High-efficiency environment-friendly LED chip cleaning agent and application method

A technology of LED chips and cleaning agents, applied in detergent compositions, detergent compounding agents, chemical instruments and methods, etc., can solve problems such as environmental hazards, human injury, and increased production costs, and achieve strong wetting ability and prevent Effects of secondary pollution or corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the product in the embodiment 1-8 is: add a certain amount of ultrapure water in the reactor, start to stir; add acetylenic glycol surfactant by mass ratio, stir for 3-5 minutes; add fluorine by mass ratio Carbon surfactant, stir for 3-5 minutes; add imidazoline amphoteric surfactant according to mass ratio, stir for 5 minutes; add emulsifier according to mass ratio, stir for 5 minutes; add corrosion inhibitor according to mass ratio, stir for 5 minutes ; Add a chelating agent according to the mass ratio and stir for 5 minutes; finally add a solubilizer and stir for 20 minutes until it is transparent, and the LED chip cleaning agent is obtained.

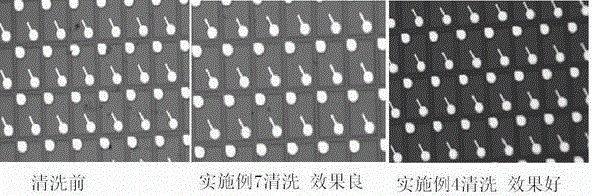

[0032] The percentages in the examples are percentages by weight unless otherwise specified. The following methods are used to test the effect of the following cleaning agents: make an aqueous solution according to the concentration of 10%, and clean the workpiece by ultrasonic at 70°C, and the cleani...

Embodiment 9

[0036] Take a 1kg product as an example, add 67.5% ultrapure water into the reaction kettle, start stirring; then add 5% of 2,4,7,9-tetramethyl-5-decyne-4,7diol 30% ethylene oxide, stirred for 3 minutes; then added 2% tripolyepoxyhexafluoropropane amido betaine, stirred for 5 minutes; then added 3% aminoethyl amphoteric imidazoline, stirred for 3 minutes; then added 15 % triethanolamine oleate, stirred for 3 minutes; then added 1.5% urotropine, stirred for 3 minutes; then added 2% nitrilotriacetic acid, stirred for 3 minutes; then added 4% alkyl glucoside, stirred for 15 minutes to transparent. The resulting product has a good cleaning effect.

[0037] The LED chip cleaning agent in this embodiment is made by mixing the ingredients in the following table.

[0038]

Embodiment 10

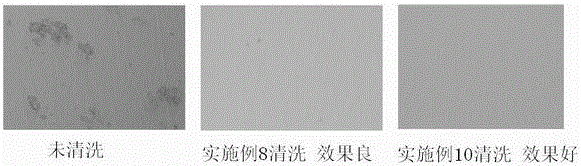

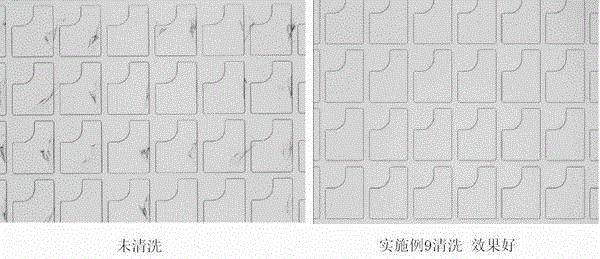

[0040] Adopt the method among the embodiment 9, what the components in the following table are mixed to cleaning agent product. The cleaning effect of this product is compared with the cleaning effect of the product in Example 8 figure 2 .

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com