Preparation method for waterproof protective perfluoro-acrylate copolymer aqueous dispersion miniemulsion for wood

A technology of perfluoroacrylate and copolymer, which is applied in the field of preparation of water-dispersed miniemulsion of perfluoroacrylate copolymer for wood waterproofing and protection, can solve problems affecting the performance of emulsion products, avoid insoluble problems, and have a large market demand , use the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation method of water-dispersed fine emulsion of perfluorinated acrylate copolymer for wood waterproof protection, it is characterized in that: specific steps are as follows:

[0025] ④ Mix 10-40% comonomer mixture, 1.0-6.0% emulsifier and 60-90% deionized water and stir for 10-30 minutes to obtain a pre-emulsion,

[0026] ⑤ Ultrasonic treatment of the obtained pre-emulsion in a sonicator for 1-10min to obtain a stable monomer miniemulsion with a particle size distribution of 30-150nm;

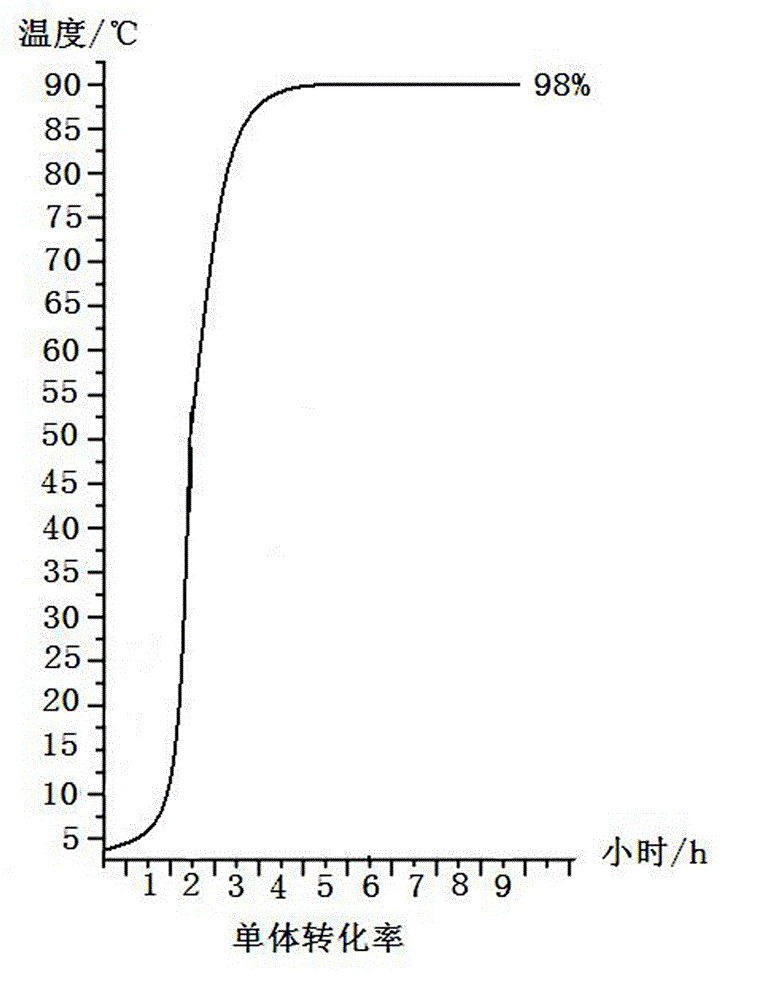

[0027] ⑥ Place the monomer miniemulsion obtained through miniemulsification into a reaction kettle, add chain transfer agent accounting for 0.05-1% of the monomer mass and initiator accounting for 0.05-1% of the monomer mass respectively, and heat up to 50-90 Initiate polymerization at ℃, react for 2-6 hours, keep warm for 1-3 hours, and cool to room temperature when the monomer conversion rate reaches above 95.0%, and obtain by filtration.

[0028] In the ste...

Embodiment 2

[0032] Described chain transfer agent is dodecyl mercaptan; Initiator can be water-soluble persulfate, also can be oil-soluble initiator, or both are used simultaneously, and water-soluble persulfate can be selected from Potassium persulfate, ammonium persulfate or sodium persulfate, the oil-soluble initiator can be selected from azobisisobutyronitrile, azobisisoheptanonitrile or benzoyl peroxide.

Embodiment 3

[0034] The method is to firstly prepare a monomer miniemulsion with uniform dispersion and stable particle size within the range of 30-150nm, then add an initiator, raise the temperature to 50-90°C to initiate polymerization to obtain a copolymer emulsion, or add the initiator first at a low temperature Perform fine emulsification at 40°C, then raise the temperature to initiate polymerization to obtain a copolymer water-dispersed emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com