Heparin sodium colored impurity removing device

An impurity removal, heparin sodium technology, applied in mixers with rotary stirring devices, transportation and packaging, separation methods, etc., can solve the problems of incomplete dissolution, slow dissolution of sodium chloride, etc. Incomplete dissolution, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

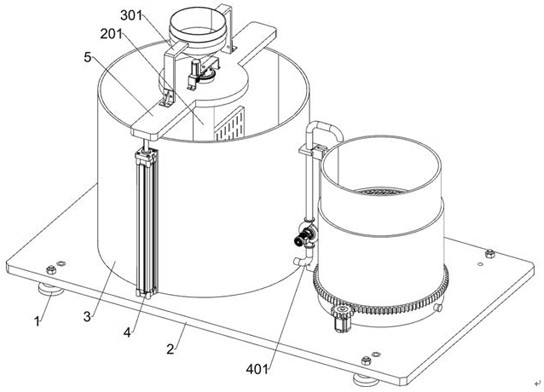

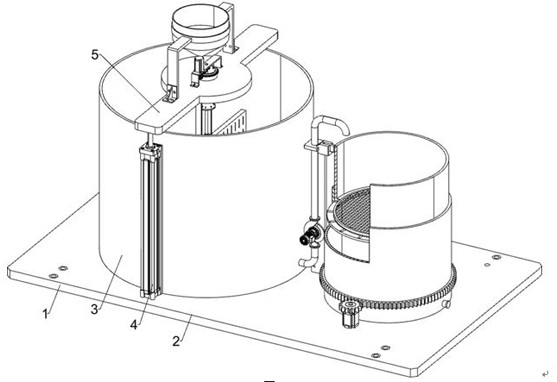

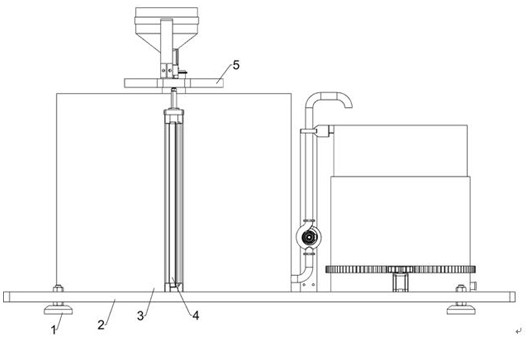

[0032] A heparin sodium colored impurity removal device, such as Figure 1-8 As shown, it includes a base 1, a bottom plate 2, a mixing barrel 3, a telescopic cylinder 4 and a linkage plate 5; the base 1 is provided with four; a bottom plate 2 is bolted between the four bases 1; the upper left part of the bottom plate 2 is fixed The mixing barrel 3 is connected; the front side and the rear side of the mixing barrel 3 are fixedly connected with a telescopic cylinder 4; the telescopic cylinder 4 is connected with the base 1; It also includes a stirring blade 202, a push block 2011, a stirring assembly, a blanking assembly and a filter assembly; a stirring assembly is installed in the middle of the linkage plate 5; two stirring blades 202 are installed at the lower part of the stirring assembly; , and the push block 2011 is located between the two stirring blades 202; the upper side of the linkage plate 5 is equipped with a feeding assembly; the feeding assembly is connected with...

Embodiment 2

[0045] On the basis of Example 1, as figure 1 and Figure 9-10 As shown, the filter assembly includes a second pipe 401, a third support frame 402, a water pump 403, a third pipe 404, a third limit block 405, a first cylinder 406, a water pipe 407, a connecting ring 408, and a third linkage block 409, the second cylinder 4010, the fourth linkage block 4011, the screen 4012, the fourth limit block 4013 and the second drive set; the lower part of the right side of the mixing tank 3 is connected with the second pipe 401; the upper middle of the bottom plate 2 is connected by bolts There is a third support frame 402; a water pump 403 is fixedly connected to the lower part of the front side of the third support frame 402; the input end of the water pump 403 is connected with the second pipeline 401; 404 is communicated with the output end of the water pump 403; the upper part of the third support frame 402 is fixedly connected with a third limit block 405; the right part of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com