Heat-conductive glue

A technology of thermally conductive adhesive and substrate, applied in the field of heat transfer, can solve the problems of poor thermal conductivity of thermally conductive adhesive, poor wetting ability of silicone oil, large substrate thickness, etc., and achieves improved thermal conductivity, reduced thickness, and reduced substrate thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings.

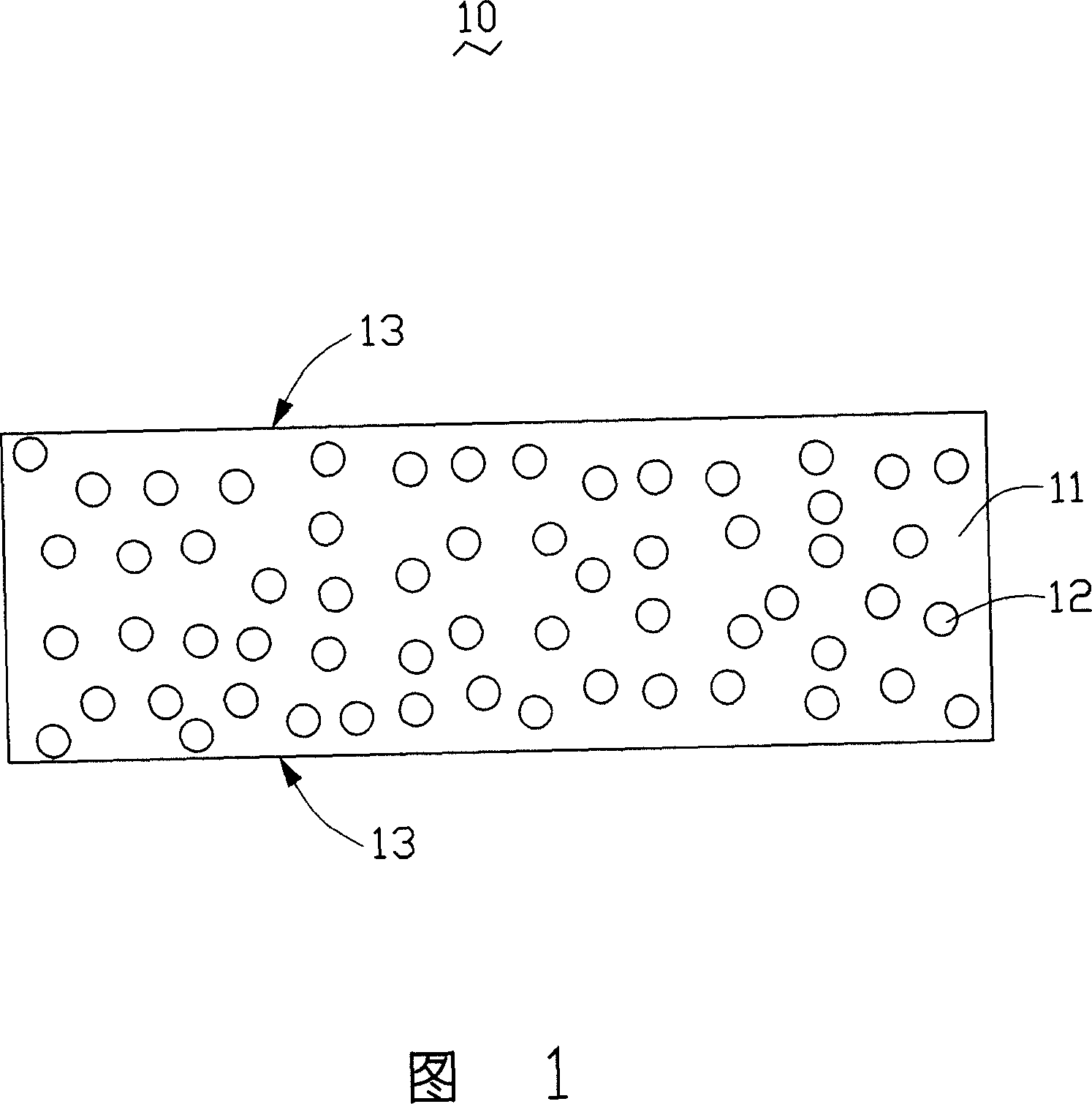

[0009] Please refer to FIG. 1 , which provides a thermally conductive adhesive 10 according to an embodiment of the present invention, which includes a matrix 11 and thermally conductive powder 12 dispersed in the matrix 11 .

[0010] The matrix 11 is a polyol, and the characteristic of the polyol is that it has a strong wettability, which can reduce the thickness of the matrix 11 filled between the heat-conducting powder 12 and between the heat-conducting powder 12 and the surface 13 of the heat-conducting adhesive 10, thereby reducing the thickness of the matrix 11. Improve the thermal conductivity of the thermally conductive adhesive 10 . The polyhydric alcohol can be one or a mixture of ethylene glycol, polyethylene glycol, polyhydroxy ester, polyhydroxy ether, polyhydroxy ketone, polyhydroxy alkene or polyhydroxy acid. The polyhydroxy ester can be polyh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com