde, acrolein and crotonaldehyde in smoke gas; and the interception efficiency of the pure polylactic acid tows is improved by more than 20% in comparison with the interception efficiency of a cellulose acetate filter trip.

Owner:彭荣淮

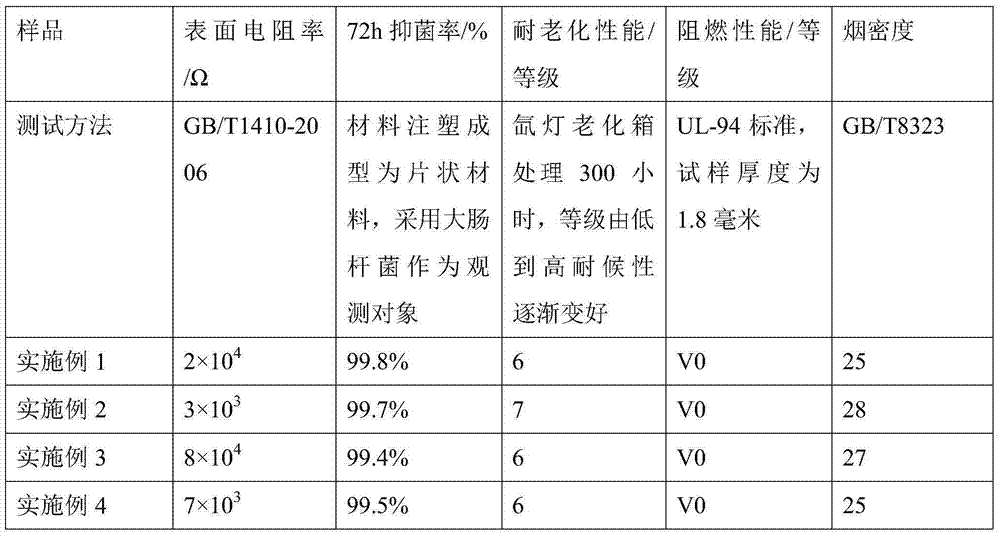

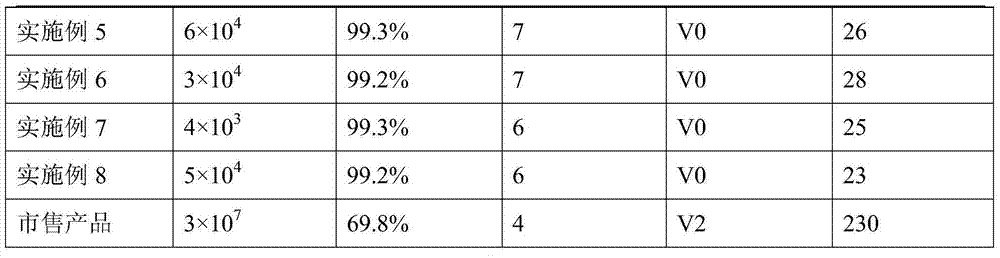

Antistatic antibacterial PC (polycarbonate)/ABS (acrylonitrile-butadiene-styrene copolymer) composite material

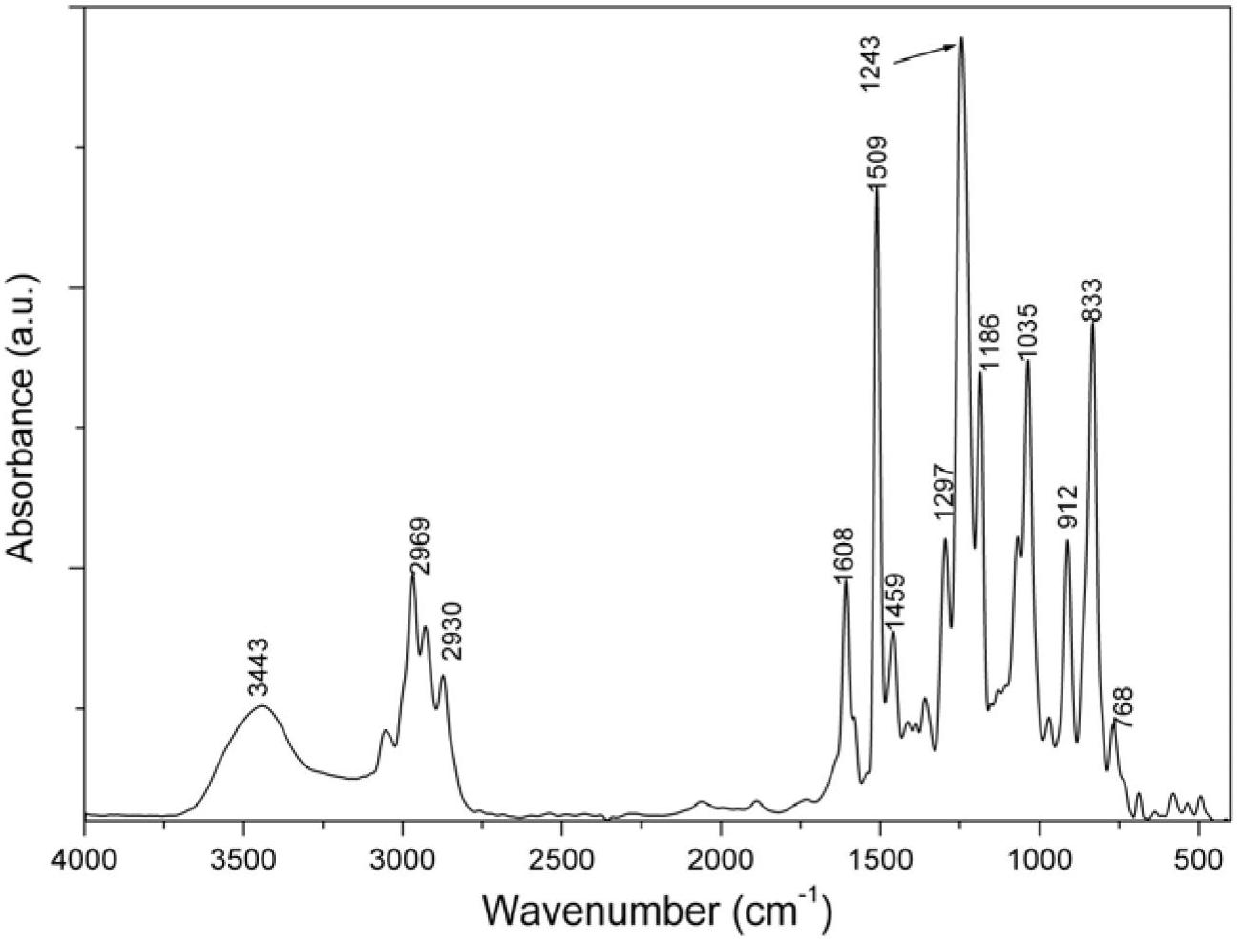

The invention discloses an antistatic antibacterial PC (polycarbonate) / ABS (acrylonitrile-butadiene-styrene copolymer) composite material comprising the following components by weight: 63-93 parts of polycarbonate, 57-65 parts of ABS, 33-47 parts of a flame retardant agent, 29-44 parts of a nano antibacterial agent, 41-47 parts of an antiaging agent, 24-32 parts of an antistatic agent, 24-32 parts of a compatibility agent, 22-26 parts of a lubricant, 19-23 parts of a toughening agent, 15-20 parts of a synergistic agent, 10-16 parts of an insulation agent, 10-16 parts of a yellowing resistant agent and 17-24 parts of a wear-resisting agent. The antistatic antibacterial PC / ABS composite material has excellent antistatic performance, avoids the deleterious effects of electrostatic, and also has antibacterial properties, more than 99% bacteriostasis rate can be maintained for a long term, the composite material has good anti-aging properties, is flame retardant, simultaneously reduces the combustion smoke density, has excellent characteristics of wear resistance, yellowing resistance, high voltage resistance and electric arc resistance, and is suitable for different use requirements.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

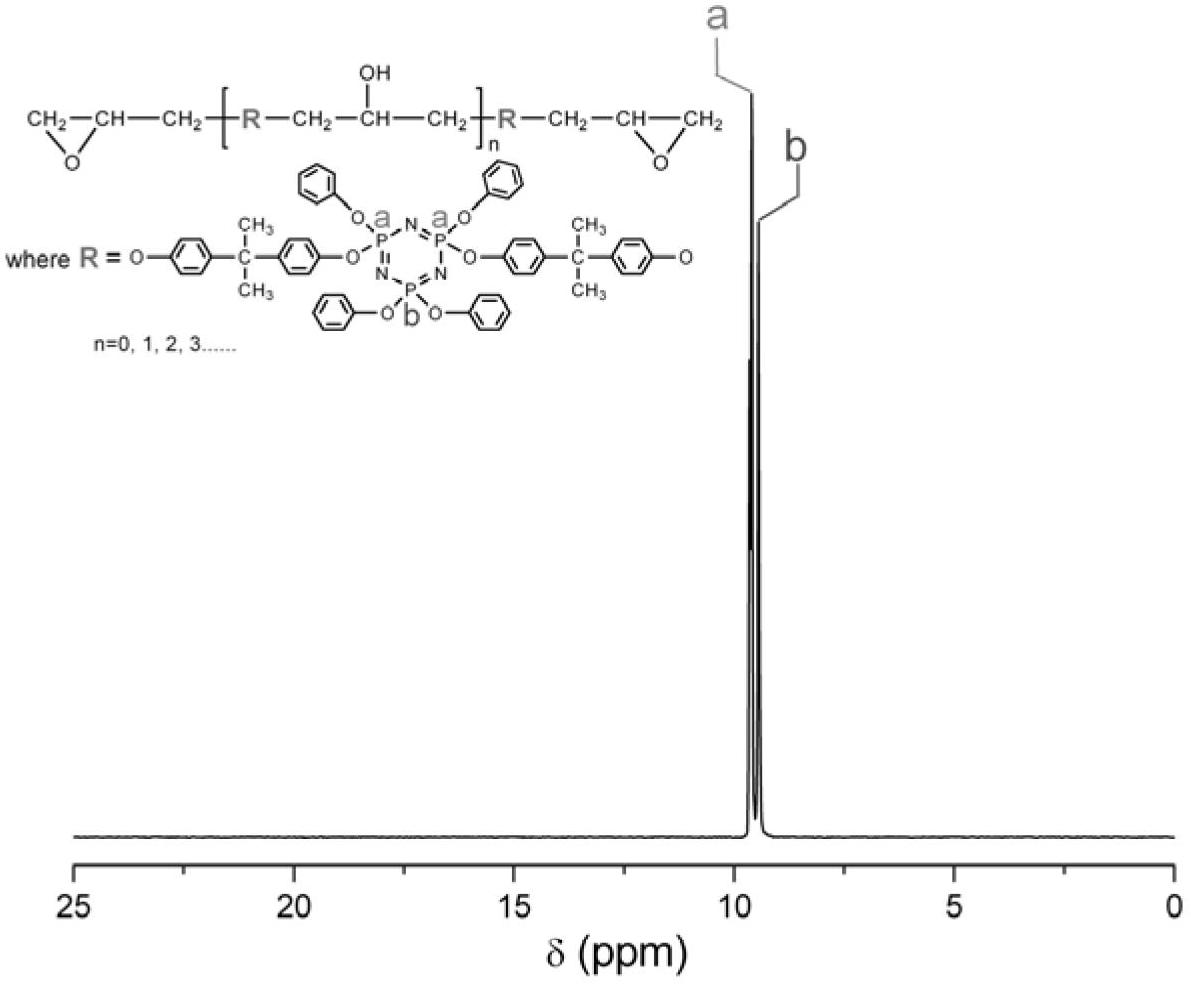

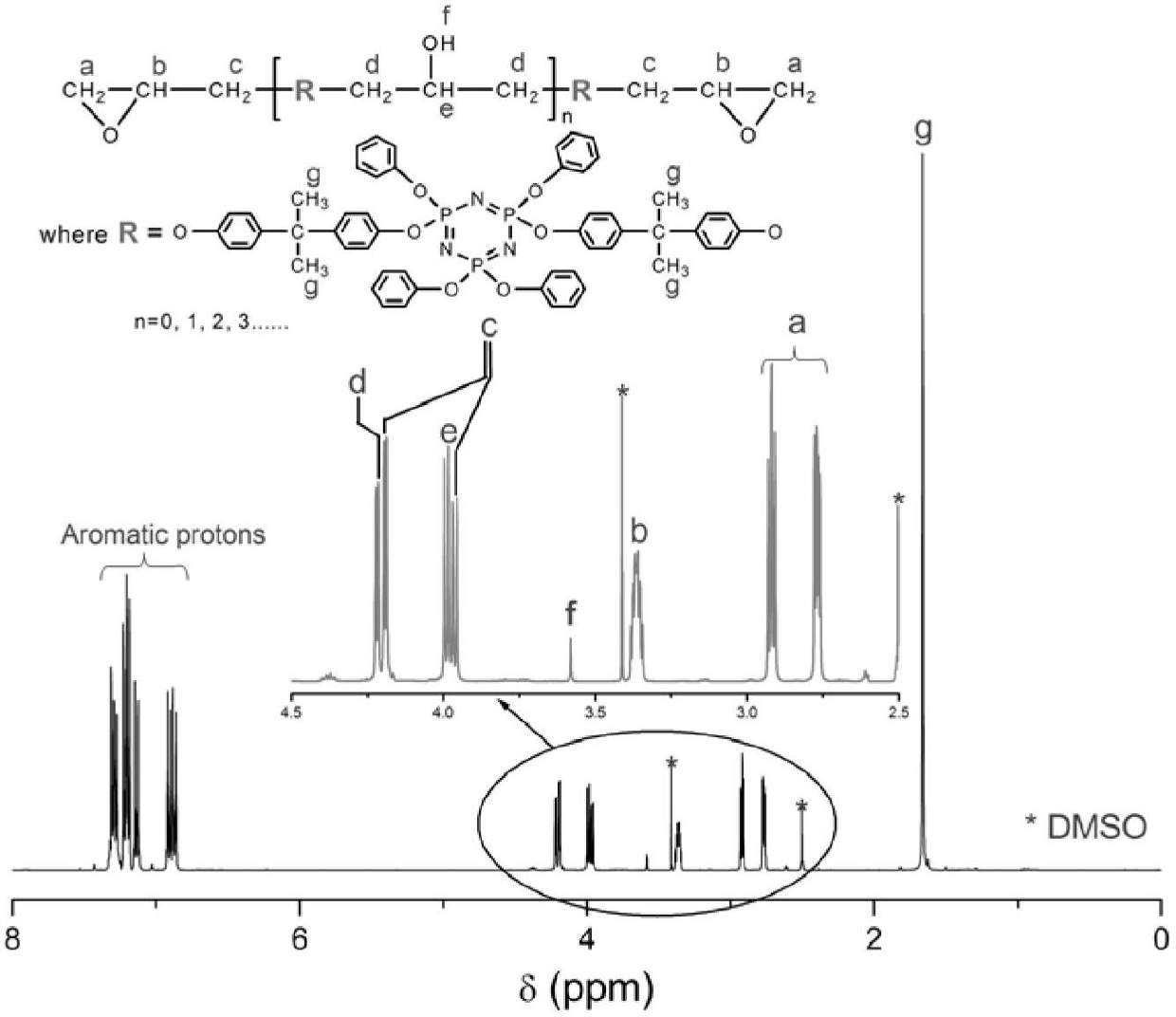

Loop-line-shaped phosphazene epoxide resin and synthetic method thereof

InactiveCN102675591AHigh nitrogen and phosphine contentImprove flame retardant performanceGroup 5/15 element organic compoundsEpoxyFire resistance

The invention discloses loop-line-shaped phosphazene epoxide resin and a synthetic method thereof and belongs to the technical field of flame-retarded resin. The resin structure is that under the inert gas protection, phenol is reacted with phosphonitrilic chloride trimer in the presence of an acid-binding agent, and 1, 1, 3, 5- tetraphenoxy-3, 5-dichlorocyclotriphosphazene (N3P3 (OC6H5)4C12) is obtained; HOROH is reacted with the N3P3 (OC6H5)4C12, two remaining helium atoms are substituted, and a compound N3P3 (OC6H5) 4 (OROH) 2 is obtained; and under the action of 28.43wt.% of sodium hydroxide aqueous solution and catalysts, the N3P3 (OC6H5) 4 (OROH) 2 is reacted with epoxy chloropropane, the epoxide resin is obtained, and the main chain of the epoxide resin contains a loop-line-shaped phosphazene structure. After the loop-line-shaped phosphazene epoxide resin and a curing agent are cured, the obtained thermosetting resin is good in heat resistance, thermal stability and fire resistance.

Owner:BEIJING UNIV OF CHEM TECH

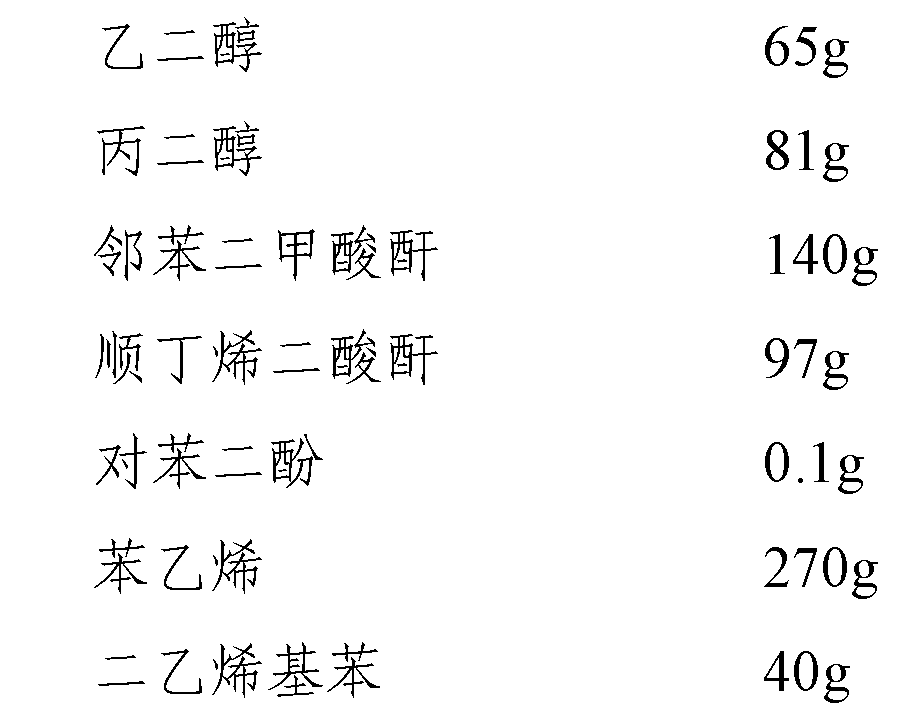

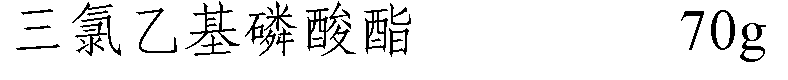

Bi-component flame-retardant low-viscosity unsaturated polyester resin and preparation method thereof

The invention relates to bi-component flame-retardant low-viscosity unsaturated polyester resin and a preparation method thereof. The unsaturated polyester resin is prepared by undergoing a polycondensation reaction on dihydric alcohol and binary acid / acid anhydride. A cross-linking agent and a flame retardant are added in the reaction, so that the aims of lowering resin viscosity and enhancing material intensity and flame retardance are fulfilled, and the unsaturated polyester resin can be taken as a grouting reinforcement material for broken surrounding rocks and loose coal-rock masses in underground constructions such as mines and the like.

Owner:TIANDI SCI & TECH CO LTD

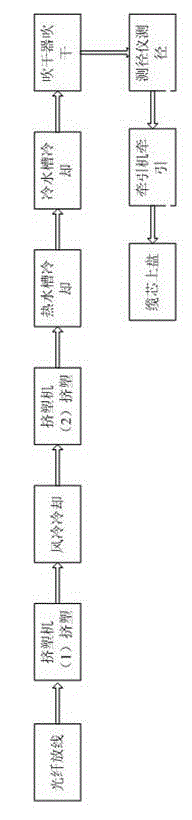

Inflame-resistance and water-resistance filling paste for optical cable and preparation method thereof

ActiveCN102005264AHas flame retardant propertiesHigh temperature resistantInsulated cablesFibre mechanical structuresElectrical conductorAntioxidant

The invention relates to inflame-resistance and water-resistance filling paste for an optical cable, which mainly contains base oil, an oil distributing inhibitor, an antioxidant, an organic thickening agent, an inorganic thickening agent, an organic flame retardant, an inorganic flame retardant, a super absorbent and a water retardant. The invention also provides a preparation method of the inflame-resistance and water-resistance filling paste. The inflame-resistance and water-resistance filling paste for the optical cable can be used for filling the air gaps among optical cable loose tubes or filling the air gaps in the cable cores of multi-conductor electric wires and optical cables or filling the gaps among the combination of the structures and any other optical cable components so as to prevent water or other fluids flowing or transferring into the optical cables; and in addition, the inflame-resistance and water-resistance filling paste provides good actions of water resistance, high temperature resistance, inflame resistance, buffering property and the like for the optical cables so as to enhance the quality of the optical cable products.

Owner:SHANGHAI HONGHUI OPTICS COMM TECH

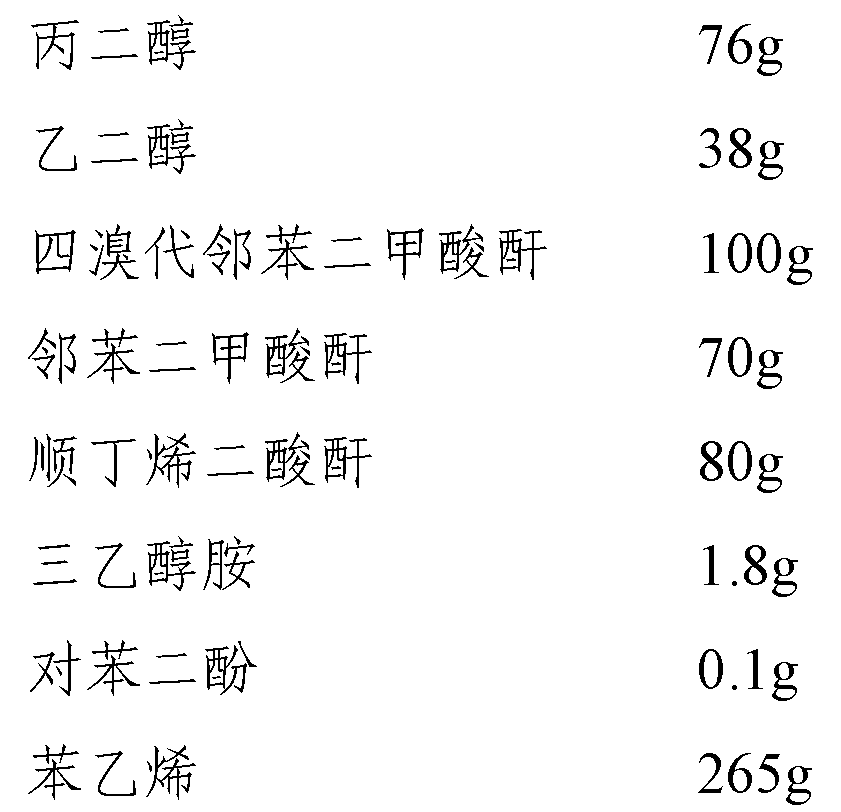

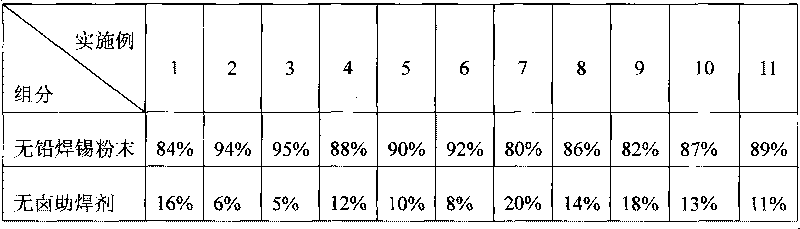

Lead-free and halogen-free environmental soldering paste for electronic industry

ActiveCN101733573AAdapt to the needs of different welding temperaturesLess corrosiveWelding/cutting media/materialsSoldering mediaSolventSolder paste

The invention discloses a lead-free and halogen-free environmental soldering paste for the electronic industry. The soldering paste comprises 80wt%-95wt% of lead-free soldering tin powder and 5wt%-20wt% of halogen-free soldering flux, wherein the halogen-free soldering flux comprises 5wt%-15wt% of activator, 32wt%-50wt% of resin, 3wt%-10wt % of resin additive, 2wt%-10wt% of thixotropic agent, 1wt%-15wt% of stabilizer, 0.5wt%-8wt% of antioxidant and the balance solvent; the activator adopts the salt prepared from organic acid and amine to replace traditional halogen salt and adopts phenolic modified rosin ester and triisocyanate to replace part of traditional resin which is largely used, the lead-free and halogen-free environmental soldering paste for the electronic industry does not contain lead and halogen, is safe and environmentally friendly and has good welding performance, electrical performance, printing performance and storability.

Owner:惠州市成利工业有限公司

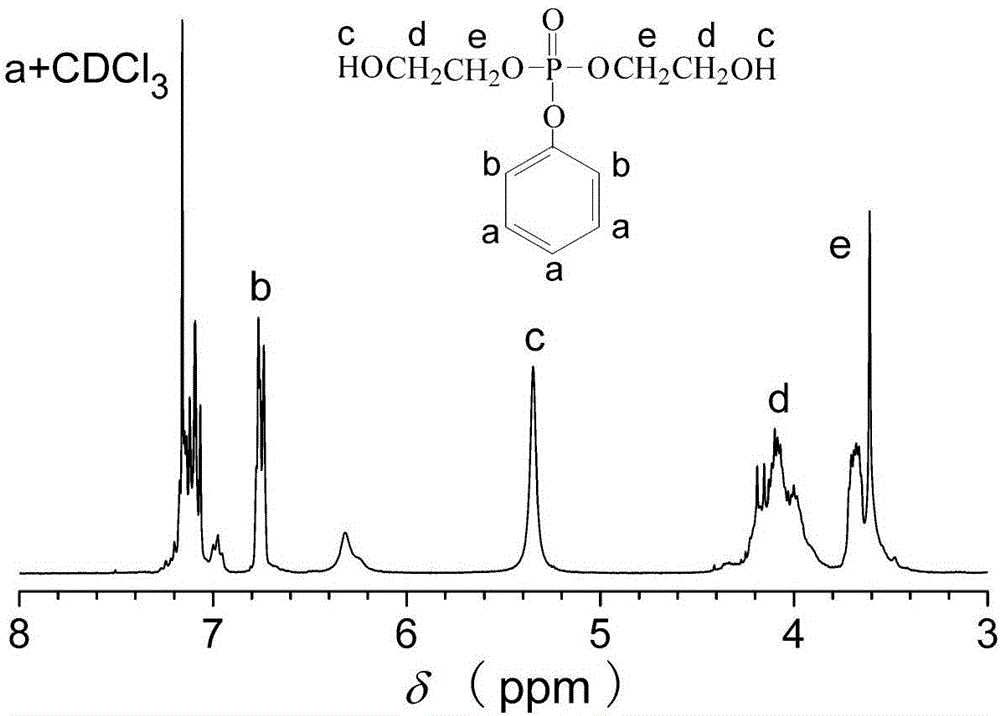

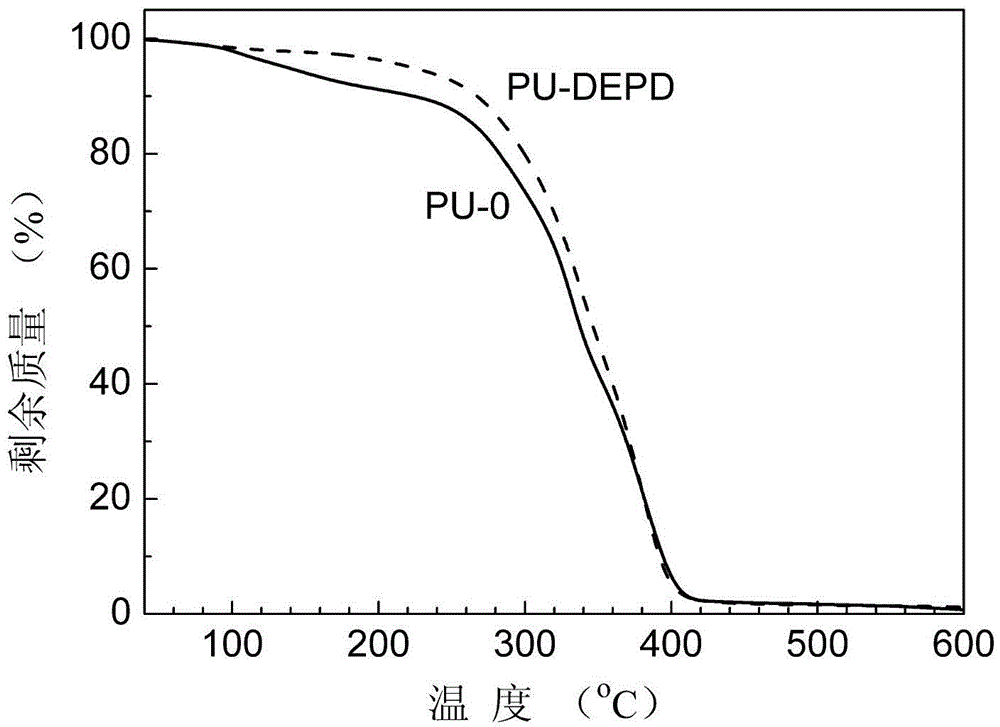

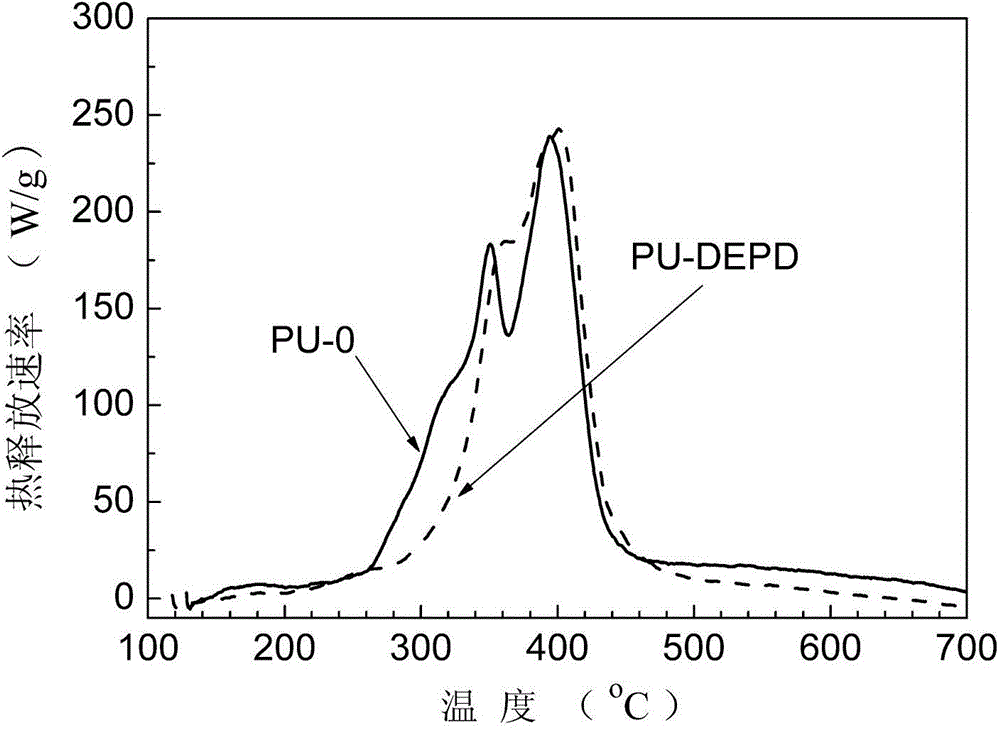

Flame-retardant glycol containing phenyl phosphate-based symmetrical structure and preparation method thereof

InactiveCN104592297AHas flame retardant propertiesRegular structureGroup 5/15 element organic compoundsEthyl acetateTetrahydrofuran

The invention discloses reaction-type flame-retardant glycol containing a phenyl phosphate-based symmetrical structure and a preparation method thereof. The preparation method is characterized by comprising the following steps: reacting phenyl dichlorophosphate with dihydric alcohol in a tetrahydrofuran or ethyl acetate solution in the presence of triethylamine, placing the tetrahydrofuran or ethyl acetate solution of dihydric alcohol and triethylamine into an ice-water bath, stirring and dropwise adding the tetrahydrofuran or ethyl acetate solution of phenyl dichlorophosphate; and filtering a precipitate and then removing the solvent in the filtrate to obtain the product with a structural general formula specified in the description, wherein n is an integer ranging from 2 to 6. According to the preparation method disclosed by the invention, micromolecular dihydric alcohol is introduced in the phenyl dichlorophosphate group in a manner of chemical bonding, so that the obtained dihydric alcohol molecular structure contains both the phenyl dichlorophosphate group and two hydroxyl groups with symmetrical structures and same reaction activity, and can partially or completely replace the micromolecular dihydric alcohol without a flame-retardant characteristic, so that the prepared polymer material has a flame-retardant characteristic; the raw materials in the preparation method disclosed by the invention are easily available, synthesis and post-treatment processes are simple, the cost is low, and the yield can achieve more than 90%.

Owner:UNIV OF SCI & TECH OF CHINA

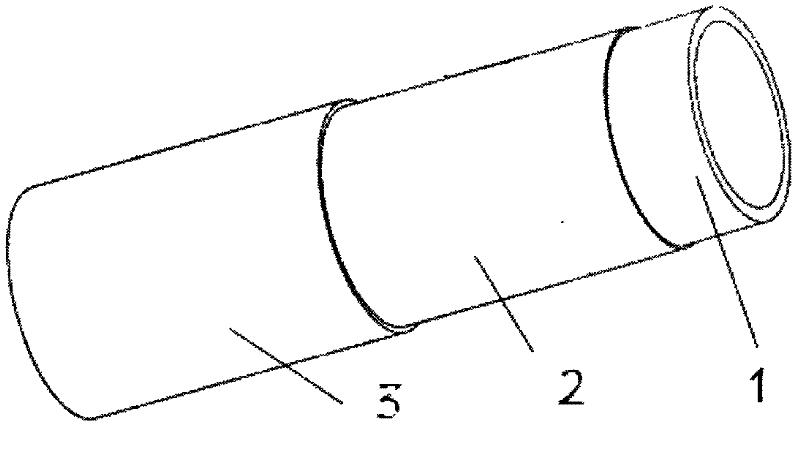

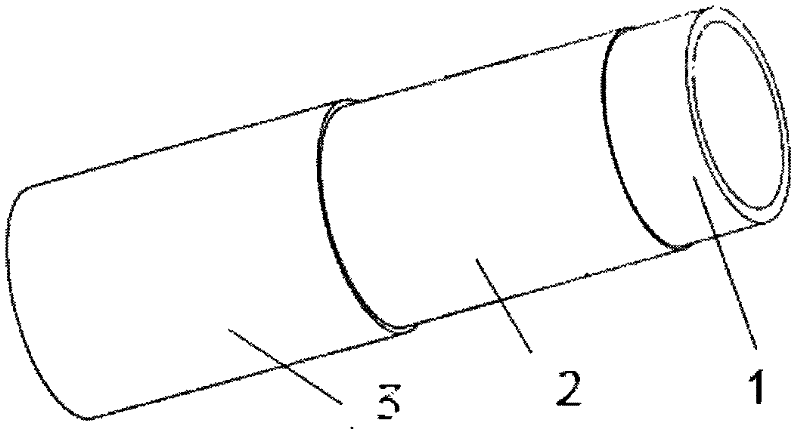

High-strength flame-retardant anti-static pipeline

InactiveCN102506240AHigh crystallinityHigh degree of interface adhesionSynthetic resin layered productsRigid pipesPolymer scienceAcrylonitrile

The invention provides a high-strength flame-retardant anti-static pipeline comprising an inner layer, a combined layer and an outer layer, wherein the inner layer contains the following proportional components: 600 to 800 parts of high-density polyethylene by weight, 5 to 15 parts of glass fibre by weight, 1 to 2 parts of wollastonite by weight, 1 to 6 parts of ethylene-propylene diene copolymer by weight, 4 to 9 parts of butadiene-acrylonitrile rubber by weight, 3 to 6 parts of styrene-butadiene-styrene terpolymer copolymer by weight, 9 to 13 parts of nano carbon tube by weight, 10 to 30 parts of polypropylene grafted maleic anhydride by weight, 15 to 25 parts of flame retardant by weight and 13 to 19 parts of graphitized carbon black by weight; the outer layer contains the following proportional components: 300 to 500 parts of medium-density polyethylene by weight, 12 to 21 parts of flame retardant by weight and 9 to 13 parts of graphitized carbon black by weight; and the main component of the combined layer is hot melting glue. The pipeline provided by the invention has favorable performances of heat insulation and flame retardant; meanwhile, the pipeline also has higher toughness; and furthermore, the erosion resistance, the high-pressure resistance and the rigidity performance are high.

Owner:ZHEJIANG NORMAL UNIVERSITY

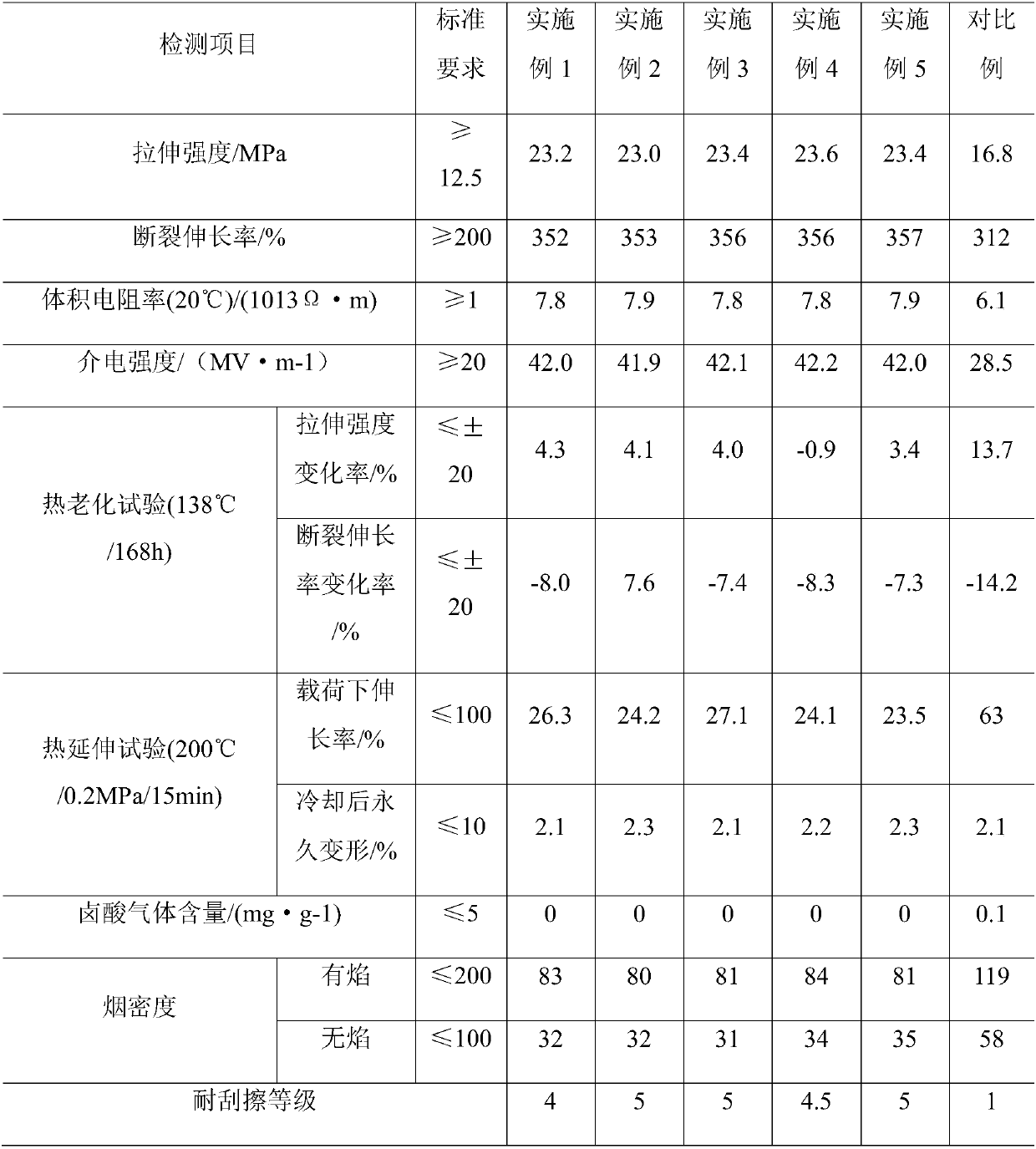

Environment-friendly cable insulation layer, and preparation method thereof

InactiveCN107722439AHas flame retardant propertiesImprove scratch resistancePlastic/resin/waxes insulatorsInsulated cablesLinear low-density polyethylenePolyolefin

The invention discloses an environment-friendly cable insulation layer, and belongs to the field of wire cable. The environment-friendly cable insulation layer comprises an internal insulation layer and an external insulation layer; a double layer co-extrusion insulation layer is composed of the internal insulation layer and the external insulation layer; the internal insulation layer is preparedfrom an irradiation crosslinked polyethylene insulation material; the external insulation layer is prepared from a low-smoke halogen-free flame-resistant irradiation crosslinked polyolefin insulationlayer; the external insulation layer comprises, by weight, 43 to 65 parts of an ethylene-vinyl acetate copolymer, 40 to 60 parts of linear low density polyethylene, 35 to 47 parts of ethylene propylene diene monomer, 54 to 75 parts of a scratch-resistant agent, 25 to 30 parts of a sensitizing agent, 48 to 60 parts of a silicon nitrogen flame retardant, 25 to 35 parts of a composite anti-aging agent, 12 to 20 parts of a reinforcing filler, and 25 to 35 parts of a composite compatilizer. The environment-friendly cable insulation layer, is friendly to the environment, and is capable of improvingthe scratch resistance of cables greatly.

Owner:南京创贝高速传动机械有限公司

Stepped flame retardant plastic and preparation method thereof

The invention discloses a stepped flame retardant plastic and a preparation method thereof. The stepped flame retardant plastic comprises the following components by weight: 800-1200 parts of plastic,30-120 parts of inorganic flame retardant powder, 3-8 parts of zinc borate, 2-5 parts of silica powder, 1-2 parts of antismoke agent, 1-2 parts of calcium carbonate, 0.3-1.2 parts of polymeric dispersant, and 0.3-2 parts of auxiliary; the preparation method comprises the following steps: preparing the inorganic flame retardant powder, modifying a flame retardant material, preparing a composite flame retardant material, and preparing the flame retardant plastic. Through the provided stepped flame retardant plastic and the preparation method of the stepped flame retardant plastic, the obtainedplastic forms different flame retardant shells at different temperatures, so that the plastic has a multi-level flame retarding effect, and the stepped flame retarding protection is formed over a plastic base material.

Owner:FOSHAN YUEJIAXIN WIRE & CABLE

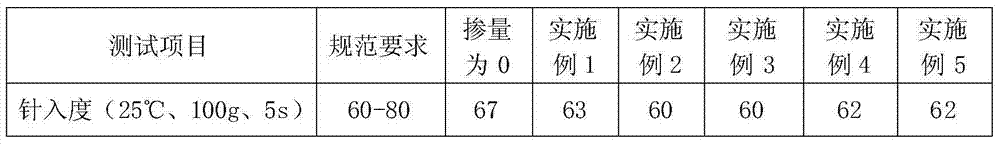

Asphalt fire retardant for tunnel pavement

ActiveCN104710803AGood storage stabilityHas a reinforcing effectBuilding insulationsFiberRoad surface

The invention belongs to the technical field of road material additives and relates to an asphalt fire retardant for a tunnel pavement. The retardant comprises the following ingredients in parts by mass: 5-30 parts of expanded perlite, 5-30 parts of expanded vermiculite, 10-50 parts of expandable graphite, 10-50 parts of nitrogenated fire retardant and 2-10 parts of mineral fiber. Compared with the prior art, the retardant has the following advantages that the retardant is free from halogen and does not generate much smoke or corrosive gas in a combustion process; a low density expansion substance serves as the fire retardant, so that the storage stability of asphalt is improved; the adopted expanded vermiculite, the expanded perlite and the expandable graphite can expand at high temperature; an expansion ratio of the nitrogenated fire retardant can be increased compared with the individual nitrogenated fire retardant, so that the fire retardance is improved; the mineral fire retardant fiber is employed, has a reinforcement effect on an asphalt mixture and can improve the pavement performance in addition to fire retardance; and a preparation method is simple and low in cost and does not require special equipment.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

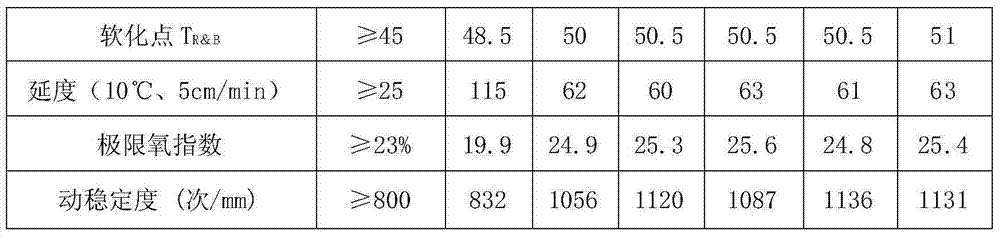

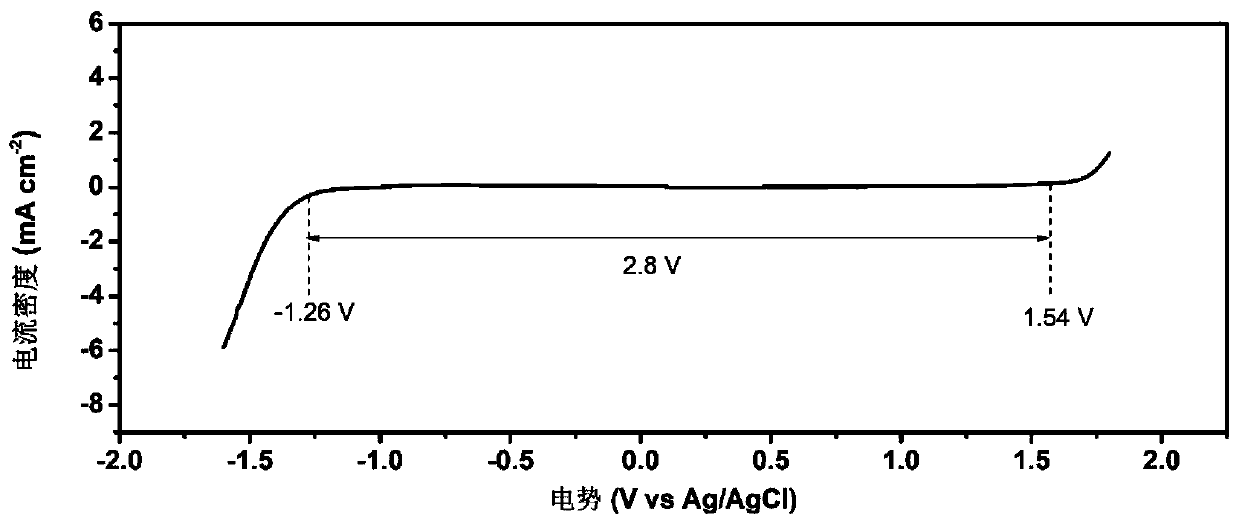

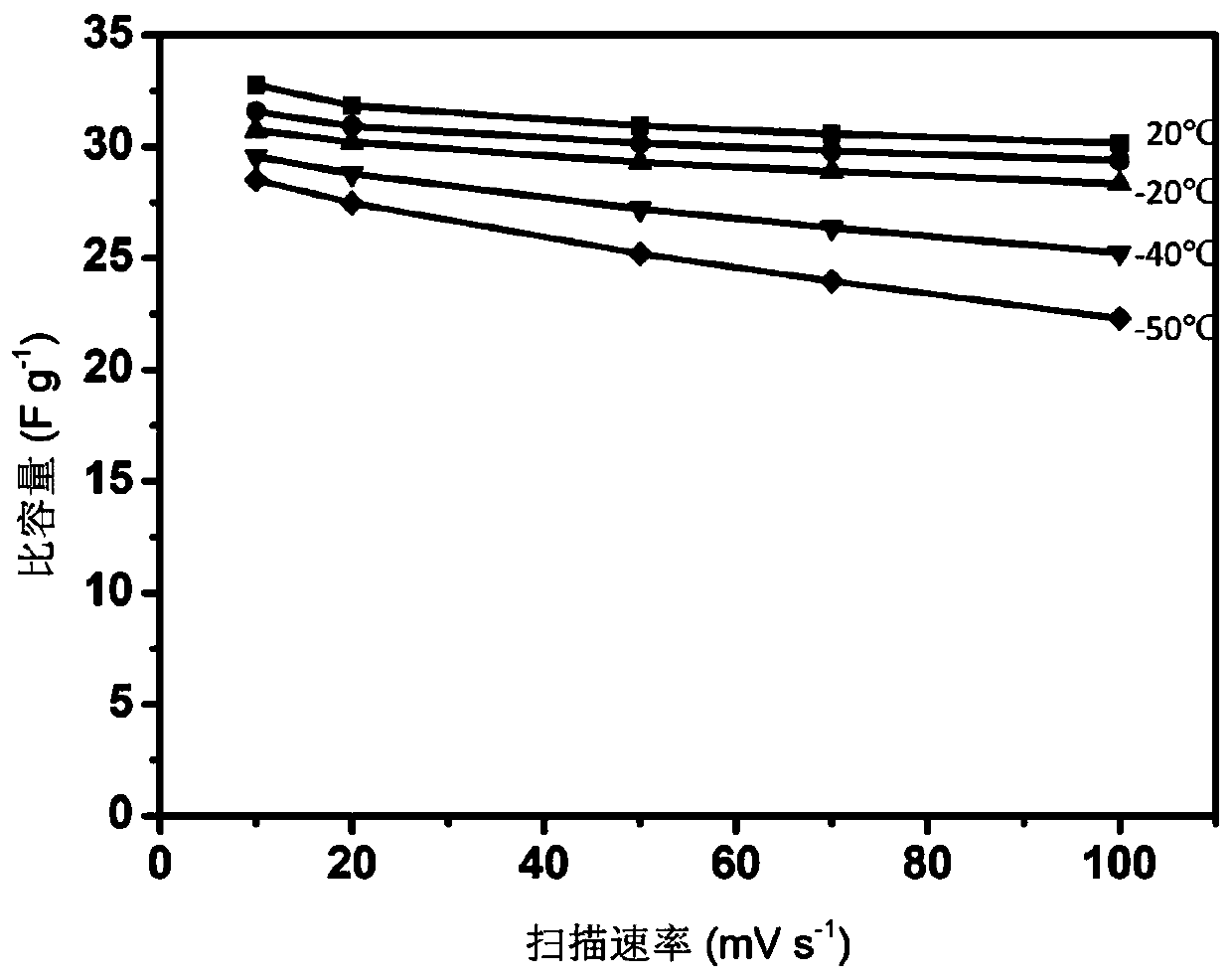

Water system high-voltage window anti-freezing electrolyte and application thereof

ActiveCN111244540AHas flame retardant propertiesLow costHybrid capacitor electrolytesSecondary cellsElectrolytic agentInorganic salts

The invention provides a water system high-voltage window anti-freezing electrolyte and application thereof. The electrolyte provided by the invention comprises an inorganic salt electrolyte, water and an organic solvent, wherein the freezing point of the organic solvent is-12 DEG C to-97 DEG C, the organic solvent and water are co-dissolved, and the inorganic salt electrolyte is soluble in the organic solvent; and the molar ratio of the inorganic salt electrolyte to the water to the organic solvent is (1.1-3.1): (4.5-6): (2-7). According to the electrolyte provided by the invention, salting-out of the electrolyte in a low-temperature environment can be avoided, a voltage window of an aqueous electrolyte can be widened, and higher ionic conductivity can be provided, so that an electrochemical energy storage device also has excellent electrochemical performance in the low-temperature environment.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

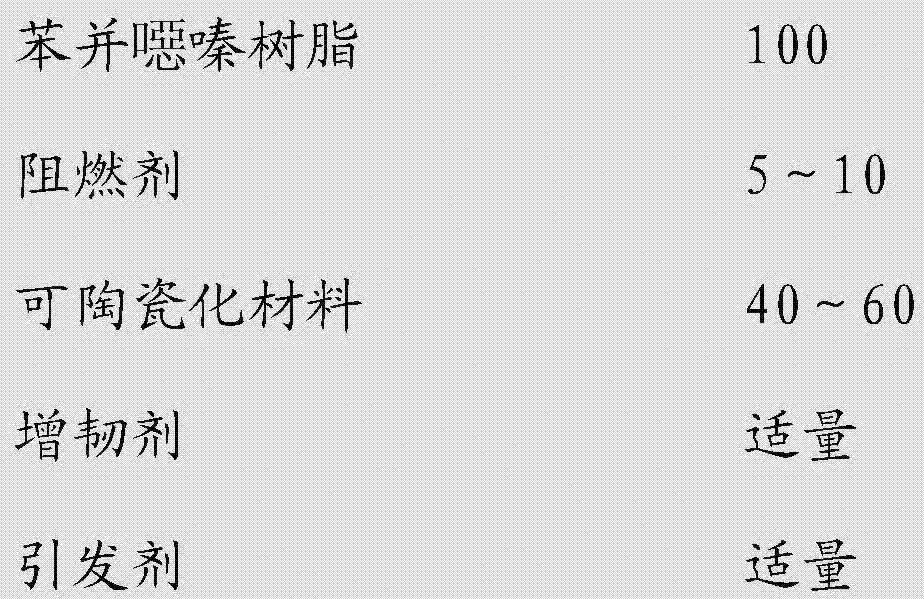

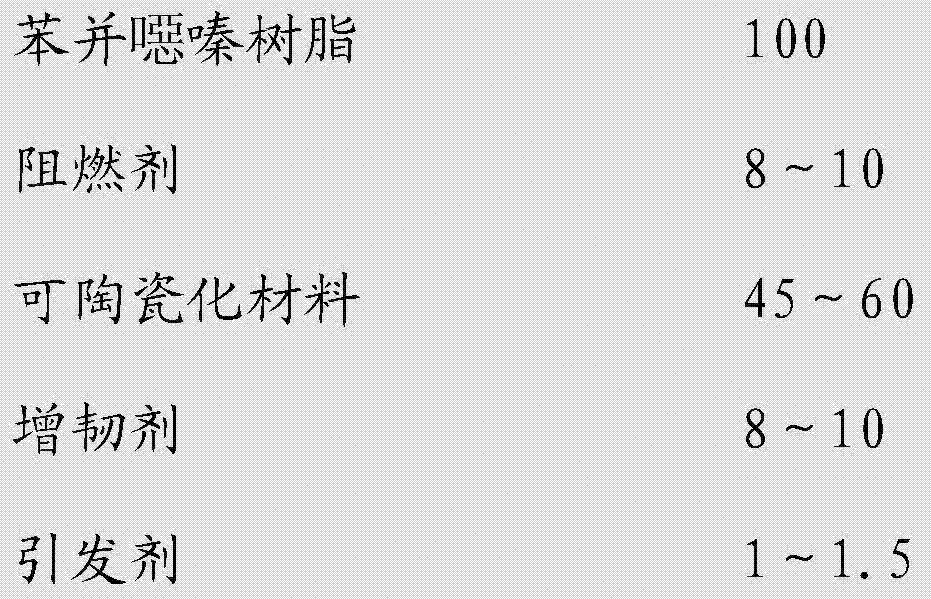

High-anti-scouring vitrified flame retardant resin and preparation method thereof

The invention provides high-anti-scouring vitrified flame retardant resin and a preparation method thereof. The high anti-scouring vitrified flame retardant resin comprises benzoxazine resin, a flameretardant, a vitrified material, a flexibilizer and an initiator, wherein the flame retardant and benzoxazine resin are in graft copolymerization to enhance the benzoxazine resin in molecular level soas to improve the heat stability and the mechanical property of the benzoxazine resin; and meanwhile, the flame retardant can be reacted with the vitrified material in a fused condition, so that formation of a ceramic layer is accelerated. The resin material is good in maintainability effect, has high anti-scouring, anti-ablating and flame retarding capacities, and can be widely applied to ablative coatings or external heat-preventing structures of guided missile bodies, rockets, spacecraft reentry cabins or ballistic missiles.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

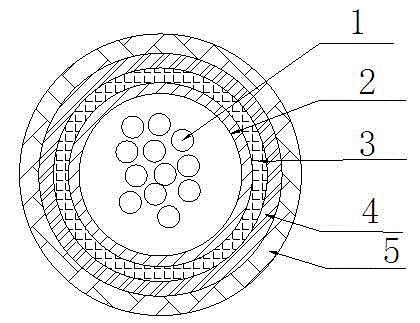

High-temperature resistant miniature armored optical cable and production method thereof

ActiveCN104614825AIngenious structural designHigh temperature resistanceFibre mechanical structuresEngineering plasticEngineering

The invention relates to a high-temperature resistant miniature armored optical cable which is characterized by comprising an optical fiber, a bushing, an engineering plastic wrapped tube or steel band wrapped and armored tube, an aramid fiber woven mesh or a steel wire woven mesh and an external protective cover from inside to outside in sequence; the optical fiber structure is of a dry type structure; and the engineering plastic wrapped tube is of a spiral shape. The high-temperature resistant miniature armored optical cable is simple in structure, safe and reliable, convenient in use and lower in cost; the produced optical fiber is higher in high-temperature resistance and fire resistance, good in anti-tensioning ability and convenient in large-scale promotion and application.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

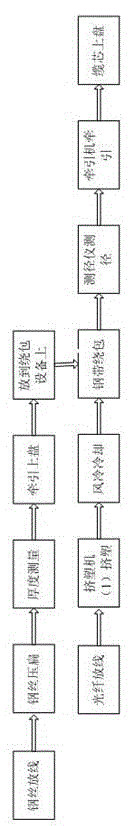

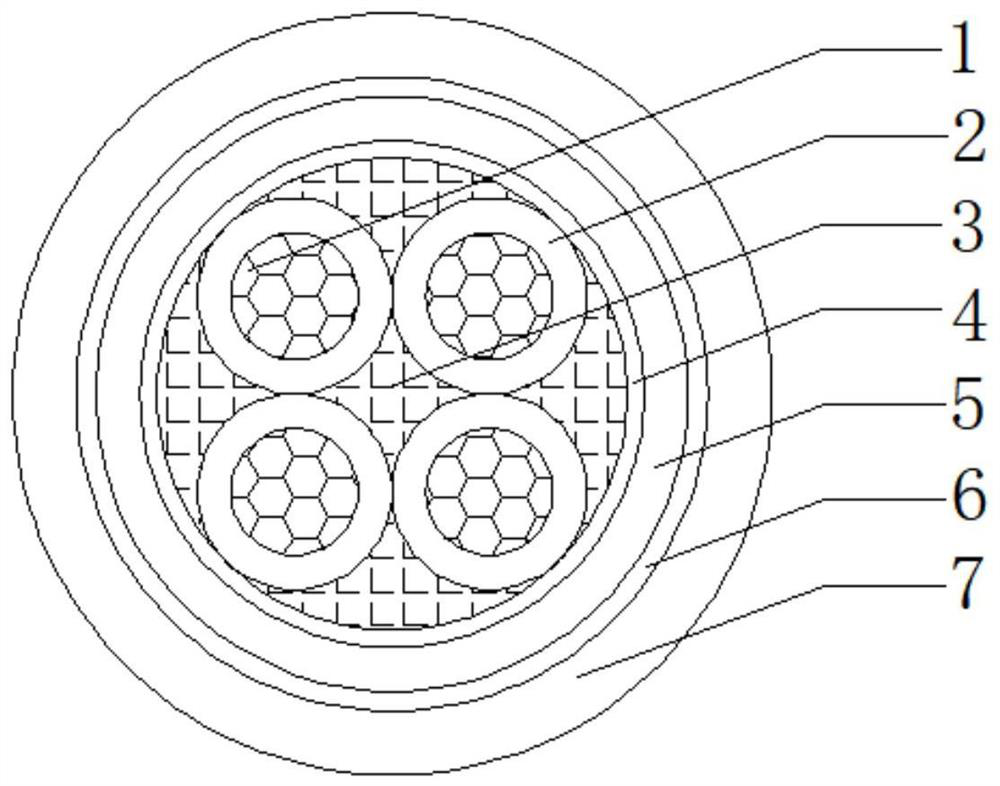

High-performance aluminium alloy cable for building

InactiveCN103337290AExtended durationHas flame retardant propertiesInsulated cablesPower cablesElectricityInsulation layer

The invention discloses a high-performance aluminium alloy cable for buildings, which solves the problems that the conventional power cables for buildings consume more copper resources, are worse in bending performance, and have short service life and the like, and has the advantages of light weight, the capability of corrosion-resistance and halogen-free flame retardant, small bending radius, excellent electrical property, long service life and the like. The high-performance aluminium alloy cable structurally comprises a cable core, wherein the cable core is formed by a plurality of wire core conductors arranged inside a filler and made of aluminium alloy; a conductor double-layer insulation layer is arranged on the outer wall of each wire core conductor; the plurality of wire core conductors are intertwisted in a symmetric arrangement manner; the outer wall of the filler is wrapped with a cable belting layer, a cable armored layer and a cable shield layer sequentially from the inside out.

Owner:SHANGDONG HUALING CABLE

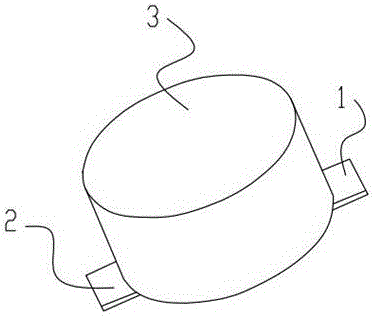

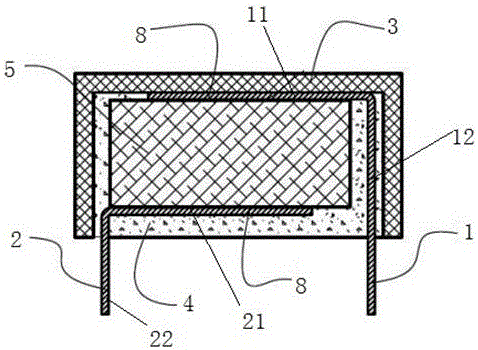

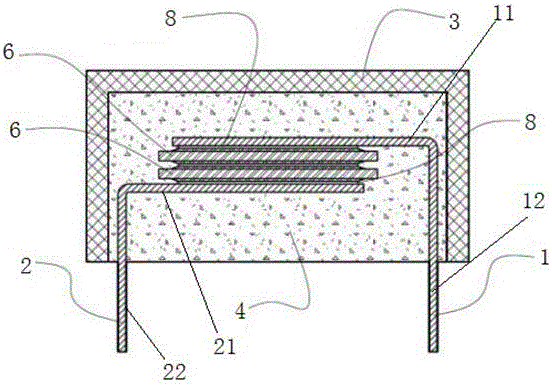

Power mode Surface Mounted Device (SMD) semiconductor component

PendingCN106783783AHas flame retardant propertiesStop fireSemiconductor/solid-state device detailsSolid-state devicesPower modeSurface mounting

The invention discloses power mode Surface Mounted Device (SMD) semiconductor components, and relates to the technical field of electronic components. The semiconductor components comprise combination chips, upper electrode sheets are welded on the upper surfaces of the combination chips, lower electrode sheets are welded on the lower surfaces; a container-shape flame retardant insulation shell is arranged on the outer side of the combination chips, the space between the shell and the combination chips is filled with package fillers, the free ends of the upper electrode sheet and the lower electrode sheet extend to the shell outside, to act as the two connection pins of the semiconductor components. According to the semiconductor components, semiconductor chips which are the same with the traditional plug-in type semiconductor components can be packaged, and can keep at the same level with the plug-in components in power and other electrical property indexes; the electrode sheets and semiconductor chip are loaded into the shell after the welding is completed, and package filler are filled, the filled package filler has flame retardant characteristics, and the shell is also of flame retardant material, the whole semiconductor chip is packaged by the flame retardant material, and fire can be effectively blocked.

Owner:BESTBRIGHT ELECTRONICS

Plastic with degradation function and production process

The invention discloses a plastic with a degradation function. The plastic with a degradation function comprises the following raw materials in parts by weight: 50-70 parts of degradable plastic masterbatches, 30-45 parts of modified starch, 12-16 parts of copolymerized polypropylene, 8-12 parts of celluloses, 2-4 parts of a degrading accelerant, 6-8 parts of MPA, 6-8 parts of a filler, 1-3 partsof environmentally friendly inorganic pigment, 1-3 parts of plant fibers, 2-5 parts of stearic acid, 1-3 parts of an antioxidant, 2-5 parts of a flame retardant, 2-5 parts of a surfactant, 2-5 parts of glycerinum and 2-4 parts of a coupling agent. Plastics in various shapes can be obtained from the novel materials through an extruder, thus, life of people is improved, and the plastic is easy to degrade, has flame retardancy and is suitable for being popularized.

Owner:芜湖市纯至网络科技有限公司

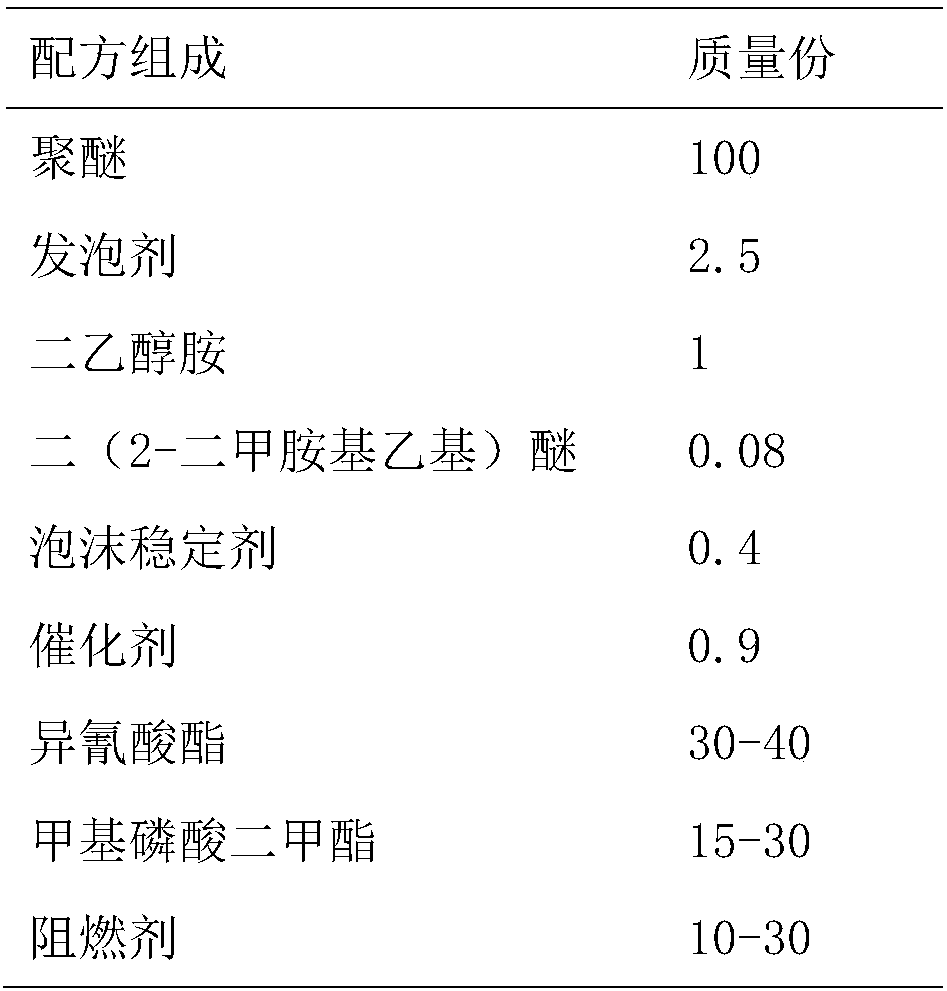

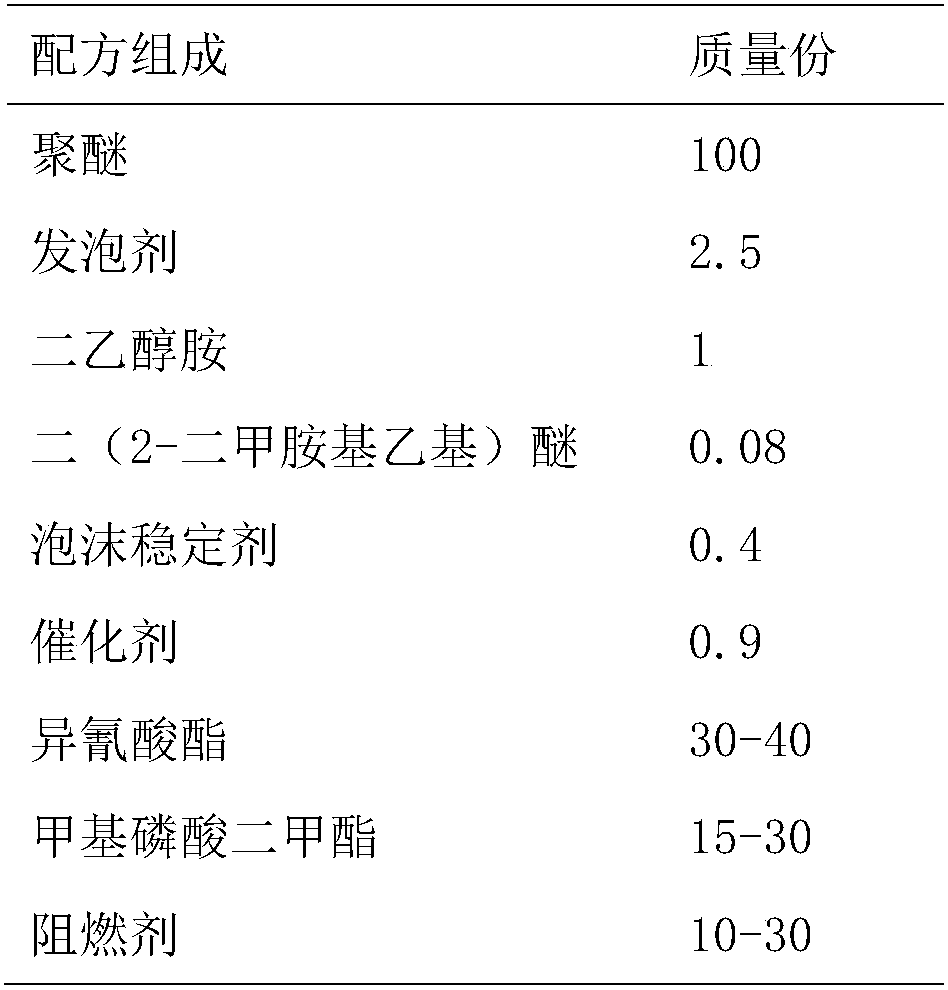

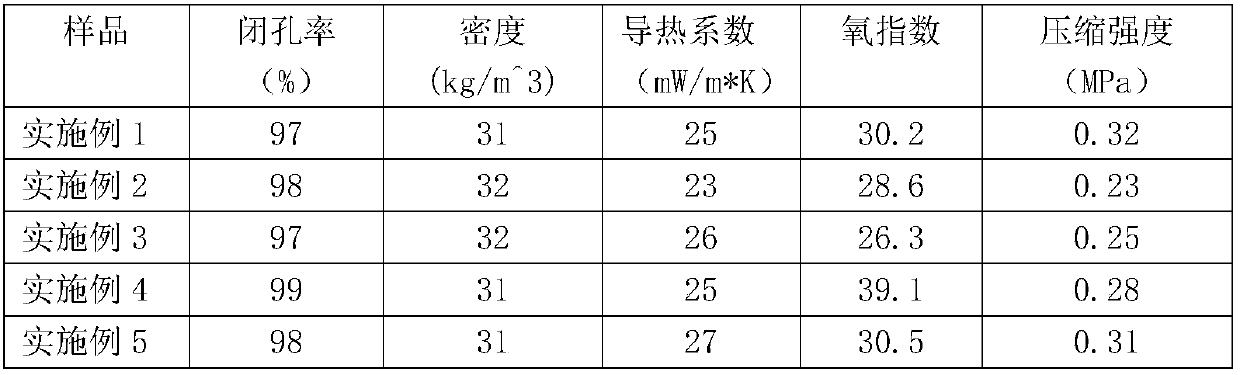

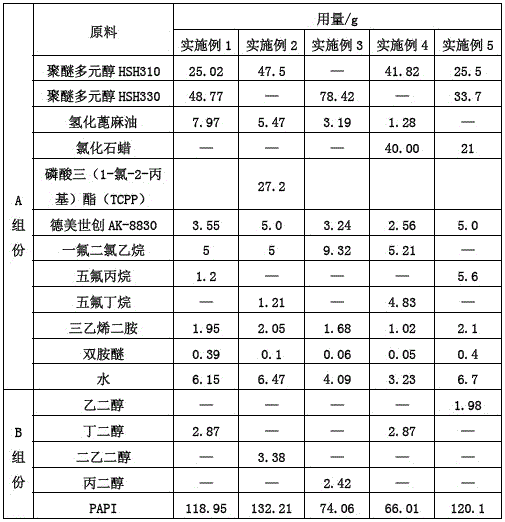

Low-density flame retardant polyurethane hard foam plastic and preparation method thereof

The invention relates to the technical field of polyurethane foam plastics, in particular to a low-density flame retardant polyurethane hard foam plastic and a preparation method thereof. According tothe preparation method, raw materials such as polyether, isocyanate, diethanolameine, catalysts, foam stabilizing agents, foaming agents, dimethyl methylphosphate and fire retardants are all mixed together through metering; high-speed stirring is performed; uniform mixing is performed to complete the foaming process; after the generation of chemical reaction, a certain step is performed; the low-density flame retardant polyurethane hard foam plastic is generated. The decabromodiphenyl ether is used as a fire retardant; meanwhile, the impact performance of inorganic filling materials and partial organic material formula is compensated. The low-density flame retardant polyurethane hard foam plastic and the preparation method have the main advantages that the flow process is simple; the equipment investment is low; the polyurethane hard foam plastic with low density, not dark color and certain flame retardant characteristics can be prepared.

Owner:合肥华福土工合成材料有限公司

Flaming-retardant and heat-resisting conveyer belt

InactiveCN105001526AHas flame retardant propertiesLow tensile strengthConveyorsAluminium hydroxideStearic acid

The invention discloses a flaming-retardant and heat-resisting conveyer belt, and relates to the field of conveyer belt manufacturing. The conveyer belt comprises, by mass, 60-100 parts of ethylene-propylene-diene monomer rubber, 60-100 parts of ethylene-propylene-diene monomer regenerated rubber, 30-60 parts of carbon black, 12-15 parts of zinc oxide, 10-20 parts of composite flame retardant, 3-10 parts of high-temperature stabilizers, 1-3 parts of stearic acid, 1-10 parts of phenolic resin BN-1, 1.5-5 parts of accelerant, 1.5-3 parts of vulcanizing agents, 2-5 parts of aluminium hydroxide, 1-3 parts of anti-aging agents and 0.1-0.3 part of sulphur. Combining smelting is carried out on synthetic rubber, the synthetic rubber is mixed with various compounding agents, compound smelting is carried out, compound rubber is prepared, after sheeting, cooling and placing are carried out on the compound rubber, rolling forming is carried out, a belt embryo is formed, and after combing is carried out on the belt embryo, the flaming-retardant and heat-resisting conveyer belt is obtained. The flaming-retardant and heat-resisting conveyer belt is a safe product which has the flaming-retardant and heat-resisting performances, raw materials are easy to obtain and can be bought in the market, the production technology is simple, and the flaming-retardant and heat-resisting conveyer belt is suitable for industrial production.

Owner:ANHUI YANGFAN MACHINERY

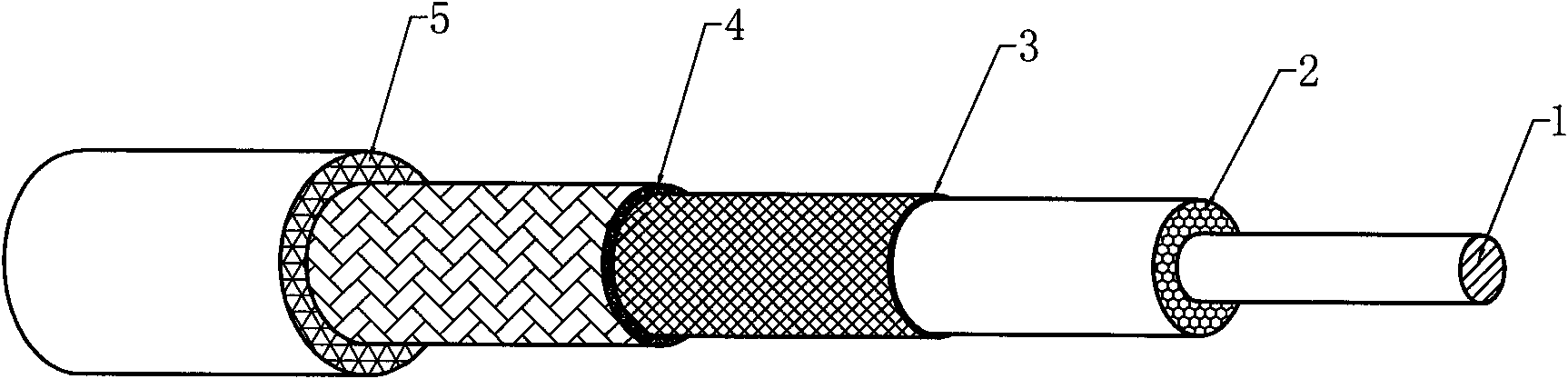

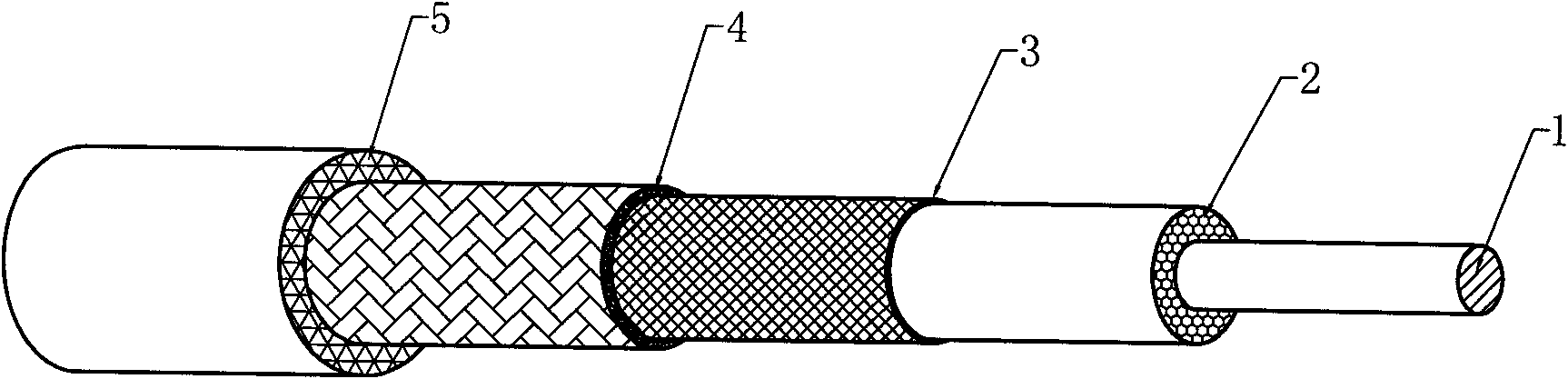

High-temperature resistant fire-retardant co-axial cable

InactiveCN101866717ANot easily oxidizedImprove transmission performanceCoaxial cables/analogue cablesClimate change adaptationInsulation layerElectrical conductor

The invention relates to a high-temperature resistant fire-retardant co-axial cable. The cable comprises, from the inside to the outside, a central conductor, an irradiation crosslinking foaming fire-retardant polyethylene insulation layer, a copper foil shielding layer, a copper wire weaving outer conductor layer and an outer protection layer, wherein PE base materials, together with a proper amount of fire-retardant masterbatch and nucleating agent, undergo foaming extrusion in a physical foaming machine to make insulation core wires, the foaming fire-retardant polyethylene insulation layer prepared by the insulation core wires is irradiated by an electron accelerator, the high-voltage electron beam current generated by the electron accelerator acts on the foaming fire-retardant polyethylene insulation layer, the internal structure of the foaming fire-retardant polyethylene insulation layer is changed from the original chain-shaped macromolecular structure to the three-dimensional network structure, so that the crosslinked foaming fire-retardant polyethylene insulation layer possesses better physical properties, an work at the temperature of 125 DEG C for a long time, and has the advantages of fire-retardant property, high voltage resistance, high weathering resistance, high mechanical property, high transmission property and the like.

Owner:SHENZHEN SUIRONG COAXIAL CABLE TECH

Preparation method for flame-retardant and antistatic pipeline with high strength

InactiveCN102501410AHigh crystallinityHigh degree of interface adhesionSynthetic resin layered productsGlass/slag layered productsHigh intensityNucleation

The invention relates to a preparation method for a flame-retardant and antistatic pipeline with high strength, wherein no degradation on the other performances of the flame-retardant and antistatic pipeline with high strength is realized to a certain extent while an inorganic modifier is greatly enhanced. Simultaneously, the crystallization of polyethylene realizes the effect of heterogeneous nucleation by using a small amount of nanometre materials. Additionally, the flame-retardant and antistatic pipeline with high strength enables to have a flame-retardant characteristic, and the resistivity thereof is decreased until electrostatic charges can be rapidly leaked by adding a flame retardant and a filler with a certain conductivity, so as to achieve the application demands of fire prevention, electrostatic prevention etc.

Owner:ZHEJIANG NORMAL UNIVERSITY

High-strength and high-contact area double-layer composite fuel filter paper and preparation method thereof

InactiveCN106192585AImprove gapImprove filtration efficiencyPaper coatingPaper/cardboardEmulsionCarbon black

The invention discloses high-strength and high-contact area double-layer composite fuel filter paper and a preparation method thereof. The high-strength and high-contact area double-layer composite fuel filter paper is characterized by being prepared from the following raw materials in parts by weight: 3 to 5 parts of glass fibers, 10 to 20 parts of hardwood pulp fibers, 3 to 5 parts of polypropylene fibers, 10 to 20 parts of coniferous pine wood pulp fibers, 10 to 20 parts of polyester fibers, 10 to 20 parts of sepiolite nano fibers, 2 to 4 parts of white carbon black, 3 to 5 parts of Fe2O3, 5 to 10 parts of TiO2, 4 to 8 parts of MgO, 25 to 35 parts of a silane coupling agent KH560, 15 to 20 parts of a polyoxyethylene aqueous solution, 2 to 4 parts of a titanate coupling agent DNZ201, 50 to 60 parts of isopropanol, 5 to 10 parts of styrene-acrylic emulsion and a proper amount of polyacrylate emulsion. According to the high-strength and high-contact area double-layer composite fuel filter paper, a gap between one layer and the other layer is improved; furthermore, the obvious porosity gradient is retained, and the filter efficiency is improved; the filter paper is subjected to crumbling treatment, so that the contact area of fuel and the filter paper is enlarged, and the filter efficiency is further improved; by the cooperated adding of the polypropylene fibers and the glass fibers, the strength of the fuel filter paper is enhanced.

Owner:BENGBU PIONEER FILTER

Double-component polyester polystyrene foam with inflaming retarding property and preparation method thereof

The invention relates to double-component polyester polystyrene foam with the inflaming retarding property and a preparation method thereof, and belongs to the field of building adhesives. The double-component polyester polystyrene foam comprises a component A and a component B. The component A comprises 40.0%-80.0% of polyether polyol, 2.0%-5.0% of foam stabilizer, 1.0%-2.5% of catalyst, 0%-10.0% of thixotropic agent, 0%-40% of fire retardant, 5.0%-10.0% of foaming agent and 2.0%-10.0% of water. The component B comprises PAPI prepolymers. The component A is prepared through the steps that polyether polyol, the foam stabilizer, the thixotropic agent and the fire retardant are mixed, heated, stirred and cooled, the catalyst, the foaming agent and the water are added, and the mixture is mixed to be uniform. The component B is prepared through the steps that PAPI is added into polyhydric alcohol, the temperature is raised, and stirring, heat preservation and cooling are carried out. The double-component polyester polystyrene foam does not contain dimethyl ether or propane or butane or other inflammable gas, and is good in inflaming retardance. The double-component polyester polystyrene foam has high inflaming retardance, and is high in foaming and curing speed, low in density, high in shear strength and high in construction efficiency.

Owner:哥俩好(辽宁)新材料有限公司 +1

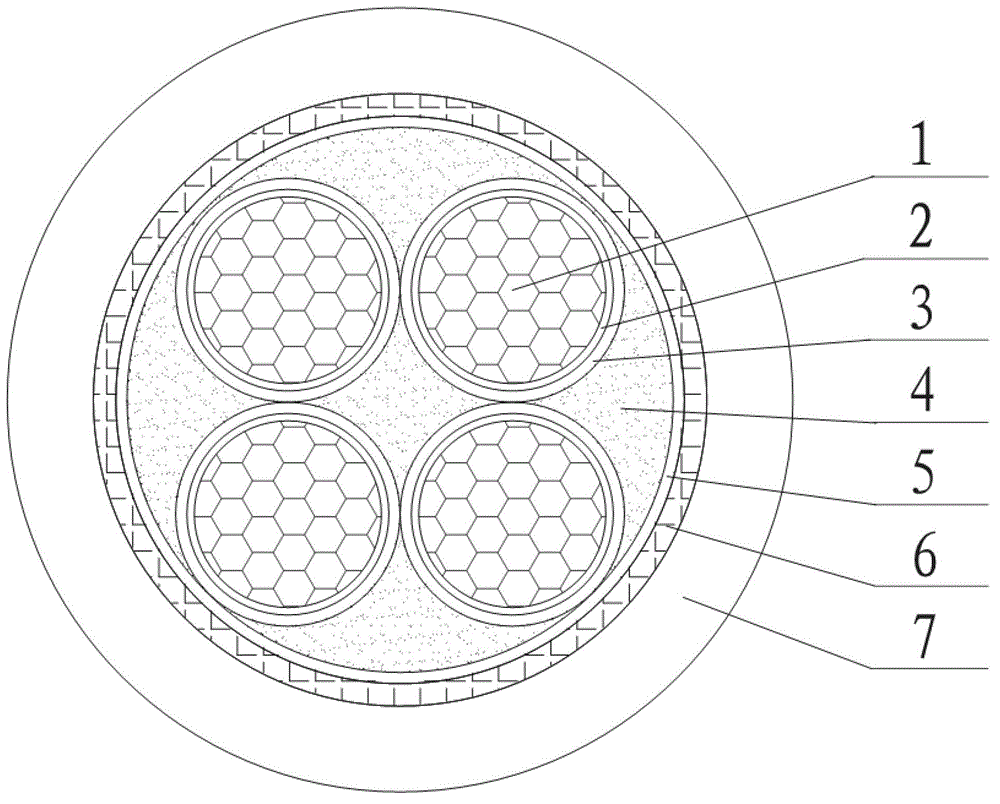

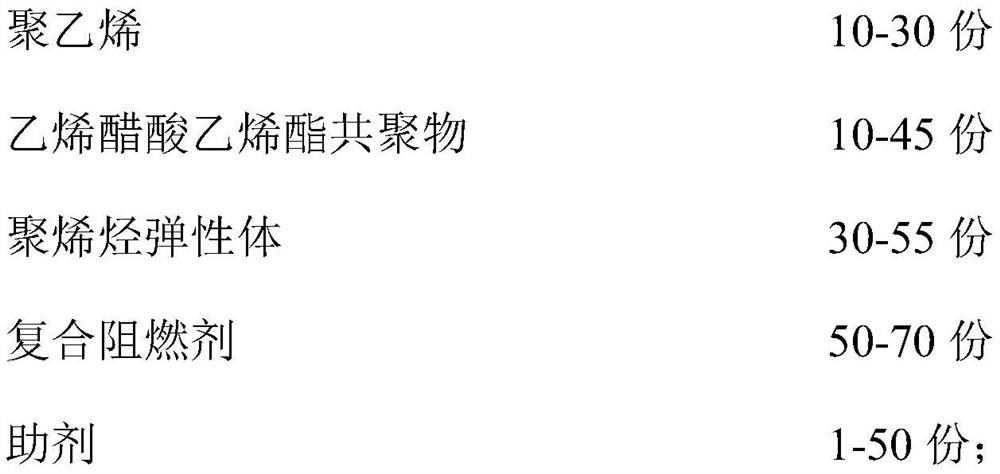

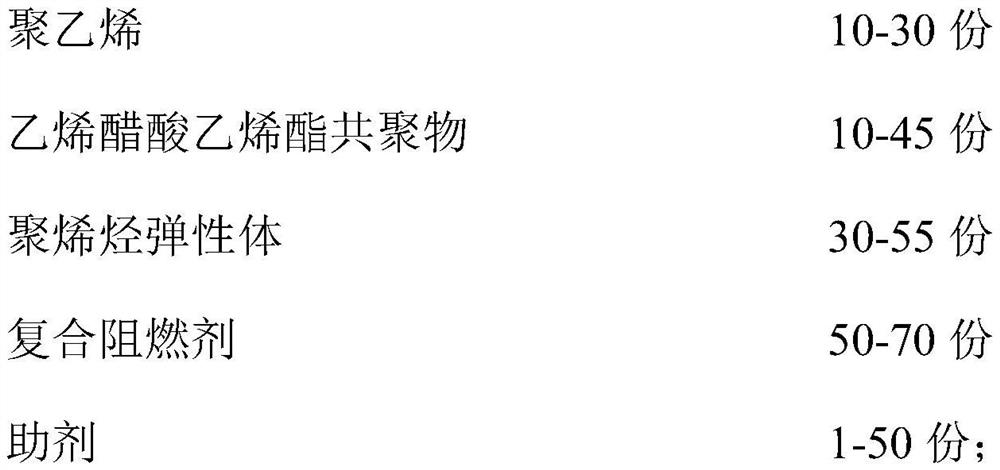

B2-grade flame-retardant cable as well as preparation method and application thereof

PendingCN113611449AHas flame retardant propertiesInsulated cablesInsulated conductorsElastomerPolyolefin

The invention relates to a B2-grade flame-retardant cable and a preparation method and application thereof. The B2-grade flame-retardant cable comprises at least two cable cores, wherein the cable cores are distributed in an array mode, and a lining layer and a protection layer are sequentially arranged outside the at least two cable cores; the cable core comprises a conductor and an insulating layer wrapping a surface of the conductor; a protective layer is prepared from the following components in parts by weight, 10 to 30 parts of polyethylene, 10 to 45 parts of ethylene-vinyl acetate copolymer, 30 to 55 parts of polyolefin elastomer, 50 to 70 parts of composite flame retardant and 1 to 50 parts of additive; the composite flame retardant comprises a combination of magnesium hydroxide, red phosphorus and a nitrogen-phosphorus flame retardant. The B2-grade flame-retardant cable disclosed by the invention has the B2-grade flame-retardant characteristic on the basis of meeting basic mechanical properties.

Owner:JIANGSU HENGTONG POWER CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com