High-temperature-resistant coating modified separator as well as preparation method and application thereof

A high-temperature-resistant polymer, temperature-sensitive technology, applied in the direction of separator/film/diaphragm/spacer element, coating, electrical components, etc., can solve the problem of reducing the energy density of lithium-ion batteries, coating layer peeling, fire and explosion and other problems, to achieve the effect of good electrolyte wettability, strong wettability and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

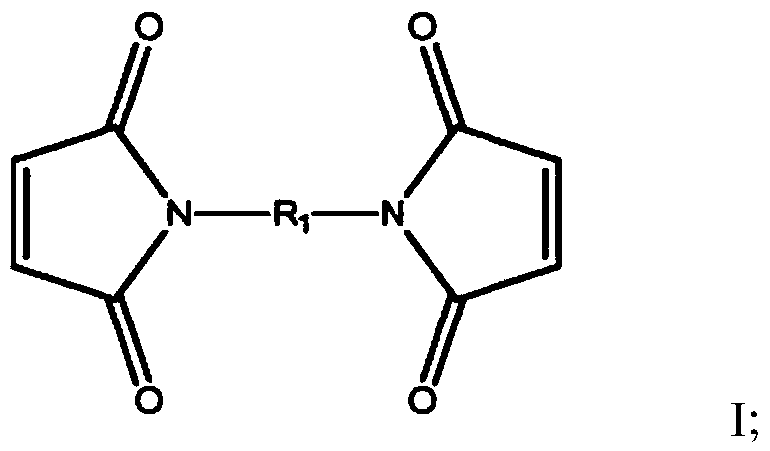

[0050] N used in this embodiment, N'-methylenebismaleimide (C 9 h 6 N 2 o 4 ) structural formula is as follows:

[0051]

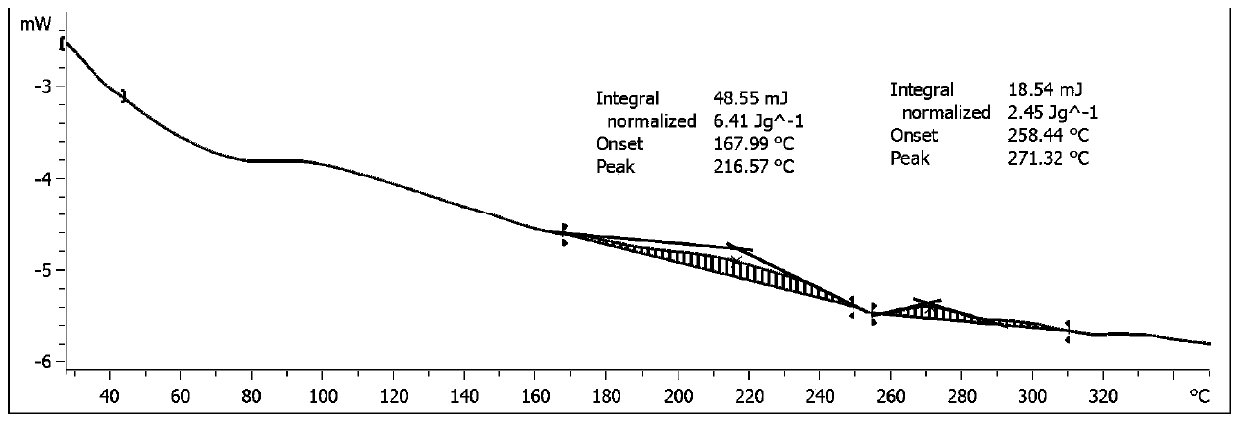

[0052] 1mol (206.16g) N, N'-methylenebismaleimide (C 9 h 6 N 2 o 4 ) mixed with 0.005 mol of azobisisobutyronitrile and 3008.25 g of N-methylpyrrolidone, reacted at 50°C for 24 hours, then weighed 1 mol of barbituric acid, divided into six equal parts, and added to the reaction system at intervals of half an hour, all Added and then reacted for 9 hours to obtain reaction solution A (temperature-sensitive high-temperature-resistant polymer) with a solid content of 10%.

[0053] Weigh 100g of the above reaction solution A, add 20g of nano ceramics and 2g of PVDF, add 198g of N-methylpyrrolidone, and stir for 2.5 hours to obtain solution B, which has a solid content of 10%, which can be used as a lithium battery separator coating material.

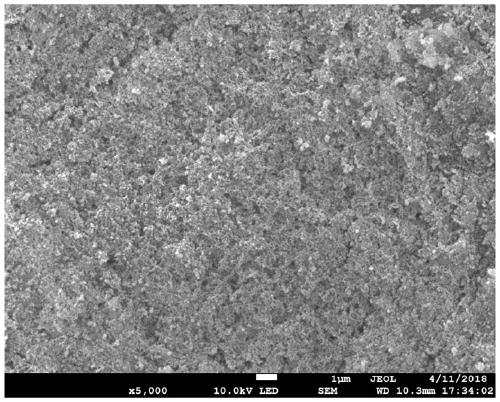

[0054] Filter the above solution B to obtain a uniformly dispersed slurry. Use the transfer coating method t...

Embodiment 2

[0056] Mix 358.35 g of 1 mol of N,N'-(methylene diphenyl) bismaleimide with 0.01 mol of azobisisobutyronitrile and 729.66 g of N-methylpyrrolidone, react at 80°C for 0.5 hours, and then Weigh 128.09 g of 1 mol of barbituric acid, divide it into 3 portions, add it into the reaction system at intervals of half an hour, and react for 2 hours after adding all of them to obtain a reaction solution A with a solid content of 40%. Take 500g of this solution A, add 70g of nano ceramics and 100g of PVDF, add 255g of N-methylpyrrolidone, and stir for 0.5 hours to obtain solution B (40% solid content, which can be used as a lithium battery separator coating material). After filtering, use In the transfer coating method, both sides of the PE base film are coated, and dried at 100° C., and the coating layer with a thickness of 5 μm after drying is obtained to obtain a modified diaphragm.

Embodiment 3

[0058] 1mol 2,2-bis[4-(4-maleimidephenoxy)phenyl]propane (C 35 h 26 N 2 o 6 ) 570.60g mixed with 0.05mol azobisisobutyronitrile and 1939g gamma-butyrolactone, reacted at 75°C for 12 hours, then weighed 0.6mol melamine 75.672g, divided into six parts, and added to the reaction system at intervals of half an hour , and reacted for 0.5 hour after adding all of them to obtain reaction solution A with a solid content of 25%. Take by weighing 100g of this solution A, add 250g of nano-ceramics and 55g of PVDF, add 1000g of gamma-butyrolactone and mix, stir for 6 hours to obtain solution B (solid content 23.5%, can be used as lithium battery diaphragm coating material), after filtration, Coating on both sides of the PE base film by means of gravure printing, drying at 120° C., and obtaining a coating layer with a thickness of 4 μm after drying, to obtain a modified diaphragm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com