High-anti-scouring vitrified flame retardant resin and preparation method thereof

A technology of ceramic flame-retardant and ceramic materials, which is applied in the field of composite materials, can solve the problems of large impact on the curing process of the resin matrix, poor anti-scouring and shape-retaining effects, and insufficient density of ceramic materials, so as to improve thermal stability. And mechanical properties, good thermal stability, and the effect of improving the ceramic production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

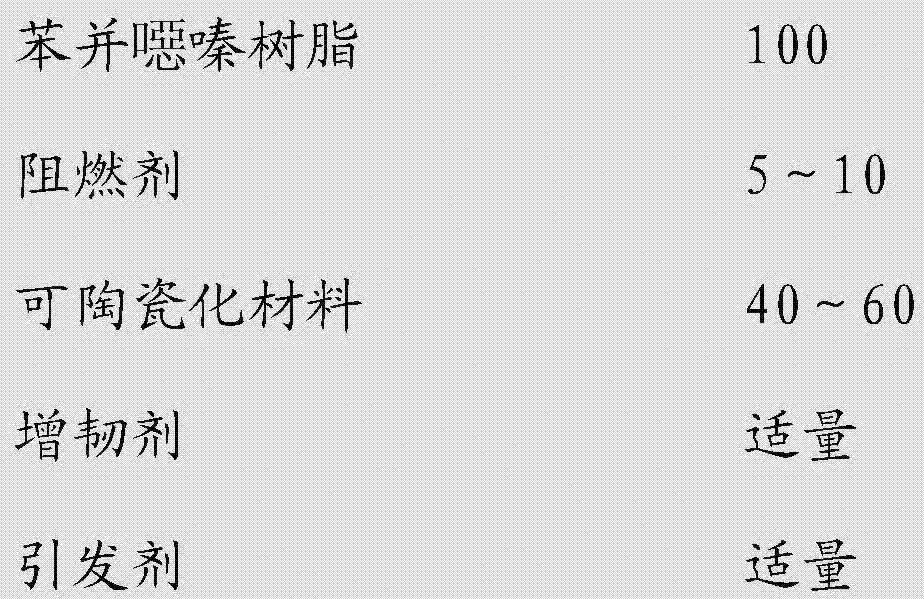

[0029]

[0030] The preparation process is as follows:

[0031] 1) Weigh 10 parts of nitrile rubber toughening agent and 5 parts of POSS-based flame retardant, add them in batches to 100 parts of benzoxazine resin, stir evenly at room temperature until no agglomeration, and obtain mixture (1);

[0032] 2) Weigh 40 parts of polycarbosilane, add it to the above mixture (1), stir and mix evenly at 55°C to obtain mixture (2), and park until the temperature drops to room temperature;

[0033] 3) Weigh 1 part of phenol, add it to the above mixture (2), stir and mix evenly at room temperature, and obtain a high-scourability ceramizable flame-retardant resin.

[0034] A high-silicone / ceramizable benzoxazine prepreg is prepared by using the high-flush ceramizable flame-retardant resin prepared in the above steps through a hot-melt method. After the above prepreg was cut, it was reacted at 160°C for 5 hours, and solidified by molding process to obtain a test sample. The thermal dec...

Embodiment 2

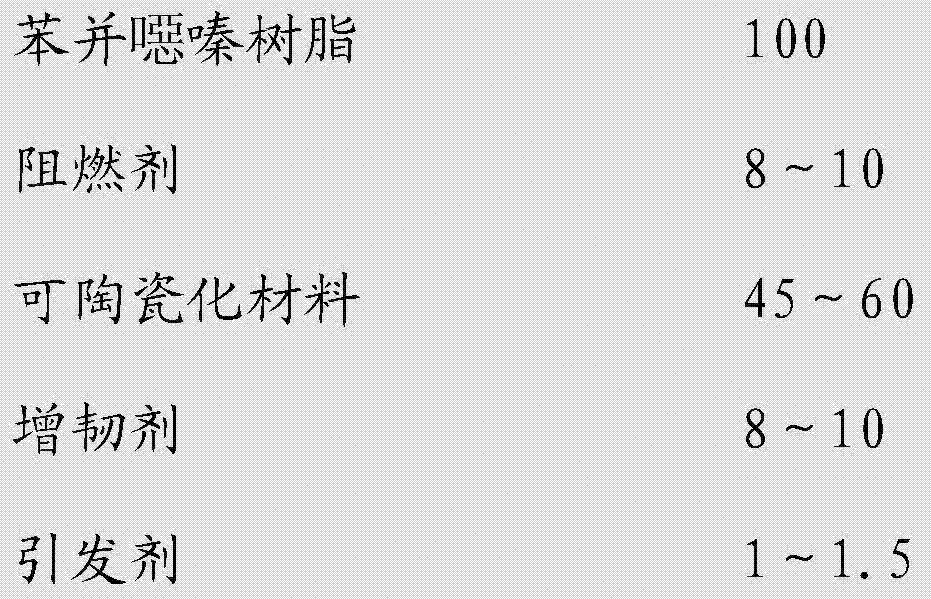

[0036]

[0037]

[0038]The specific preparation method, prepreg preparation method, curing method and performance test of the composite material of the high-scouring ceramizable flame-retardant resin provided in this example are the same as those in Example 1. Decomposition temperature, oxygen index, bending strength at room temperature, interlaminar shear strength at room temperature, linear ablation rate, and residual carbon rate at 900 °C in air atmosphere are shown in Table 1.

Embodiment 3

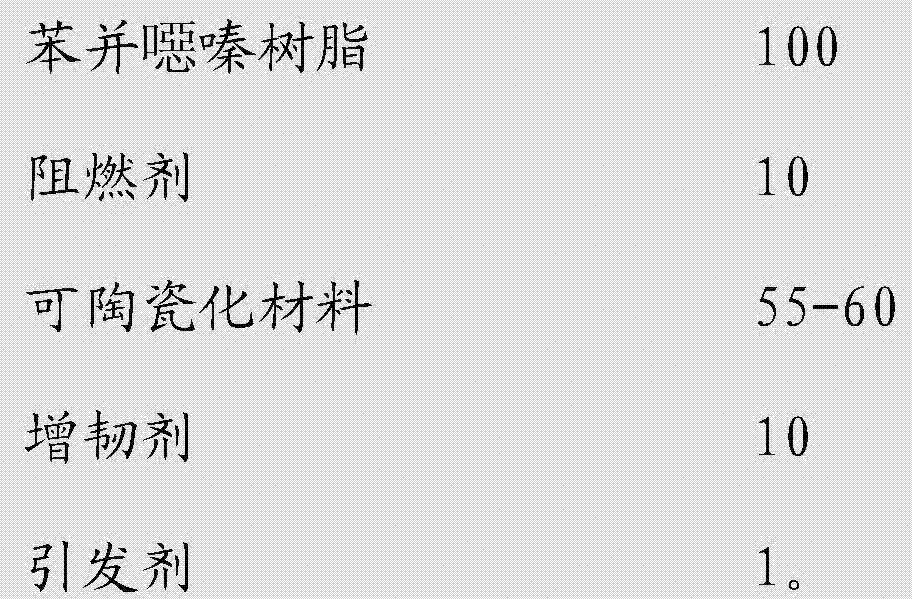

[0040]

[0041] The specific preparation method, prepreg preparation method, curing method and performance test of the composite material of the high-scouring ceramizable flame-retardant resin provided in this example are the same as those in Example 1. Decomposition temperature, oxygen index, bending strength at room temperature, interlaminar shear strength at room temperature, linear ablation rate, and residual carbon rate at 900 °C in air atmosphere are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com