Patents

Literature

192results about How to "Improve wetting ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

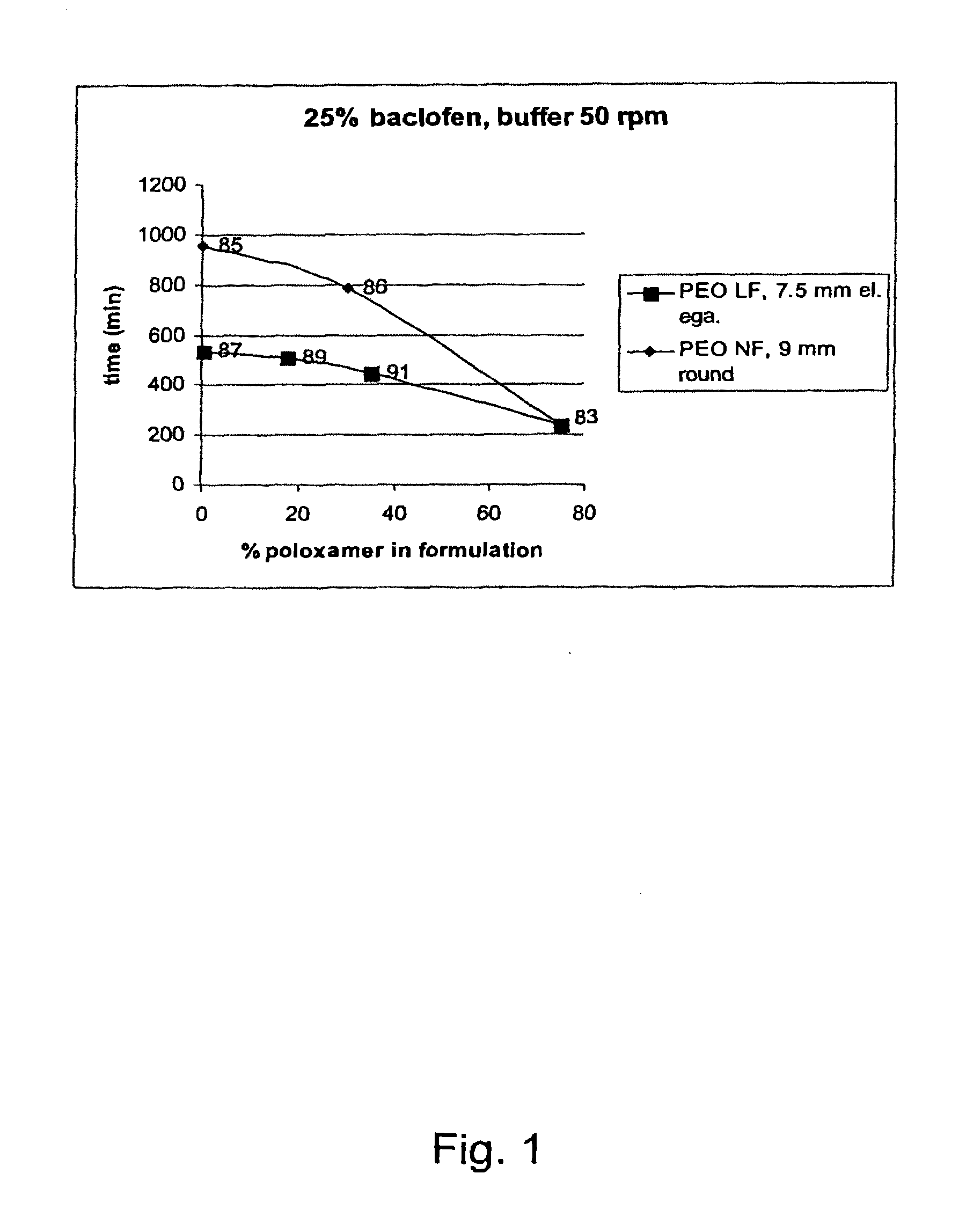

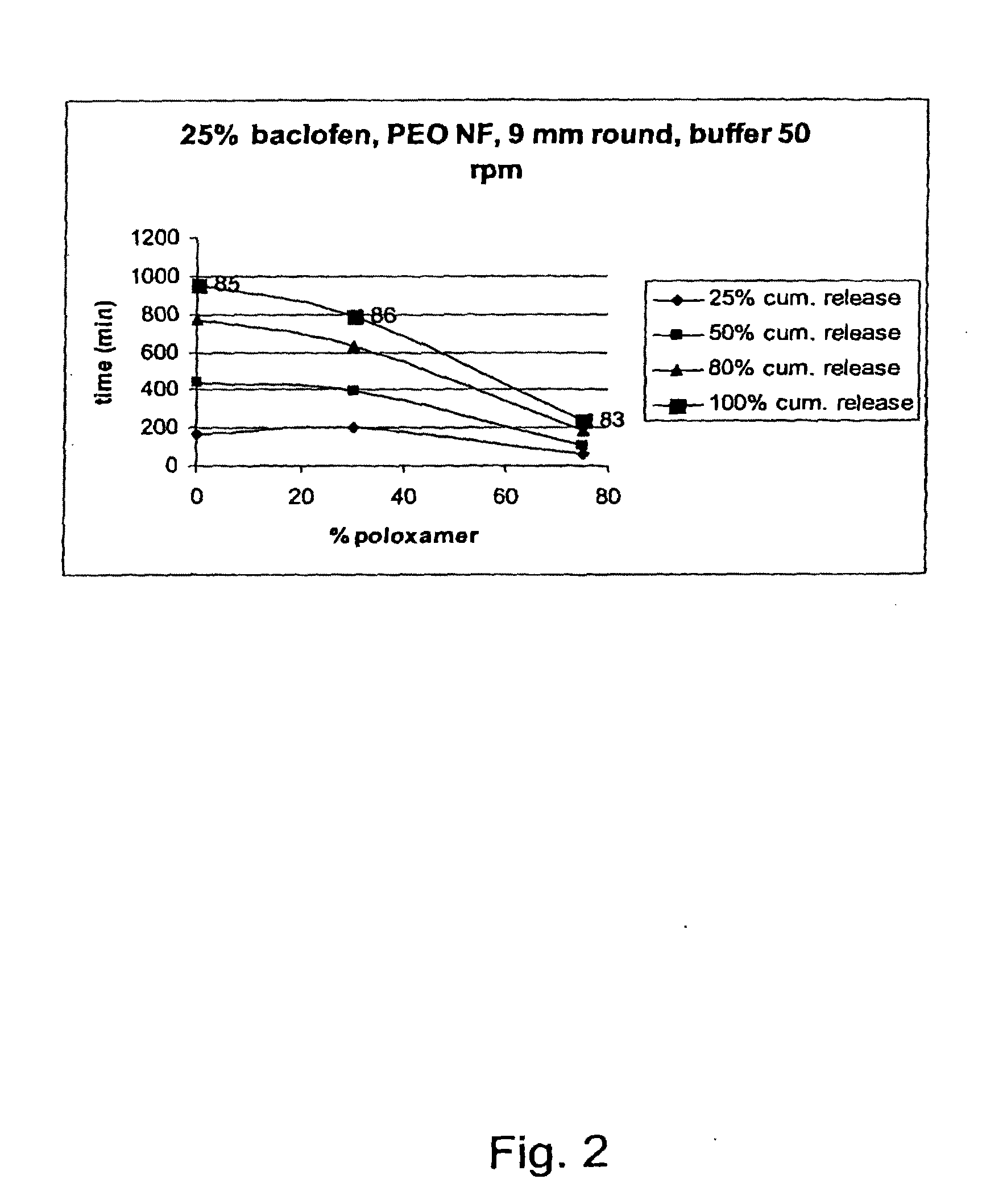

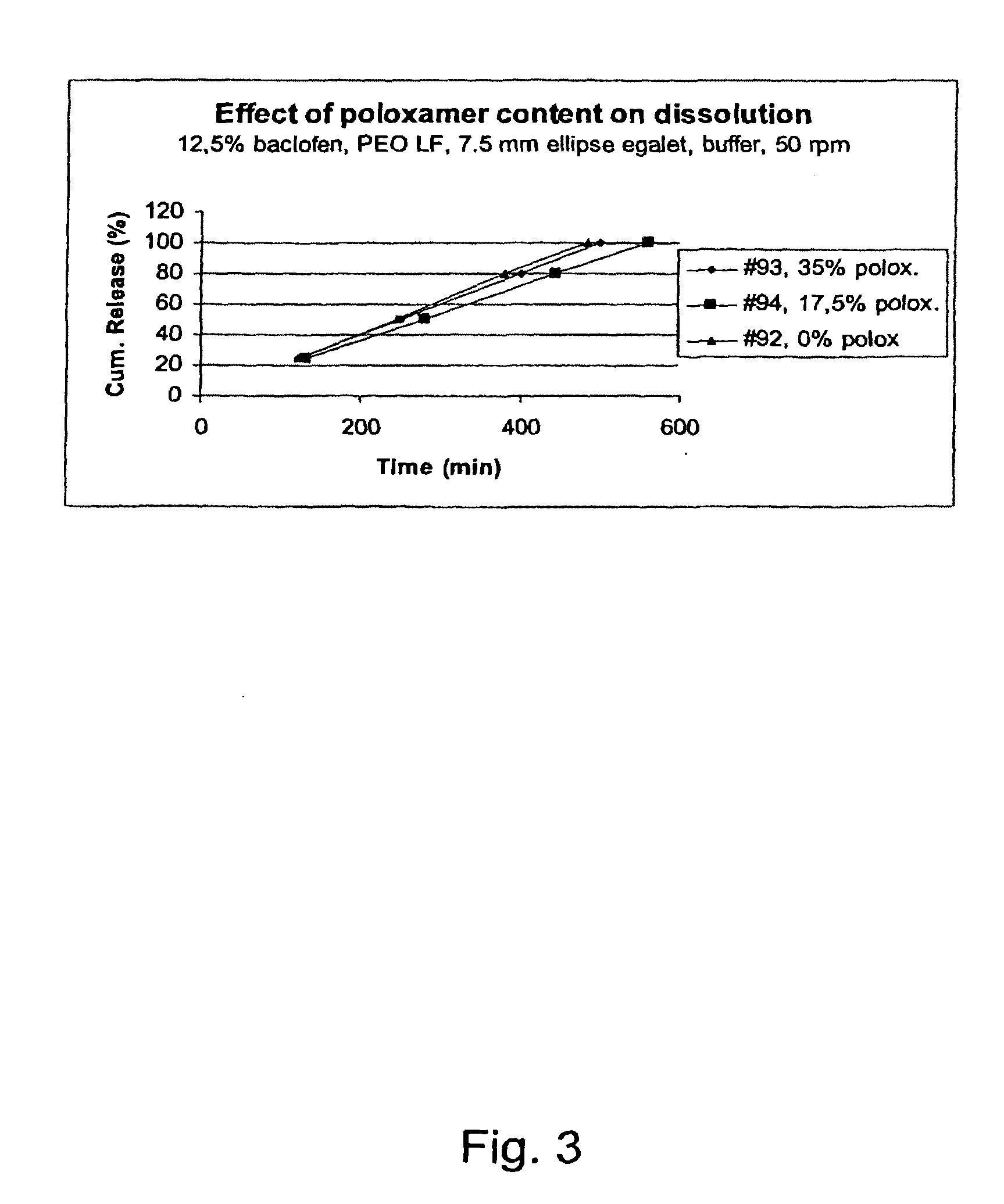

Matrix compositions for controlled delivery of drug substances

InactiveUS20070042044A1Improve solubilityImprove oral bioavailabilityBiocidePowder deliveryPolyethylene oxidePEG-PLGA-PEG

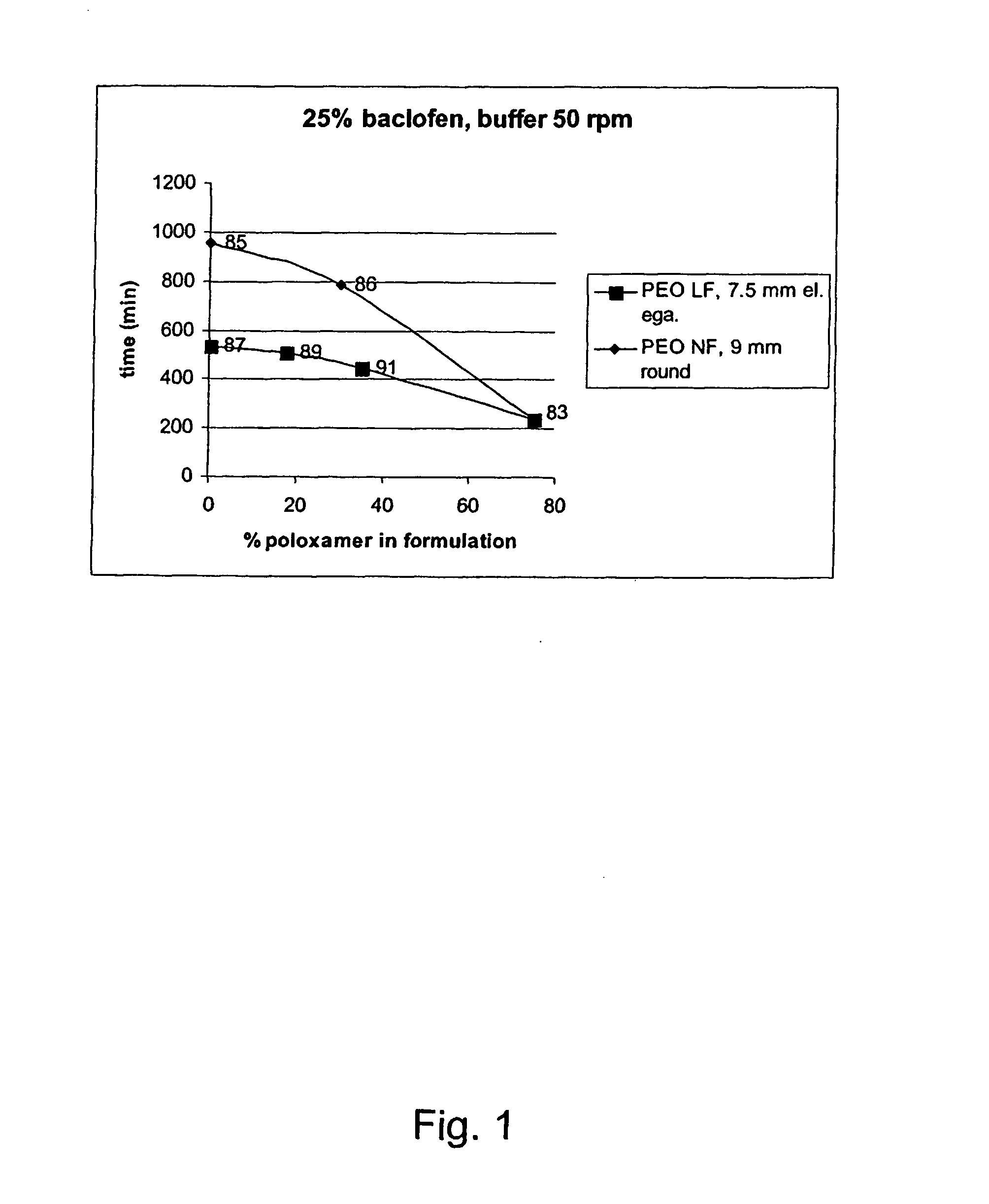

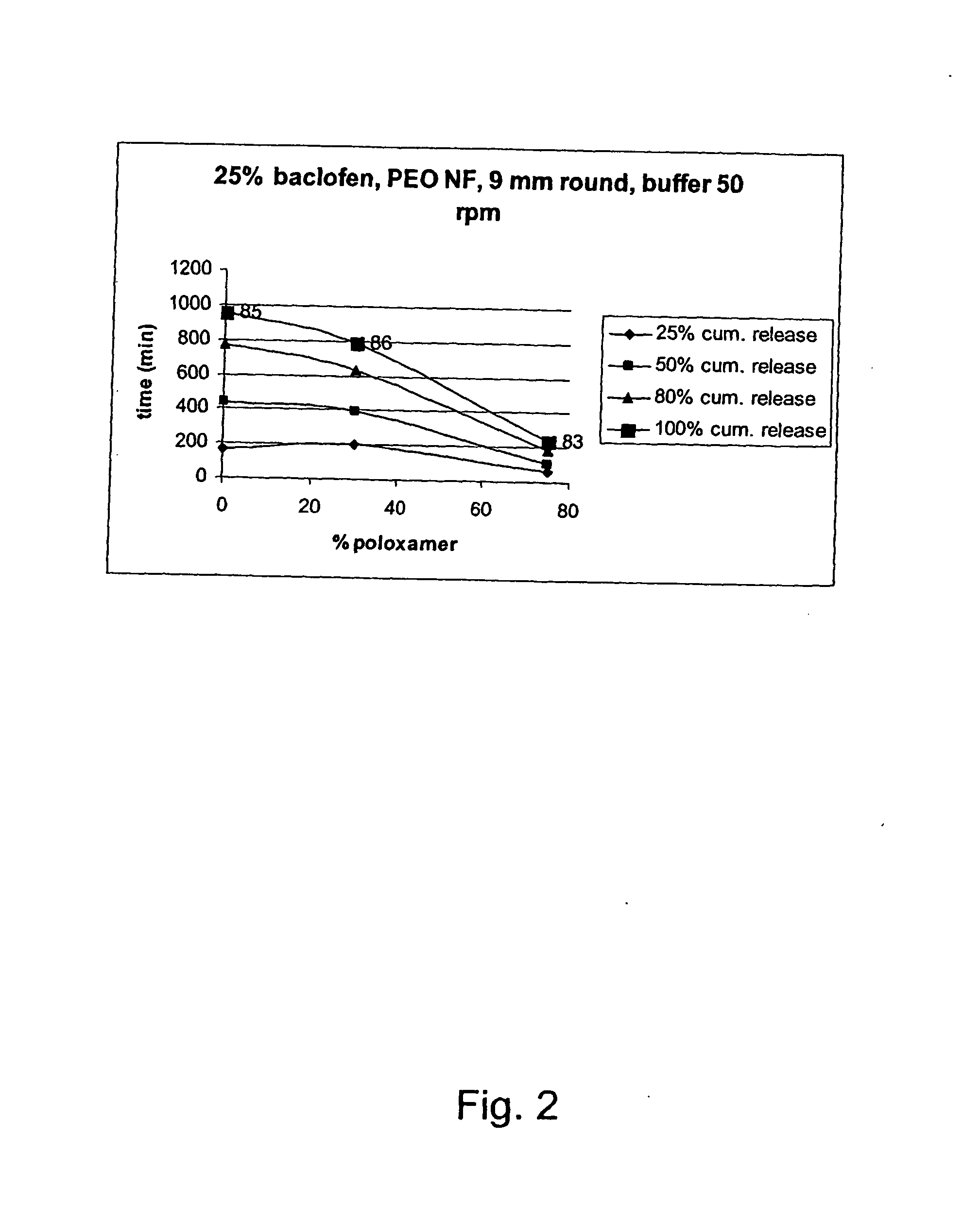

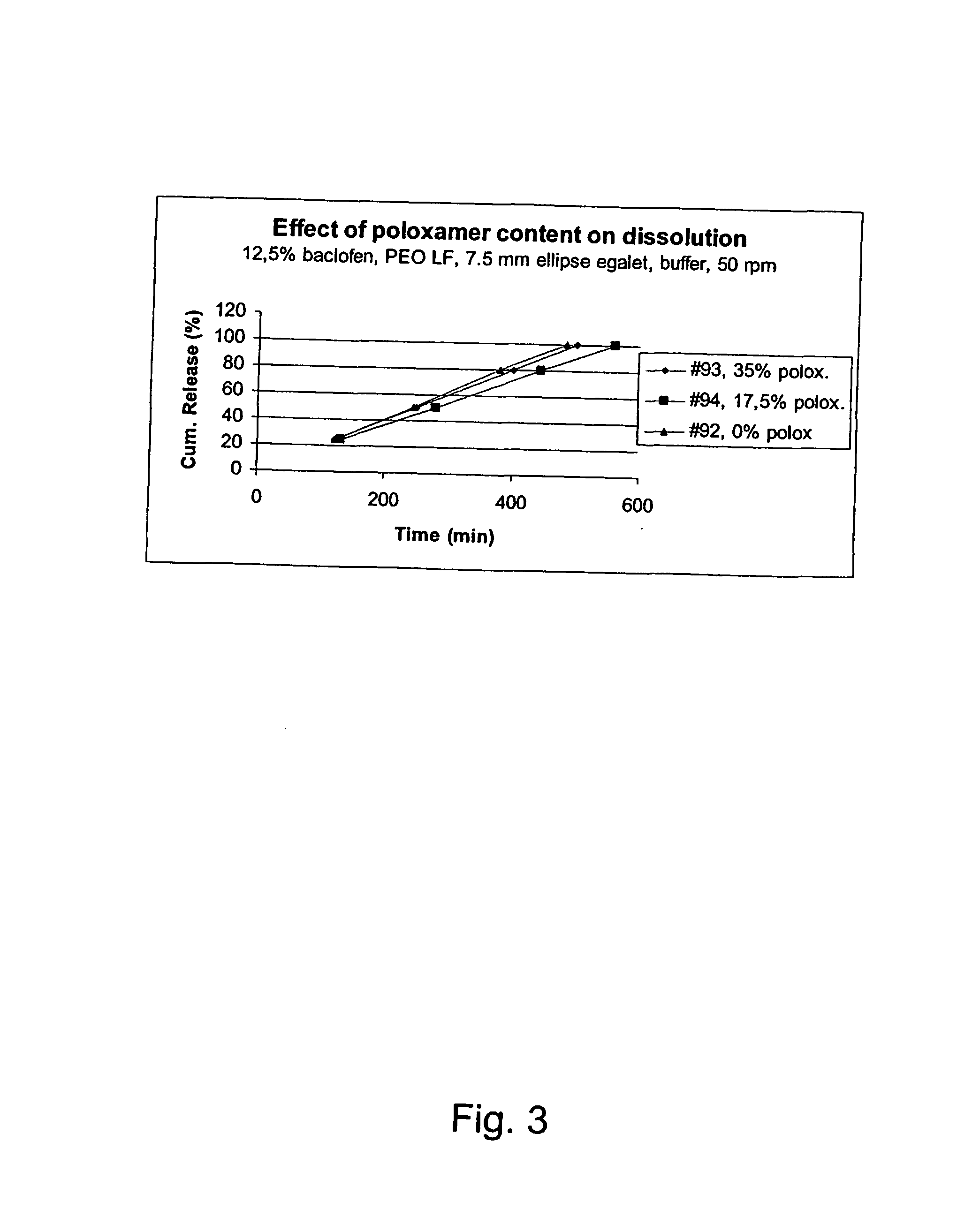

A novel matrix composition for pharmaceutical use. The matrix composition has been designed so that it is especially suitable in those situation where an improved bioavailability is desired and / or in those situation where a slightly or insoluble active substance is employed. Accordingly, a controlled release pharmaceutical composition for oral use is provided in the form of a coated matrix composition, the matrix composition comprising i) a mixture of a first and a second polymer that have plasticizing properties and which have melting points or melting intervals of a temperature of at the most 200° C., the first polymer being selected from the group consisting of polyethylene glycols and polyethylene oxides, and the second polymer being selected form block copolymer of ethylene oxide and propylene oxide including poly(ethylene-glycol-b-(DL-lactic acid-co-glycolic acid)-b-ethylene glycol (PEG-PLGA PEG), poly((DL-lactic acid-co-glycolic acid)-g-ethylene glycol) (PLGA-g-PEG), poloxamers and polyethylene oxide-polypropylene oxide (PEO-PPO), ii) a therapeutically, prophylactically and / or diagnostically active substance, the matrix composition being provided with a coating having at least one opening exposing at one surface of said matrix, wherein the active substance is released with a substantially zero order release.

Owner:EGALET LTD

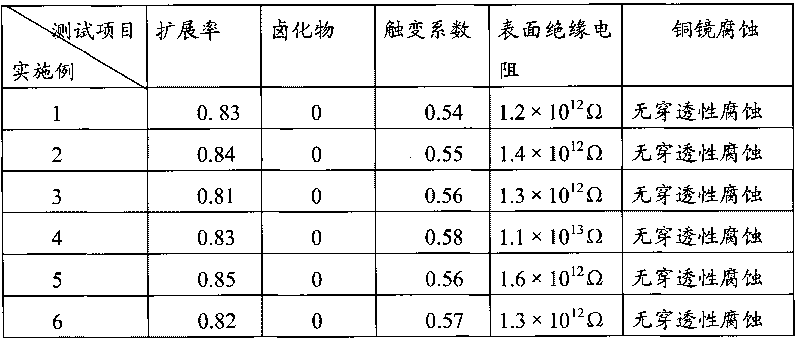

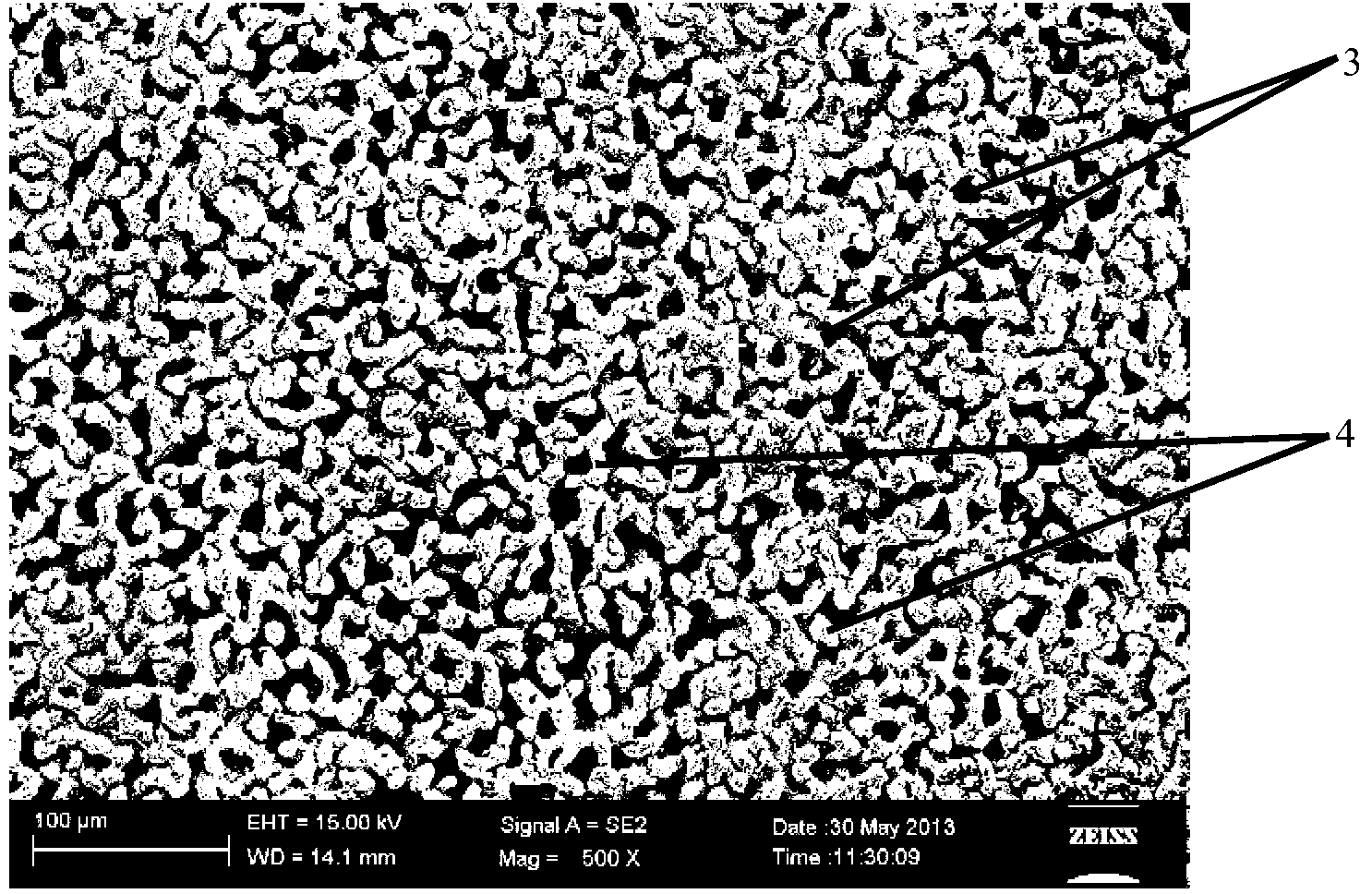

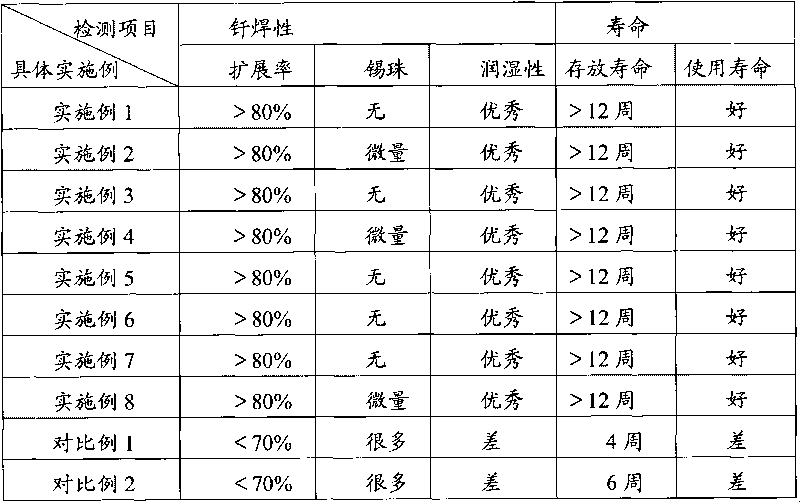

Halogen-free tin-bismuth-copper soldering paste and preparation method thereof

InactiveCN101695794AExtended shelf lifeExtended service lifeWelding/cutting media/materialsSoldering mediaAntioxidantExpansion rate

The invention relates to the technical field of soldering pastes, in particular to a halogen-free tin-bismuth-copper soldering paste and a preparation method thereof. A soldering flux of the halogen-free tin-bismuth-copper soldering paste consists of the following components in percentage by weight: 20 to 40 percent of polymerized rosin, 1 to 6 percent of rosin amine, 4 to 8 percent of thixotropic agent, 5 to 10 percent of organic acid, 5 to 10 percent of organic amine, 1 to 5 percent of antioxidant, 0.5 to 3 percent of surfactant and an organic solvent. The halogen-free tin-bismuth-copper soldering paste is mainly characterized by adopting the organic acid and the organic amine serving as activating agents and comprising no halogens at all, so not only the solderability is not reduced, but also the expansion rate and the insulation resistance value of the soldering paste are improved, and simultaneously the corrosivity of residues after soldering to a base material is reduced and the service life of the soldering paste is prolonged; and particularly, the peak temperature of the soldering paste during soldering is lower in favor of reducing the thermal damages to electronic components.

Owner:东莞市特尔佳电子有限公司

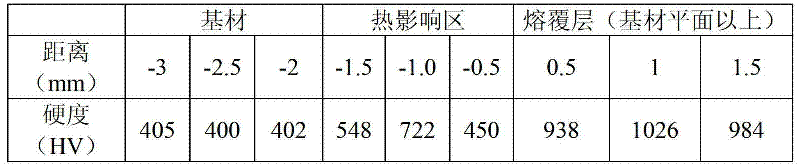

Special cobalt-based metal ceramic alloy powder for optical fiber laser cladding

ActiveCN102650012AHigh hardnessImprove plastic toughnessMetallic material coating processesHigh energyAlloy

The invention discloses special cobalt-based metal ceramic alloy powder for optical fiber laser cladding, which is matched with characteristics of optical fiber laser. The special cobalt-based metal ceramic alloy powder contains the following components by weight percent: 1-2% of carbon, 1-2% of silicon, 2-4% of iron, 1.5-2.5% of nickel, 3-4% of molybdenum, 8-12% of chromium, 3-4% of tungsten, 13-17% of tungsten carbonate, 2-3% of calcium fluoride, 1-2% of silicon nitrate and cobalt for the rest. The metal ceramic alloy powder is specially applied to a cladding process of a high-energy optical fiber laser device, a metal ceramic cladding layer with high hardness, high flexibility and high corrosion resistance can be formed on the surface of a work die of a steel and iron basis material, and the cladding layer is compact in structure, has no defects such as air holes, cracks, shrinkage cavities and the like, and has excellent metallographic performance such as high hardness, high plasticity, flexibility and corrosion resistance, and the like; moreover, the process is convenient and the thermal treatment does not need to be carried out in advance and afterwards. The special cobalt-based metal ceramic alloy powder is particularly suitable for the surface treatment of the die and can greatly prolong the service life of the die.

Owner:CHANGZHOU TIANZHENG IND DEV CO LTD

Matrix compositions for controlled delivery of drug substances

InactiveUS20100166866A1Improve solubilityImprove oral bioavailabilityPowder deliveryBiocidePolyethylene oxidePEG-PLGA-PEG

Owner:EGALET LTD

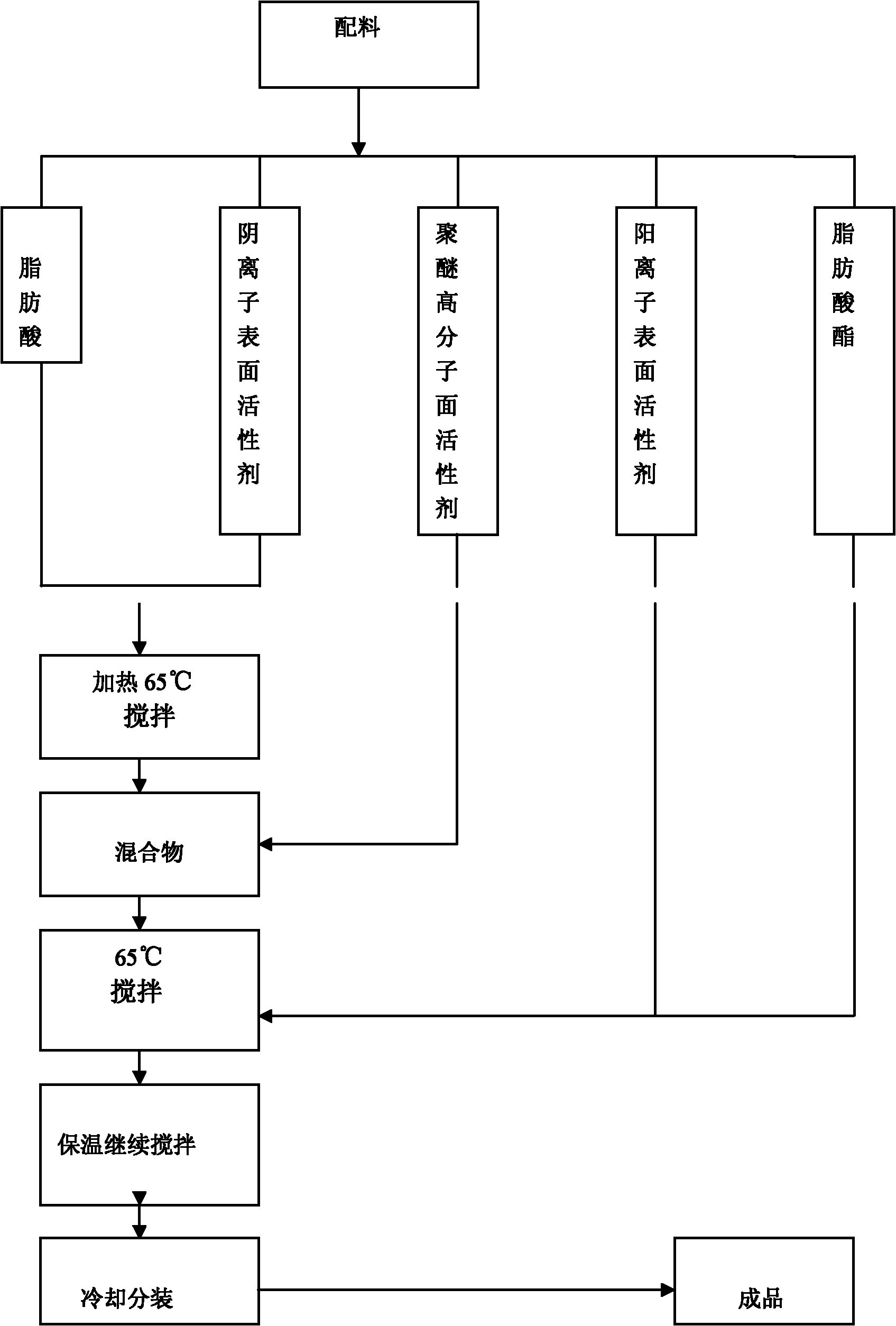

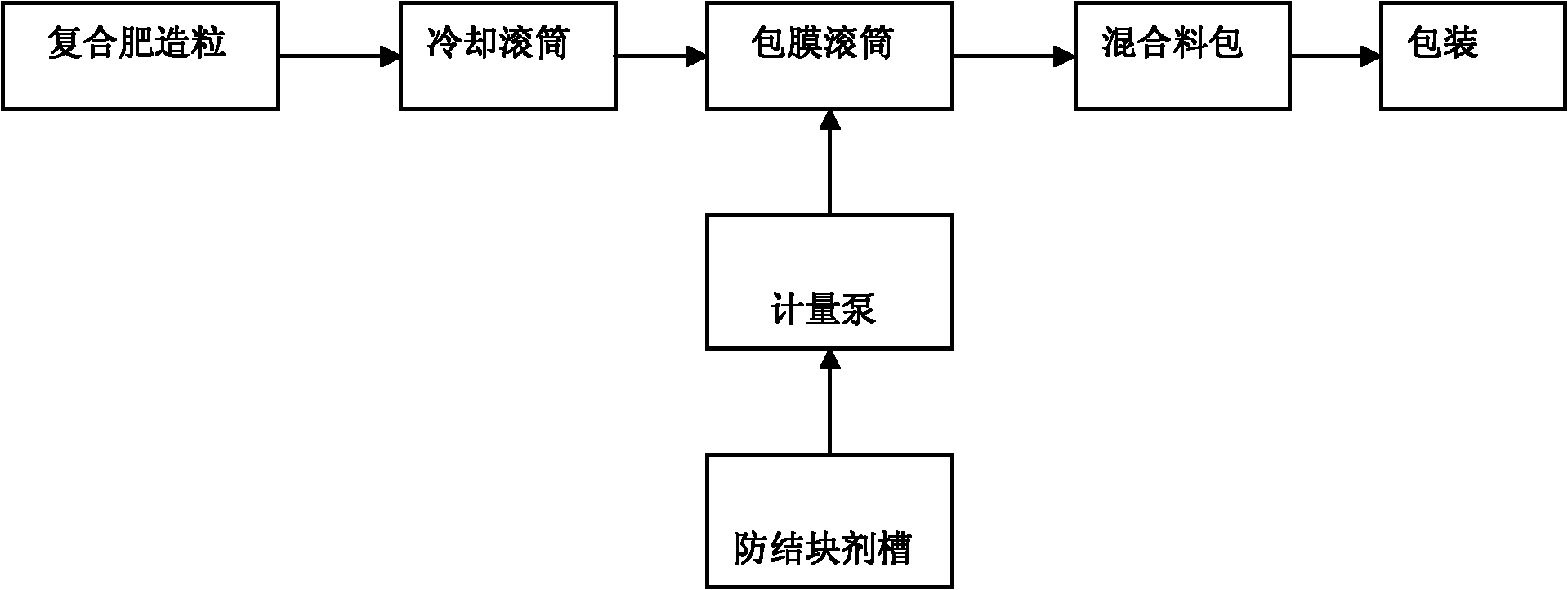

Full-biodegradable anti-caking agent for compound fertilizer/blended fertilizer and preparation method thereof

InactiveCN101870607AReduce surface tensionEasy to spreadFertilizer mixturesFoaming agentAnticaking agent

The invention belongs to the technical field of agricultural chemical fertilizer production, and particularly relates to an anti-caking agent for a compound fertilizer (blended fertilizer) and a preparation method thereof. The full-biodegradable anti-caking agent for the compound fertilizer / blended fertilizer is characterized by comprising the following components in percentage by mass: 84.5 to 90 percent of fatty acid, 2 to 3 percent of anionic surfactant, 0.2 to 1 percent of cationic surfactant, 0.5 to 1.5 percent of polyether macromolecular surfactant and 5 to 10 percent of aliphatic ester. The prepared anti-caking agent can be fully degraded under a natural environment, and has good anti-caking effect.

Owner:WUHAN HAIDING CHEM INDAL

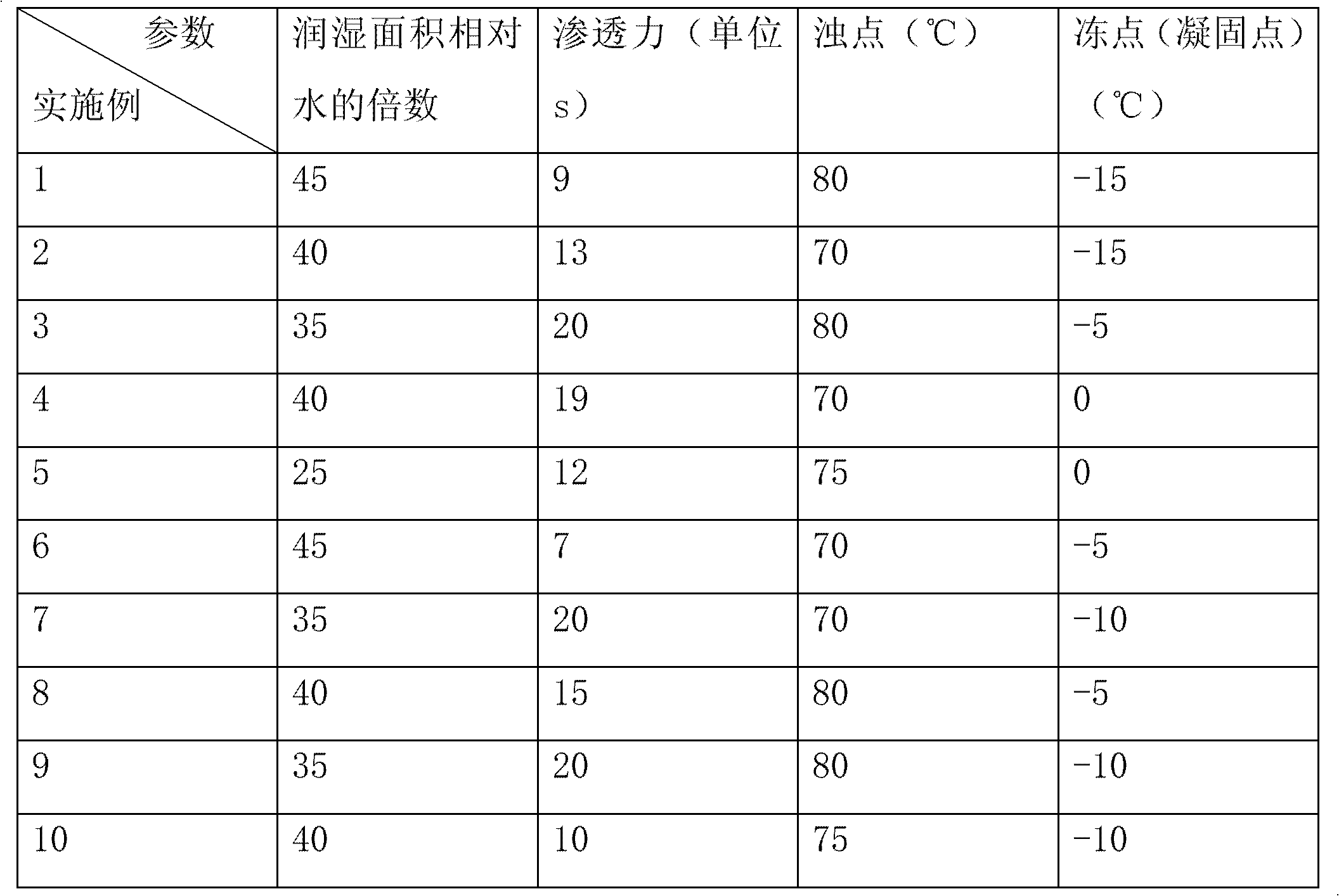

Wetting and penetrating agent for hard surfaces and fabrics

InactiveCN102493196AImprove wetting abilityEfficient wettingTransportation and packagingFibre treatmentPolyethylene glycolFatty alcohol

The invention discloses a wetting and penetrating agent for hard surfaces and fabrics. The wetting and penetrating agent is prepared from the following components in percentage by weight: 5 to 43 percent of iso-tridecanol polyoxyethylene ether, 3 to 30 percent of fatty alcohol polyoxyethylene ether, 0.5 to 7 percent of anionic surfactant, 0.5 to 20 percent of polyethylene glycol, 0 to 10 percent of fatty acid methyl ester polyoxyethylene ether and the balance of water. By the formula combination, a wetting and spreading area is large, the wetting capacity is high, the penetrating speed of several seconds within 20 seconds is a high-quality index of a high-efficiency wetting and penetrating agent, ethoxylates of green natural oil and alcohol are selected as raw materials, are easily biodegraded and contribute to environmental protection, the characteristic of low freezing point is reflected by the appearance, the wetting and penetrating agent is not required to be heated and is used and operated at low temperature, and energy is saved.

Owner:天津浩元精细化工股份有限公司

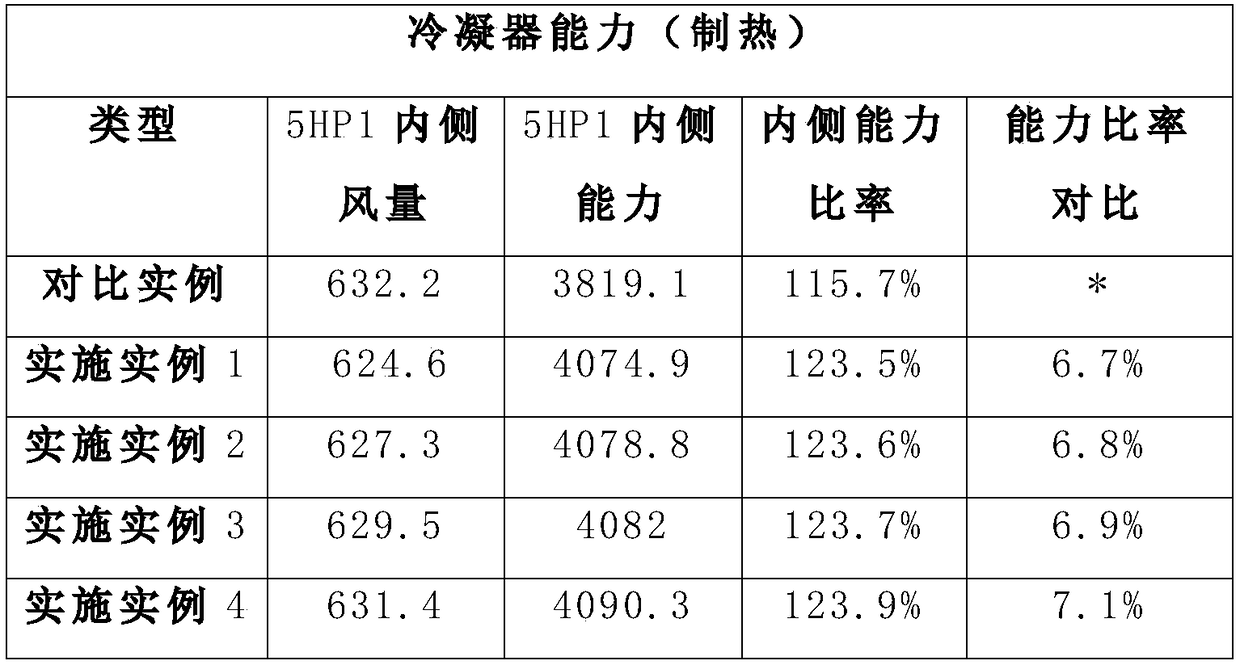

High heat conductivity graphene coating for heat dissipation device and preparation method and application

InactiveCN108165120AImprove work efficiencyImprove thermal conductivityPolyurea/polyurethane coatingsHeat-exchange elementsGraphene coatingAdhesive

The invention relates to a high heat conductivity graphene coating for a heat dissipation device and a preparation method and application. The high heat conductivity graphene coating disclosed by theinvention is prepared through the following steps: preparing graphene dispersion liquid, then adding an adhesive and a thickener to the graphene dispersion liquid, dispersing to obtain a homogeneous and stable graphene mixed slurry, uniformly coating the graphene mixed slurry on the surface of a heat dissipation component of the heat dissipation device, then drying, thus being capable of obtaininga uniformly coated graphene coating. According to the invention, the high heat conductivity graphene coating is directly coated on the surface of the heat dissipation component, and high in binding force with a substrate of the heat dissipation component, so that thermal conduction properties of the heat dissipation component can be obviously improved, furthermore, the waterproof adhesive and thehydrophilic thickener are used, therefore, the wettability of the graphene coating on water can be further enhanced to prevent condensate water from directly condensing into water drops on the surface of heat dissipation component so as to increase the heat exchange area.

Owner:SU ZHOU CSTAR MATERIAL TECH CO LTD

Corrosion proof impregnating varnish used for water-based metal components and manufacturing method thereof

ActiveCN101560351ALong-lasting colorHigh hardnessAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention discloses a corrosion proof impregnating varnish used for water-based metal components and a manufacturing method thereof. The corrosion proof impregnating varnish is made of de-ionized water, propanediol, dispersant, antifoaming agent, wetting agent, carbon black, iron oxide black, water borne acroid resin, water borne epoxy resin, dipropylene glycol butyl ether, propylene glycol ether and polyaniline water solution, polyaniline carrier particles or polyaniline emulsion. The manufacturing method comprises: the propanediol and the de-ionized water are mixed and stirred, and then added with the dispersant, the antifoaming agent, the wetting agent and the polyaniline water solution or the water solution of emulsion or carrier particles to be evenly mixed together; the carbon black and the iron oxide black are added in to the mixed solution to form uniform pigment paste which is then put into a blending tank after being ground to be evenly stirred; the obtained mixture is added with the water borne acroid resin, the water borne epoxy resin, the dipropylene glycol butyl ether and the propylene glycol ether to be stirred; finally, the stirred mixture is added with the de-ionized water to be diluted and ground. The invention has the advantages of high coating efficiency, stable coating quality, uniform paint film of dip coating, flat and smooth paint film, good hardness, strong adhesive attraction, good corrosion proof performance, excellent painting performance at edges and corners, no leaking painting, good salt mist resistance, environmental protection, low cost, etc.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Heat-conductive glue

InactiveCN1970666AReduce thicknessImprove thermal conductivityHeat-exchange elementsAdhesivesOptoelectronicsWetting

The invetnio disclosese heat conductive glue, which consists of base and heat conductive powder in the base, wherein the base is polyol, which possesses strong wetting ability; the thickness among heat conductive powders and between heat conductive powder and heat conductive glue surface becomes thinner, which improves heat conductive property of heat conductive glue.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

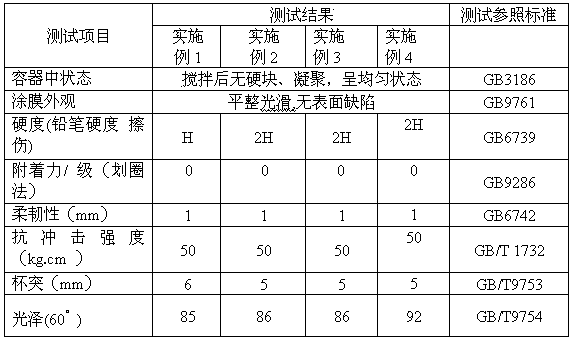

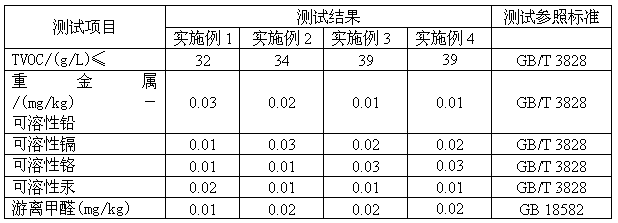

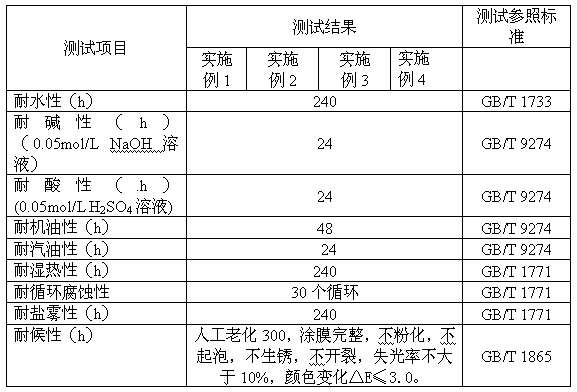

Water-based automotive paint, and preparation method and application method thereof

The invention discloses a water-based automotive paint, and a preparation method and an application method thereof. The water-based automotive paint is prepared from water-based castor oil-modified alkyd resin, water-based acrylic resin, water-based color paste, amino resin A, amino resin B, a coalescing agent, deionized water, a dispersing agent, a wetting agent, a pH regulator, a defoamer, anti-settling pulp, a corrosion remover, a thickener, an adhesion promoter and a flatting agent. The preparation method refers to orderly adding the raw materials to evenly agitate. The application method comprises the following steps: evenly mixing and stirring the water-based automotive paint and water according to the ratio of 1:(0.1-0.3), and then spraying, placing, baking and solidifying, so as to obtain a stoving varnish coating. A solvent stoving varnish is replaced by using the water-based automotive paint disclosed by the invention; a complete coating, of which the adhesive force is 0 level, and the flexibility is 1mm, which is excellent in weather fastness, high in fullness, and vivid in color and luster, and has excellent protectiveness and decorative property can be formed on the metal surface; the water-based automotive paint is safe in production procedure, environment-friendly, simple, and environment-friendly and convenient in construction.

Owner:肇庆千江高新材料科技股份公司

Composite zinc-aluminum flux cored wire containing beryllium and magnesium and rubidium salt and preparation method of flux cored wire

ActiveCN102935559AImprove cleanlinessImprove intergranular corrosion resistanceWelding/cutting media/materialsSoldering mediaRare-earth elementAluminum fluoride

The invention discloses a composite zinc-aluminum flux cored wire containing beryllium and magnesium and rubidium salt. The composite zinc-aluminum flux cored wire comprises a wire body consisting of an outer metal skin and core brazing flux powder, wherein the outer metal skin is prepared by the following raw materials by weight percent: 80.5 to 98.5% of zinc, 0.01 to 6.5% of silver, 0.01 to 3% of copper, 0.001 to 2% of nickel, 0.001 to 0.5% of beryllium, 0.001 to 1.2% of magnesium, 0.001 to 0.5% of rare earth element and the balance of aluminum; and the brazing flux powder is prepared by the following raw materials by weight percent: 15 to 35% of aluminum fluoride, 30 to 75% of cesium fluoride, 2.5 to 10% of rubidium fluoride, and the balance of potassium fluoride. The invention also provides a preparation method of the composite zinc-aluminum flux cored wire. The preparation method has the advantages that trace Be and Mg are introduced based on the conventional Zn-Al-Ag-Cu alloy system in the brazing filed, so that the cleanness of the wire can be improved, the quality and the reliability of a brazing joint are ensured, and the intercrystalline corrosion resistance of the wire can be greatly improved, and as a result, the phenomenon of 'embrittlement' can be delayed or inhibited.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

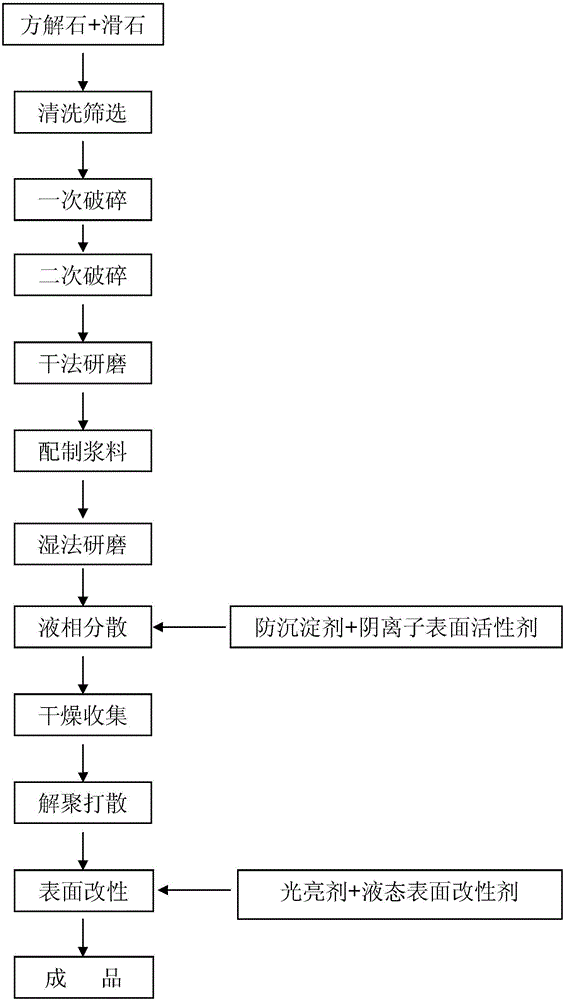

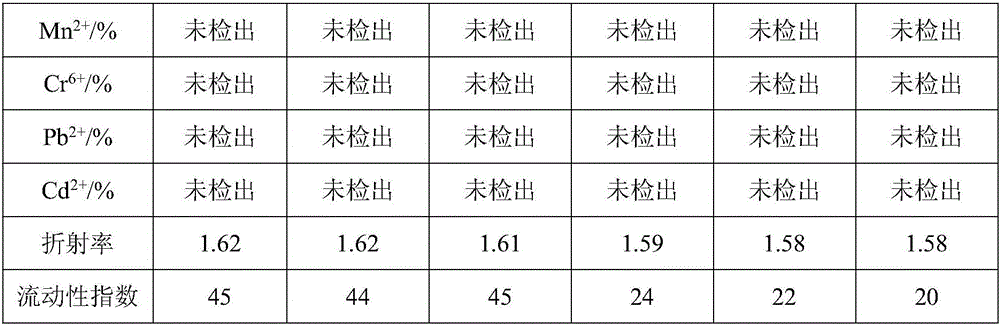

Preparation method of modified calcium carbonate

ActiveCN106317963AGood printabilityEvenly dispersedPigment treatment with organosilicon compoundsPigment physical treatmentDispersityCalcite

The invention provides a preparation method modified calcium carbonate. The preparation method includes: mixing and crushing calcite and talcum, performing dry grinding to obtain raw slurry with solid content being 70-75%, performing constant-temperature stirring and grinding to obtain processed slurry with average particle size being 0.9-1.1 micrometers, adding naphthalene sulfonate type anti-precipitation agent and anionic surfactant into the processed slurry to perform liquid-phase dispersing, drying, collecting, depolymerizing and dispersing, adding brightener and liquid surface modifier to perform wrapping treatment, and stirring to obtain the modified calcium carbonate. By the preparation method, the modified calcium carbonate which is good in printing performance, good in dispersity, good in surface brightness and applicable to films adhered to car bodies can be prepared.

Owner:JIANGXI GUANGYUAN CHEM

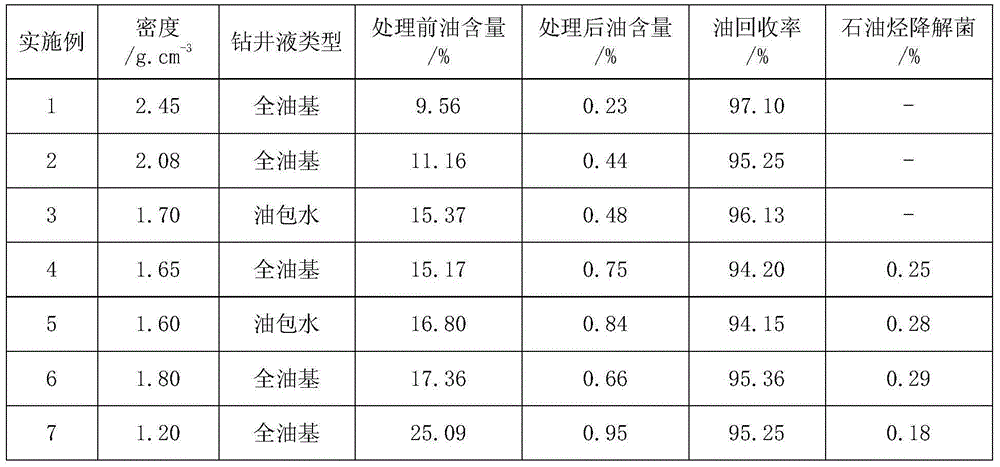

Oil base drill chip processing method

InactiveCN104373065AHigh recovery rateImprove wetting abilityFlushingDrilling compositionEnvironmental resistancePetroleum

The invention relates to an oil base drill chip processing method, belongs to the field of environment protection, and particularly belongs to the technical field of drilling waste processing in oil and natural gas industry. The method comprises the following steps of: (1) demulsification: adding demulsifying agents accounting for 0.4 percent to 1.0 percent of the mass of oil base drill chips into the oil base drill chips in a stirring state; (2) cleaning: adding a non-ionic surfactant solution accounting for 10 percent to 30 percent of the mass of the oil base drill chips and an anionic surfactant solution accounting for 20 percent to 30 percent of the mass of the oil base drill chips into the demulsified oil base drill chips in the first step in the stirring state to obtain an oil-water-solid mixture; (3) separation: carrying out centrifugal separation on the mixture in the step (2); and (4) processing by hydrocarbon degradation bacteria: regulating the pH of the separated oil base drill chips and then adding nutrients, nutrient providers, bulking agents and the hydrocarbon degradation bacteria. The method has the advantages that the oil recovery rate is higher than 94 percent; the oil content of the drill chips is less than 0.3 percent; the operation is simple; the equipment investment is low; and reclamation and harmlessness are realized.

Owner:CHINA PETROCHEMICAL CORP +1

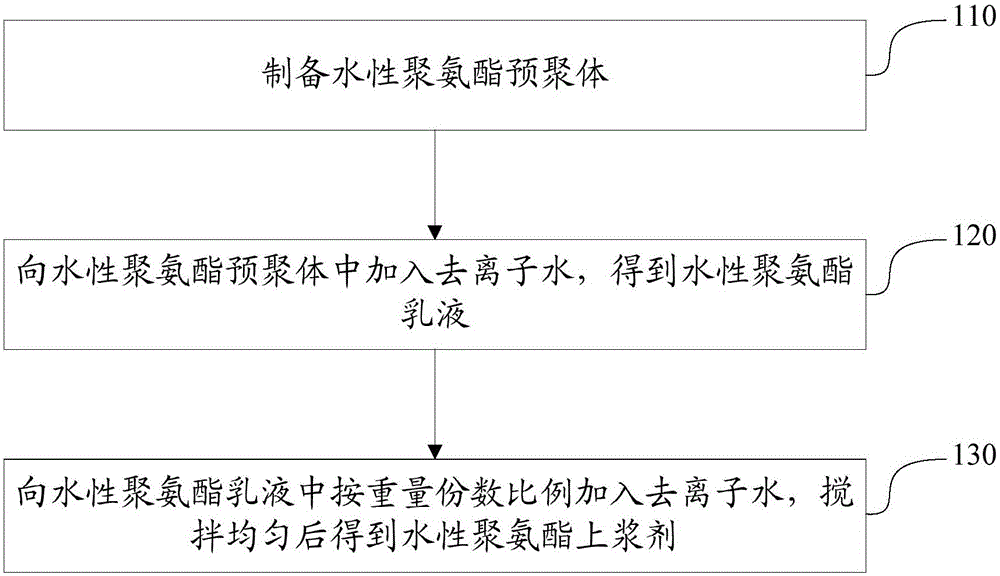

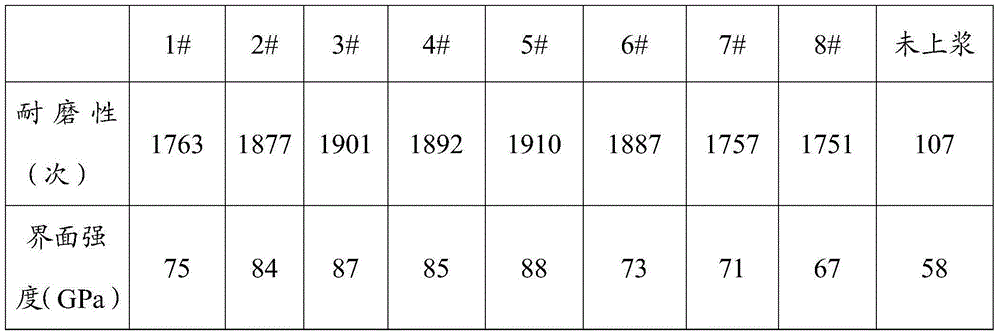

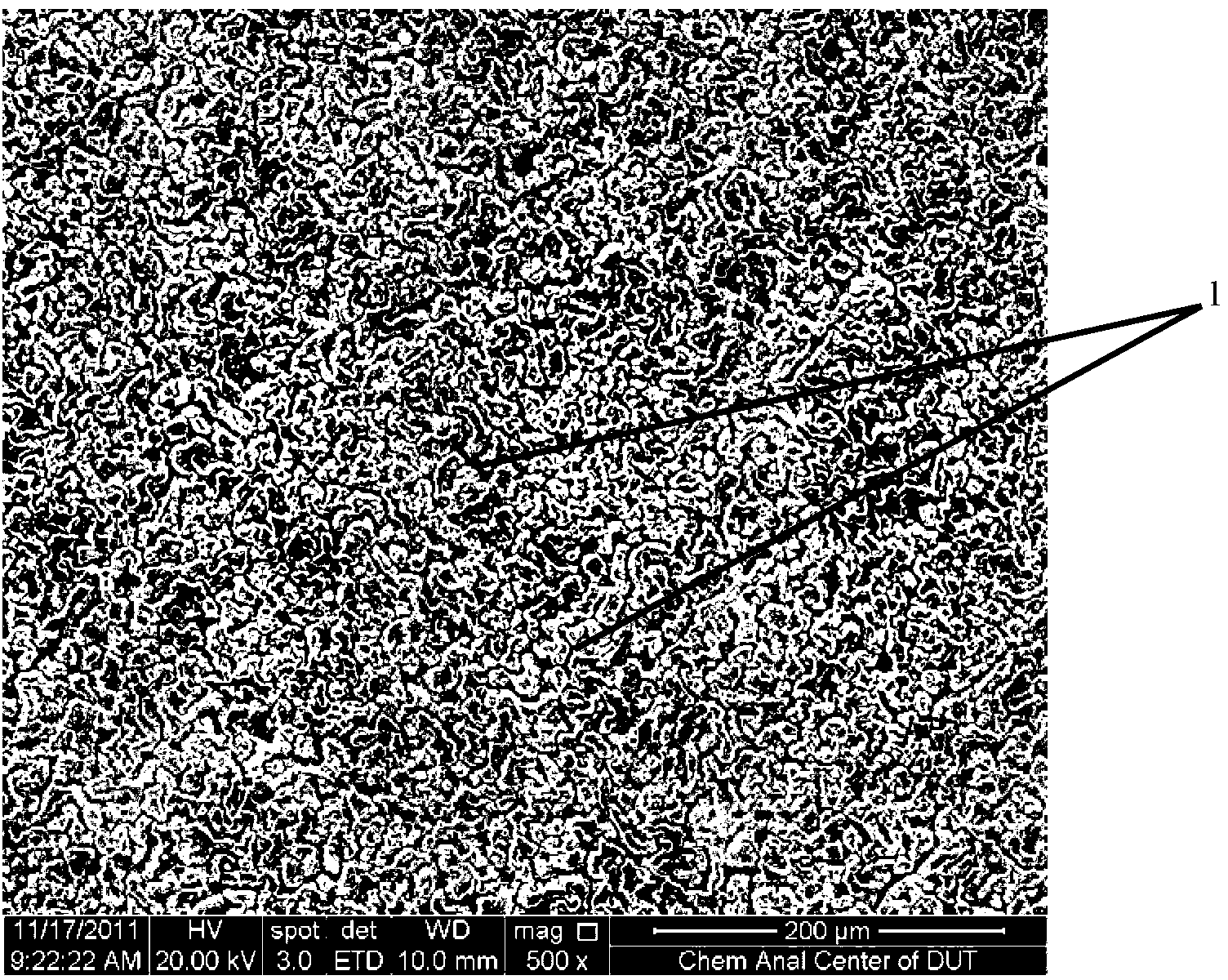

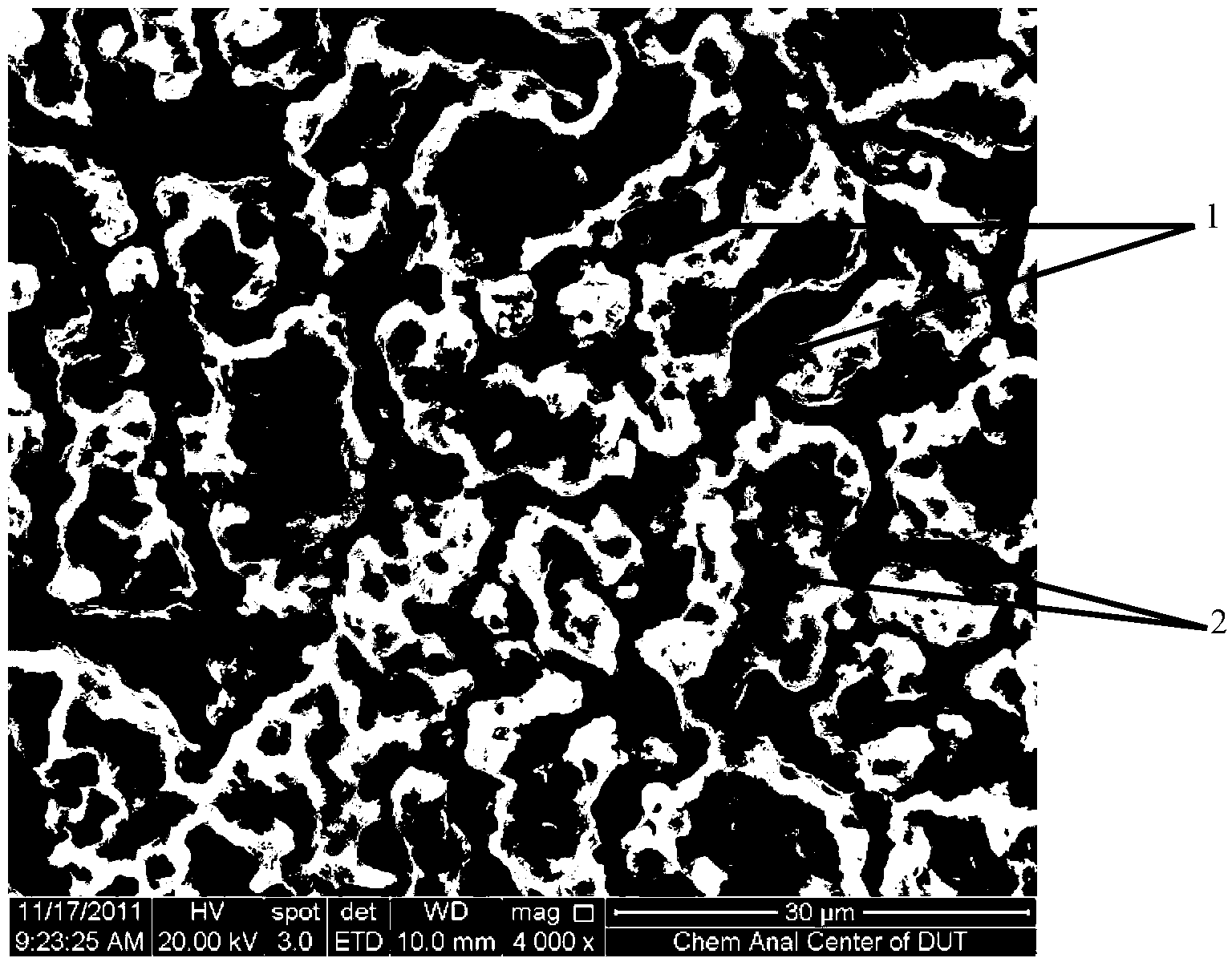

Aqueous polyurethane sizing agent and preparation method thereof

The present invention relates to the technical field of carbon fiber sizing, and more particularly relates to an aqueous polyurethane sizing agent and a preparation method thereof. The aqueous polyurethane sizing agent comprises the following ingredients by weight: 5-25 parts of aqueous polyurethane emulsion and 75-95 parts of deionized water. The preparation method of the aqueous polyurethane sizing agent comprises the steps of: (1) preparing an aqueous polyurethane prepolymer; (2) adding deionized water to the aqueous polyurethane prepolymer to obtain an aqueous polyurethane emulsion; and (3) adding deionized water into the aqueous polyurethane emulsion by weight ratio, and stirring evenly to obtain an aqueous polyurethane sizing agent. The aqueous polyurethane sizing agent provided by the present invention has good dilution stability, increases the wetting ability of sizing agent for carbon fiber, is more conducive to adhering to the surface of the carbon fiber, so that the carbon composite fiber material shows better mechanical properties.

Owner:BEIJING GUANGHUA TEXTILE GRP +1

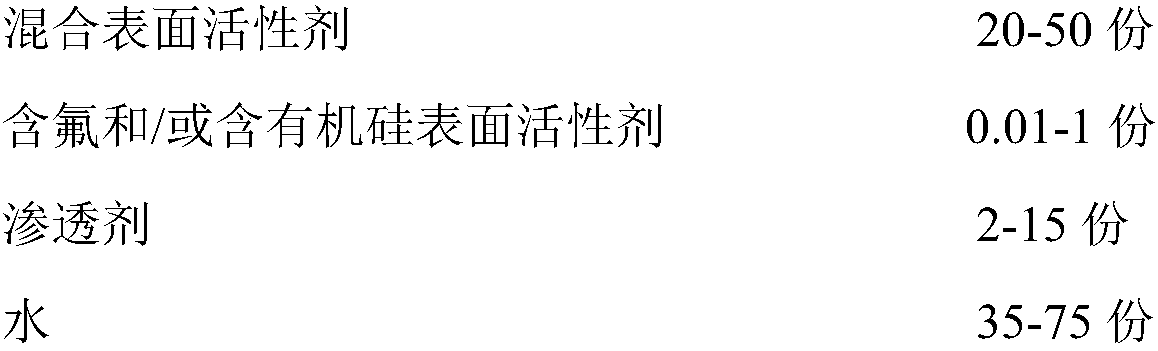

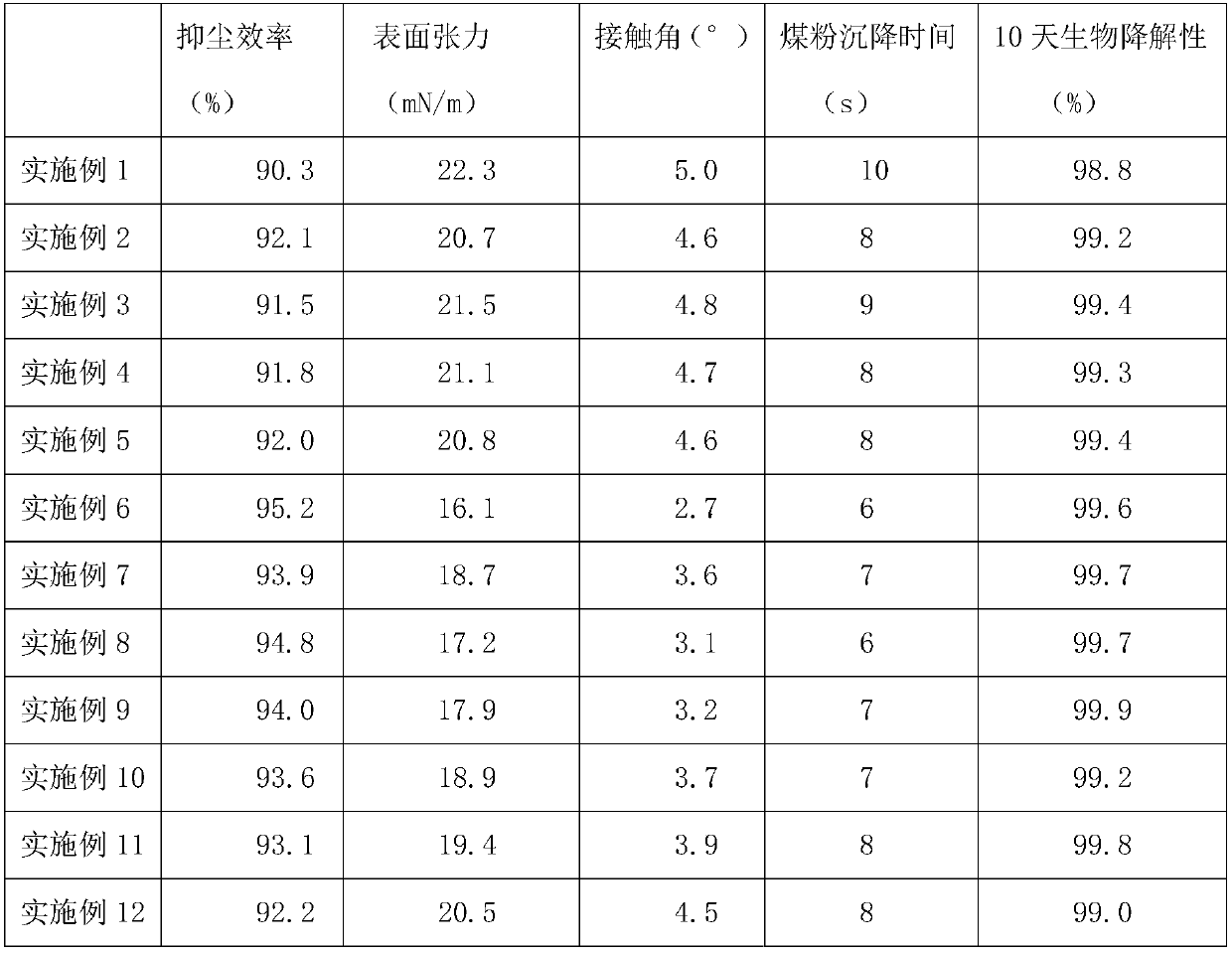

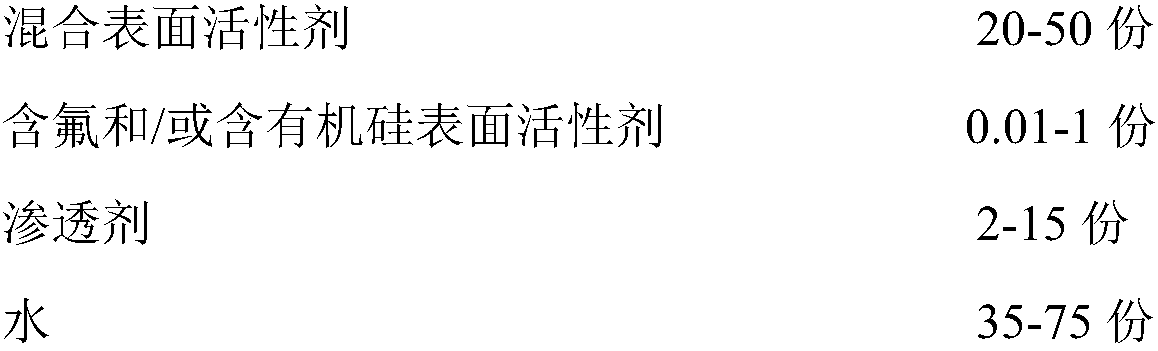

Environment-friendly wetting-type dust suppressant and preparation method thereof

ActiveCN109609091AImprove dust suppression effectImprove biodegradabilityOther chemical processesChemistryEnvironmentally friendly

The invention relates to the technical field of environmental protection, and particularly relates to an environment-friendly wetting-type dust suppressant and a preparation method thereof. The environment-friendly wetting-type dust suppressant disclosed by the invention comprises the following raw materials: a mixed surfactant, a fluorine-containing and / or organic silicon-containing surfactant, apenetrating agent and water, wherein the mixed surfactant is a mixture of a nonionic surfactant and an ionic surfactant. According to the environment-friendly wetting-type dust suppressant disclosedby the invention, the surfactants in the raw materials are all green, environmentally friendly and degradable, so that relatively high biodegradability is achieved, high wettability and permeability are achieved, dust suppression efficiency is high, and dust suppression requirements under various dynamic dust raising working condition environments can be met.

Owner:NANJING NARI GROUP CORP +1

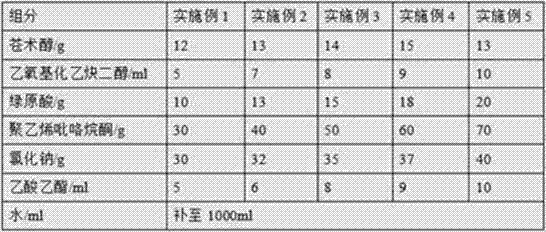

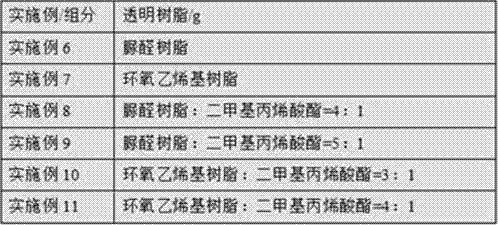

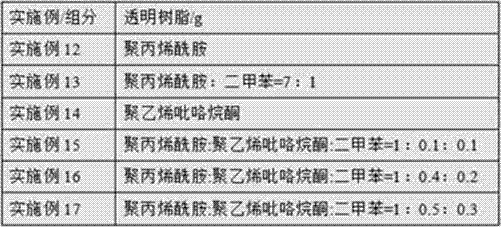

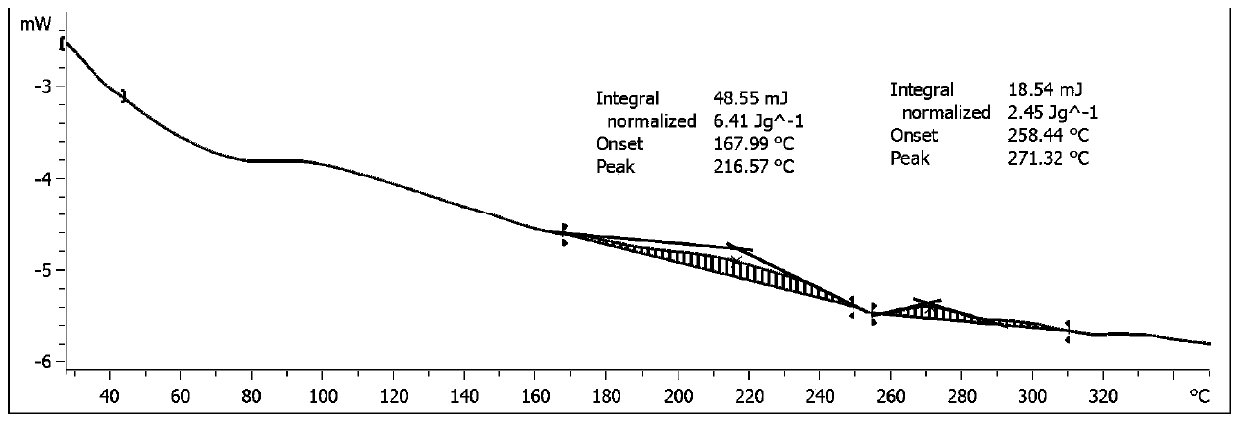

Pathological specimen processing method

InactiveCN106908294ABroad antimicrobial effectAntioxidantPreparing sample for investigationChlorogenic acidSpecimen Handling

The invention discloses a pathological specimen processing method and belongs to the field of specimen processing technology. According to the processing method, sampled pathological tissues successively undergo fixation, dehydration, transparency, wax impregnation, embedding, slicing, staining and mounting so as to obtain a pathological specimen. The fixation is to fix the pathological tissues by the use of a fixative for 4-15 h. The fixative is composed of atractylol, ethoxylated acetylenediol, chlorogenic acid, polyvinylpyrrolidone, sodium chloride, ethyl acetate and pure water. The mounting is to carry out mounting on the stained pathological tissues by the use of a mixture of polyacrylamide, polyvinylpyrrolidone and xylene. According to the invention, toxicity of reagents used in the invention is obviously reduced, the fixation effect is good, degradation and transparency degree are easy to control. Then, the tissues are not easy to deform, embrittle or harden, and mounting is complete and staining is remarkable.

Owner:LUOHE MEDICAL COLLEGE

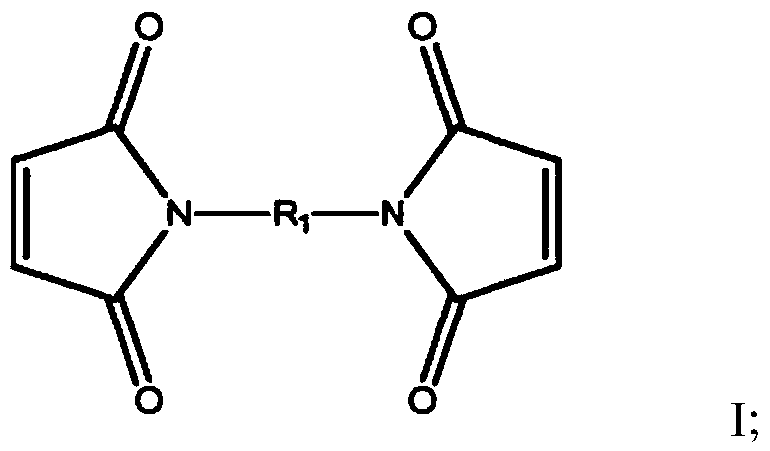

High-temperature-resistant coating modified separator as well as preparation method and application thereof

ActiveCN109988330AImprove temperature sensitivityImprove wettabilityCell seperators/membranes/diaphragms/spacersCoatingsTemperature resistanceLithium-ion battery

The invention belongs to the technical field of lithium batteries, and particularly relates to a high-temperature-resistant coating modified separator as well as a preparation method and application thereof. The modified separator provided by the invention is formed by coating a single surface or double surfaces of a base membrane with a coating material, wherein the coating material comprises a temperature-sensitive high-temperature-resistant polymer, a binder and nano ceramic; the temperature-sensitive high-temperature-resistant polymer is obtained by a polymerization reaction of a bismaleimide monomer and an amine monomer with multiple reaction functional groups. The modified separator prepared by the invention has the advantages of high temperature sensitivity, strong electrolyte wettability, high safety, high temperature resistance and the like, and can greatly improve the use safety and prolong the service life of the lithium ion battery when being used for preparing the lithiumion battery.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

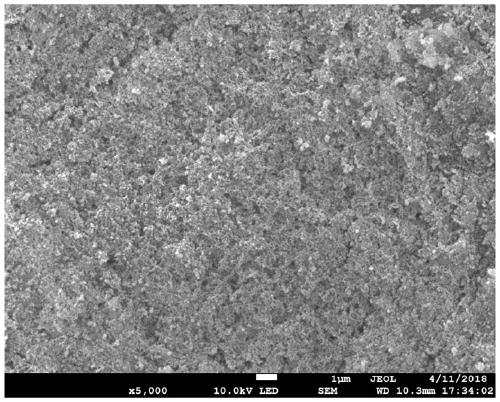

Titanium micro/nanometer double-structured dioxide thin film with high biological activity and preparation method thereof

InactiveCN103290455ASimple preparation processEase of mass production and industrializationSurface reaction electrolytic coatingMicro arc oxidationTitanium metal

The invention relates to a titanium micro / nanometer double-structured dioxide thin film with high biological activity and a preparation method thereof, and belongs to the field of biomedical materials and surface engineering. The preparation method of the thin film comprises steps of: micro-arc oxidizing a cleaned titanium metal surface, and utilizing a lithium tetraborate aqueous solution as an electrolyte and a bipolar pulse micro-arc oxidation power supply as a power supply, wherein the working voltage is 360-500V, the current density is 1-4A / dm<2>, the impulse frequency is 400-700Hz, the duty ratio is 10%-30%, and the oxidation time is 1-30 minutes. The obtained thin film has a structure that homodisperse micron-order grooves and nanometer-order holes are distributed on the surface of the whole thin film in an overlapping manner. The micro / nanometer double-structured dioxide thin film has a special performance, i.e. the film has superstrong wetting ability, and the contact angles of the water and oil are zero. The film has an important meaning on a new generation of a dental implant which can bear large occlusal force and has a short healing phase. The preparation method is simple, the electrolyte is pollution-free, and the film is easy for large-scale production and industrial popularization.

Owner:DALIAN UNIV OF TECH

Halogen-free lead-free soldering paste and preparation method thereof

InactiveCN101695795AHalogen freeExcellent brazeabilityWelding/cutting media/materialsSoldering mediaWaxOrganic solvent

The invention relates to the technical field of soldering pastes, in particular to a halogen-free lead-free soldering paste for soldering an electronic device and a preparation method thereof. The halogen-free lead-free soldering paste consists of a soldering flux and tin-based alloy powder distributed in the soldering flux, wherein the soldering flux consists of the following components in percentage by weight: 25 to 45 percent of polymerized rosin, 5 to 20 percent of hydrogenated rosin, 1 to 4 percent of modified hydrogenated castor oil, 1 to 4 percent of hydrogenated castor oil wax, 3 to 5 percent of activating agent, 1 to 2 percent of stearic amide, 2 to 4 percent of amine and phosphate, and an organic solvent. Because the soldering paste is added with a composition of the amine and the phosphate, not only the solderability of the soldering paste is much better than that of the soldering paste without the composition, but also the soldering paste added with the composition of the amine and the phosphate almost has no tin sweats and particularly can be stored for a long time at normal temperature to keep a good state.

Owner:东莞市特尔佳电子有限公司

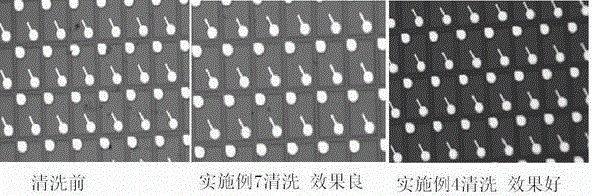

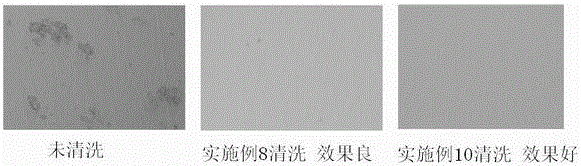

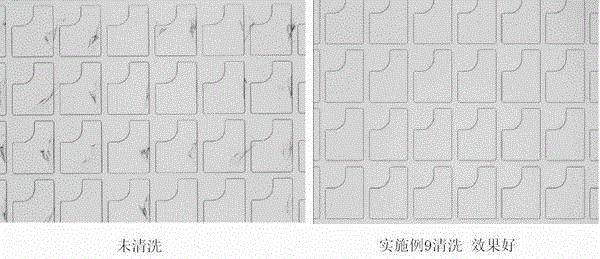

High-efficiency environment-friendly LED chip cleaning agent and application method

ActiveCN106350296APlay a protective effectAvoid secondary pollutionOrganic detergent compounding agentsPolymeric surface-active compoundsPhosphateSolid particle

The invention relates to a high-efficiency environment-friendly LED chip cleaning agent and an application method, belonging to the field of electronic cleaning of photoelectron devices. The cleaning agent is prepared from the following components by weight percent: 1 to 10 percent of alkynediols surfactants, 0.1 to 5 percent of fluorocarbon surfactants, 2 to 10 percent of imidazoline ampholytic surfactants, 3 to 20 percent of emulsifiers, 0.5 to 5 percent of corrosion inhibitors, 1 to 5 percent of chelating agents, 1 to 5 percent of solubilizers, and 40 to 91.8 percent of ultrapure water. The cleaning agent contains the alkynediols surfactants, so that the moisturizing capacity is extremely high, and dirt such as polishing wax, grinding cream and the like on the surface of a chip can be rapidly stripped and dissolved. The cleaning agent contains the imidazoliine ampholytic surfactants, so that a layer of molecular film can be formed on the surface of the chip so as to protect the surface of a chip electrode, and to prevent the electrode from being secondarily polluted or corroded. The cleaning agent is mainly used for cleaning residues such as the polishing wax, the grinding cream, organic contaminants, solid particles and the like, on the surface of the polished LED chip, contains no phosphate, and can completely substitute the existing acid pickling process. The cleaning agent is also suitable for cleaning other workpieces.

Owner:ZHEJIANG AUFIRST MATERIAL TECH CO LTD

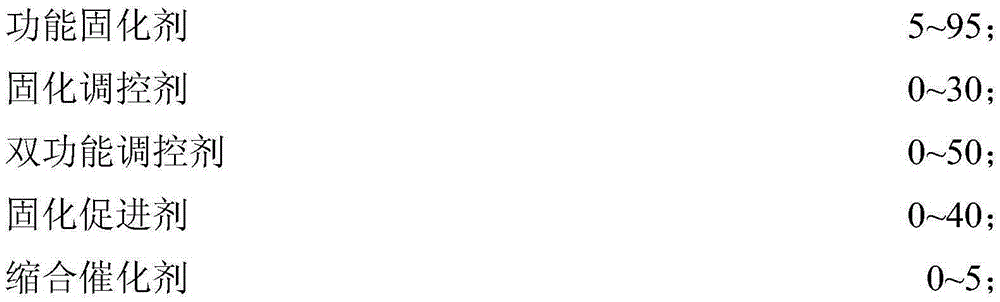

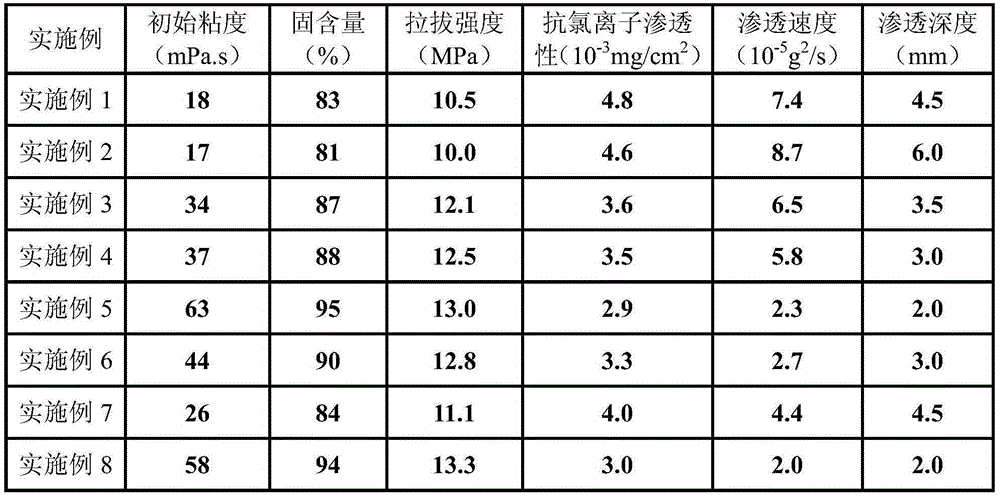

Permeation consolidation type solvent-free epoxy anticorrosive coating, and preparation method and application thereof

ActiveCN105238217AImprove wetting abilityImprove bonding abilityAnti-corrosive paintsEpoxy resin coatingsSolventSurface corrosion

The invention belongs to the technical field of anticorrosive coatings, and discloses a permeation consolidation type solvent-free epoxy anticorrosive coating, and a preparation method and an application thereof. The anticorrosive coating consists of a component A and a component B. The component A consists of the following components in parts by weight: 18-89 parts of epoxy resin, 5-50 parts of enhanced type reactive solvents, 5-60 parts of permeation type reactive solvents, 0-5 parts of interfacial modifiers and 0-3 parts of permeation enhancers. The component B consists of the following components in parts by weight: 5-95 parts of functional curing agents, 0-30 parts of curing regulators, 0-50 parts of double-function regulators, 0-40 parts of curing accelerators and 0-5 parts of condensation catalysts. The coating is low in viscosity and excellent in permeability, and has an excellent mechanical property after being cured. In addition, the permeation consolidation type solvent-free epoxy anticorrosive coating disclosed by the present invention has good wettability and viscocity with concrete, and strength of the concrete can be improved, water on the surface of the concrete can be removed, and surface corrosion factors of the concrete are reduced.

Owner:SOUTH CHINA UNIV OF TECH

Coal flow dust suppressant as well as preparation method and application thereof

InactiveCN107828380AHigh viscosityWeight increaseOther chemical processesEngineeringSURFACTANT BLEND

The invention belongs to the technical field of control for coal flow flying dust and particularly relates to a coal flow dust suppressant as well as a preparation method and an application thereof. The coal flow dust suppressant comprises components in parts by weight as follows: starch-grafted acrylic polymer, a surfactant and water. The coal flow dust suppressant has good coagulation property,wettability and permeability, dust particles are wetted rapidly and coagulated together, grain size and weight of the dust particles are increased, meanwhile, the coal flow dust suppressant can rapidly permeate into the coal flow, and the dust suppression effect is realized. According to the coal flow dust suppressant, the technical defect of low dust suppression speed of a traditional dust suppressant can be effectively overcome.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Novel 4Al3 aluminum alloy used for vacuum soldering

ActiveCN102357744AIncrease contentLow melting pointWelding/cutting media/materialsSoldering mediaTrace elementSoldering

The invention provides a novel 4Al3 aluminum alloy used for vacuum soldering, which can solve the problems of high soldering temperature and undesirable soldering quality of the traditional 4Al3 aluminum alloy used for vacuum soldering, and can solve the problem that a surface oxide film of a workpiece can be removed only by Mg-contained soldering flux by the 4Al3 aluminum alloy to carry out vacuum soldering, and the vacuum soldering technology can be simplified. The novel 4Al3 aluminum alloy is characterized by comprising the following raw materials according to 100 parts by weight: more than 8.2-9 parts of Si, 0-6 parts of Fe, 0-0.2 part of Cu, 0-0.2 part of Mn, 0.08-0.2 part of Mg, 0-0.2 part of Zn, 0-0.15 part of Ti, 0-0.15 part of other impurity trace elements and the balance of Al.

Owner:YINBANG CLAD MATERIAL

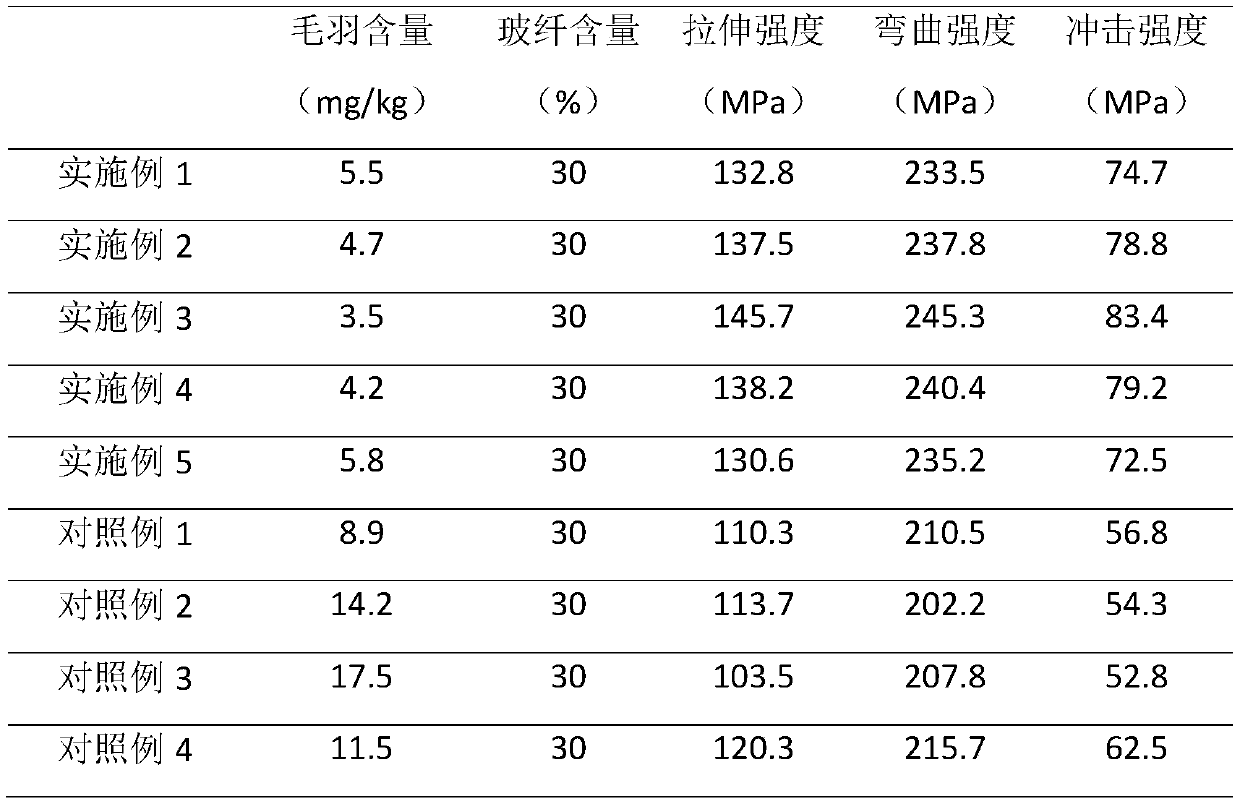

Glass fiber impregnating compound for polyurethane pultrusion composite material and preparation method of glass fiber impregnating compound

The invention discloses a glass fiber impregnating compound for a polyurethane pultrusion composite material and belongs to the technical field of polyurethane pultrusion processes. The glass fiber impregnating compound comprises the following components in percentage: 0.2-0.6wt% of a silane coupling agent A, 0.4-0.8wt% of a silane coupling agent B, 6.2-8.2wt% of a film-forming agent, 0.3-0.7wt% of a lubricant A, 0.2-0.8wt% of a lubricant B, 0.2-0.6wt% of an auxiliary agent, 0.2-0.4wt% of a pH regulator and the balance of water. The glass fiber impregnating compound disclosed by the inventionis high in compatibility with a polyurethane pultrusion composite material, can enable glass fiber yarn to be good in bundling property and small in hairiness amount, and can improve mechanical properties of a glass fiber reinforced polyurethane composite material.

Owner:NEIJIANG HUAYUAN ELECTRONICS MATERIALS

Preserving stationary liquid for pathological tissues

InactiveCN106689120AImprove hygroscopicityReasonable combinationDead animal preservationChemistrySpecimen Handling

Owner:NANYANG MEDICAL COLLEGE

Environmental-protection lubricating water-based cutting fluid

InactiveCN104327933AGood emulsification and dispersionGood dispersionLubricant compositionSolubilityWater based

The present invention discloses an environmental-protection lubricating water-based cutting fluid, which comprises the following raw materials by weight: 8-20 parts of sodium abietate, 15-25 parts of a rosin amine glucose ester surfactant, 5-10 parts of rosin amine polyoxyethylene ether, 12-18 parts of a polyaniline aqueous anti-corrosion agent, 5-15 parts of triethanolamine oleate, 3-8 parts of triethanolamine, 3-10 parts of diisopropanolamine, 10-15 parts of sodium carbonate, 5-15 parts of hydrophilic alcohol, 3-6 parts of a sterilization agent, 2-5 parts of a foaming agent, 3-10 parts of a stabilizer, and 80-100 parts of water. The environmental-protection lubricating water-based cutting fluid has functions of excellent cleaning, excellent lubrication, excellent corrosion resistance and excellent cooling, and further has characteristics of environmental protection, long service life, good water solubility, low cost, and high stability.

Owner:CHAOHU GUANGFENG METAL PROD

Sr and multi-combination-metamorphism low-zinc hot-dipping-coating aluminum alloy coating materials

InactiveCN103131990AHigh strengthImprove corrosion resistanceHot-dipping/immersion processesSolderabilityAlloy coating

The invention discloses Sr and multi-combination-metamorphism low-zinc hot-dipping-coating aluminum alloy coating materials. According to element weight percentage, alloy constituent is that Zn: 28-30, Sr: 0.01-0.02, Li: 0.1-2.0, solvent deactivator: 0.8-1.0, Bi: 0.025-0.035, grain refiner: 0.1-0.2, rare earth additives: 0.1-0.5, basal body interface reaction buffering agent: 0.1-0.8, and the rest of the alloy constituent is Al and inevitable micro impurity. The Sr and multi-combination-metamorphism low-zinc hot-dipping-coating aluminum alloy coating materials have the advantages of being good in wettability of base steel, strong in combination force, high in strength, good in extensibility, high-temperature-resistant, thin in thickness of a coating layer, strong in corrosion resistance, and good in machinability and weldability and the like.

Owner:贵州铝厂有限责任公司

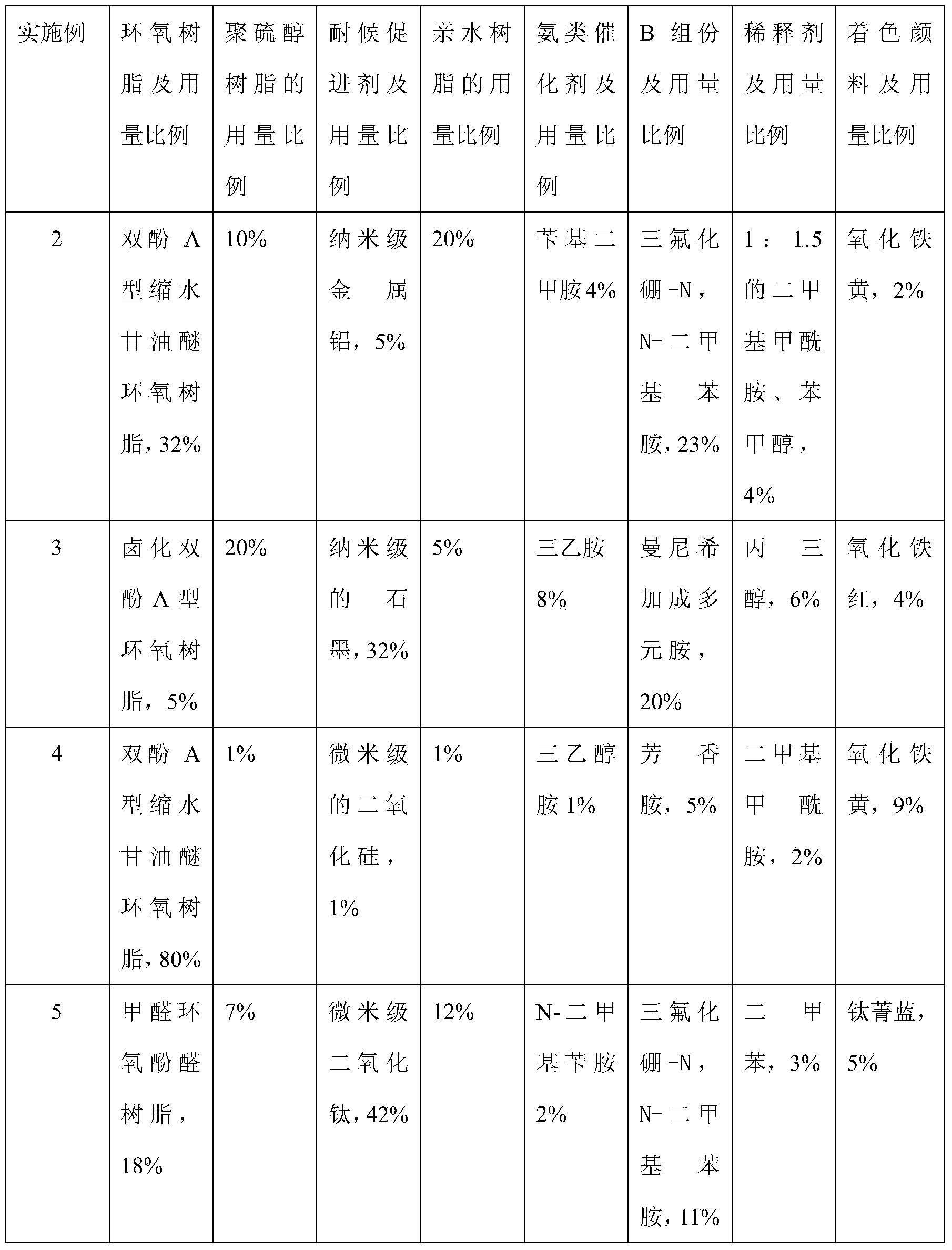

Binder and preparation method thereof

The invention relates to a binder. The binding comprises a component A and a component B, wherein the component A comprises the following materials by mass percent: 5%-80% of epoxy resin, 1%-20% of poly-mercaptan resin, 1%-50% of weather-proof accelerant, 1%-40% of hydrophilic resin, and 1%-8% of ammonia catalyst; the component B comprises the following material by mass percent: 5%-60% of one or more of boron trifluoride-amine complex curing agent, aromatic amine and mannich addition polyamine; hydrophilic perssad is introduced into the molecule of the hydrophilic resin through chemical reaction, so that the hydrophilic resin becomes the resin capable of reacting and has self-emulsifying property. The binder and solid particle aggregate with grain size of 0.08-1.18mm are mixed to be used as a road pavement material and directly paved on permeable concrete, the mixture of the binder and the solid particle aggregate and the concrete are bonded so as to form a precast block body with a bilayer structure, so that the whole precast block body has good drainability and permeability.

Owner:拉法基豪瑞投资有限公司

Novel poly urethane (PU) yellowing-resistant quick-drying open varnish

InactiveCN102391769AShorten drying timeIncrease opennessPolyurea/polyurethane coatingsPolymer scienceCarboxyl radical

The invention provides novel poly urethane (PU) yellowing-resistant quick-drying open varnish, which is characterized by comprising main paint and curing agent, wherein the main paint comprises hydroxy acrylic resin and chloroacetic resin with the self-drying performance of a repeating unit in a formula (I); in the formula (I), R1 is a hydrogen atom, an alkyl or a carboxyl, R2 is a hydrogen atom, an alkyl, a carboxyl or a hydroxyl, and n is more than 30; and the curing agent is polyisocyanate. According to the novel PN open varnish, dependence on nitrocotton by the traditional open paint can be gotten rid of, and the yellowing-resistance problem can be favorably solved. In addition, the drying speed of the novel yellowing-resistant quick-drying open varnish disclosed by the invention is high, hardness is further improved, and the novel yellowing-resistant quick-drying open varnish has a favorable open effect. Under the condition of keeping excellent paint film performance and improving the quality of wood products after the wood products are lacquered, PU paint drying time in the furniture coating process is drastically saved, and production efficiency is improved.

Owner:SHANGHAI CHANGRUNFA PAINT

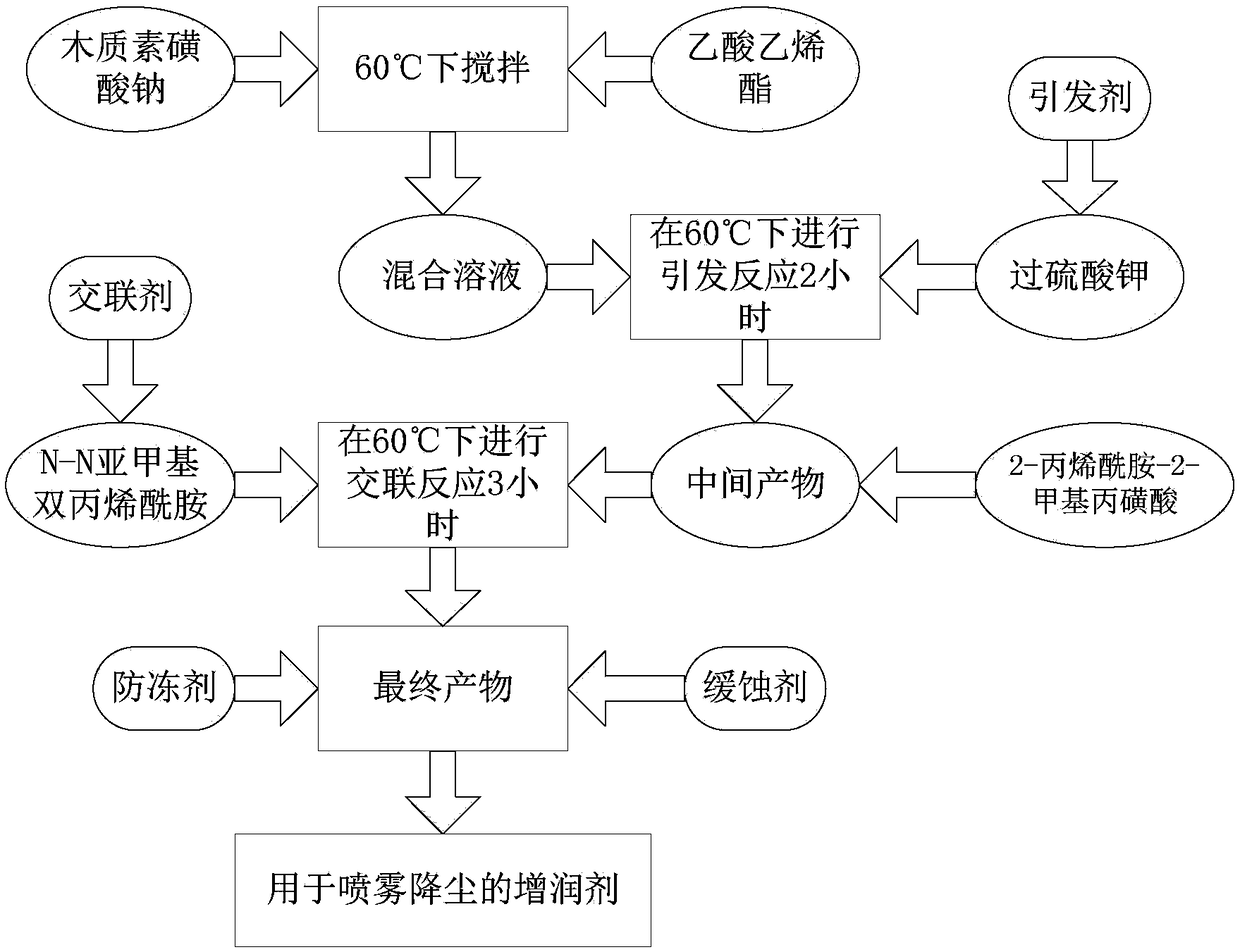

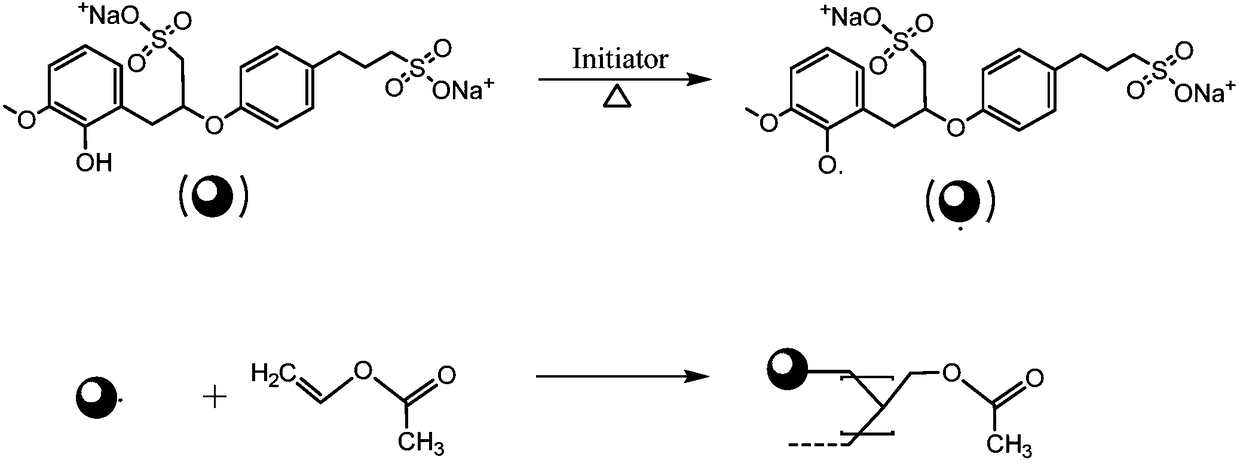

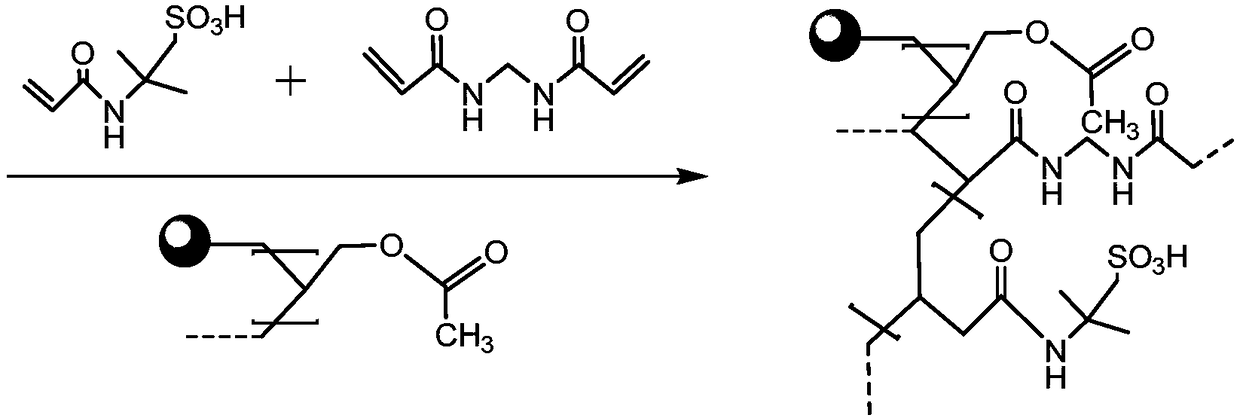

Moistening agent for coal mine spray and dust reduction and preparation method

ActiveCN108864382AImprove wetting abilityReduce surface tensionOther chemical processesChemistryLignosulfonates

The invention discloses a moistening agent for coal mine spray and dust reduction and a preparation method thereof. The moistening agent is prepared from 3% to 5% of lignosulfonate, 3% to 5% of vinylacetate, 3% to 5% of 2-acrylamide-2-methyl propanesulfonic acid, 0.05% to 0.1% of an initiator, 0.02% to 0.04% of a crosslinking agent, 0.3% to 0.6% of an antifreezing agent, 0.2% to 0.4% of a corrosion inhibitor and the balance of water, wherein sodium lignosulphonate is utilized as a matrix to perform polymerization reaction with vinyl acetate and 2-acrylamide-2-methyl propanesulfonic acid, so that generated polymer not only keeps degradable performance of sodium lignosulphonate, but also can make fog drops have moistening and bonding functions. When the moistening agent for coal mine sprayand a surface active agent are compounded to be applied into a spray system, wettability of spray to coal dust is further improved, the fog drops can effectively moisten and wrap the dust; thus, the dust suppression efficiency is greatly improved, and dust dispersion is reduced; furthermore, the moistening agent can be naturally decomposed, so that the situation of secondary pollution caused by dust fall is prevented from happening.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com