Porcelain granule produced by using river, lake and sea sludge and shellfish powder as raw materials and preparation method of porcelain granule

A technology for rivers, lakes, seas, and shellfish, which is applied in the production of ceramic materials, chemical instruments and methods, ceramic products, etc., can solve the problems of good sewage treatment effects, etc., and achieve good sewage treatment effects, wide sources, good economic benefits and social benefits. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

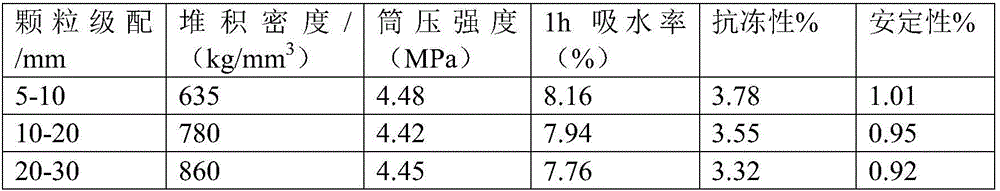

Embodiment 1

[0021] The ceramsite produced from river, lake and sea sludge and shellfish powder is made of the following raw materials in parts by weight: shell powder 26.8, kaolin 12.2, peat ash 3.4, siliceous shale 20.5, slag 30.2, fly ash 18.4, zeolite 32.6, sea mud 25.5, peat 18.7.

[0022] Said shell powder comes from rivers, lakes and seas, and is crushed to a particle size of about 100 meshes.

[0023] The silicon dioxide content in the siliceous shale is 87.6%.

[0024] The preparation method of the ceramsite produced by the present invention with rivers, lakes and sea sludge and shellfish powder is made by the following concrete steps:

[0025] (1) Take ingredients: take raw materials according to the above-mentioned parts by weight;

[0026] (2) Crushing: crush kaolin, siliceous shale, slag, fly ash, zeolite, sea mud, and peat to 40 meshes;

[0027] (3) Stirring: mix shell powder, peat ash and the materials in step (2) evenly, add water to stir, and adjust the water content of...

Embodiment 2

[0038] The ceramsite produced from river, lake and sea sludge and shellfish powder is made of the following raw materials in parts by weight: shell powder 15, kaolin 5, peat ash 1, siliceous shale 15, slag 15, fly ash 10. Zeolite 15. Sludge from lakes 10. Peat 10.

[0039] The shell powder comes from rivers, lakes and seas, and is crushed to a particle size of 60 meshes.

[0040] The silicon dioxide content in the siliceous shale is 88.4%.

[0041] The preparation method of the ceramsite produced by the present invention with rivers, lakes and sea sludge and shellfish powder is made by the following specific steps:

[0042] (1) Take ingredients: take raw materials according to the above-mentioned parts by weight;

[0043] (2) Crushing: crush kaolin, siliceous shale, slag, fly ash, zeolite, sludge from lakes, and peat to 40 meshes;

[0044] (3) stirring: shell powder, peat ash and the material in step (2) are mixed evenly, add water and stir, and the water content of materia...

Embodiment 3

[0049]The ceramsite produced from river, lake and sea sludge and shellfish powder is made of the following raw materials in parts by weight: shell powder 50, kaolin 15, peat ash 5, siliceous shale 30, slag 40, fly ash 20. Zeolite 40. Sludge from Yangtze River 30. Peat 25.

[0050] The shell powder comes from rivers, lakes and seas, and is crushed to a particle size of 80 meshes.

[0051] The silicon dioxide content in the siliceous shale is 88.4%.

[0052] The preparation method of the ceramsite produced by the present invention with rivers, lakes and sea sludge and shellfish powder is made by the following concrete steps:

[0053] (1) Take ingredients: take raw materials according to the above-mentioned parts by weight;

[0054] (2) Crushing: crush kaolin, siliceous shale, slag, fly ash, zeolite, sludge from the Yangtze River, and peat to 40 meshes;

[0055] (3) stirring: shell powder, peat ash and the material in step (2) are mixed evenly, add water and stir, and the wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com