Instant plant total-nutrient food replacement powder and preparation method thereof

A technology for meal replacement powder and full nutrition, which is applied in the field of plant full nutrition convenient meal replacement powder and its preparation, can solve the problems of increased production energy consumption cost and production cycle, uncoordinated flavor fusion, low thermal efficiency and the like, and achieves reduction of calorie intake. , The effect of improving processing and edible characteristics and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

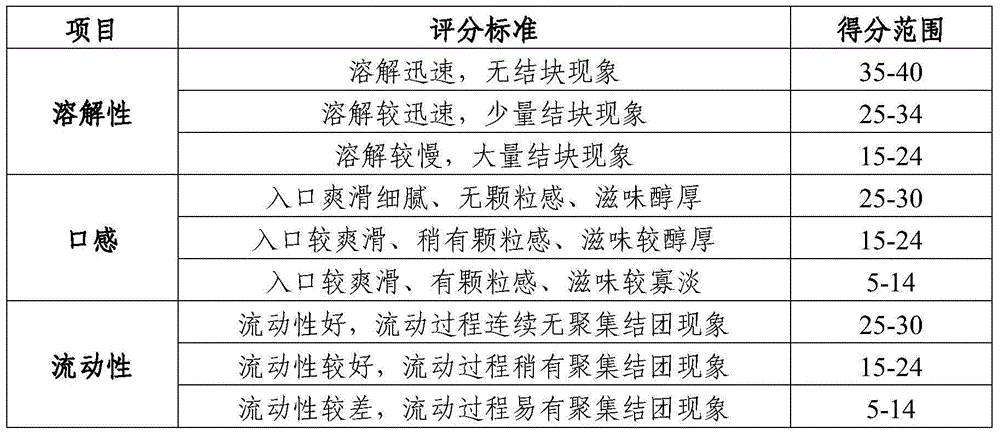

Image

Examples

Embodiment 1

[0037] Embodiment 1: A kind of plant complete nutrition convenient meal replacement powder

[0038] 1. Composition: 90kg compound grain fruit, vegetable and nut powder, 10kg natural sweetener, of which:

[0039] Compound grain 40kg (15kg oats, 15kg black beans, 10kg black rice, 5kg brown rice);

[0040] Compound fruits and vegetables 30kg (10kg tremella, 8kg yam, 6kg wolfberry, 6kg strawberry);

[0041] Compound nuts 20kg (8kg black sesame, 6kg pumpkin seeds, 6kg black dates);

[0042] Composite natural sweetener 10kg (5kg fructose, 5kg maltose) mixed composition.

[0043] 2. Preparation method:

[0044] 1) Grinding the de-impured grain raw materials to 20 meshes, weighing the grains according to the proportioning, and setting aside;

[0045] 2) Weigh the compound fruits and vegetables according to the ratio, rinse the fresh and mature raw materials of fruits and vegetables and put them in a beater for 10 minutes, and set aside;

[0046] 3) The shellless nuts without impu...

Embodiment 2

[0048]Embodiment 2: A kind of plant complete nutrition convenient meal replacement powder

[0049] 1. Composition: 91.8kg compound grain fruit, vegetable and nut powder mixed with 8.2kg natural sweetener. in,

[0050] Compound grain 36kg (20kg oats, 10kg black beans, 3kg black glutinous rice, 3kg triticale);

[0051] Compound fruits and vegetables 28.8kg (15kg purple sweet potato, 10kg mulberry, 3kg black fungus, 0.8kg wolfberry);

[0052] Compound nuts 27kg (15kg pine nuts, 10kg lotus seeds, 2kg ginkgo nuts);

[0053] Compound natural sweetener 8.2kg (0.2kg stevia, 8kg erythritol).

[0054] 2. Preparation method:

[0055] 1) Grinding the de-impured grain raw materials to 40 meshes, weighing the grains according to the proportion, and setting aside;

[0056] 2) Weigh the fruits and vegetables according to the ratio, rinse the fresh and ripe fruit and vegetable raw materials and beat them with a beater for 10 minutes, and set aside;

[0057] 3) The shellless nut raw mater...

Embodiment 3

[0059] Embodiment 3: A kind of plant complete nutrition convenient meal replacement powder

[0060] 1. Composition: 90kg compound grain fruit, vegetable and nut powder mixed with 10kg natural sweetener. in,

[0061] Compound grain 39kg (15kg red beans, 10kg barley, 8kg red rice, 6kg glutinous rice);

[0062] Compound fruits and vegetables 28kg (13kg yam, 10kg strawberry, 5kg cherry);

[0063] Compound nuts 23kg (13kg peanuts, 10kg black dates);

[0064] Compound natural sweetener 10kg (6kg fructose, 4kg xylitol).

[0065] 2. Preparation method:

[0066] 1) Grinding the de-impured grain raw materials to 40 meshes, weighing the grains according to the proportion, and setting aside;

[0067] 2) Weigh the fruits and vegetables according to the ratio, rinse the fresh and ripe fruit and vegetable raw materials and beat them with a beater for 10 minutes, and set aside;

[0068] 3) The shellless nut raw materials without impurities are baked at 140°C for 15 minutes, then put int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com