Preparation process of water swellable rubber

A technology of water-swellable rubber and preparation process, which is applied in the field of concrete road and bridge building waterproof materials, which can solve the problems of inability to recover water-stop function independently, loss of water-stop function, low expansion rate, etc., and achieve good waterproof and water-stop effect , Excellent aging resistance and high expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

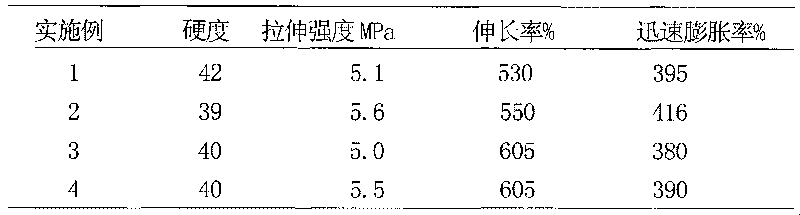

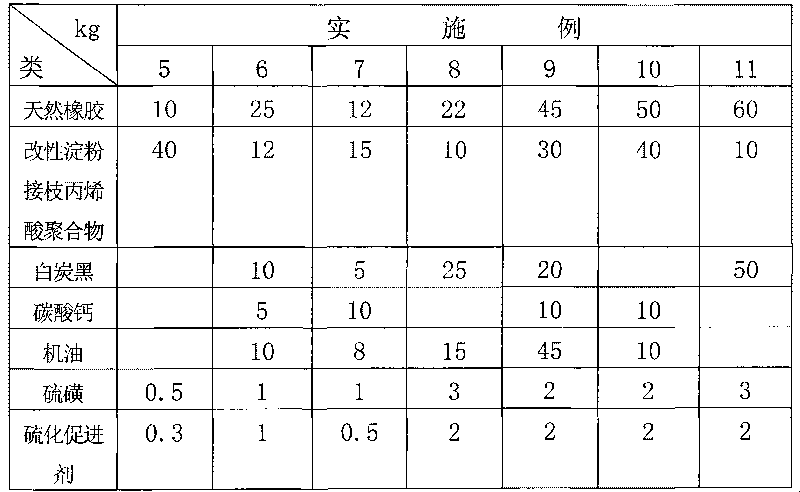

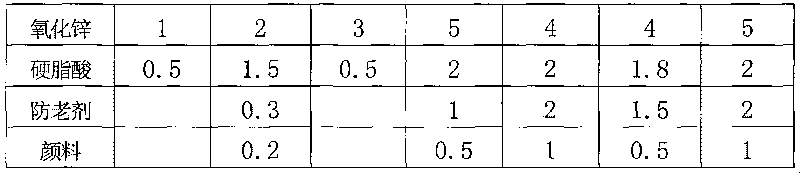

Examples

Embodiment 1

[0015] 18 kg of natural rubber; 10 kg of modified starch grafted acrylic acid polymer; 7.5 kg of calcium carbonate; 7.5 kg of white carbon black; 10 kg of machine oil; 0.8 kg of sulfur; 0.5 kg of accelerator M; 1 kg of zinc oxide; 0.5 kg; anti-aging agent 4010NA 0.3 kg. Put it into the internal mixer for internal mixing, then open the mixing, and finally vulcanize at 150°C for 20 minutes to obtain the water-swellable rubber product.

Embodiment 2

[0017] 17 kilograms of natural rubber; 10 kilograms of modified starch grafted acrylic acid polymer; 7.5 kilograms of calcium carbonate; 7.5 kilograms of white carbon black; 10 kilograms of machine oil; 1 kilogram of zinc oxide; 0.5 kilogram of stearic acid; 0.5 kg. Put it into the internal mixer for internal mixing, and then start the mixing. When starting the mixing, add 0.5 kg of sulfur; 0.3 kg of accelerator CZ; finally, vulcanize at 152°C for 25 minutes to obtain a water-swellable rubber product.

Embodiment 3

[0019] 20 kg of natural rubber; 10 kg of modified starch grafted acrylic acid polymer; 13 kg of calcium carbonate; 8 kg of engine oil, 1 kg of sulfur; 0.5 kg of accelerator TDTM; 1.2 kg of zinc oxide; stearic acid: 0.8 kg; antioxidant 4010 Or anti-aging agent 4010NA 0.4 kg; pigment 0.5 kg. Put it into the internal mixer for internal mixing, then open the mixing, and finally vulcanize at 150°C for 25 minutes to obtain the water-swellable rubber product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com