Patents

Literature

119results about How to "Good expansion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

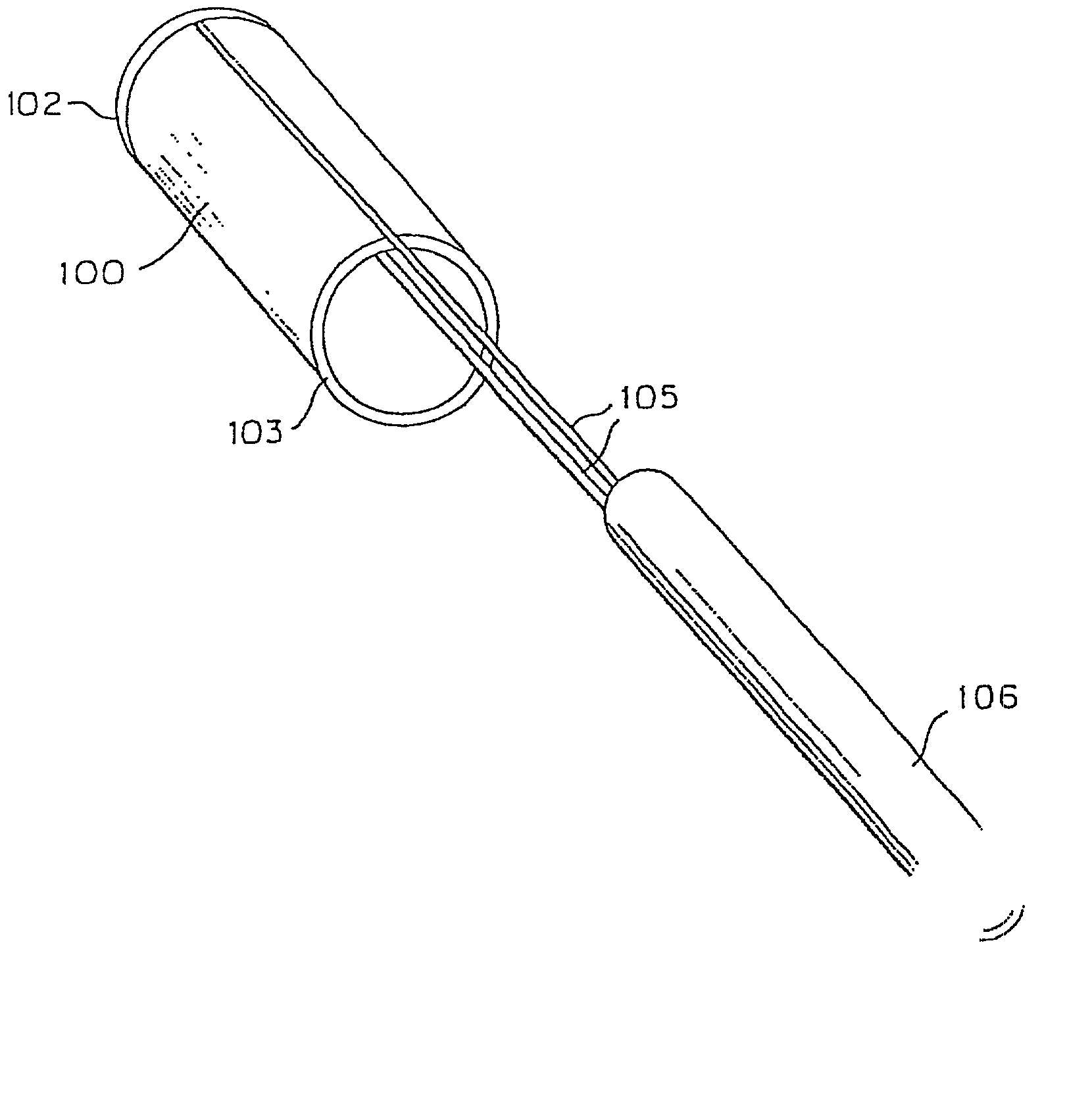

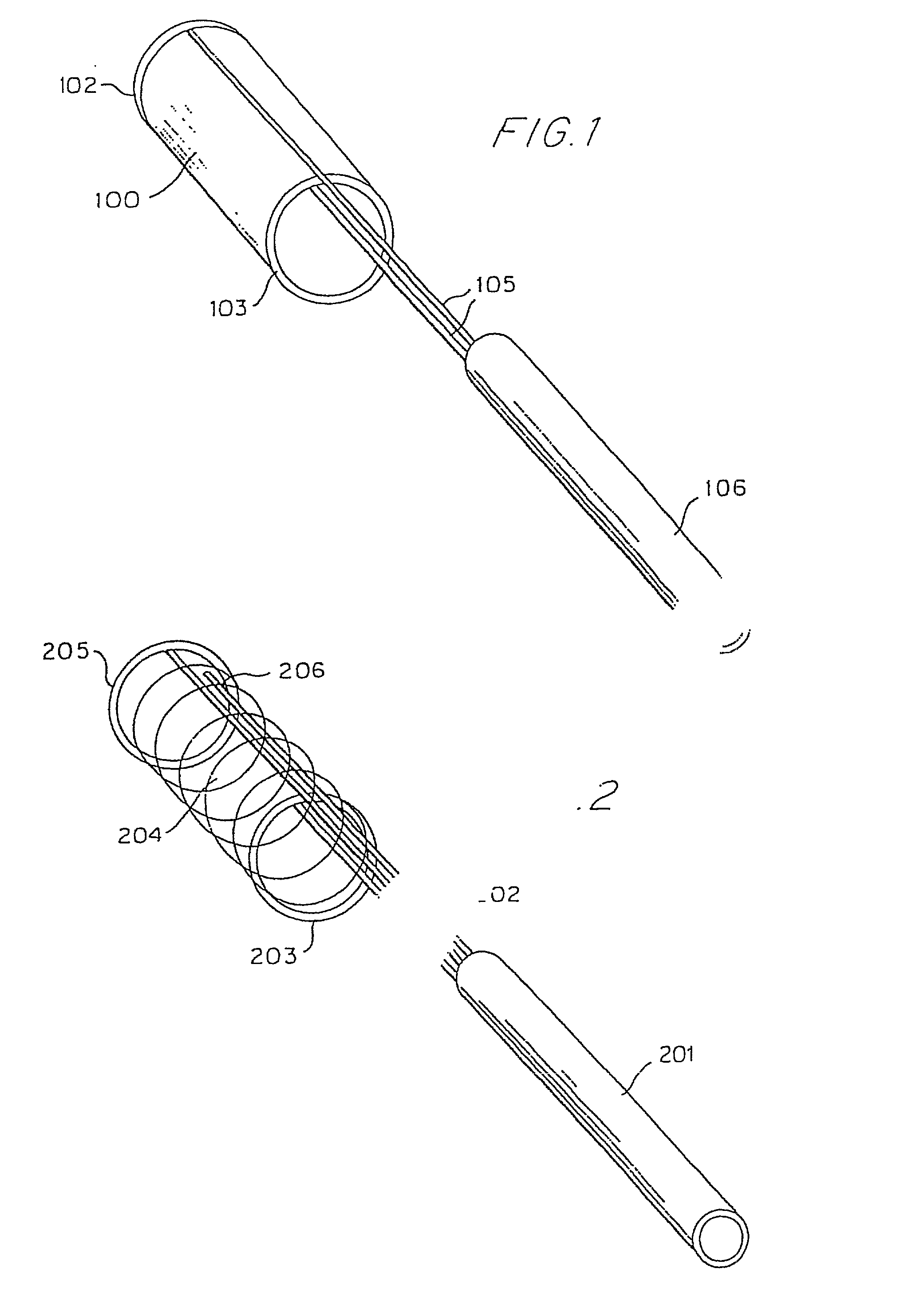

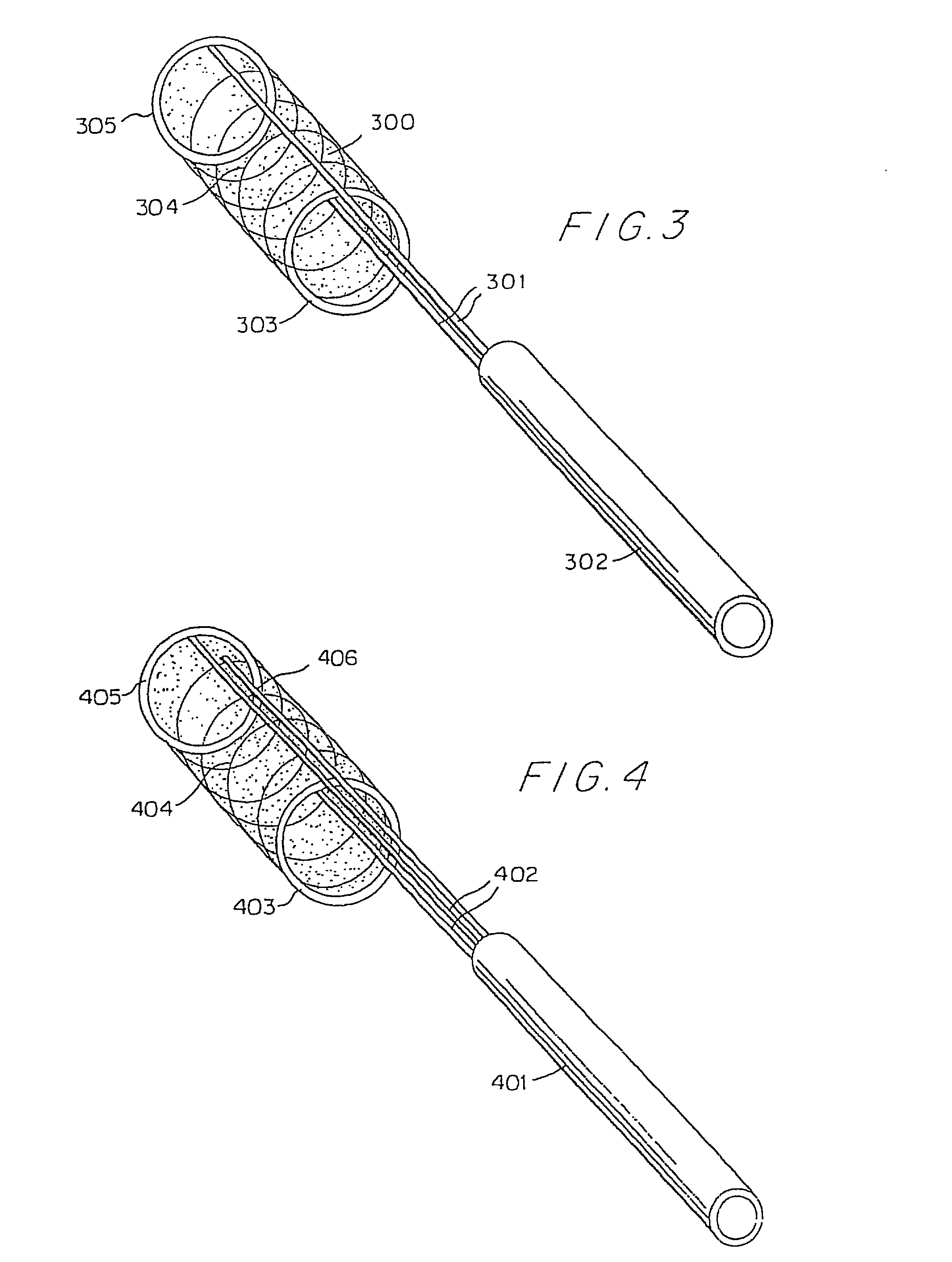

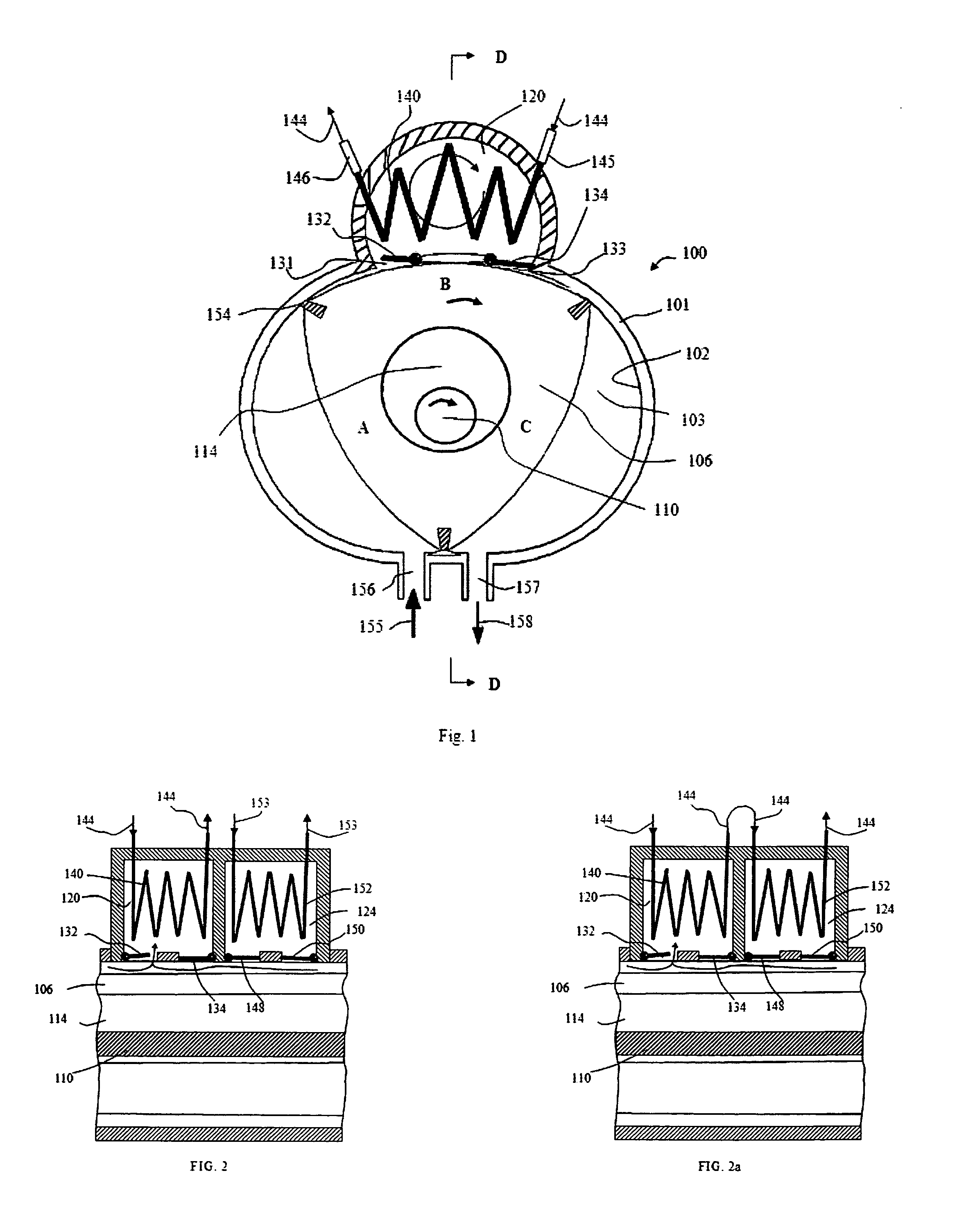

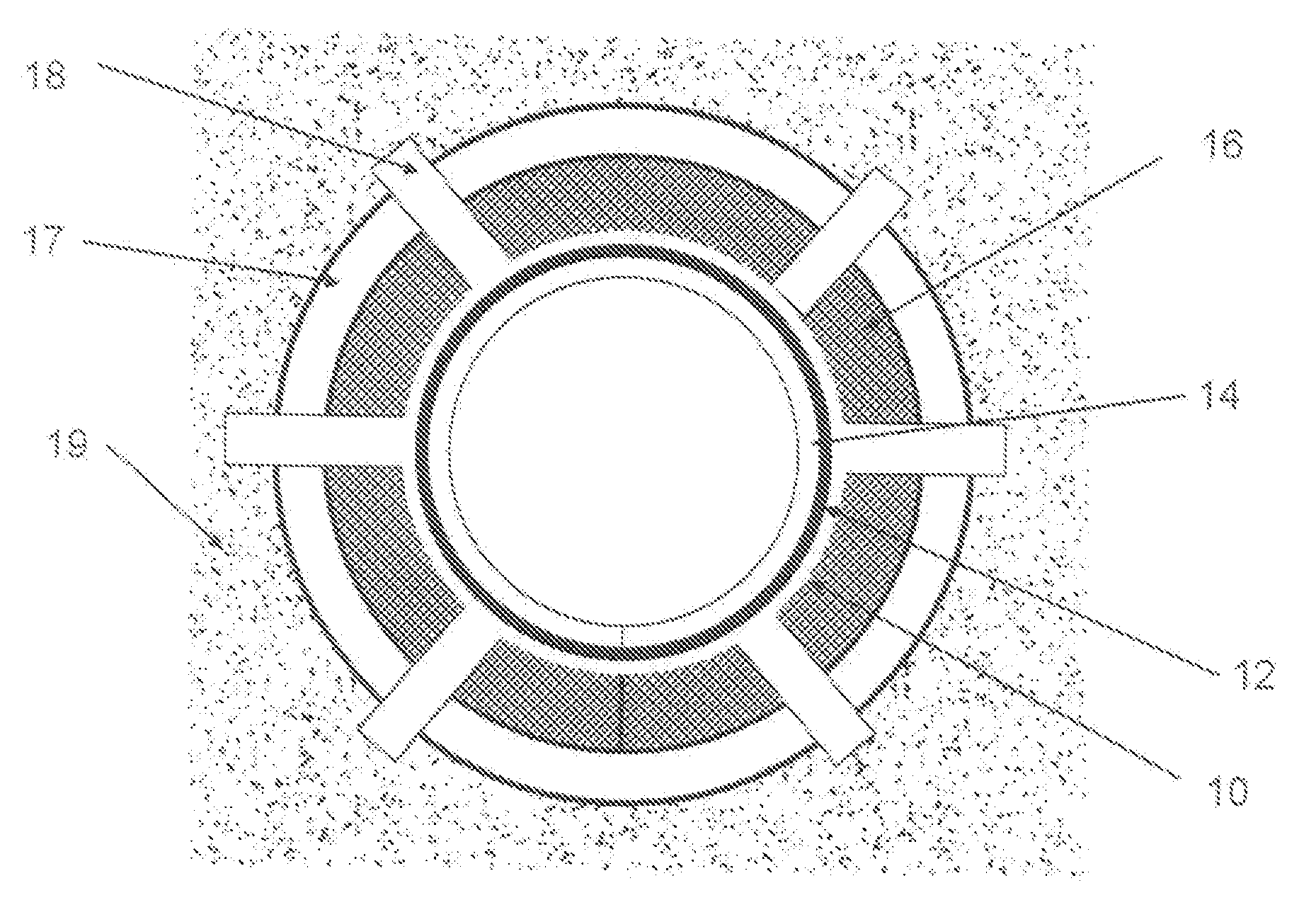

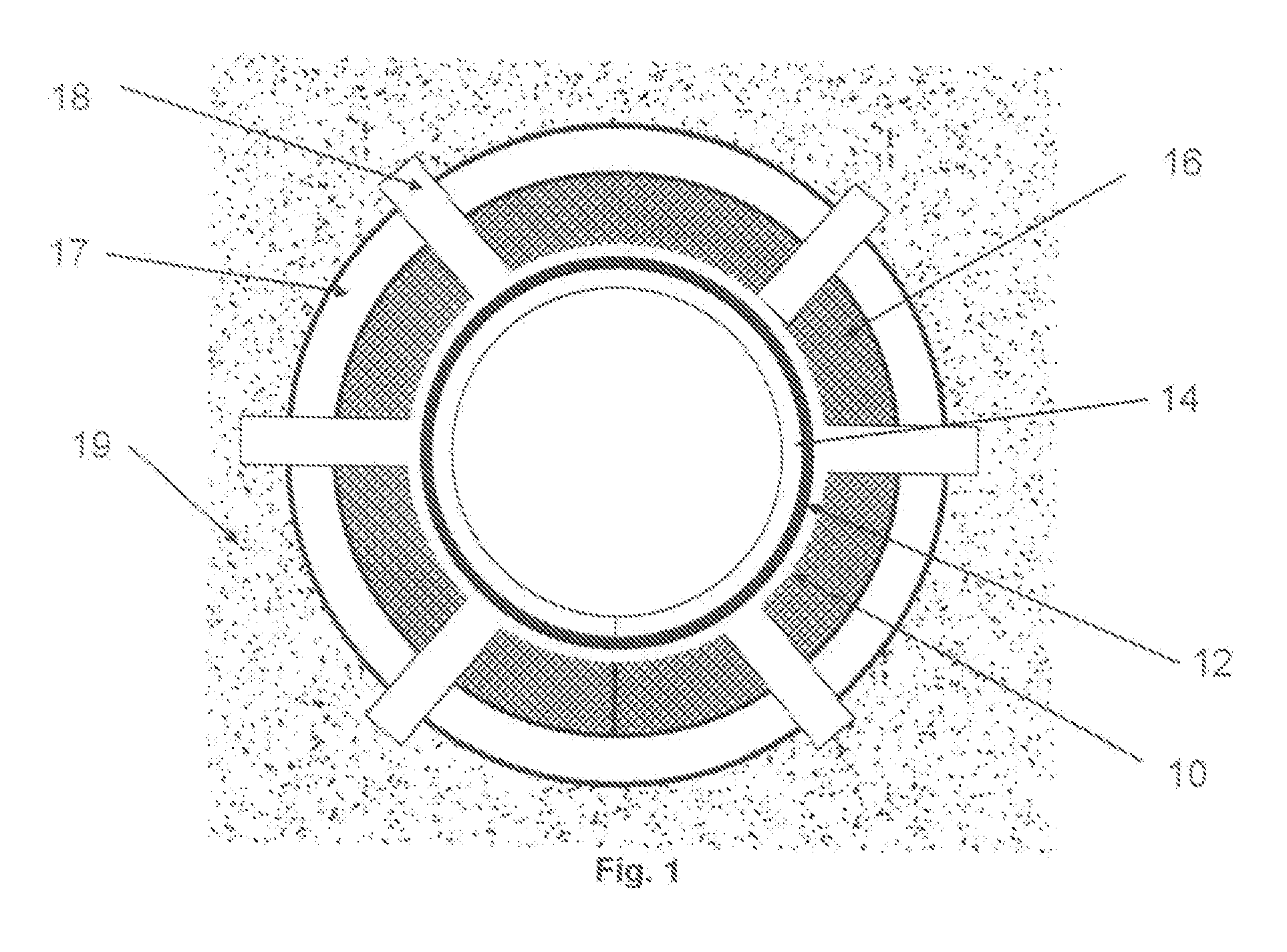

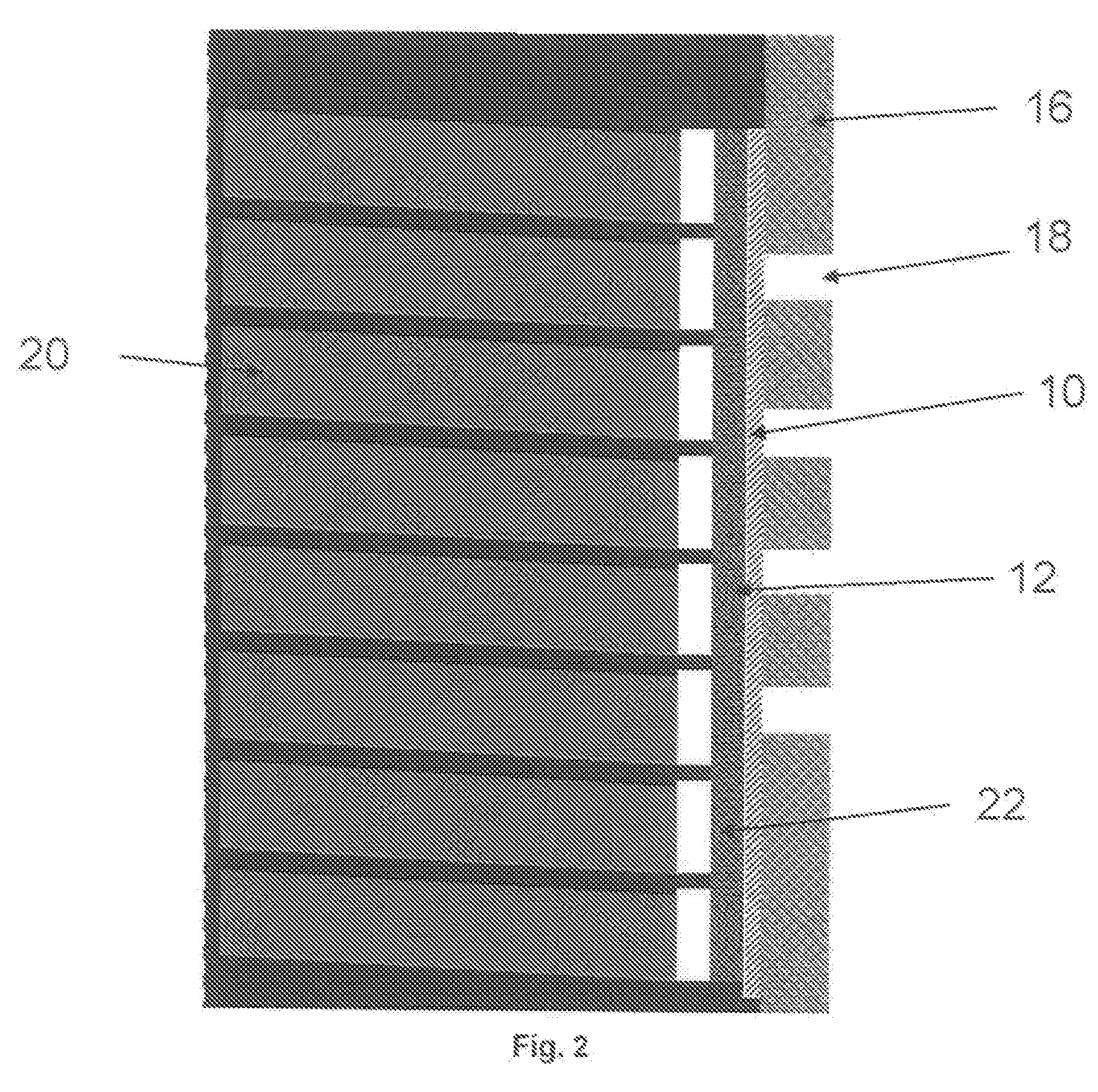

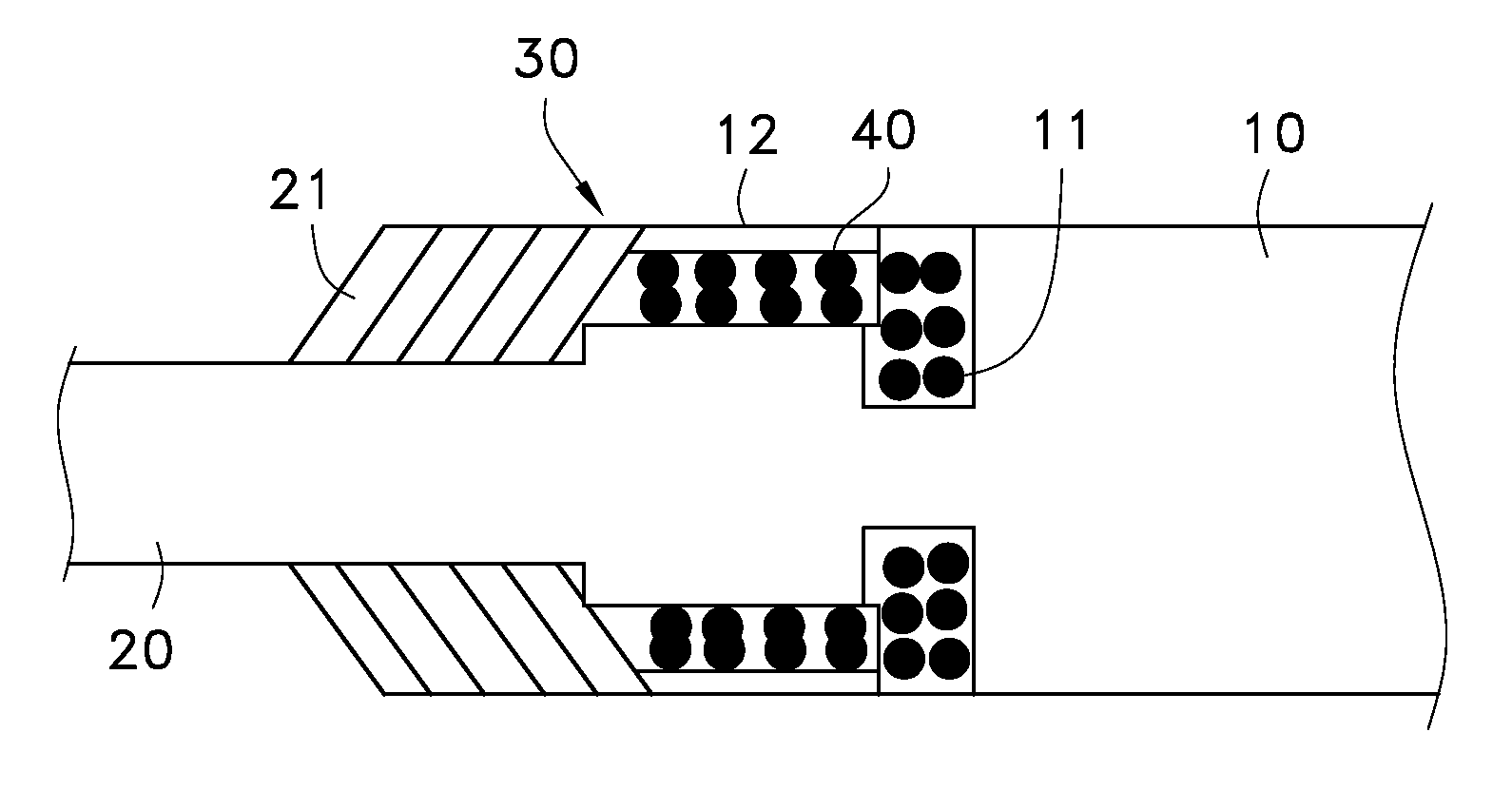

Endovascular thin film devices and methods for treating and preventing stroke

InactiveUS20030060782A1Safely and permanently excludingPreventing initial or recurrent aneurysmal subarachnoid hemorrhageStentsCatheterIn situ polymerizationProsthesis

Devices for excluding aneurysms and treating atherosclerotic disease, for intra-aneurysmal occlusion; and devices for preventing distal emboli. The devices are generally pliable and collapsible thin film devices which can be delivered via a microcatheter into the desired location where they are deployed and undergo either a shape memory phase transformation or in situ polymerization to assume the stable configuration of a permanent endoluminal prosthesis. Prior to being caused to assume their final shape, the devices remain soft, collapsible and pliable to ensure atraumatic delivery through the vascular system. Upon reaching the endoluminal defect in the vessel, the device is extruded from the microcatheter. Devices are also provided for retrieving clots.

Owner:NEW YORK UNIV

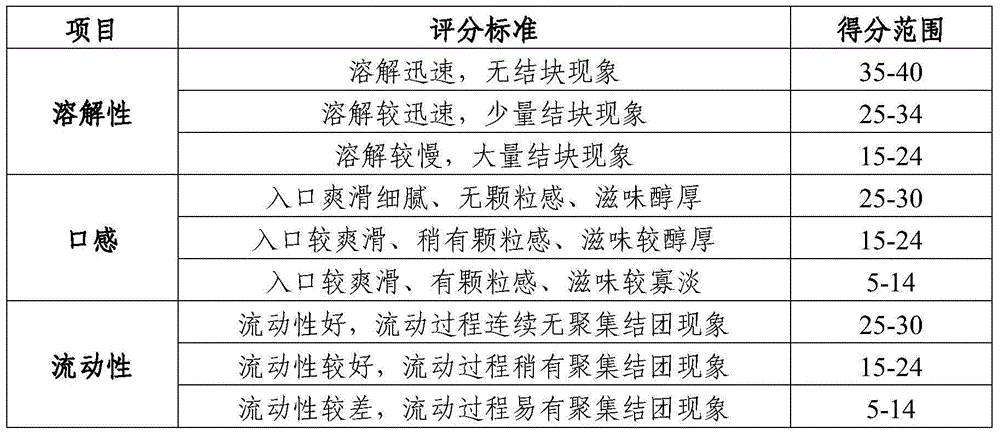

Instant plant total-nutrient food replacement powder and preparation method thereof

The invention relates to instant plant total-nutrient food replacement powder which comprises the following raw materials in parts by weight: 10-98 parts of grains, fruits and vegetables, and nut powder, and 0-10 parts of a natural sweetening agent. According to the instant plant total-nutrient food replacement powder, the grains, the fruits and the vegetables, and nuts are mixed and blended, treated by virtue of microwaves, subjected to enzymolysis, and once extruded and cooked, and crushed to prepare the instant plant total-nutrient food replacement powder. The instant plant total-nutrient food replacement powder is complete in nutrients, convenient to prepare, and convenient to digest and absorb, and has the advantages of that the processing period is greatly shortened, the energy consumption is reduced, the cost is lowered, and the storage is easy since microorganisms are killed.

Owner:BEIJING SHUOFANG SCI & TECH DEV CO LTD

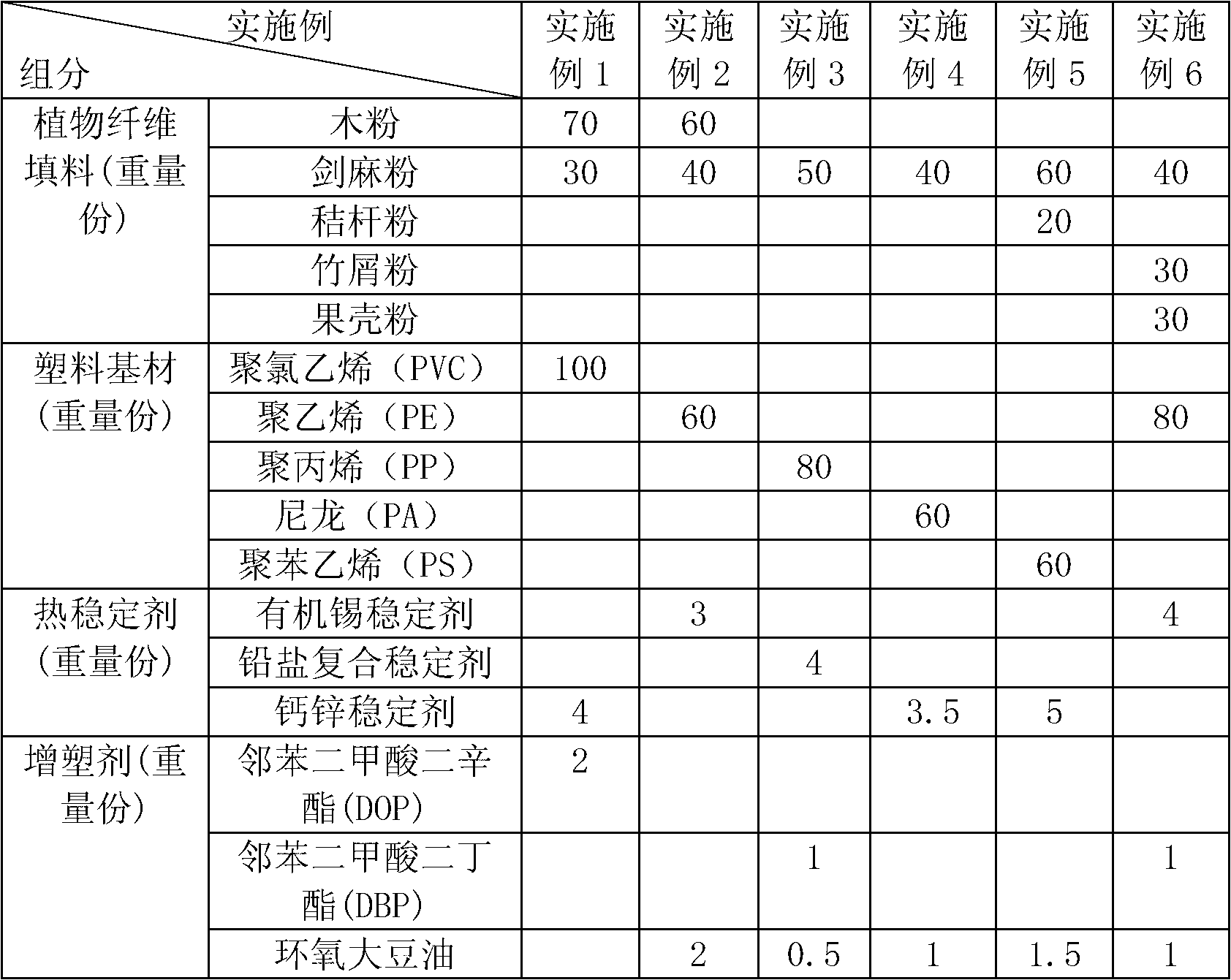

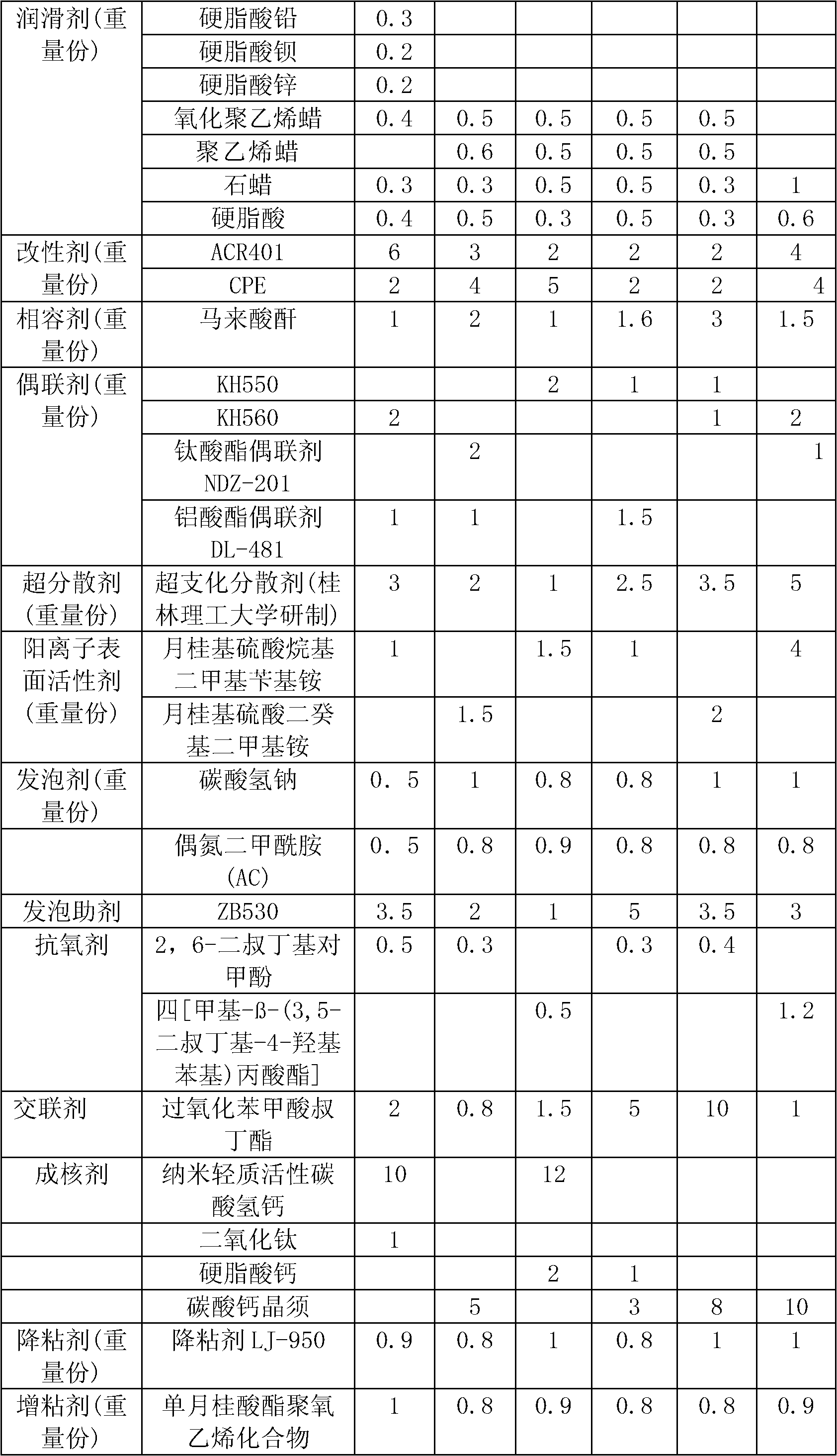

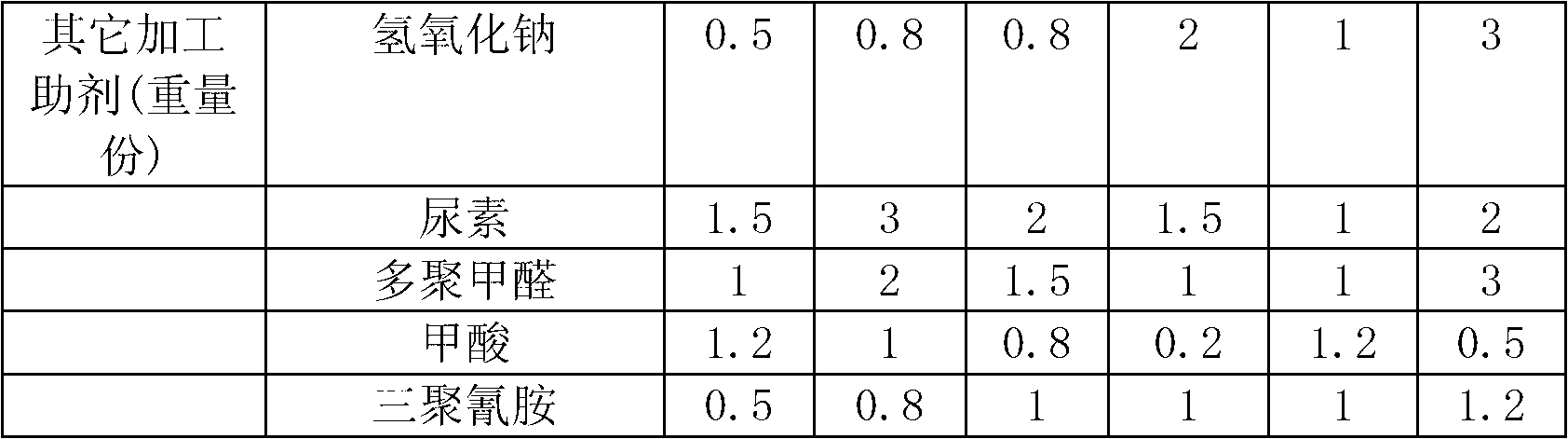

New macromolecule fiber composite material

The invention discloses a new macromolecule fiber composite material which is prepared by the following components in parts by weight, 40-100 parts of plant fiberfill, 60-100 parts of plastic base material, 3.5-5 parts of heat stabilizer, 1-2 parts of plasticizer, 1.6-2 parts of lubricating agent, 4-8 parts of modifying agent, 1-3 parts of compatilizer, 2-3 parts of coupling reagent, 1-5 parts of super dispersing agent, 1-4 parts of positive ion surface active agent, 1-1.8 parts of foaming agent, 1-5 parts of blowing promoter, 0.3-1.2 parts of antioxygen, 1-10 parts of cross-linking agent, 1-20 parts of nucleating agent, 0.8-1 part of viscosity reducer, 0.8-1 part of tackifier and 3.2-13.4 parts of other auxiliaries. The new composite material can not easily cause wet swelling and air shrinkage, and is low in expansibility and water absorbability, so that the prepared product has good stability.

Owner:GUILIN SHUKANG BUILDING MATERIAL

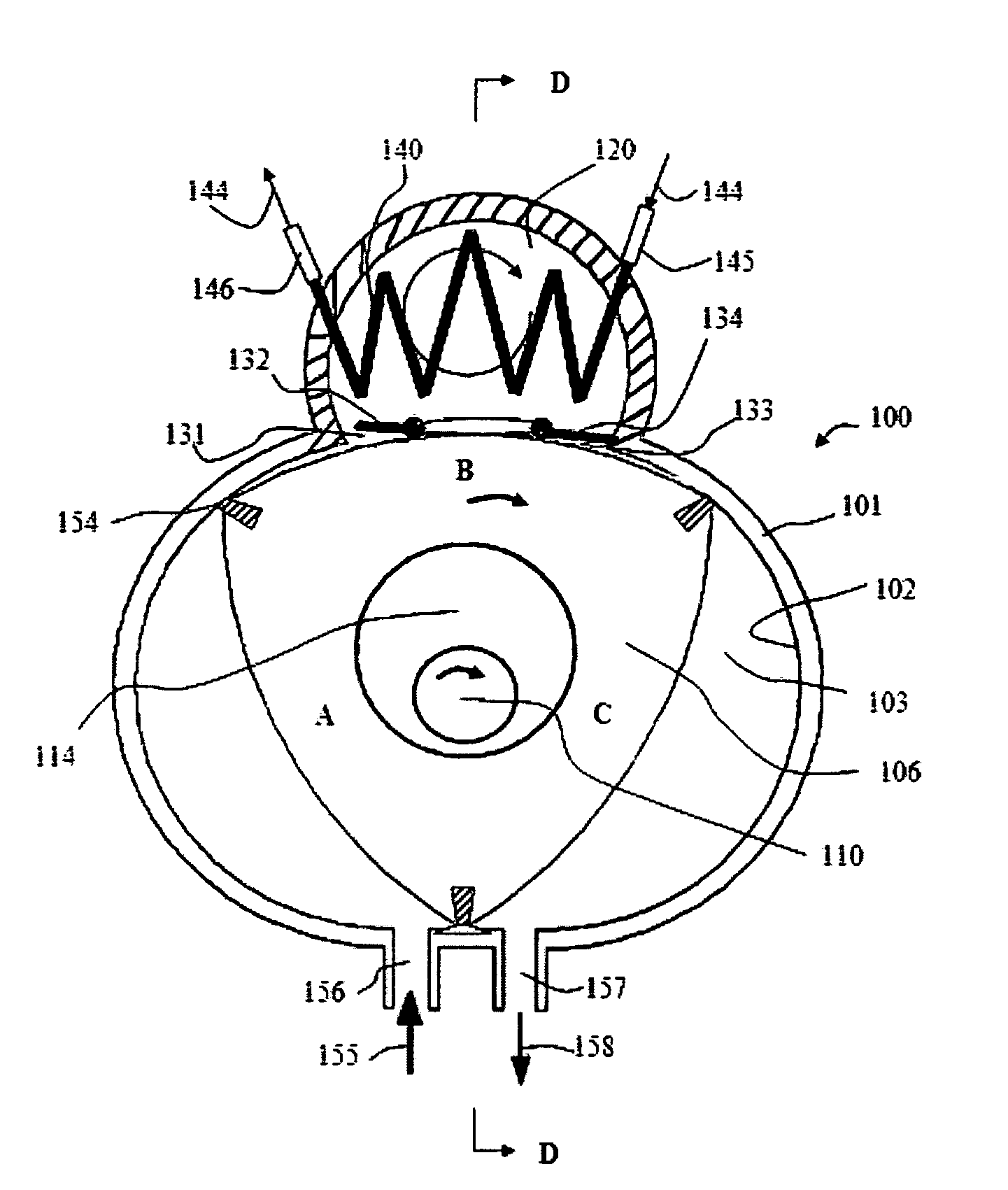

Cao heat engine and refrigerator

InactiveUS20100089062A1Increase the number ofExtended durationAuxillary drivesInternal combustion piston enginesThermal energyAir cycle machine

Owner:CAO YIDING

Leadless solder for electronic industry and preparation method

InactiveCN1927526AImprove printing effectEasy to remove the filmWelding/cutting media/materialsSoldering mediaRosinSolvent

The invention relates to a method for producing leadless soldering paste. Wherein, it is formed by 87-93% leadless tin solder powder and 7-13% welding flux; the leadless soldering powder is 25-45micrometer powder made from Cu, Ag, Ce, and Sn; the welding flux is formed by improved rosin, thixotropic agent, stabilizer, activator and solvent; first fusing the improved rosin, adding thixotropic agent, stabilizer, activator and solvent, to obtain welding flux; then mixing the leadless tin solder powder and welding flux in tin paste machine to be bottled. The invention has better protective property, less corrosion and high insulated property.

Owner:昆山成利焊锡制造有限公司

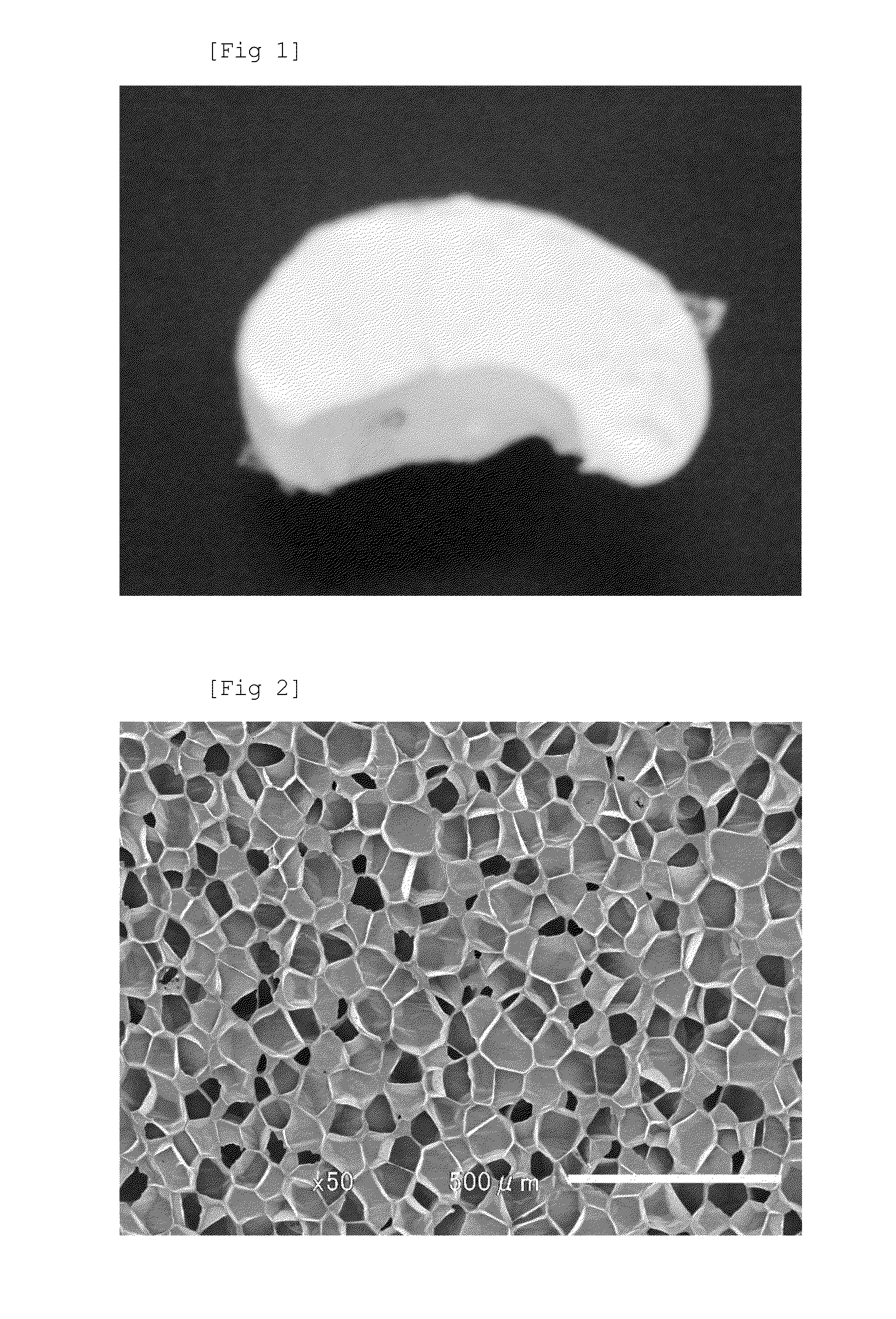

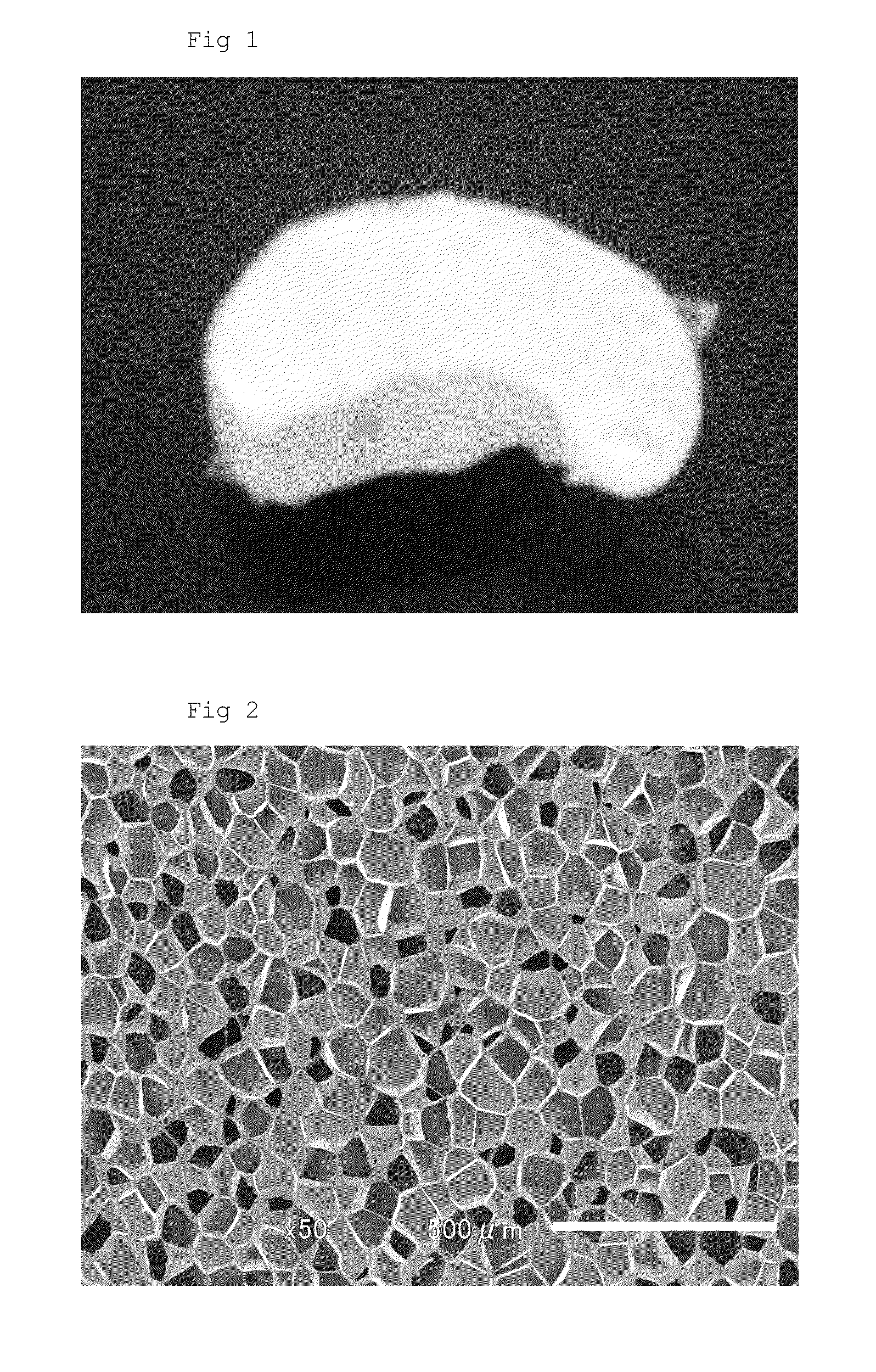

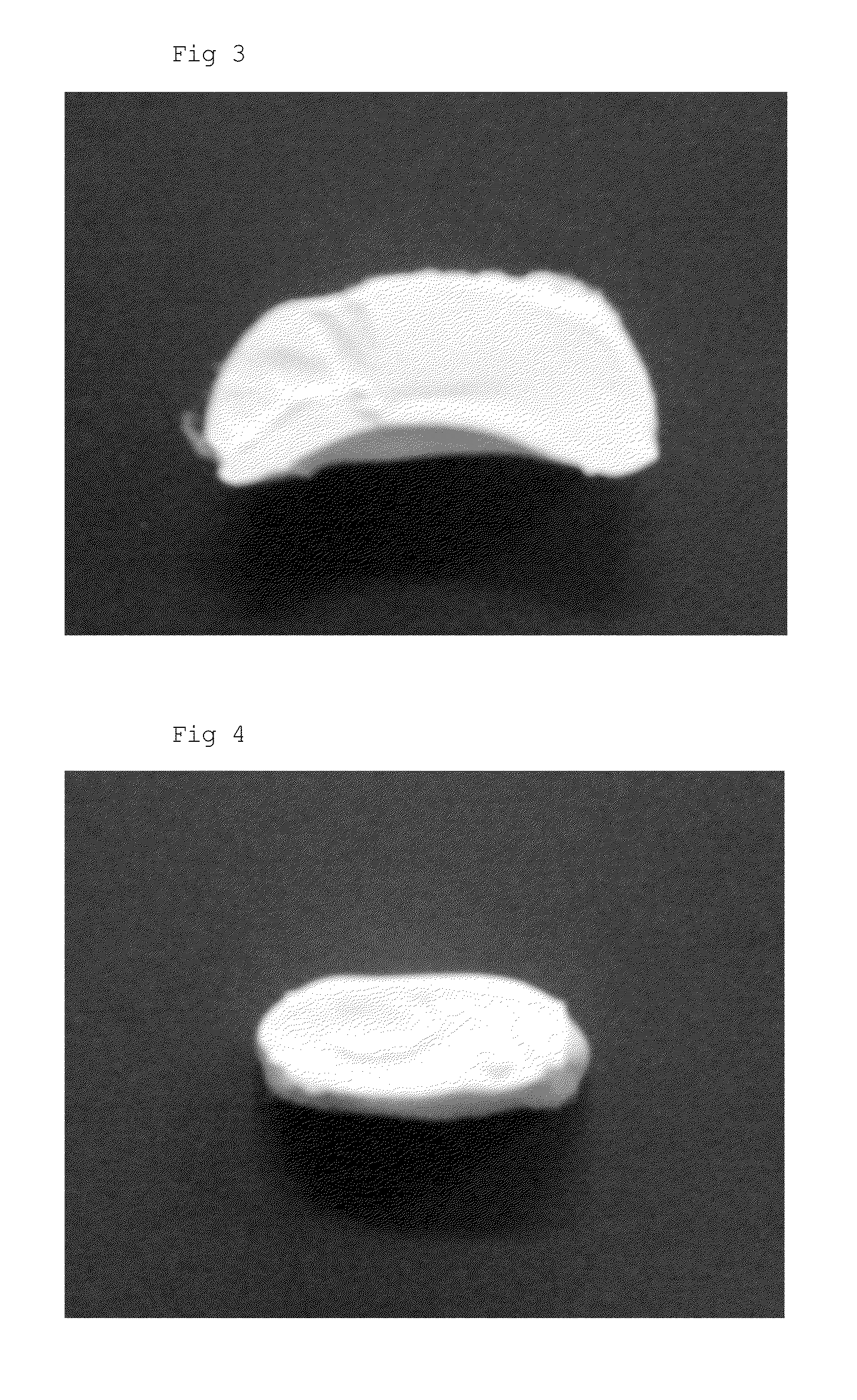

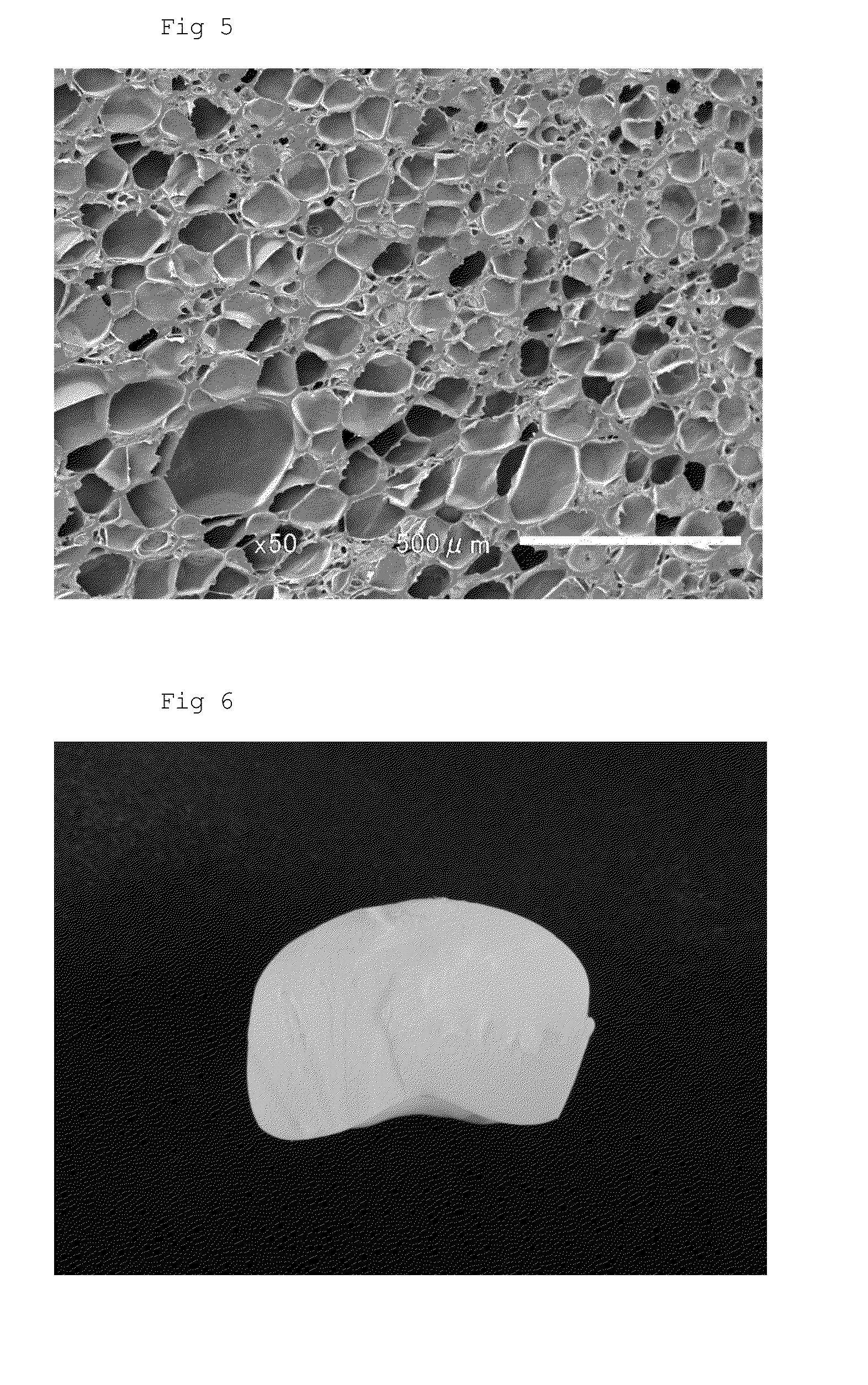

Propylene-based copolymer, propylene-based copolymer composition, molded product thereof and foamed product thereof, and production process therefor

ActiveUS20140088214A1Increase in melt tensionExcellent molding processabilityExpansion ratioVacuum forming

To provide a propylene-based copolymer and a propylene-based copolymer composition, each of which has a high melt tension because it has a long-chain branched structure, exhibits excellent molding processability during molding, such as inflation molding, extrusion molding, blow molding, injection molding or vacuum forming, and is capable of favorably providing a foamed product having an excellent expansion ratio and excellent cell uniformity in the foaming stage. The propylene-based copolymer (A) of the present invention comprises 50 to 95% by mol of constituent units [i] derived from propylene, 4.9 to 49.9% by mol of constituent units [ii] derived from an α-olefin of 2 to 10 carbon atoms other than propylene and 0.1 to 10% by mol of constituent units [iii] derived from a non-conjugated polyene (with the proviso that the total amount of the constituent units [i], [ii] and [iii] is 100% by mol), and is characterized by satisfying specific requirements (a) and (c).

Owner:MITSUI CHEM INC

Method for preparing quick frozen deep-fried puffy dough strips

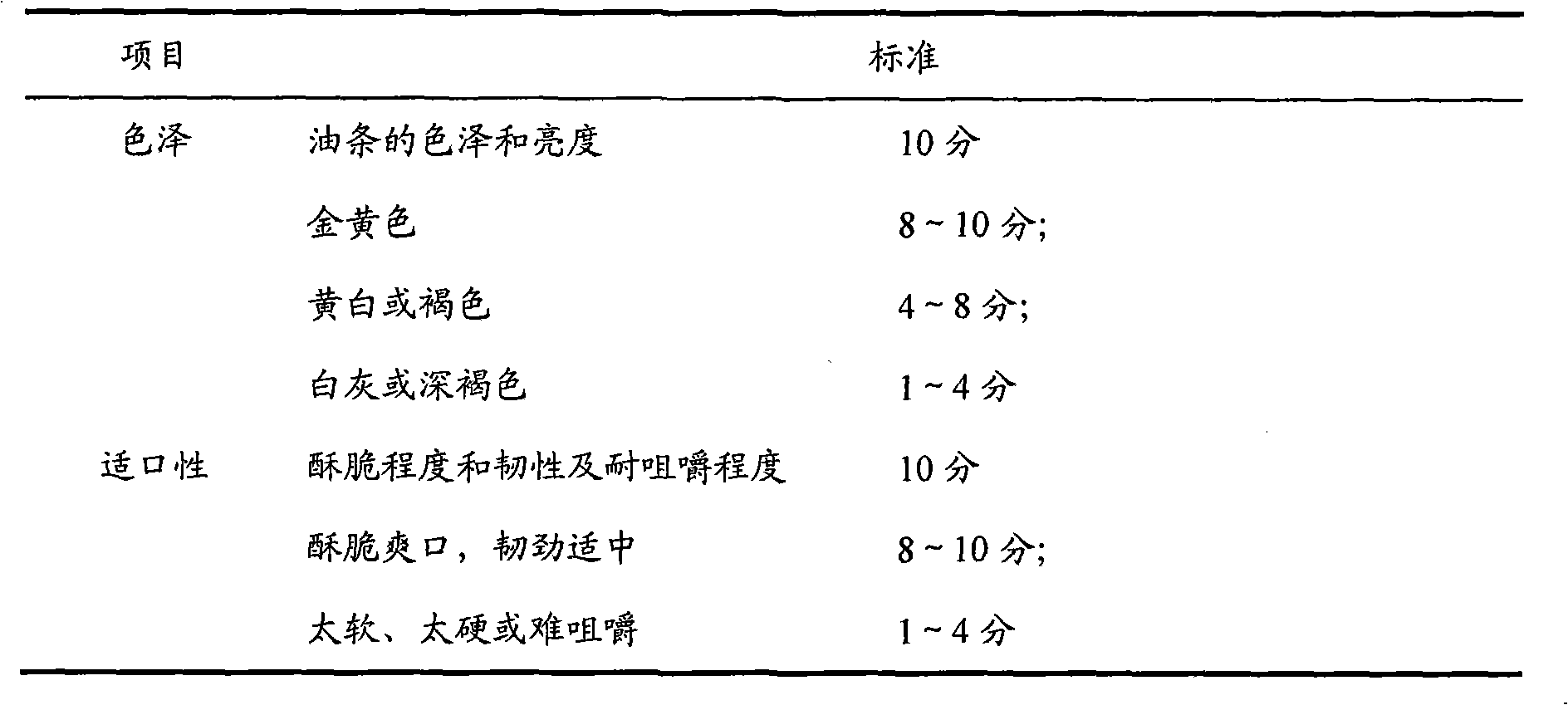

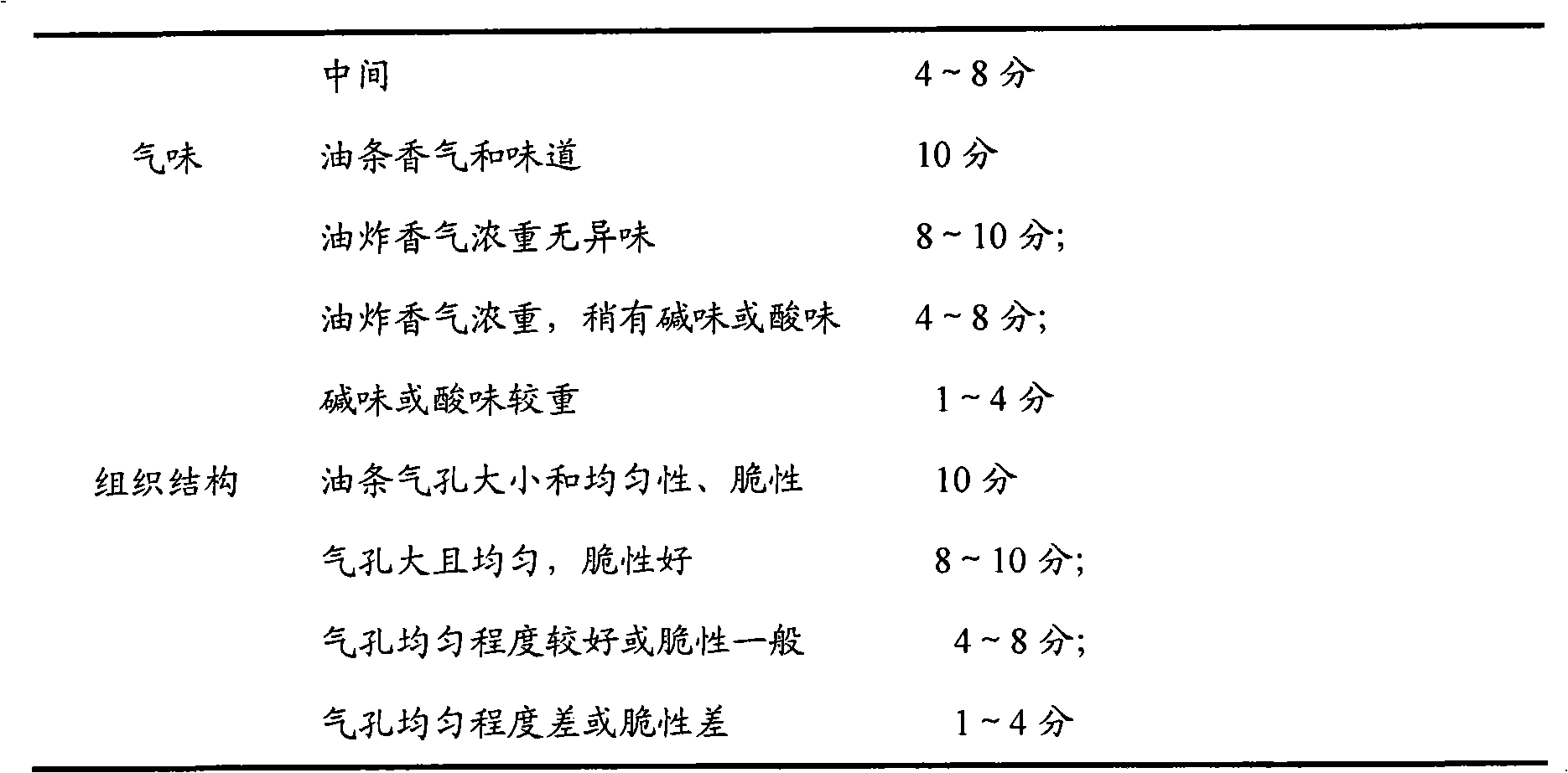

ActiveCN101816392AReduce usageImprove securityBakery productsFood preparationSodium bicarbonateAdditive ingredient

The invention relates to a method for preparing novel aluminum-free quick frozen deep-fried puffy dough strips. The method comprises the steps of: making dough by taking ingredients, such as gluconic acid-delta-lactone, calcium dihydrogen phosphate, sodium bicarbonate, glycerol monolaurate and the like, as a leavening agent and performing the processes of blanks making, frying, quick freezing and the like. Compared with the deep-fried puffy dough strips prepared by the traditional alums formula, the deep-fried puffy dough strips prepared by the method has the advantages that the evaluation result of sense organ is better, and the grease content is reduced by 9.7 percent, so that the process of the deep-fried puffy dough strips is simplified and convenient, the market is convenient to develop and the economic benefit is better.

Owner:JIANGNAN UNIV +2

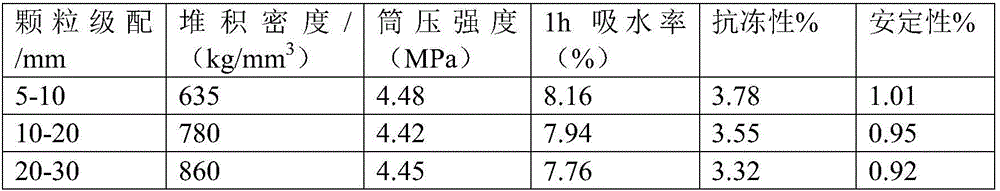

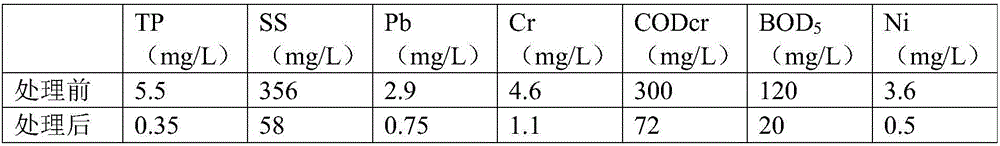

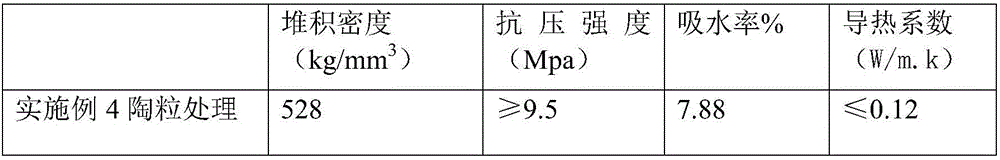

Porcelain granule produced by using river, lake and sea sludge and shellfish powder as raw materials and preparation method of porcelain granule

ActiveCN106495731AWide variety of sourcesConvenient sourceOther chemical processesSolid waste managementHazardous substanceAdditive ingredient

Owner:QINGDAO YI ECO ENVIRONMENTAL PROTECTION TECH CO LTD

Expandable Sleeve

InactiveUS20070089886A1ThinnerTendency is resistedFluid removalSealing/packingEngineeringMaterial Perforation

Owner:SCHLUMBERGER TECH CORP

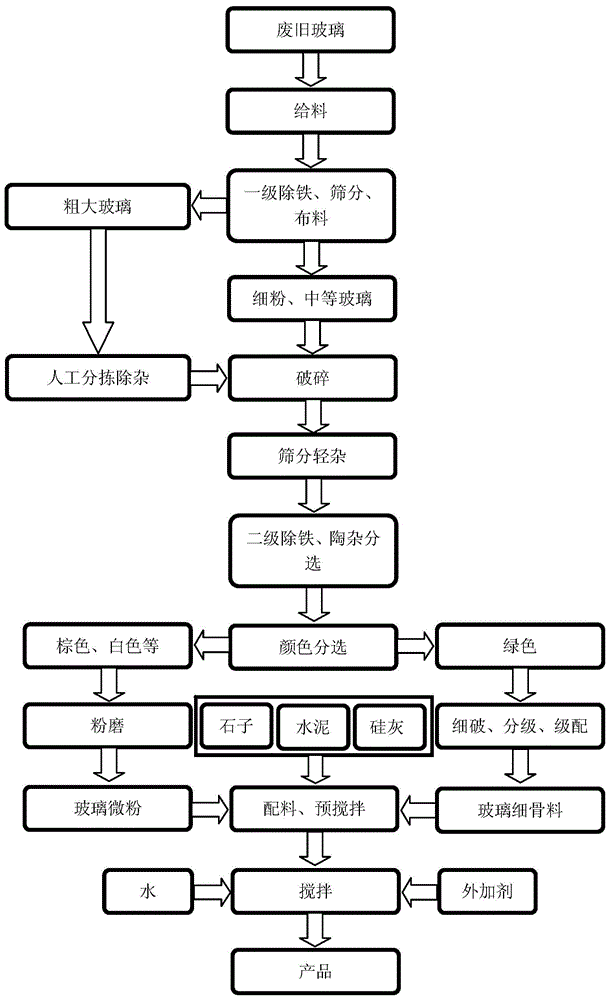

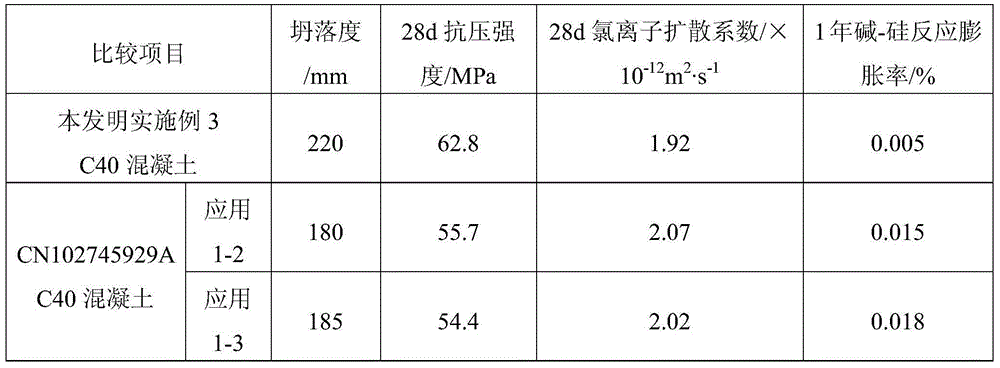

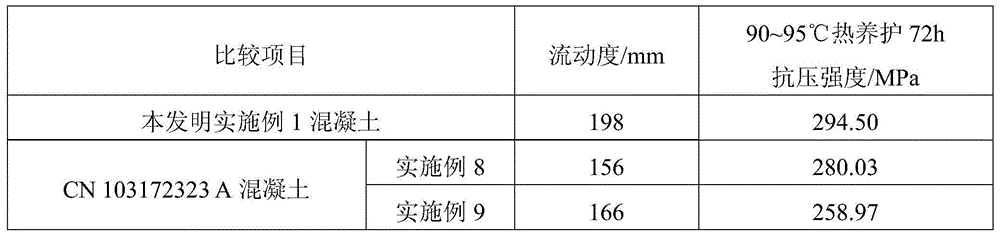

Concrete mainly prepared from waste glass and preparation method thereof

The invention discloses concrete mainly prepared from waste glass. The concrete is prepared from the following components in parts by weight: 10-30 parts of gel material, 30-40 parts of fine aggregate, 40-50 parts of coarse aggregate, 0.05-0.45 part of admixture and 3.8-16.5 parts of water, wherein the gel material comprises the following components in percentage by weight: 70-85wt% of cement, 10-20wt% of waste glass micropowder with the particle size being less than or equal to 30 micrometers and 5-10w% of silica dust; the fine aggregate is zone-II medium sand grading class waste glass powder, and the coarse aggregate is stones with the particle size being 5-16mm. The waste glass is utilized in the concrete to the maximum degree, and the cement has excellent compressive strength and mobility. The invention also provides a concrete preparation method.

Owner:北京元泰达环保科技有限公司

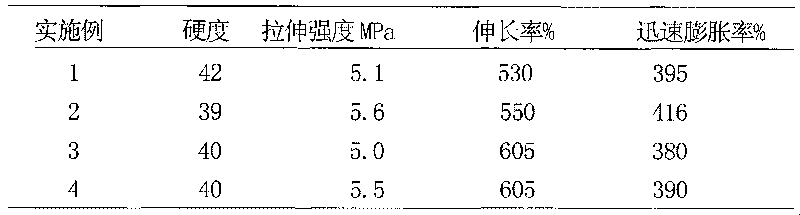

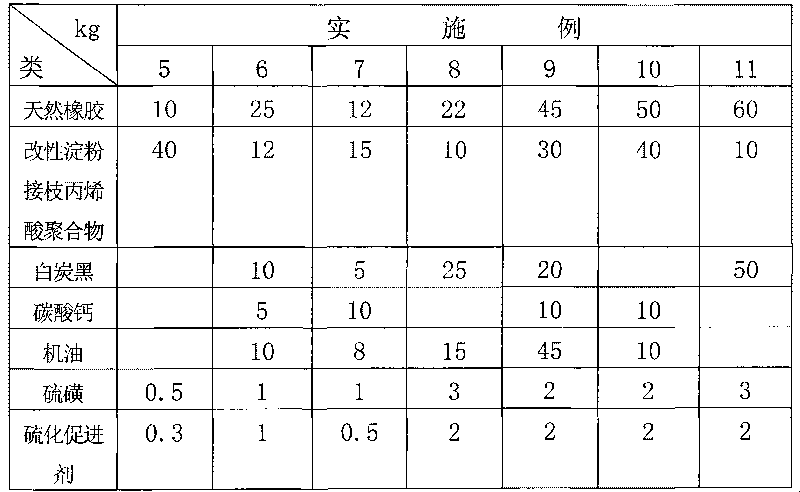

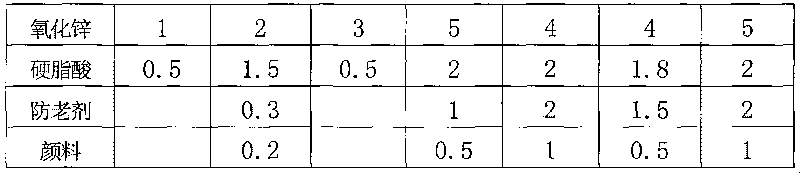

Preparation process of water swellable rubber

ActiveCN101759885ASolve the costSolve the technical problem of low expansion rateVulcanizationStearic acid

The invention relates to a preparation process of water swellable rubber which relates to the technical field of waterproof materials for concrete road and bridge building and is characterized rubbery being prepared by mixing, milling and vulcanizing natural rubber, a modified starch grafted acrylate copolymer and an additive, wherein raw materials are in the following parts by weight: 10-60 parts of natural rubber, 10-40 parts of modified starch grafted acrylate copolymer, 0.3-3 parts of sulfur, 1-2 parts of vulcanization accelerator, 1-5 parts of zinc oxide and 0.5-2 parts of stearic acid. The preparation process is simple and has unique principle; and a prepared product has better elasticity, strength and extensibility, particularly has water swelling property, higher swelling rate and good water preventing and stopping effects and simultaneously has corrosion resistance to organic solvents, such as acid, alkali, salt, oil and the like, superior aging resistant performance, no flow at high temperature, no embrittlement cracking at low temperature, long service life, convenient construction, lower cost, no toxicity, no pollution and wide application range.

Owner:衡水大禹工程橡塑科技开发有限公司

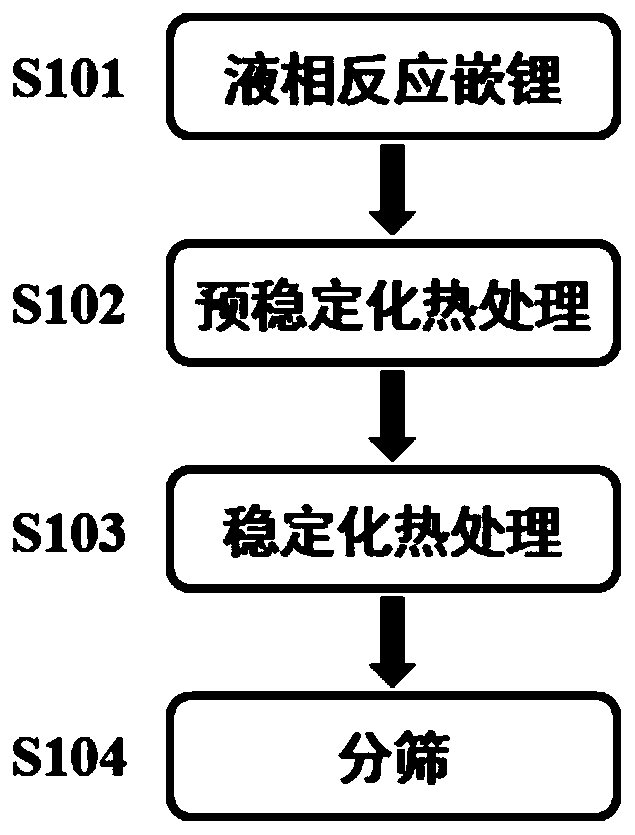

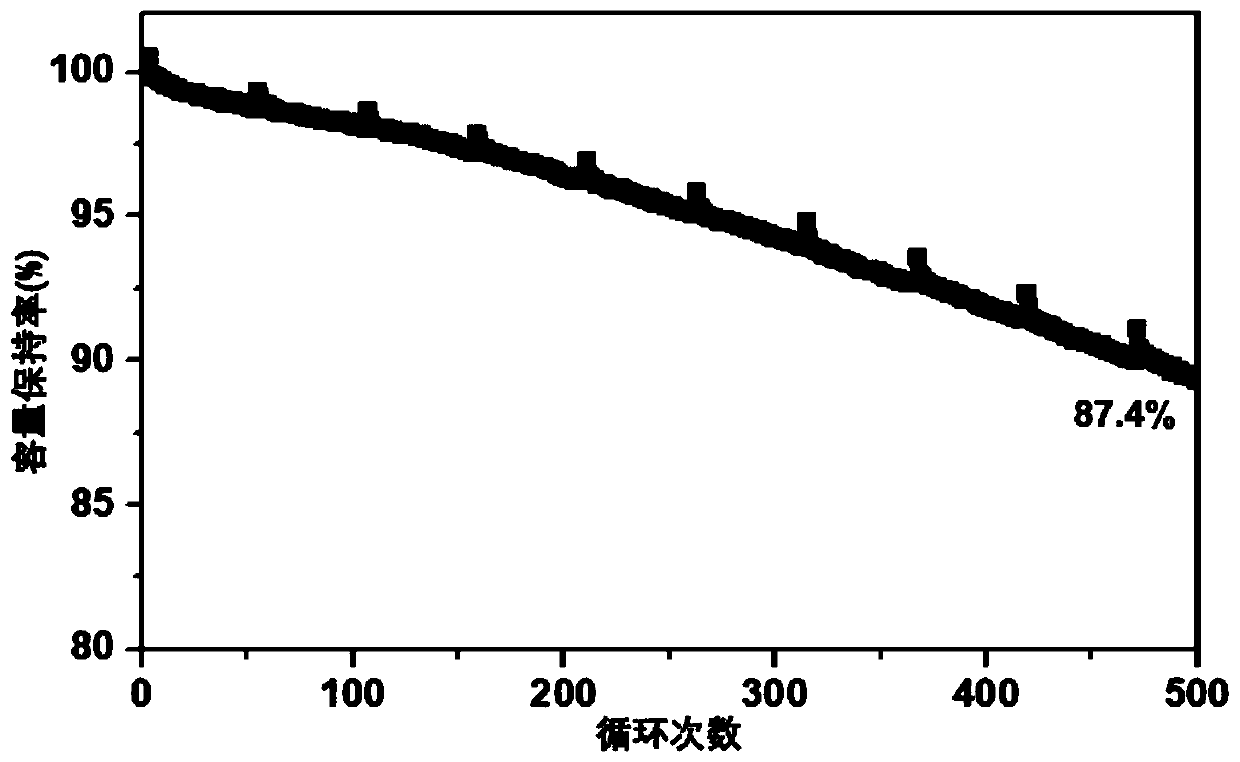

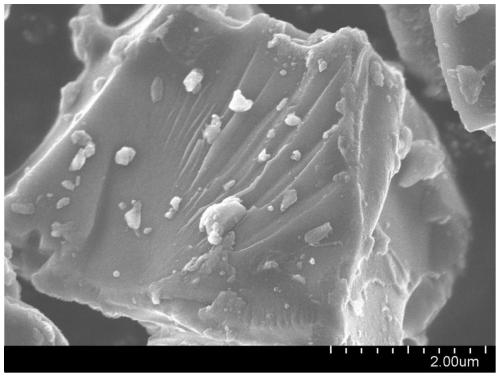

Anode active material and preparation method and application thereof

ActiveCN111180693AIncrease capacityImprove Coulombic efficiencyCell electrodesSecondary cellsPhysical chemistrySilicon oxide

The invention relates to an anode active material and a preparation method and application thereof. The anode active material includes: silicon oxide particles; and elemental silicon nanoparticles dispersed in the silicon oxide particles, wherein the median particle size of the monatomic silicon nanoparticles is 0.2-20 nm; the silicon oxide particles comprise lithium, the lithium in the silicon oxide particles comprises a lithium silicate compound, and the lithium silicate compound comprises one or more of Li2Si2O5, Li6Si2O7, Li2SiO3, Li8SiO6 and Li4SiO4. The anode active material disclosed bythe invention has the advantages of high capacity and coulombic efficiency, good multiplying power and cycle performance, the low expansion rate and the like when being used in a secondary battery. The preparation method is good in repeatability and high in safety. The secondary battery provided by the invention has the characteristics of high volume energy density, good rate capability, good cycling stability, low expansion rate and the like.

Owner:BERZELIUS (NANJING) CO LTD +1

High performance concrete expanding agent

The invention which relates to a high performance concrete expanding agent belongs to the technical field of expansive cement. The high performance concrete expanding agent is characterized in that the high performance concrete expanding agent comprises, by weight, 40-60 parts of waterless calcium sulfoaluminate, 20-40 parts of calcium sulfate and 10-25 parts of calcium oxide. The high performance concrete expanding agent has the advantages of high expansion energy, good stability, safety and reliability, simple preparation process, low production cost, excellent product performance and the like. The expansion rate of the high performance concrete expanding agent is in harmony with the strength development of concrete, so the expansion rate is fast, the expansion stabilization phase is early, and the expanding agent has good anti-crack anti-seepage functions, thereby the expanding agent is an ideal material for preparing high performance expansive concrete.

Owner:TIANJIN BAOMING BUILDING ENG MATERIAL

Process for combining flax enzyme and chemical degumming with bleaching

InactiveCN102703994AImprove hydrophilicityImprove the lubrication effectVegetable materialFibre treatment to obtain bast fibreYarnPhotochemistry

The invention discloses a process for combining flax enzyme and chemical degumming with bleaching. The process comprises the steps of flax filling and preliminary acid water washing; enzyme degumming; bleaching pre-treatment; water washing; oxidation bleaching; water washing; neutralization and water washing; dehydration; softening treatment; dehydration; and loosing for drying. The process improves the hydrophilicity and lubricity of fibers, enhances the whiteness and softness of fibers and greatly reduces the content of lignin in fibers, thereby enhancing the spinnability of fibers. The fibers treated by the process have the advantages of strong tension, softness, good fineness, weak electrical conductivity, rapid water absorption and diffusion, high expansivity and the like, and have the functions of temperature control, antianaphylaxis, antistativity and antibacterium, and the fibers can be spun into high and low yarns or blended with other fibers to make high-class cloth. The profit rate is about 50%, thereby creating good economic benefit..

Owner:芜湖金亚特亚麻科技有限公司

Iron-supply konjak full vegetable meat analogue and preparing method thereof

InactiveCN105815711AImprove dietPromote good healthLipidic food ingredientsFood ingredient functionsFructoseIron absorption

The invention relates to the field of food processing, in particular to an iron-supply konjak full vegetable meat analogue and a preparing method thereof. According to the iron-supply konjak full vegetable meat analogue and the preparing method thereof, konjak serves as a main material, textured soybean protein, vital gluten, starch and edible mushrooms serve as auxiliary materials, then food materials such as kelp, laver, longan and celery rich in iron element and plant extracts such as vitamins C and fructose which are capable of promoting iron absorption in the human body are added, and the full vegetable meat analogue with the iron-supply effect is prepared. The iron-supply konjak full vegetable meat analogue and the preparing method thereof have the advantages that meat food is replaced with vegetable protein, the dietary structure is improved, and body health is promoted; the konjak contains 10 or more amino acids and a plurality of microelements needed by the human body; iron element lacking caused when vegetable diet is eaten for a long time is replenished; as the vitamins C and the fructose are added, the absorbing effect of the human body on the iron elements can be effectively improved; nutrition arrangement is balanced, and the body health is facilitated.

Owner:FOSHAN JUCHENG BIOCHEM TECH RES & DEV CO LTD

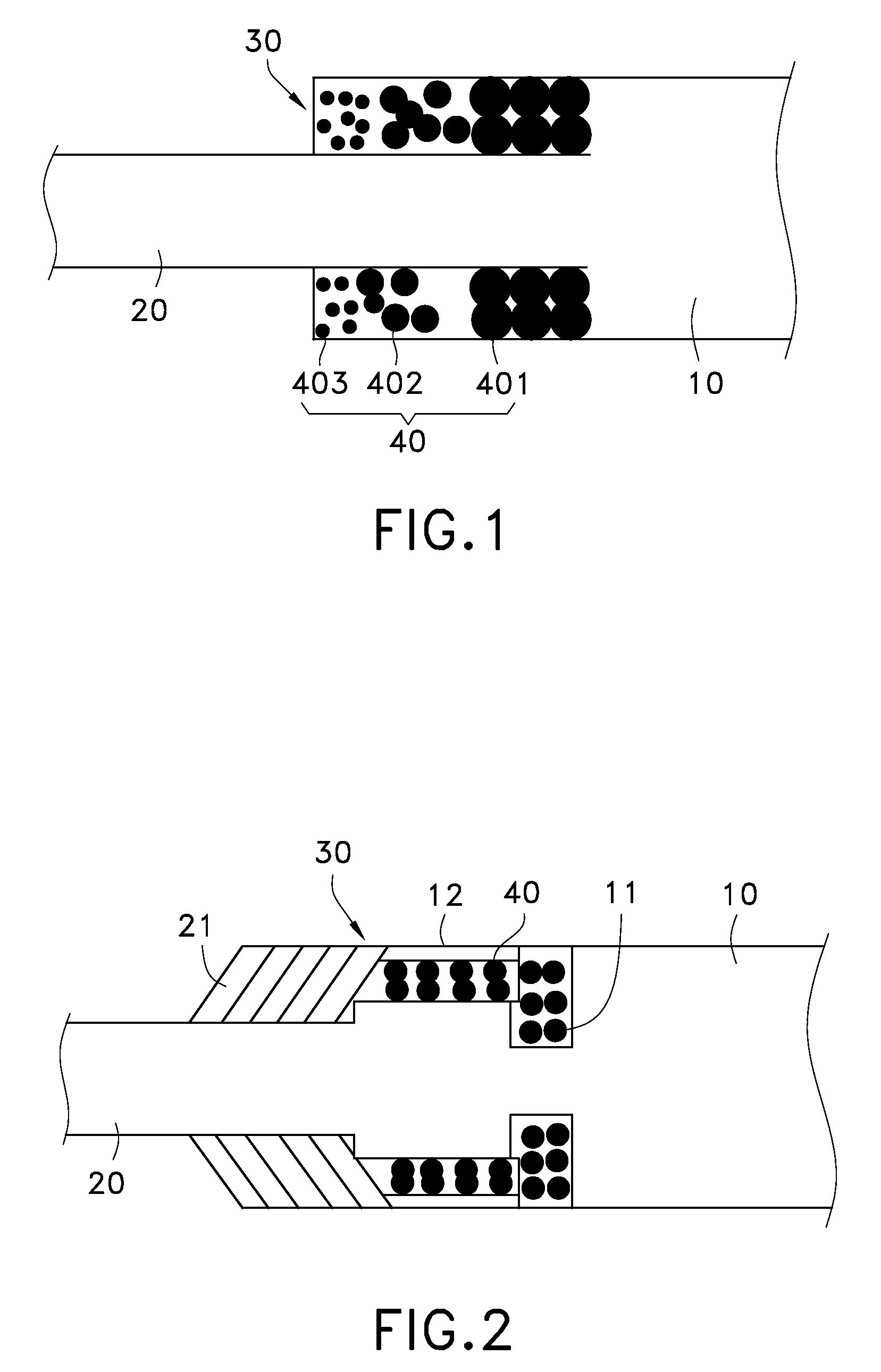

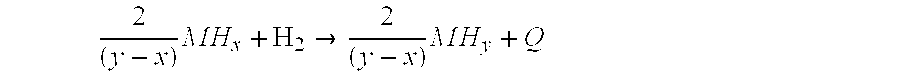

Method and apparatus of preventing gas leak in pipeline

InactiveUS20090091130A1Good expansion rateEffective compensationSleeve/socket jointsEngine sealsGas leakProcess engineering

This invention discloses a method and an apparatus of preventing a gas leak in a pipeline, and the characteristic of expansion occurred when a hydrogen storage material absorbs hydrogen gas is used for setting the hydrogen storage material in a joint between a first pipeline and a second pipeline, such that if hydrogen leaks at the joint, the hydrogen storage material will absorb hydrogen to expand, and the expansion pressure presses the joint to give a tighter connection, so as to achieve the effects of preventing and locking a leak, and compensating a deficiency of tightness due to an accumulated error occurred during the manufacture of the first pipeline and the second pipeline.

Owner:NAT CENT UNIV

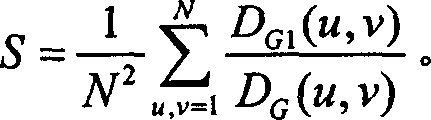

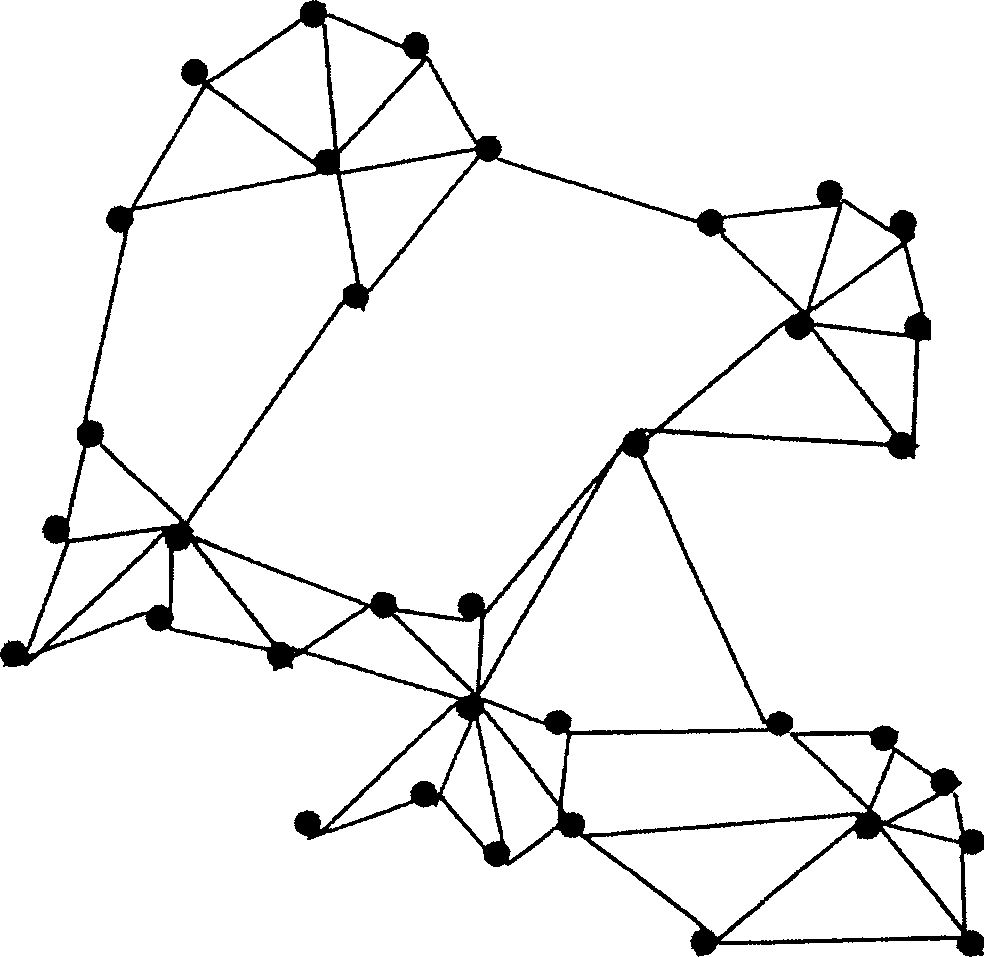

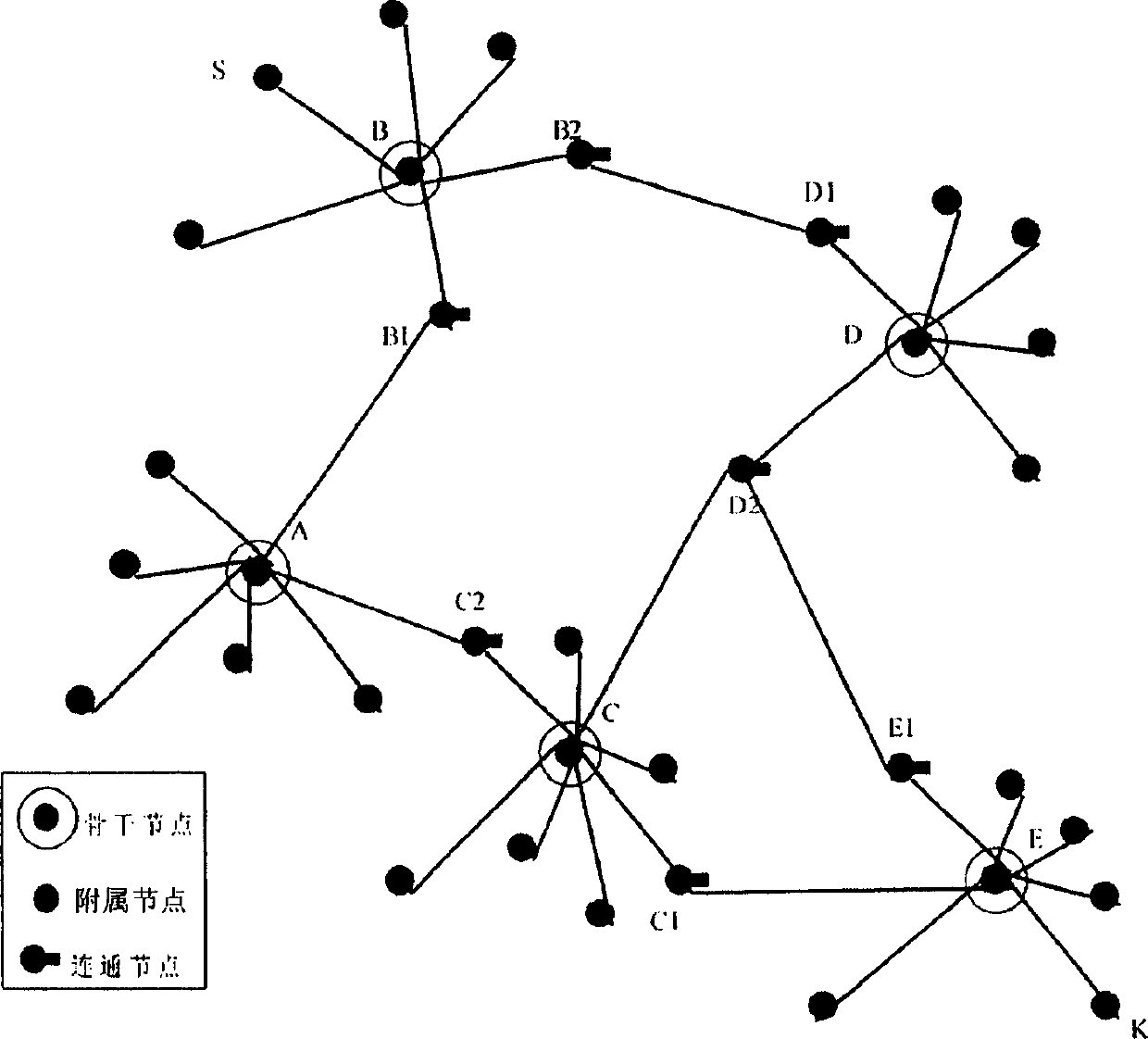

Method for building self-organized network skeleton structure

InactiveCN1738270AGood expansion rateImprove transmission efficiencyData switching by path configurationNetworked systemStructure of Management Information

The invention provides a construction method of self-organizing network main structure for realizing a self-organizing network with better rate of expansion, smaller size of main structure and less consumption of network system to improve the transmission efficiency and the property of network. The invention comprises: setting the type of start nodes of all nodes as initial nodes which send the status information pack periodically; setting all initial nodes as main nodes or auxiliary nodes according to the received status information pack of adjacent nodes; the auxiliary nodes receive the status information of adjacent nodes and send the 'adjacent nodes status information pack' periodically; the main codes generate and cooperate the auxiliary nodes to complete the arrangement of connected nodes according to the received 'adjacent nodes status information pack'; when said arrangement is completed, all the nodes of network adjust the type of nodes according to the received adjacent nodes status information pack in present period and the last period.

Owner:TSINGHUA UNIV +1

Selenium-rich ceramic appliance and preparation technology thereof

The invention relates to a selenium-rich ceramic appliance. A ceramic appliance body is fired from raw materials in parts by mass as follows: 30-50 parts of selenium-rich soil, 35-45 parts of petalite, 5-15 parts of spodumene, 1-15 parts of quartz, 10-15 parts of kaolin, 5-8 parts of microcrystalline ceramic powder, 1-3 parts of halloysite nanotubes, 0.5-1 part of nano tungsten carbide powder, 0.5-1 part of nano technetium oxide powder and 0.3-0.5 parts of polyacrylamide. The inner wall of the ceramic appliance body is coated with a selenium-containing coating. The selenium-rich ceramic appliance is prepared from main materials including cheaper petalite and selenium-rich soil, is coated with the selenium-rich coating, has good thermal shock resistance, crack resistance, wear resistance and heat conductivity and can separate out trace selenium element to supplement the human body with selenium.

Owner:JIANGXI JINGSHANG IND CO LTD

Propylene-based copolymer, propylene-based copolymer composition, molded product thereof and foamed product thereof, and production process therefor

To provide a propylene-based copolymer and a propylene-based copolymer composition, each of which has a high melt tension because it has a long-chain branched structure, exhibits excellent molding processability during molding, such as inflation molding, extrusion molding, blow molding, injection molding or vacuum forming, and is capable of favorably providing a foamed product having an excellent expansion ratio and excellent cell uniformity in the foaming stage. The propylene-based copolymer (A) of the present invention comprises 50 to 95% by mol of constituent units [i] derived from propylene, 4.9 to 49.9% by mol of constituent units [ii] derived from an α-olefin of 2 to 10 carbon atoms other than propylene and 0.1 to 10% by mol of constituent units [iii] derived from a non-conjugated polyene (with the proviso that the total amount of the constituent units [i], [ii] and [iii] is 100% by mol), and is characterized by satisfying specific requirements (a) and (c).

Owner:MITSUI CHEM INC

Petalite heat-resistant ceramic wok and preparation process thereof

ActiveCN108101525AIncrease productionImprove control effectCooking-vessel materialsCrack resistanceTalc

The invention relates to a petalite heat-resistant ceramic wok. The petalite heat-resistant ceramic wok is prepared by firing the following raw materials in parts by weight: 45 to 65 parts of petalite, 15 to 40 parts of spodumene, 12 to 20 parts of quartz, 15 to 20 parts of kaolin, 6 to 9 parts of talc, 5 to 8 parts of microcrystalline ceramic powder, 1 to 3 parts of halloysite nanotubes, 0.5 to 1part of nanometer tungsten carbide powder, 0.5 to 1 part of nanometer technetium oxide powder, 0.3 to 0.5 part of polyacrylamide. The petalite heat-resistant ceramic wok utilizes the cheaper petaliteas a main raw material, and the prepared petalite heat-resistant ceramic wok has good thermal shock resistance, good crack resistance, good wear resistance and good thermal conductivity.

Owner:JIANGXI JINGSHANG IND CO LTD

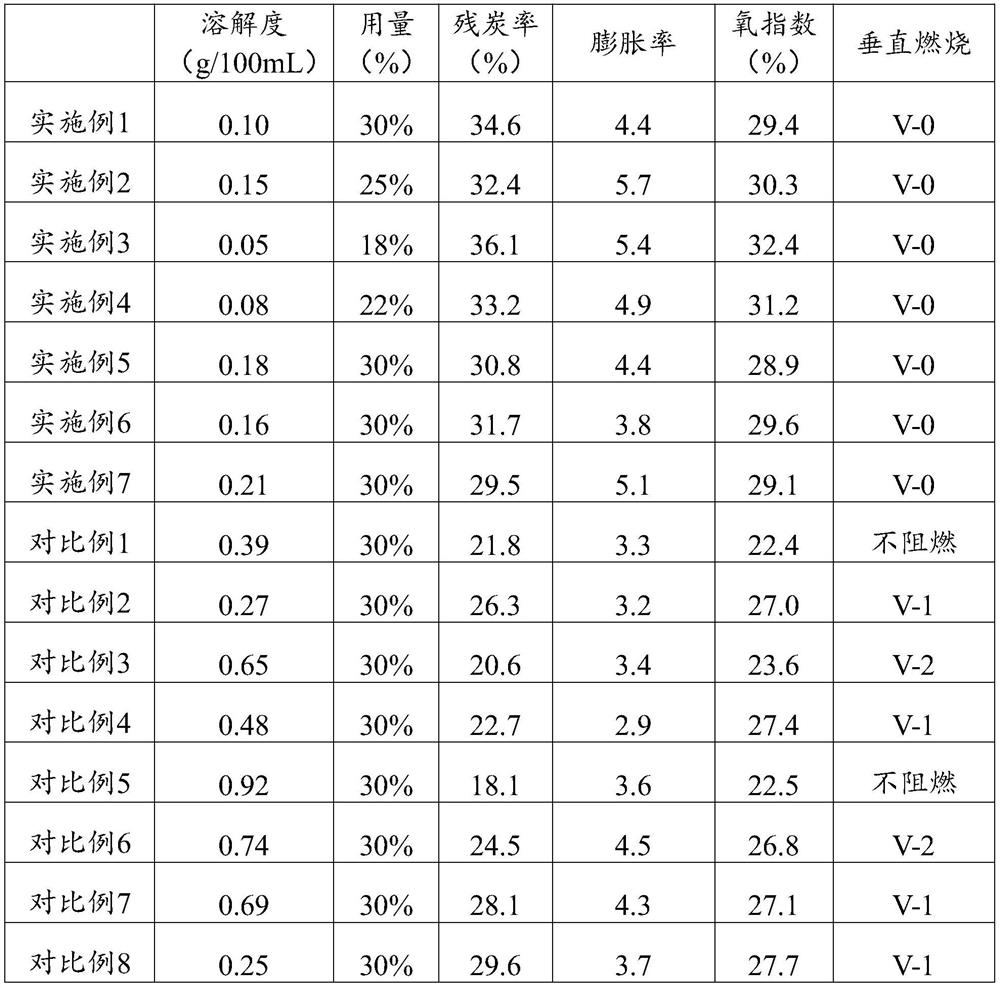

Modified ammonium polyphosphate composite intumescent flame retardant and preparation method and application thereof

The invention discloses a modified ammonium polyphosphate composite intumescent flame retardant and a preparation method and application thereof. According to the intumescent flame retardant, ammoniumpolyphosphate serves as a matrix, chitosan derivatives and phytic acid are used for coating and modifying the ammonium polyphosphate through electrostatic interaction, a chitosan derivative / phytic acid composite layer rich in carbon, nitrogen and phosphorus is formed on the surface of the ammonium polyphosphate, and the three-in-one composite intumescent flame retardant is formed. The modified ammonium polyphosphate composite intumescent flame retardant disclosed by the invention fully utilizes carbon-rich chitosan as a carbon source and phosphorus-rich phytic acid as an acid source to modifyammonium polyphosphate, so that the water resistance and the intumescent flame retardant efficiency of ammonium polyphosphate are improved, and the modified ammonium polyphosphate composite intumescent flame retardant is simple in preparation method, environment-friendly and good in flame retardant property, and can be used for flame retardance of polyolefin.

Owner:HUBEI ENG UNIV

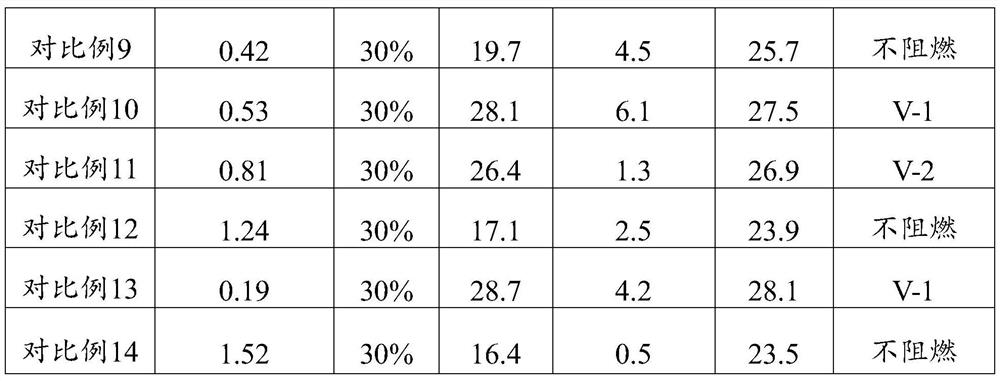

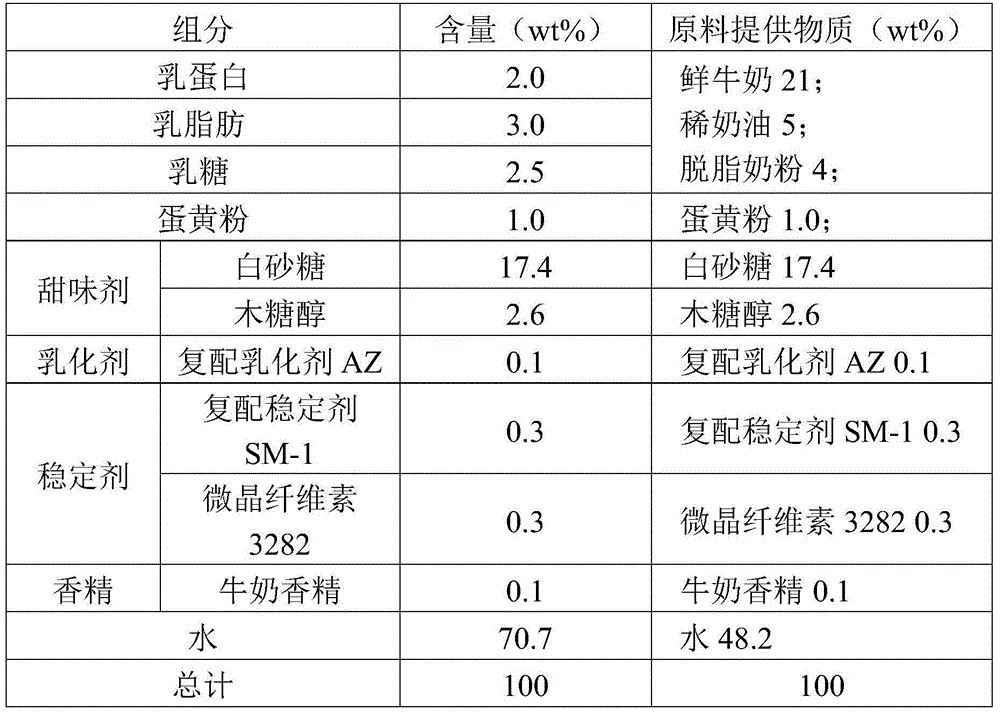

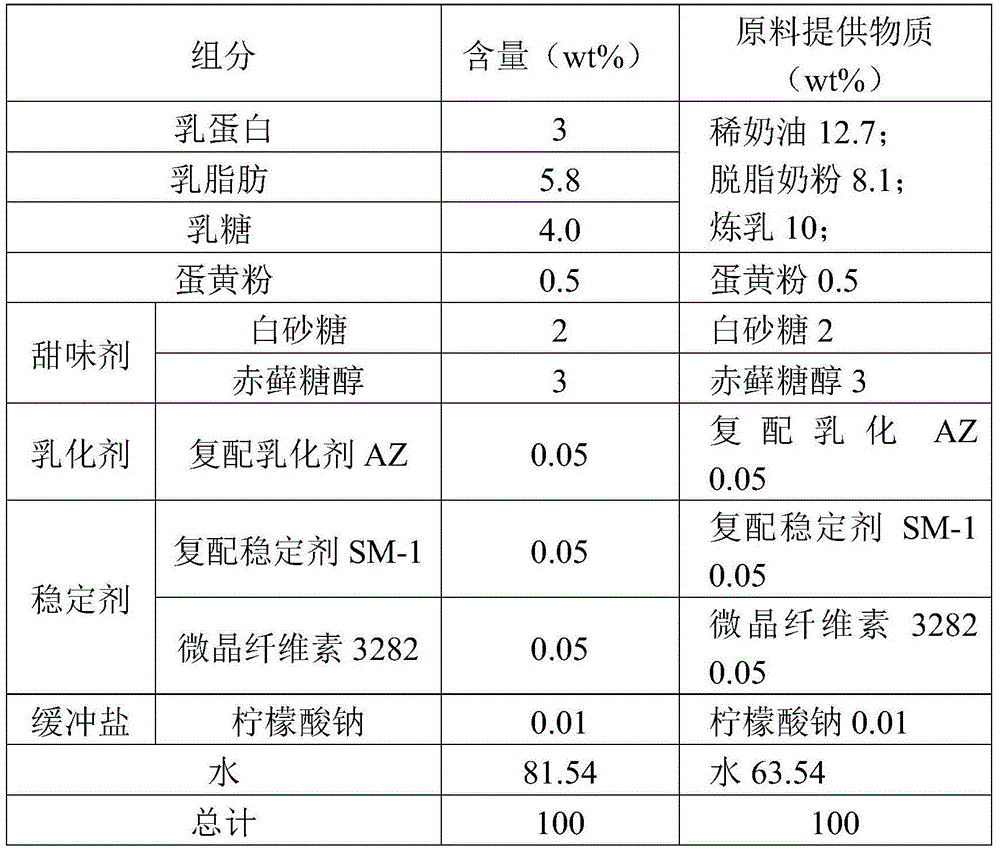

Ice cream milk paste and preparation method and soft ice cream thereof

The invention discloses an ice cream milk paste and a preparation method and a soft ice cream thereof. The ice cream milk paste comprises the following active ingredients in percentage by weight: 3-6% of milk fat, 2-3.5% of lactoprotein, 2.5-4.5% of lactose, 0.2-1.0% of yolk powder, 5-20% of sweetening agent, 0.05-0.5% of an emulsifying agent, and 0.05-0.6% of a stabilizer and water; the method comprises the following steps: (1) evenly mixing the yolk powder, sweetening agent and water, heating to 60-80DEG C, and then evenly mixing together with the emulsifying agent and the stabilizer to obtain a liquor A; (2) cooling to 30-63DEG C, then evenly mixing together with milk fat raw material, the lactoprotein raw material, the lactose raw material and water to obtain a liquor B, and controlling pH to be 6.5-6.8; and (3) performing scraper type ultrahigh-temperature instantaneous sterilization and sterile homogenization and cooling. The prepared ice cream milk paste is off-white color or faintly yellow, fine in mouth feeling, standout in flavor, and good in stability, and pipe blocking or pipe coking cannot be caused during preparation.

Owner:BRIGHT DAIRY & FOOD CO LTD

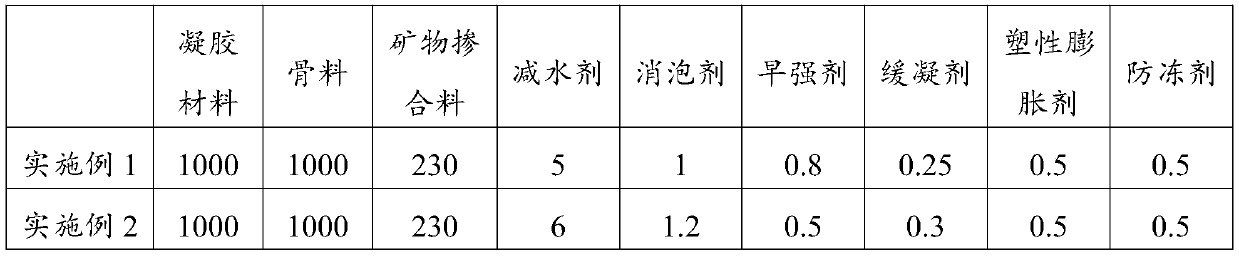

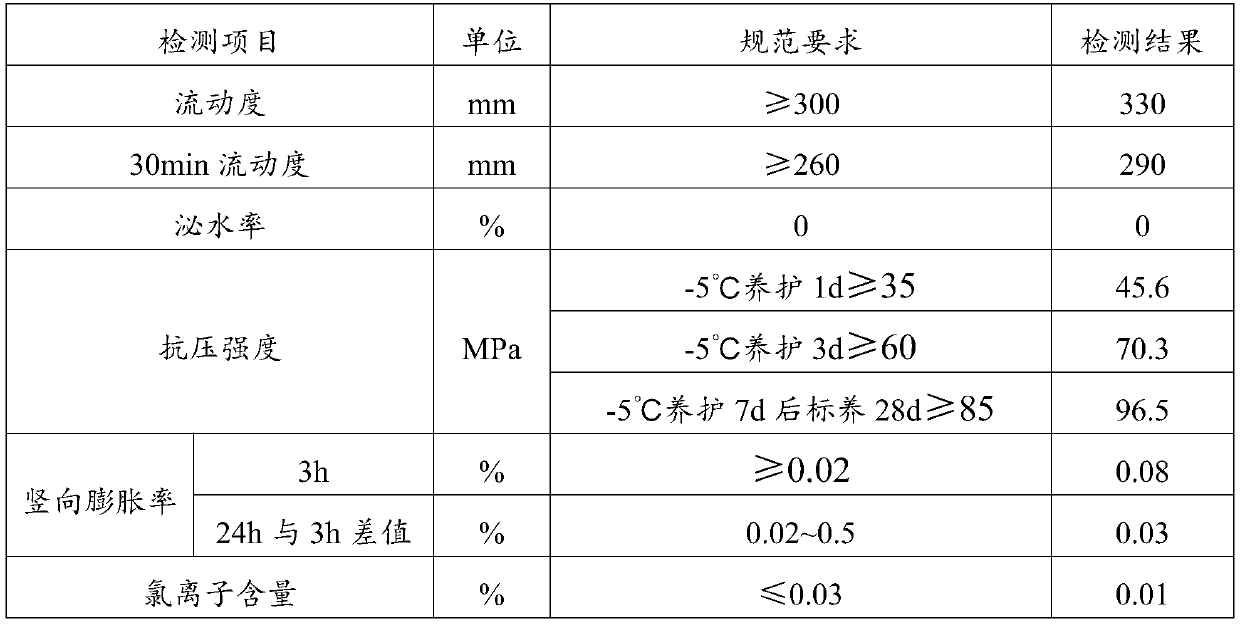

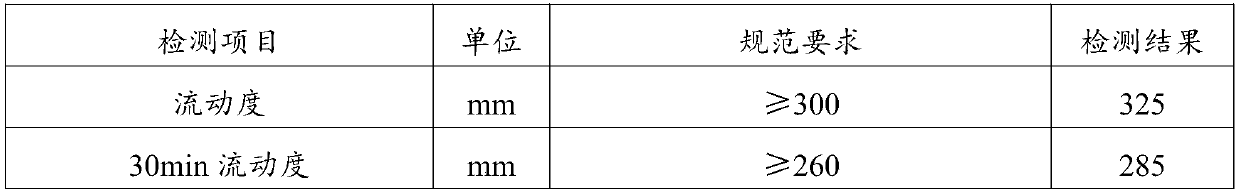

Grouting material for low-temperature steel bar sleeve connection and preparation method and application thereof

The invention belongs to the technical field of building materials, and particularly relates to a grouting material for low-temperature steel bar sleeve connection and a preparation method and application thereof. The grouting material comprises the following components in parts by mass: 100 parts of a gel material, 100 parts of aggregate, 22 to 25 parts of a mineral admixture, 0.5 to 0.8 parts ofa water reducing agent, 0.08 to 0.12 part of a defoaming agent, 0.05 to 0.08 parts of an early strength agent, 0.02 to 0.04 parts of a retarder, 0.03 to 0.05 parts of a plastic expanding agent and 0.05-0.15 parts of an antifreezing agent. Experimental results show that the grouting material for low-temperature steel bar sleeve connection is suitable for a construction environment at -5 DEG C to 10 DEG C, the fluidity reaches 330 mm, after construction and curing, the compressive strength reaches 96.5 MPa, the vertical expansion rate reaches 0.08% after 3 hours, and the strength and the expansion rate are good.

Owner:BEIJING MUNICIPAL ENG RES INST +2

Spicy ice cream or popsicle and preparation method thereof

The present invention discloses a spicy ice cream or a popsicle and a preparation method thereof. Peppers are added into the raw materials of the ice cream, then several specific colloids and several accessory materials are added, and the raw material adding orders are selected in the preparation technology. The prepared spicy ice cream or the popsicle is unique in flavor, good in expansion and melting rates, and high in nutritional value.

Owner:胡方芽

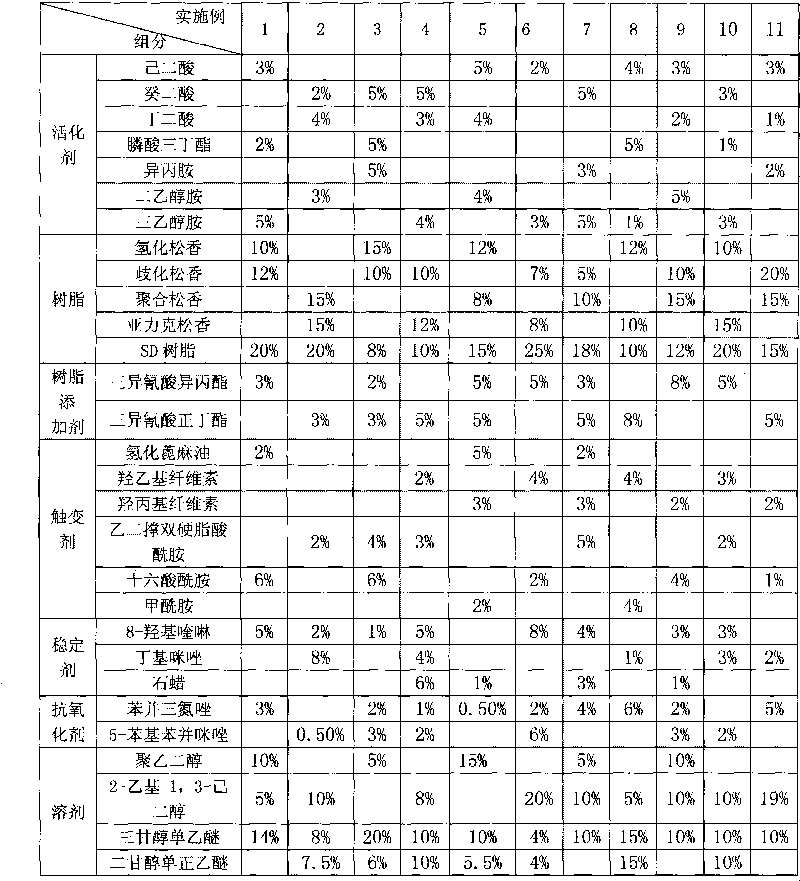

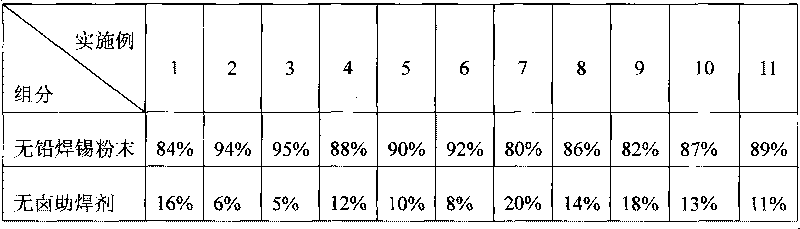

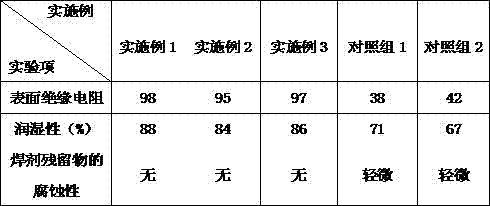

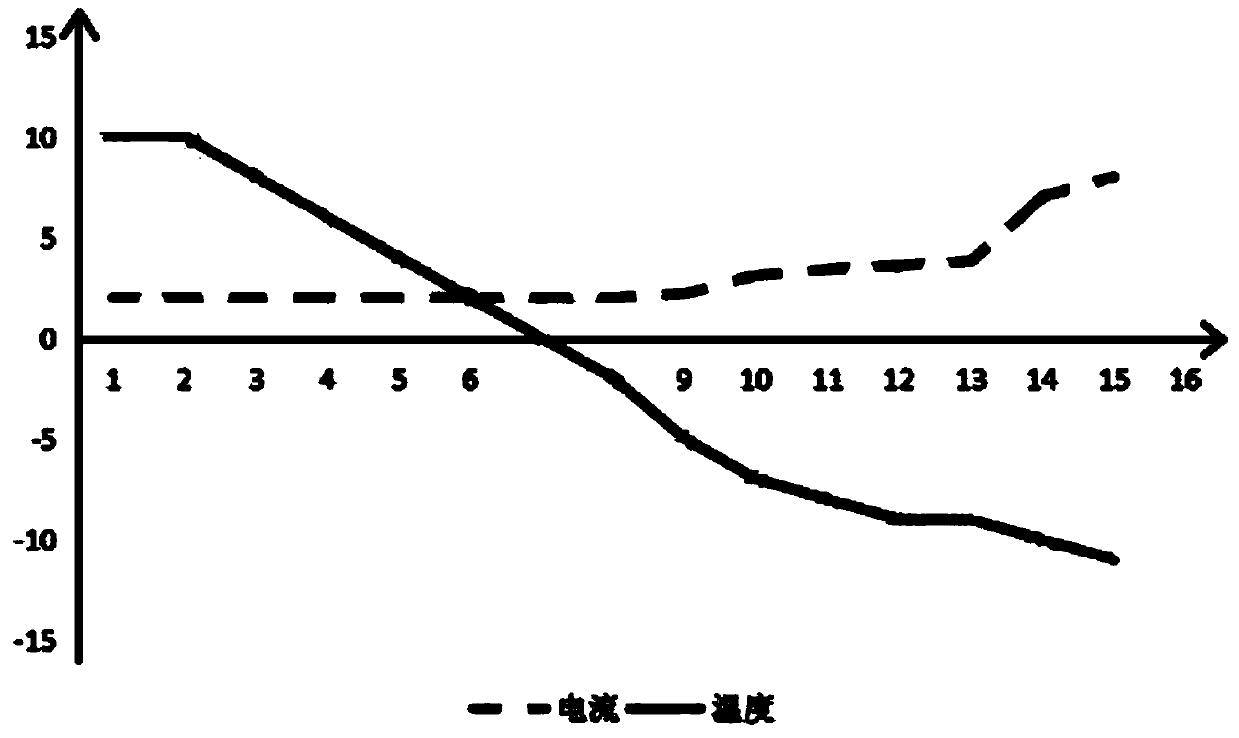

Lead-free and halogen-free environmental soldering paste for electronic industry

ActiveCN101733573AAdapt to the needs of different welding temperaturesLess corrosiveWelding/cutting media/materialsSoldering mediaSolventSolder paste

The invention discloses a lead-free and halogen-free environmental soldering paste for the electronic industry. The soldering paste comprises 80wt%-95wt% of lead-free soldering tin powder and 5wt%-20wt% of halogen-free soldering flux, wherein the halogen-free soldering flux comprises 5wt%-15wt% of activator, 32wt%-50wt% of resin, 3wt%-10wt % of resin additive, 2wt%-10wt% of thixotropic agent, 1wt%-15wt% of stabilizer, 0.5wt%-8wt% of antioxidant and the balance solvent; the activator adopts the salt prepared from organic acid and amine to replace traditional halogen salt and adopts phenolic modified rosin ester and triisocyanate to replace part of traditional resin which is largely used, the lead-free and halogen-free environmental soldering paste for the electronic industry does not contain lead and halogen, is safe and environmentally friendly and has good welding performance, electrical performance, printing performance and storability.

Owner:惠州市成利工业有限公司

Solder paste for signal processing substrate and preparation method thereof

ActiveCN105397343AModerate viscosityExtended shelf lifeWelding/cutting media/materialsSoldering mediaIndiumPolyethylene glycol

The invention discloses a solder paste for a signal processing substrate and a preparation method thereof. The method comprises the following steps: 1) mixing Sn-Zn alloy, copper, indium, chloroauric acid hydrated, polyvinylpyrrolidone, a reducing agent and water to enable contact reaction so as to obtain an activating metal composition; 2) heating and dissolve rosin, rosin amine, organic acid, imidazole and tris(2-carboxyethyl) isocyanurate to obtain mixed liquor I; 3) mixing the mixed liquor I, a thixotropic agent and a preservative, and then cooling to obtain mixed liquor II; 4) mixing the mixed liquor II and polyethylene glycol to obtain a soldering flux; 5) refrigerating the soldering flux, and then performing dispersion mixing for the soldering flux and the activating metal composition under a vacuum condition and in the presence of X-rays, so as to obtain the solder paste for the signal processing substrate. The solder paste prepared by the preparation method is outstanding in chemical stability, low in welding temperature, and outstanding in expansion rate.

Owner:芜湖雅葆轩电子科技股份有限公司

No-clean lead-free solder scaling powder and preparation method thereof

InactiveCN107186387AImprove wetting abilityImprove solderabilityWelding/cutting media/materialsSoldering mediaAntioxidantRaw material

The invention discloses no-clean lead-free solder scaling powder. The scaling powder comprises the following raw materials in parts by weight: 10-30 parts of special-grade rosin resin, 2-8 parts of an organic acid activating agent, 0.5-5 parts of a nonionic surfactant, 0.1-2 parts of an antioxidant, 0.1-1.5 parts of a wetting enhancer, 0.05-0.5 part of a corrosion inhibitor and 75-85 parts of an organic solvent. A preparation method comprises the following steps: weighing the various raw materials in parts by weight, placing the raw materials in a stirrer, and blending the raw materials to obtain a mixture; and heating and stirring the mixture, and leaving the mixture standstill for 3-5 hours after the temperature of the mixture reaches the room temperature to obtain the no-clean lead-free solder scaling powder. The no-clean lead-free solder scaling powder has high wetting ability to lead-free solder; the weldability of the lead-free solder can be improved; the no-clean lead-free solder scaling powder can adapt to welding temperatures of various lead-free solders and does not corrode lead-free solder alloy; and after welding, the number of residues is small, the insulation resistance is high, the lead-free solder does not need to be cleaned, and therefore, the no-clean lead-free solder scaling powder is perfect for the lead-free solder.

Owner:合肥市闵葵电力工程有限公司

Taste maintenance method for ice cream machine

PendingCN109938153AGreat tasteExtension of timeFrozen sweetsProgramme control in sequence/logic controllersLower limitAll solid state

The invention discloses a taste maintenance method for an ice cream machine. The ice cream machine is provided with a freezing cylinder, a stirring device, a main refrigeration system and a control system. When ice cream materials in the freezing cylinder stay in a forming solid state stage, the control system controls the ice cream machine to stay in a taste maintaining state, wherein the formingsolid state stage refers to the stage when all the ice cream materials in the freezing cylinder are converted into all-solid-state ice creams until the preset hardness or a preset viscosity value isreached; the taste maintaining state refers to the state in which the main refrigeration system conducts refrigeration on the ice cream materials in the freezing cylinder at a refrigerating capacity approximate to a lower limit refrigerating capacity; moreover, the ice cream machine can discharge the all-solid-state ice creams in the freezing cylinder in the taste maintaining state. According to the taste maintenance method for the ice cream machine, the time for the ice creams in the freezing cylinder to stay in the forming solid state stage can be prolonged so that the ice creams in the freezing cylinder can maintain a better taste state for a longer period of time, and that is to say that the hardness or the viscosity and the expansion ratio are high.

Owner:ZHONGSHEN TECH (GUANGDONG) CO LTD

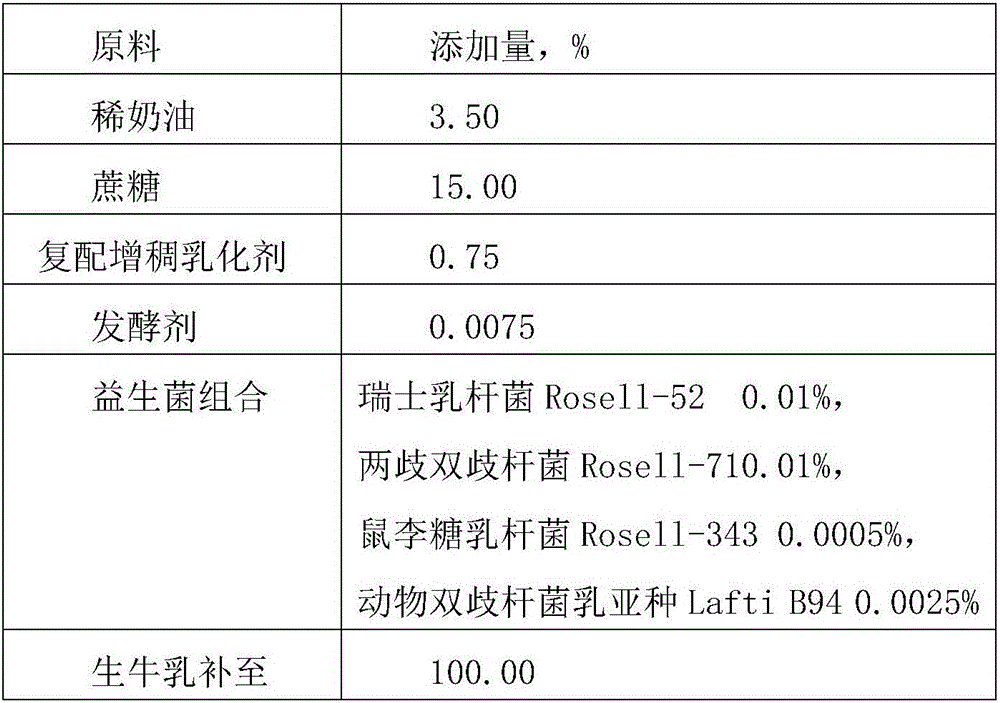

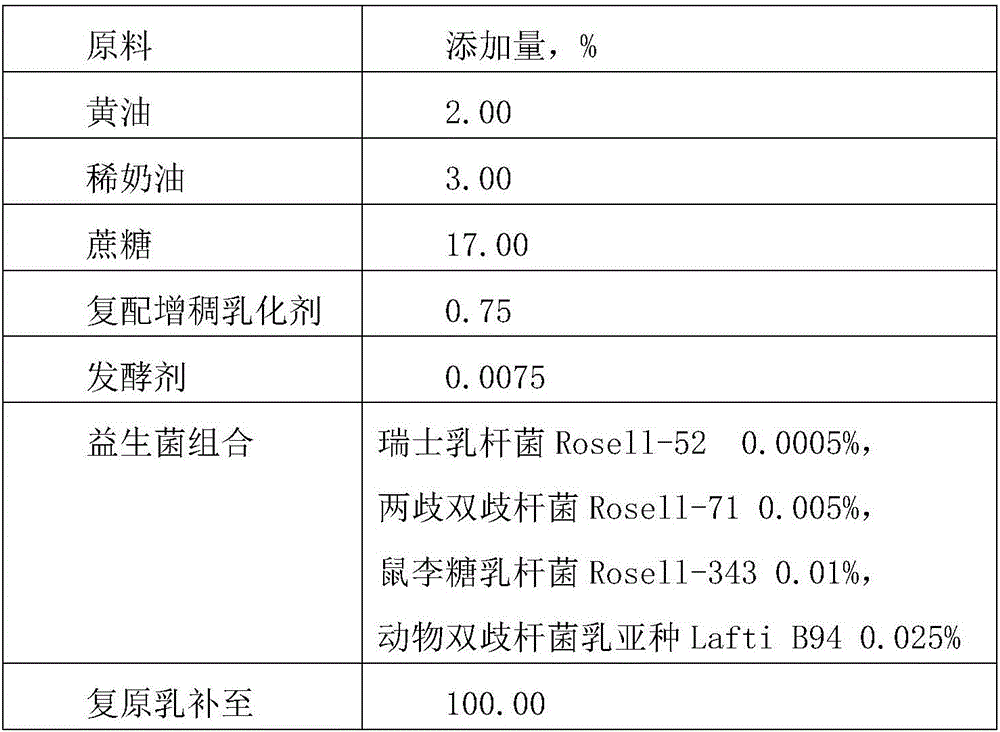

Fermented yoghourt soft ice cream milk sauce containing various probiotics, and production method of milk slurry

InactiveCN106359592AFine and even textureEntrance smoothMilk preparationFrozen sweetsSlurrySweetness

The invention discloses a fermented yoghourt soft ice cream milk sauce containing various probiotics. The milk sauce comprises, by mass, 70-85% of raw milk or reconstituted milk, 10-30% of a sweetener, 0.3-1.2% of a compounded thickening emulsifier, 0-5% of oil, 0-10% of a dairy product raw material, 0.005-0.02% of a starter and 0.0085-0.065% of probiotics, and the sum of the mass percentages of all above raw materials is 100%. The invention also discloses a production method of the milk sauce. The shelf life of the milk sauce stored at 4-10 DEG C can reach 21 d; the shelf life of the milk sauce stored in a refrigeration manner can reach 12 months; and ice cream obtained by using the milk sauce has the advantages of smooth and fine texture, smooth mouthfeel, and sour-sweet and tasty taste.

Owner:XUZHOU YITONG FOOD IND CO LTD

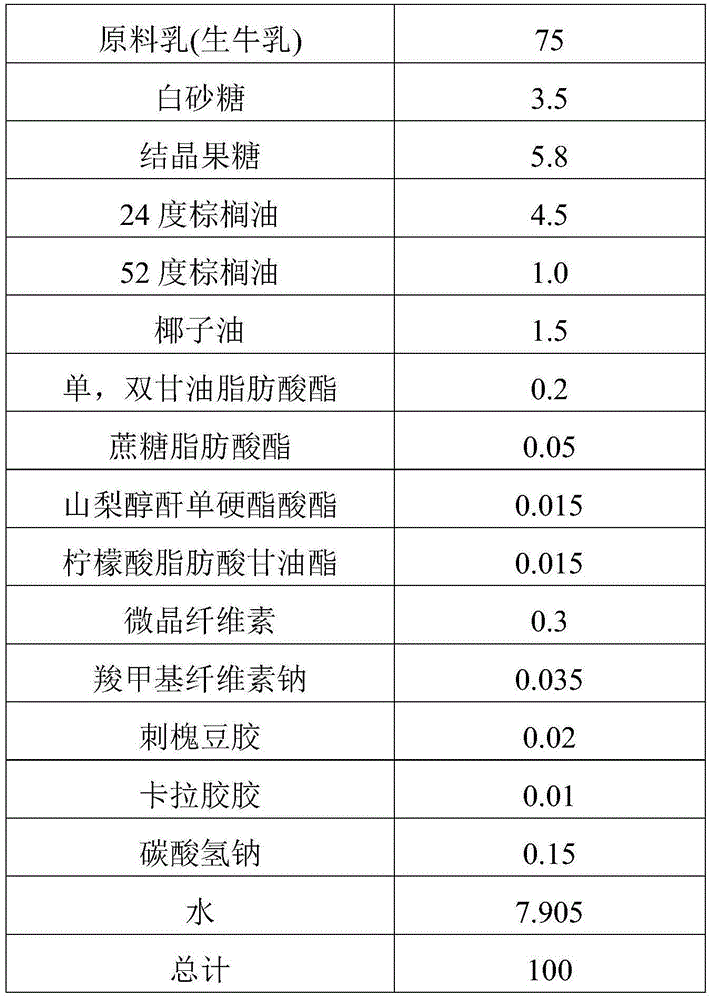

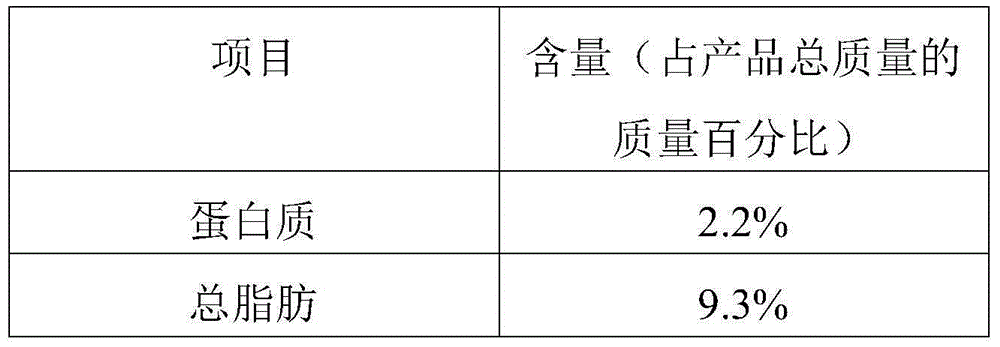

Preparation method for ice cream milk pulp and product and ice cream containing the same

ActiveCN105010717AEasy to prepareLow equipment requirementsFrozen sweetsCholesterolAdditive ingredient

The invention discloses ice cream milk pulp, a preparation method thereof and an ice cream containing the same. The ingredients of the ice cream milk pulp comprise raw milk, sweetening agents, 24-degree palm oil, 52-degree palm oil, coconut oil, stabilizing agents, emulsifying agents and water. The preparation method comprises the steps of mixing the ingredients uniformly, and obtaining an ingredient solution; conducting pre-homogenizing, ultra high temperature sterilization, sterility homogenizing and cooling, and obtaining the ice cream milk pulp. According to the ice cream milk pulp, a part of butter oil is replaced with vegetable fat, the cholesterol content of a product is reduced, the production cost is greatly reduced as well, and the stability and sensory effect of the product are not affected on account of poor compatibility of the vegetable fat. The ice cream milk pulp is great in texture, smooth to taste, outstanding in flavor and good in liquidity and stability, the guarantee period can reach nine months under the normal temperature condition, and the ice cream prepared with the same is uniform in state, good in firmness, ideal in expansion rate, smooth to taste and good in flavor.

Owner:BRIGHT FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com