Emulsifier for branched chain reaction type epoxy resin and preparation method thereof

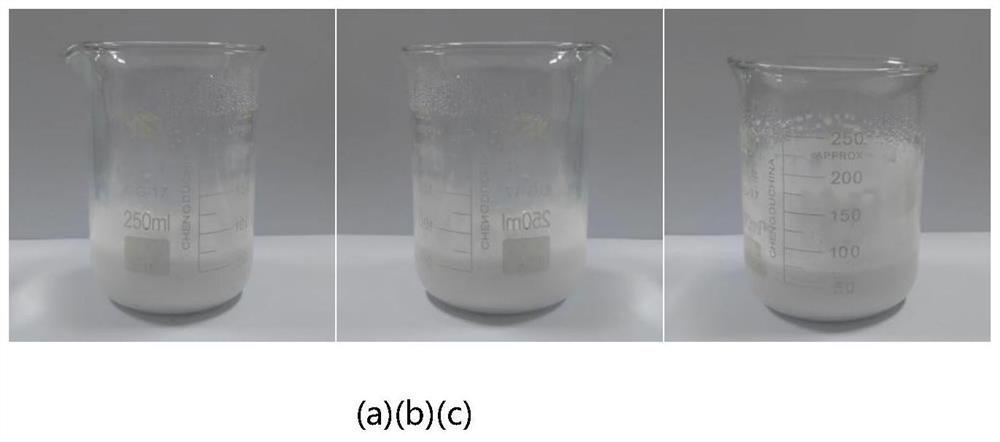

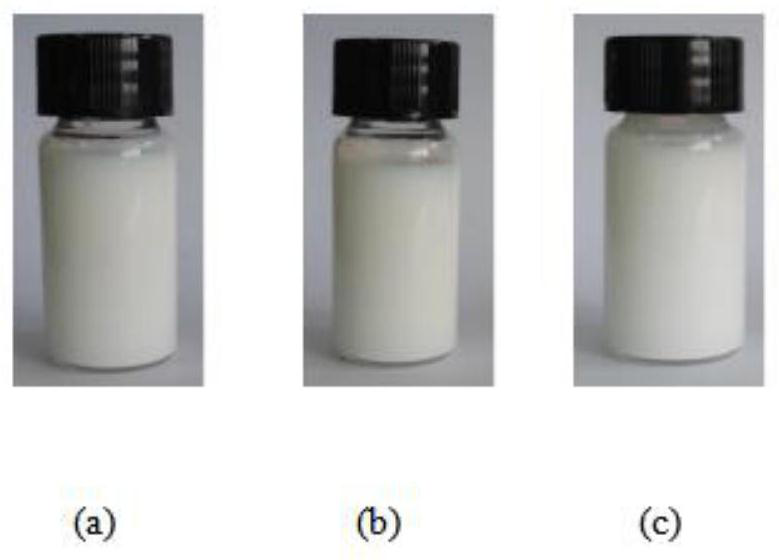

A branched chain reaction technology for epoxy resin, applied in epoxy resin coatings, coatings, etc., can solve the problems of unclear emulsifier structure and complicated production process, and achieve fine dispersed phase particles, simple preparation process, good The effect of storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Synthesize the emulsifier for branched reaction type epoxy resin, the steps are as follows:

[0037] (1) Take 55g of monoamine polyetheramine MEP-1100 and 5.88g of tris(2-hydroxyethyl)isocyanuric acid triacrylate (THEICTA) into a three-necked flask;

[0038] (2) Raise the temperature to 120°C and keep for 3 hours;

[0039] (3) Lower the reaction temperature to 70°C and add 36g of bisphenol A epoxy resin E-20, keep the temperature for 1 hour, and then increase to 130°C for 3 hours; take it out to obtain the emulsifier for the branched reaction type epoxy resin.

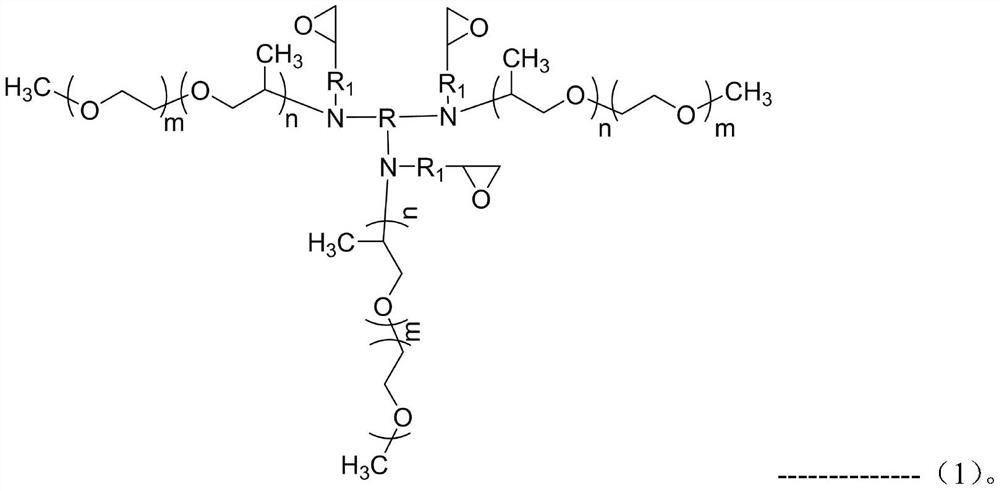

[0040] The structural formula of the emulsifier is as follows:

[0041]

Embodiment 2

[0043] (1) Take 55g of monoamino polyetheramine MEP-1100 and 4.51g of pentaerythritol triacrylate into a three-necked flask;

[0044] (2) Raise the temperature to 130°C and keep for 4 hours;

[0045] (3) Lower the reaction temperature to 80°C and add 30g of bisphenol A epoxy resin E-20, keep it warm for 0.5h, and then increase to 120°C for 4h; take it out to get the emulsifier for branched reaction epoxy resin .

[0046] The structural formula of the emulsifier is as follows:

[0047]

Embodiment 3

[0049] (1) Take 55g of monoamino polyetheramine MEP-1100 and 5g of trimethylolpropane triglycidyl ether into a three-necked flask;

[0050] (2) Raise the temperature to 110°C and keep for 2h;

[0051] (3) Reduce the reaction temperature to 65°C and add 30g of bisphenol A epoxy resin E-20, keep the temperature for 1.5 hours, and then rise to 140°C for 2 hours; take it out to obtain the emulsifier for the branched reaction type epoxy resin .

[0052] The structural formula of the emulsifier is as follows:

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com