High-temperature resistant miniature armored optical cable and production method thereof

A technology of armored optical cable and high temperature resistance, applied in the field of communication, can solve the problems of optical cable high temperature resistance, poor flame retardancy, poor tensile strength of optical cable, large bending radius of optical cable, etc., achieve low cost, high production efficiency, and save space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

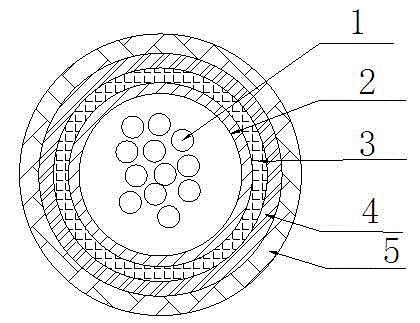

[0023] see figure 1 , a high-temperature-resistant miniature armored optical cable, the optical cable from the inside to the outside is an optical fiber 1, a sleeve 2, an engineering plastic wrapping tube or a steel tape wrapping armor tube 3, an aramid braided mesh or a steel wire braided mesh 4, and an outer The sheath 5, the optical fiber structure is a dry structure, and the engineering plastic wrapping tube is arranged in a spiral shape. The optical fiber is made of tensile optical fiber, the tensile strength of ordinary optical fiber is 40-50N, and the tensile strength of tensile optical fiber can reach 100N, so the service life of the optical cable can be greatly increased during use. Aramid braided mesh and steel wire braided mesh have good tensile strength, and armored tube optical cable wrapped with steel tape has good mechanical properties such as impact resistance and pressure measurement. The optical cable has an ingenious structural design, good tensile and pres...

Embodiment 2

[0025] see figure 1 , as an improvement of the present invention, the casing material is modified polypropylene, referred to as PP; the modified polypropylene is added with high temperature resistant resin, halogen-free flame retardant, wherein the proportion of high temperature resistant resin: 25% -50%; halogen-free flame retardant: 25%-50%; the modified PP has the characteristics of high temperature resistance and flame retardancy, so that the optical cable has high temperature resistance and high flame retardancy.

Embodiment 3

[0027] see figure 1 , as an improvement of the present invention, the engineering plastic wrapping pipe is made of polycarbonate, referred to as PC. PC is heat-resistant, impact-resistant, and flame-retardant, which makes the optical cable have stronger impact resistance and flame retardancy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com