Oil base drill chip processing method

An oil-based drilling cuttings, processing method technology, applied in chemical instruments and methods, earthwork drilling, drilling composition and other directions, can solve the problems of not being well separated, many potential safety hazards, and large equipment investment, etc. Realize the effect of resource utilization and harmlessness, improve the ability to remove oil pollution, and reduce equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

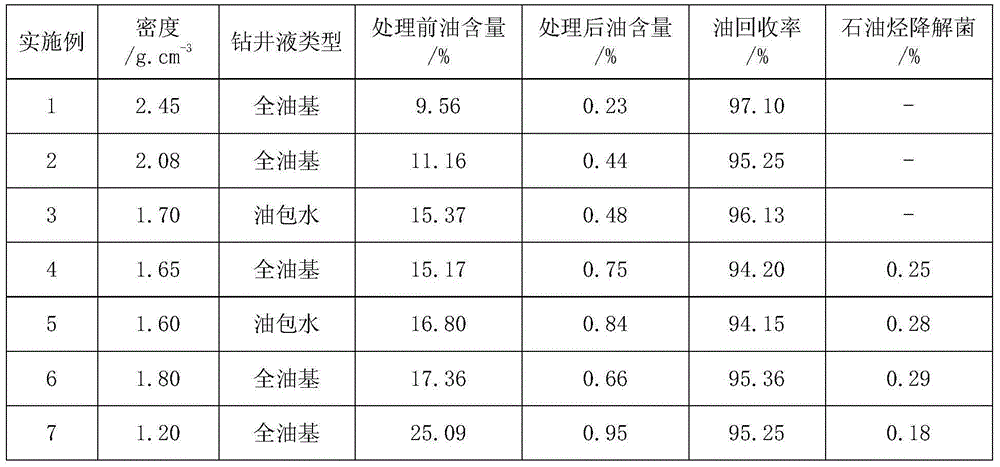

Embodiment 1

[0026] Put the oil-based cuttings in an oilfield in a container with stirring facilities, add 0.4% of the mass of the oil-based cuttings W-035 under continuous stirring at 200rpm, and stir for 3 minutes; add 10% of the mass of the oil-based cuttings and Mass fraction is 10% methanol solution of ethylene glycol stearate and 20% and mass fraction is 10% secondary alkyl sodium sulfate aqueous solution, stir 5min, obtain a mixture; The above-mentioned mixture is 2500rpm at rotating speed, separation time Separation under the condition of 5min.

Embodiment 2

[0028] Put the oil-based cuttings of an oilfield in a container with a stirring facility, add 0.6% of the mass of the oil-based cuttings W-013 under continuous stirring at 300rpm, and stir for 2 minutes; add 10% of the mass of the oil-based cuttings and Mass fraction is 10% ethanol solution of sorbitan monooleate and 20% and mass fraction is 10% sodium dodecylsulfonate aqueous solution, stirs 10min, obtains a mixture; Be 3000rpm at rotating speed, separation time is Under the condition of 5 min, the above mixture was separated.

Embodiment 3

[0030] Put oil-based cuttings in an oilfield in a container with stirring facilities, add 1.0% of the mass of oil-based cuttings W-035 under continuous stirring at 300rpm, and stir for 3 minutes; add 20% of the mass of oil-based cuttings and Mass fraction is 10% ethyl acetate solution of glyceryl monostearate and 20% and mass fraction is 20% sodium lauryl sulfate aqueous solution, continue to stir for 5min, obtain a mixture; The above mixture was separated under the condition that the separation time was 5 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com