Special cobalt-based metal ceramic alloy powder for optical fiber laser cladding

A fiber laser and ceramic alloy technology, applied in the coating process and coating of metal materials, can solve the problems of uneven heat transfer and melting, shrinkage porosity, cracks, etc., and achieve excellent metallurgical properties, compact structure, and thermal conductivity. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 10 grams of carbon, 10 grams of silicon, 20 grams of iron, 15 grams of nickel, 30 grams of molybdenum, 80 grams of chromium, 30 grams of tungsten, 130 grams of tungsten carbide, 20 grams of calcium fluoride, 10 grams of silicon nitride, 645 grams of cobalt, After thorough mechanical mixing, a cobalt-based cermet alloy powder with a particle size of 30-65 micrometers (μm) is obtained.

Embodiment 2

[0023] 20 grams of carbon, 20 grams of silicon, 40 grams of iron, 25 grams of nickel, 40 grams of molybdenum, 120 grams of chromium, 40 grams of tungsten, 170 grams of tungsten carbide, 30 grams of calcium fluoride, 20 grams of silicon nitride, 475 grams of cobalt, After thorough mechanical mixing, a cobalt-based cermet alloy powder with a particle size of 30-65 micrometers (μm) is obtained.

Embodiment 3

[0025] 15 grams of carbon, 15 grams of silicon, 30 grams of iron, 20 grams of nickel, 35 grams of molybdenum, 100 grams of chromium, 35 grams of tungsten, 150 grams of tungsten carbide, 25 grams of calcium fluoride, 15 grams of silicon nitride, 560 grams of cobalt, After thorough mechanical mixing, a cobalt-based cermet alloy powder with a particle size of 30-65 micrometers (μm) is obtained.

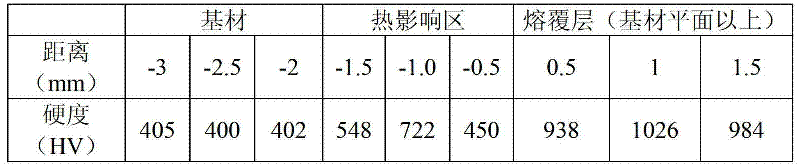

[0026] The cobalt-based metal-ceramic alloy powder prepared in Example 3 was used with a 1.5-kilowatt fiber laser with a spot size of 10 mm. 2 , the traveling speed is 2mm / s, and the powder spraying rate is 8g / min. After laser cladding is performed on the surface of the workpiece whose base material is No. 45 steel, the obtained data and performance indicators are as follows:

[0027] Tensile strength of fiber laser cladding cermet alloy tensile specimen at room temperature: [σ]=1200MN / m 2 , the section shrinkage of the fiber laser cladding cermet alloy tensile specimen: Ψ=7%, and the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com