Fermented yoghourt soft ice cream milk sauce containing various probiotics, and production method of milk slurry

A technology for soft ice cream milk syrup and probiotics, which is applied in the directions of milk preparations, dairy products, frozen desserts, etc., can solve the problems of difficult fermentation of high-sugar and high-solids, unsatisfactory flavor and taste, etc., and achieves good fine texture and texture Delicate, uniform, high-finesse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

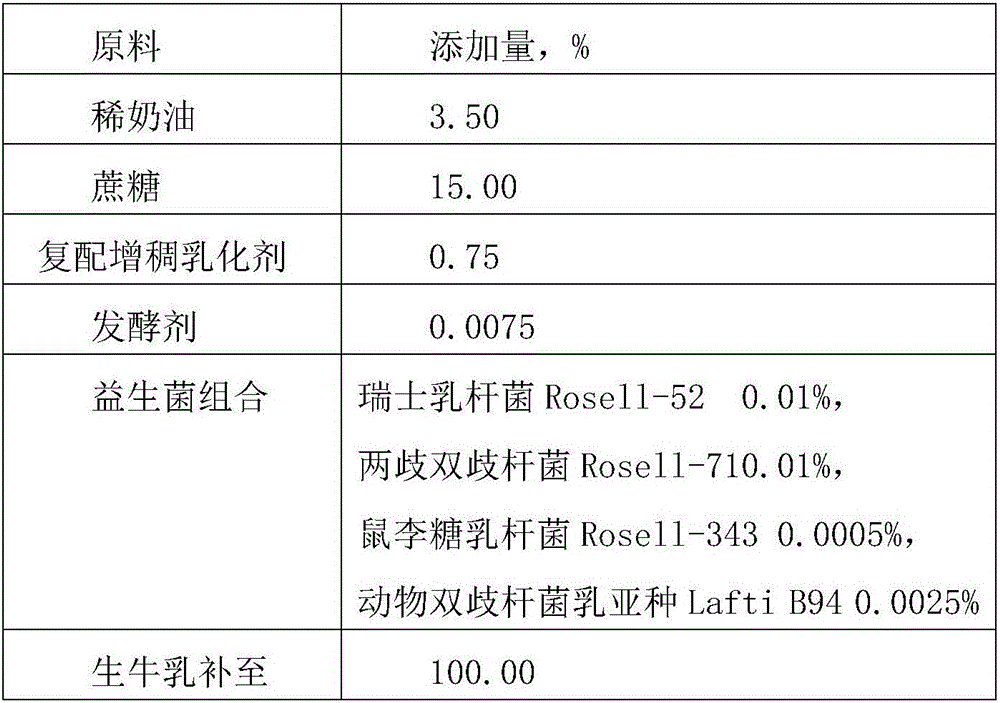

[0032] 1. The raw material formula is shown in Table 1

[0033] Table 1

[0034]

[0035] 2. Preparation method

[0036] ⑴ Add the cream to the raw milk and mix well.

[0037] (2) Raise the temperature of the prepared material liquid to 55-60°C, disperse the material mixed with the compound thickening emulsifier and sucrose into the above milk liquid, fully dissolve until completely dissolved, and then add the remaining ingredients to dissolve completely.

[0038] ⑶ homogeneous: 50-60 ℃ / 18 ~ 20MPa.

[0039] ⑷Sterilization: 95℃ / 300s.

[0040] (5) Cool to 42°C, add starter, and disperse evenly. Keep the temperature at 42°C and ferment until the titrated acidity is 80-90°C.

[0041] ⑹ Cool to 10-20°C, break the emulsion until the viscosity is 500-800mpa.s, and fill.

[0042] 3. Evaluate the product results, the results are as follows:

[0043]The yogurt soft ice cream product has uniform color and luster, certain fluidity, coordinated sweet and sour ratio, and mellow ...

Embodiment 2

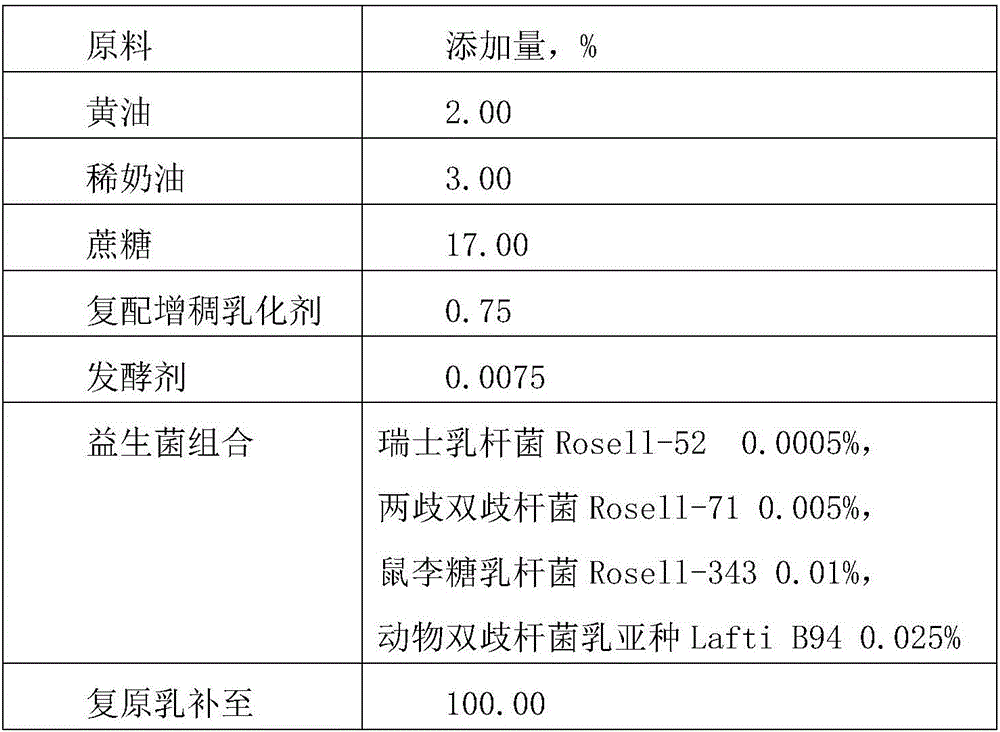

[0045] 1. The raw material formula is shown in Table 2

[0046] Table 2

[0047]

[0048] 2. Preparation method

[0049] (1) Add skimmed milk powder into purified water at 40-50°C, mix well, hydrate and keep warm for at least 30 minutes to obtain reconstituted milk.

[0050] ⑵Raise the temperature of ⑴ to 65-60℃, disperse the compound thickening emulsifier into the milk, fully dissolve until completely dissolved, then add cream, butter, sucrose, and dissolve completely.

[0051] ⑶ homogeneous: 65-70 ℃ / 18 ~ 20MPa.

[0052] ⑷Sterilization: 95℃ / 300s.

[0053] (5) Cool to 42°C, add starter, and disperse evenly. Keep the temperature at 42°C and ferment until the titrated acidity is 80-90°C.

[0054] ⑹ Cool to 10-20°C, break the emulsion until the viscosity is 500-800mpa.s, and fill.

[0055] 3. Evaluate the product results, the results are as follows:

[0056] The yogurt soft ice cream product has uniform color and luster, certain fluidity, coordinated sweet and sour ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com