Lead-free and halogen-free environmental soldering paste for electronic industry

An electronic industry, lead-free soldering technology, applied in the direction of welding media, manufacturing tools, welding equipment, etc., can solve the problems of ion pollution, solder paste printing performance, unsatisfactory storage, weak mechanical strength of solder joints, etc. Achieve good electrical insulation, good film-forming performance, and high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

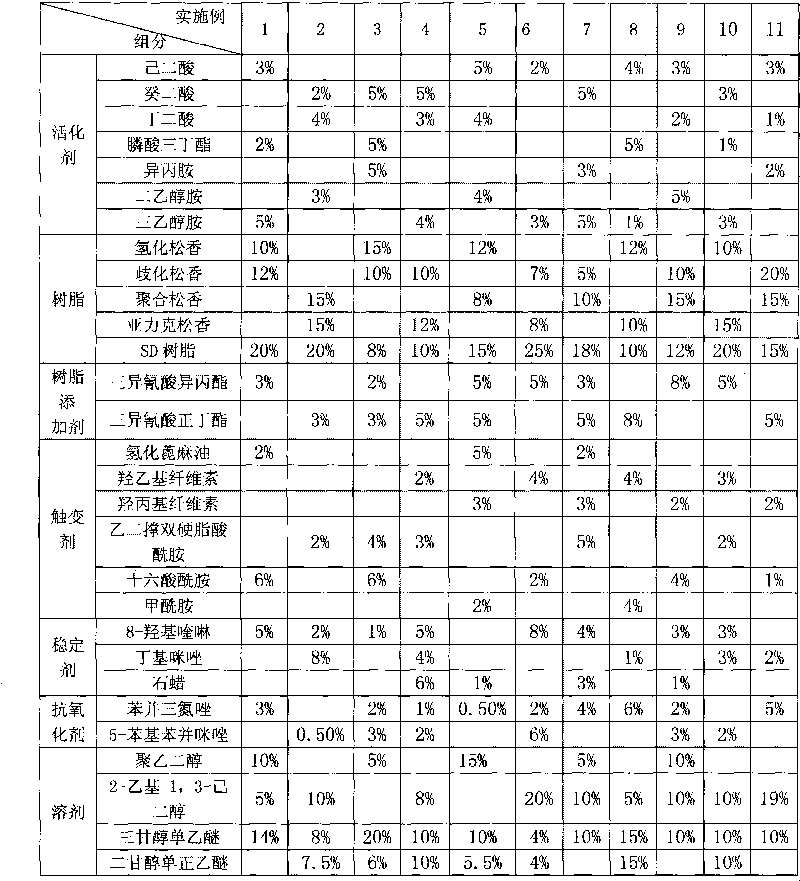

[0024] The formula of halogen-free flux in each embodiment of the present invention is shown in Table 1:

[0025] Table 1 (in terms of total weight percentage of halogen-free flux)

[0026]

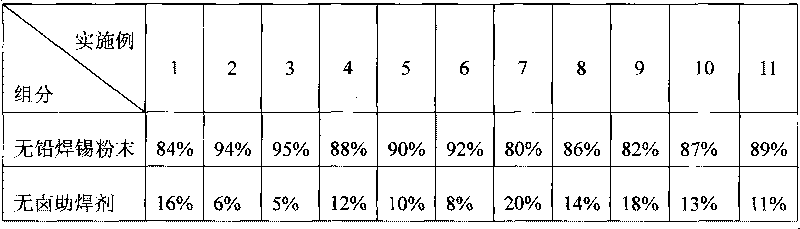

[0027] The proportioning of lead-free solder powder and halogen-free flux described in each embodiment of the present invention is shown in Table 2:

[0028] Table 2 (based on the total weight percentage of lead-free and halogen-free environmentally friendly solder paste for the electronics industry)

[0029]

[0030] The preparation method of lead-free halogen-free environment-friendly solder paste for electronic industry of the present invention is carried out according to the following steps:

[0031] 1. Add the resin and the resin additive into the reactor, heat and stir until completely melted. After melting, adjust the temperature to 150°C-200°C and keep it for 10 minutes, let it cool down slowly and uniformly, Add activator, thixotropic agent, stabilizer, antioxidant and so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com