Full-biodegradable anti-caking agent for compound fertilizer/blended fertilizer and preparation method thereof

An anti-caking agent and compound fertilizer technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of affecting fertilizer efficiency, storage, transportation and use difficulties, etc., to achieve reduced possibility, low surface tension, and good spreadability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

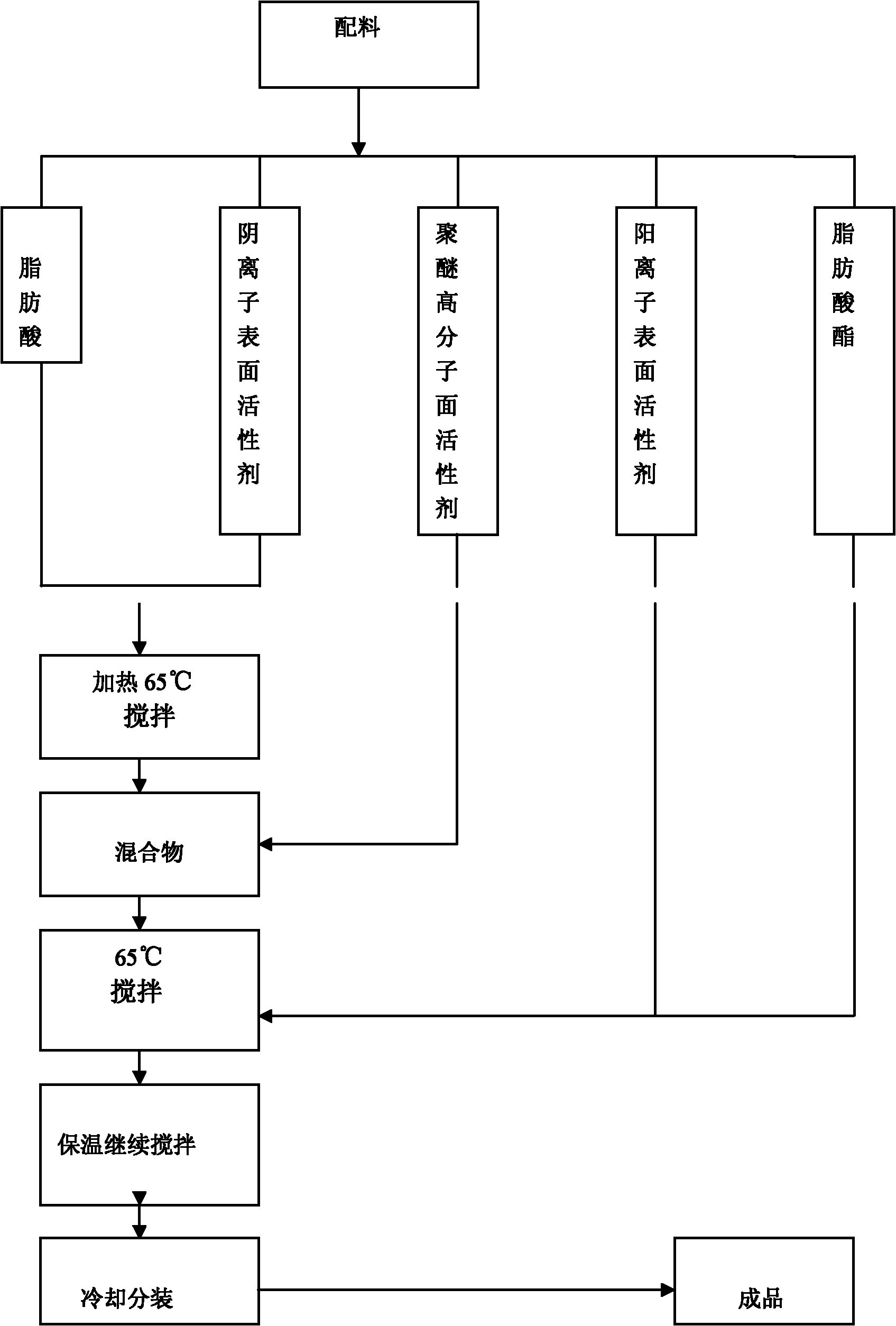

[0022] Such as figure 1 Shown, a kind of preparation method of fully biodegradable compound fertilizer / compound fertilizer anti-caking agent, it comprises the steps:

[0023] 1) Ingredients: according to the mass percentage of each component:

[0024] Anionic surfactant (sodium octadecylphenylsulfonate) 2%,

[0025] Fatty acid (oleic acid and stearic acid, the mass ratio of oleic acid and stearic acid is 1:1) 86.3%,

[0026] Polyether polymer surfactant [octadecyl (EO) 40 (PO) 10 Ether] 1.2%,

[0027] Cationic surfactant (octadecylaminodimethylammonium bromide) 0.5%,

[0028] Fatty acid ester (isopropyl stearate) 10%,

[0029] Select fatty acids, anionic surfactants, cationic surfactants, polyether polymer surfactants and fatty acid esters for subsequent use:

[0030] Among them, octadecyl (EO) 40 (PO) 10 The manufacturer of ether is Liaoyang Aoke Chemical Co., Ltd.; the manufacturer of octadecylaminodimethylammonium bromide is Jiangsu Feixiang Chemical Co., Ltd.

[...

Embodiment 2

[0039] A preparation method of fully biodegradable compound fertilizer / compound fertilizer anti-caking agent, it comprises the steps:

[0040] 1) Ingredients: according to the mass percentage of each component:

[0041] Anionic surfactant (octadecylphenylsulfonate) 2.3%,

[0042] Fatty acid (stearic acid and oleic acid, the mass ratio of stearic acid and oleic acid is 1:1) 87.9%,

[0043] Polyether polymer surfactant [octadecyl (EO) 60 Ether] 1.5%,

[0044] Cationic surfactant (octadecylamine dimethyl ammonium chloride) 0.3%,

[0045] Fatty acid ester (methyl oleate) 8%,

[0046] Select fatty acids, anionic surfactants, cationic surfactants, polyether polymer surfactants and fatty acid esters for subsequent use:

[0047] Among them, octadecyl (EO) 60 The manufacturer of ether is Liaoyang Aoke Chemical Co., Ltd.; the manufacturer of octadecylamine dimethyl ammonium chloride is Jiangsu Feixiang Chemical Co., Ltd.; octadecylphenylsulfonate is octadecylphenylsulfonate Sodiu...

Embodiment 3

[0056] A preparation method of fully biodegradable compound fertilizer / compound fertilizer anti-caking agent, it comprises the steps:

[0057] 1) Ingredients: according to the mass percentage of each component:

[0058] Anionic Surfactant [Nonylphenol Polyoxyethylene (EO) 20 ether sulphate] 3%

[0059] Fatty acid (oleic acid, linoleic acid and stearic acid, the mass ratio is 2:1:1) 84.7%

[0060] Polyether polymer surfactant [octadecyl (EO) 60 (PO) 20 Ether] 1.5%

[0061] Cationic surfactant (octadecylamine dimethyl ammonium chloride) 0.8%

[0062] Fatty acid ester (ethyl oleate) 10%

[0063] Select fatty acids, anionic surfactants, cationic surfactants, polyether polymer surfactants and fatty acid esters for subsequent use:

[0064] Among them, nonylphenol-based polyoxyethylene (EO) 20 The manufacturer of ether sulfate is Hunan Lichen Daily Chemical Co., Ltd.; Octadecyl (EO) 60 (PO) 20 The manufacturer of ether is Liaoyang Aoke Chemical Co., Ltd.; the manufacturer o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com