Aqueous polyurethane sizing agent and preparation method thereof

A technology of water-based polyurethane and sizing agent, applied in the direction of carbon fiber, etc., can solve the problems of toxic solvent environment, separation of effective components, poor storage stability, etc., and achieve the effects of good adhesion, good mechanical properties, and increased wetting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

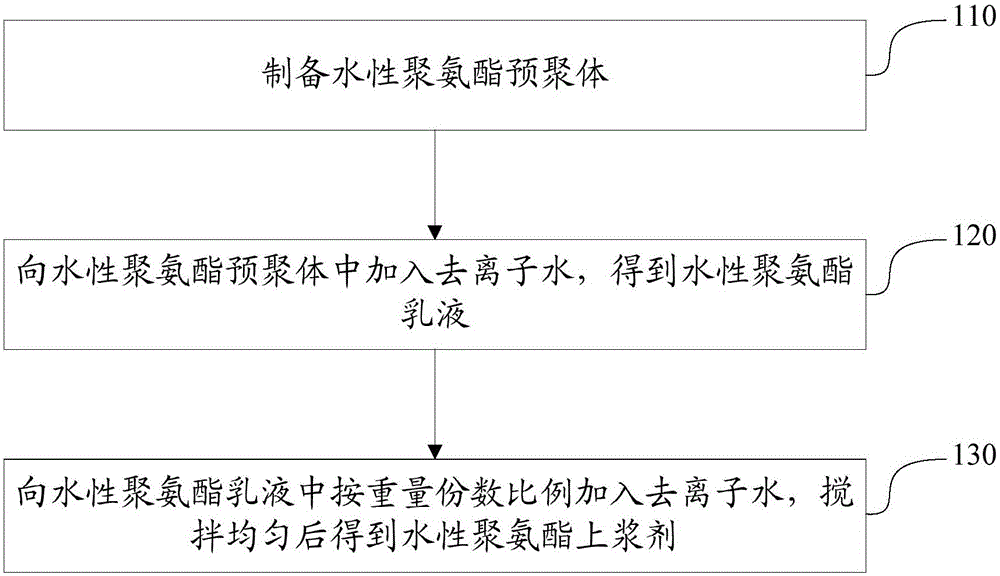

[0032] Such as figure 1 Shown, the present invention also provides a kind of preparation method of aqueous polyurethane sizing agent, comprises the steps:

[0033] Step 110: preparing waterborne polyurethane prepolymer;

[0034] The step 110 specifically includes adding 110-135 parts by weight of glycol into the reaction vessel, mixing evenly, vacuuming and dehydrating at 120°C for 20-30 minutes, cooling down to 70-80°C, adding 15-40 parts by weight 1 part of isocyanate reacts with 0-0.01 weight part of catalyst for 3-6 hours, and the temperature is lowered to 40-50 DEG C to obtain a water-based polyurethane prepolymer whose terminal group is a hydroxyl group.

[0035] Step 120: adding deionized water to the water-based polyurethane prepolymer to obtain a water-based polyurethane emulsion;

[0036] The step 120 specifically includes adding deionized water to the water-based polyurethane prepolymer whose end groups are hydroxyl groups under a high-speed stirring shear force o...

Embodiment 1

[0040] In a 500ml four-necked flask equipped with an electric stirrer, a reflux condenser and a thermometer, add 70g parts by weight of polytetrahydrofuran ether glycol and 60g parts by weight of polyethylene glycol, and mix them uniformly. After vacuum dehydration for 30 minutes, cool down to 70°C, add 22g parts by weight of isophorone diisocyanate and 0.005g parts by weight of dibutyltin dilaurate, control the reaction temperature at 70°C, react for 3 hours, and cool down to 50°C. Pour 350 g of deionized water in parts by weight, and disperse under high shear at 1200 r / min to obtain an aqueous polyurethane emulsion.

[0041] Take 50g parts by weight of the above-mentioned water-based polyurethane emulsion, put it into a stirring tank, add 450g parts by weight of deionized water under continuous stirring, and discharge after stirring evenly to obtain a water-based polyurethane sizing agent for carbon fibers (number 1#).

Embodiment 2

[0043] In a 500ml four-necked flask equipped with an electric stirrer, a reflux condenser and a thermometer, add 84.5g parts by weight of polytetrahydrofuran ether glycol and 45.5g parts by weight of polyethylene glycol, and mix them uniformly. After vacuum dehydration for 30 minutes, cool down to 70°C, add 22g parts by weight of isophorone diisocyanate and 0.005g parts by weight of dibutyltin dilaurate, control the reaction temperature at 70°C, react for 3 hours, and cool down to 50°C °C, pour 350 g of deionized water in parts by weight, and disperse under high shear at 1200 r / min to obtain an aqueous polyurethane emulsion.

[0044] Take 50g parts by weight of the above water-based polyurethane emulsion, put it into a stirring tank, add 450g parts by weight of deionized water under continuous stirring, and discharge after stirring evenly to obtain a water-based polyurethane sizing agent for carbon fibers (number 2#).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com