High heat conductivity graphene coating for heat dissipation device and preparation method and application

A technology of high thermal conductivity and heat dissipation device, applied in chemical instruments and methods, coatings, heat exchange materials, etc. Difficulties in the field and other problems, to achieve the effect of making up for thermal conductivity, fast thermal conductivity, and strong wetting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

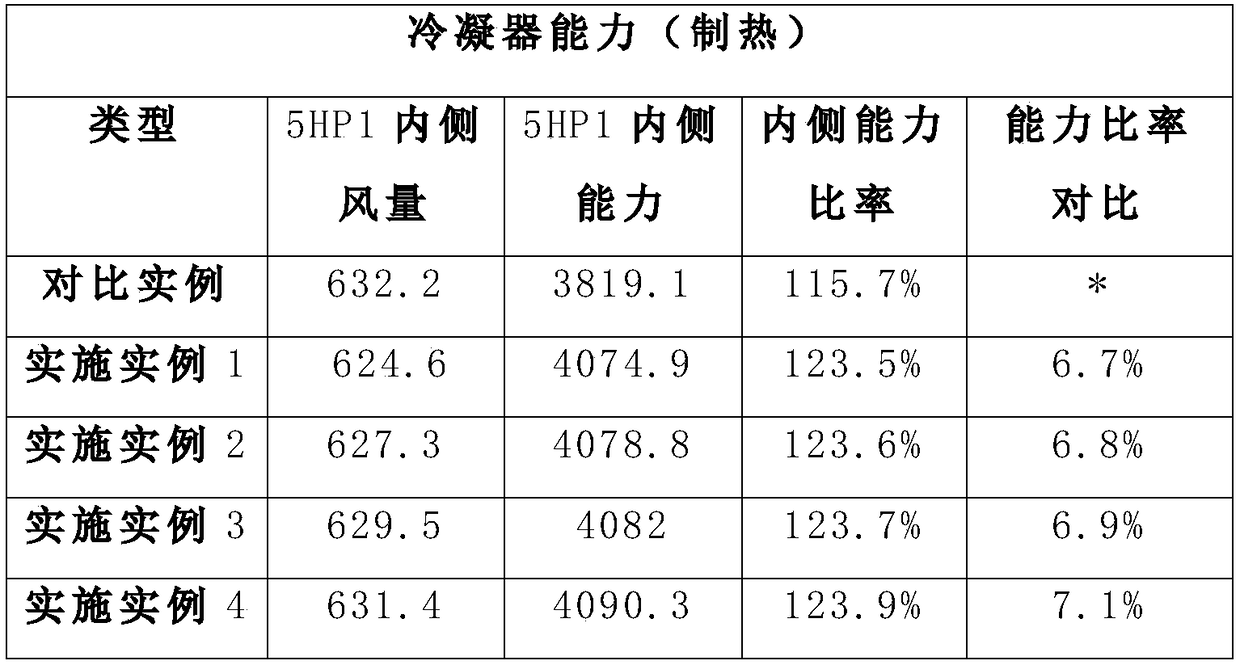

Examples

Embodiment 1

[0034] a. Weigh 1g graphene and 99g ultrapure water, equip a graphene solution with a mass fraction of 1%, weigh 0.001g sodium hexadecylbenzenesulfonate according to the mass ratio of graphene: dispersant=1:0.001 Add it into the graphene solution as a dispersant, and ultrasonically disperse it for 50 minutes to form a uniform and stable graphene dispersion.

[0035] b. according to graphene: adhesive: mass ratio of thickener=1:0.2:0.3, weigh 0.2g aqueous epoxy resin and 0.3g gum arabic respectively, add successively in the graphene dispersion in step a, Stir magnetically for more than 6 hours until a uniform and stable graphene slurry with a certain viscosity is formed.

[0036] c1. At room temperature, spray the graphene slurry in step b and deposit it on the surface of the heat dissipation component of the heat dissipation device by brushing, and then perform drying treatment at a temperature of 70°C for 25 minutes.

[0037] c2. Coating the heat dissipation parts after dryi...

Embodiment 2

[0039]a. take by weighing 3g graphene and 97g ultrapure water, be equipped with the graphene solution that mass fraction is 3%, according to the mass ratio of graphene: dispersant=1:0.005, weigh 0.015g hexadecyl trimethyl bromide Ammonium chloride was added into the above-mentioned graphene solution as a dispersant, and the cell pulverizer was dispersed for 40 minutes to form a uniform and stable graphene dispersion.

[0040] b. according to graphene: adhesive: mass ratio of thickener=1:0.4:0.2, weigh 1.2g aqueous polyurethane and 0.6g sodium carboxymethyl cellulose respectively, add the graphene dispersion in step a successively , magnetic stirring for more than 6h until a uniform and stable graphene slurry with a certain viscosity is formed.

[0041] c1. At room temperature, the graphene slurry in step b is atomized and deposited on the surface of the heat dissipation component of the heat dissipation device using a scraper coating method, and then dried at a temperature of ...

Embodiment 3

[0044] a. take by weighing 4g graphene and 96g ultrapure water, be equipped with the graphene solution that mass fraction is 4%, according to the mass ratio of graphene: dispersant=1:0.008, weigh 0.032g lauryl polyoxyethylene ether as dispersion Add the above-mentioned graphene solution, and ball mill for 120min until a uniform and stable graphene dispersion is formed.

[0045] b. according to graphene: adhesive: the mass ratio of thickener=1:0.7:0.1, weigh 2.8g polyacrylamide and 0.4g polyethylene oxide respectively, add successively in the graphene dispersion in step a, Stir and disperse for more than 6 hours until a uniform and stable graphene slurry with a certain viscosity is formed.

[0046] c1. At room temperature, adopt the spraying method, which is the electrostatic spraying method in the present embodiment, so that the graphene slurry in step b is evenly deposited on the surface of the heat dissipation component of the heat dissipation device, and then dried at a tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com