Patents

Literature

47results about How to "Good centrifugal stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

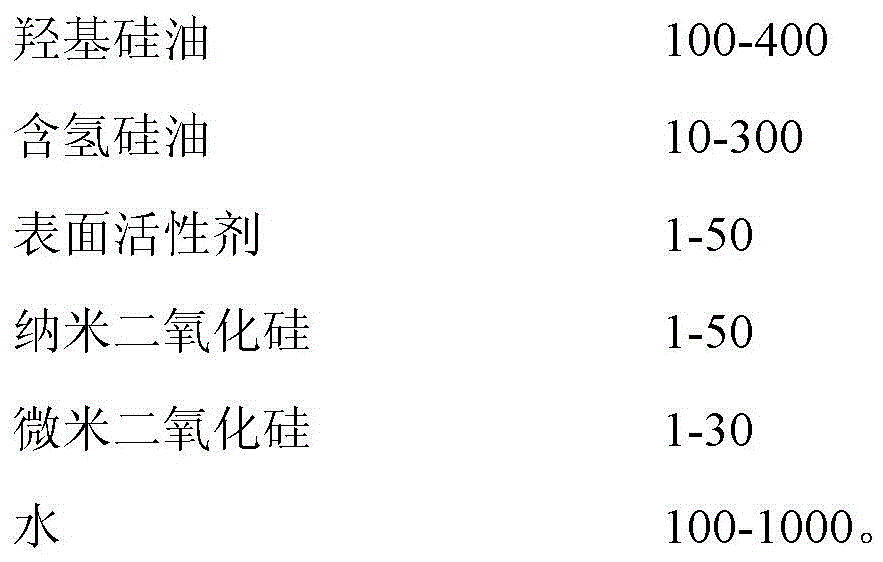

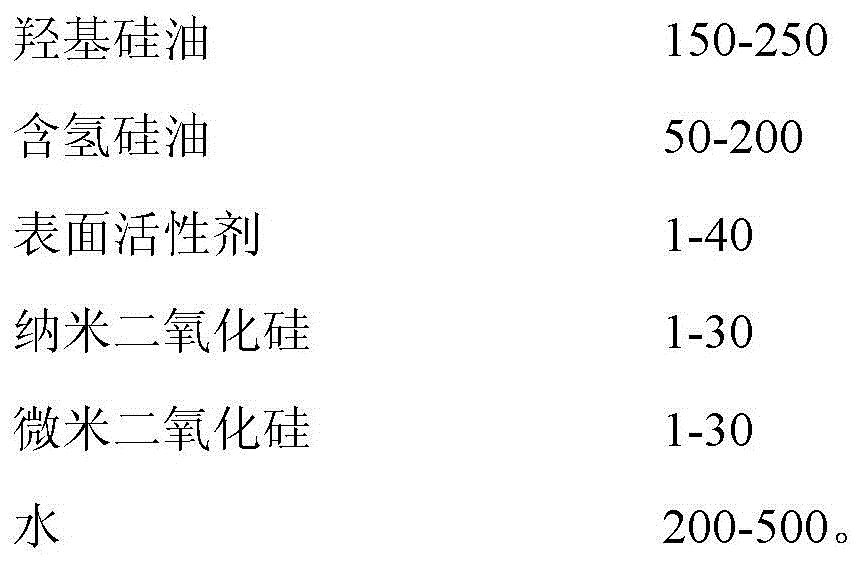

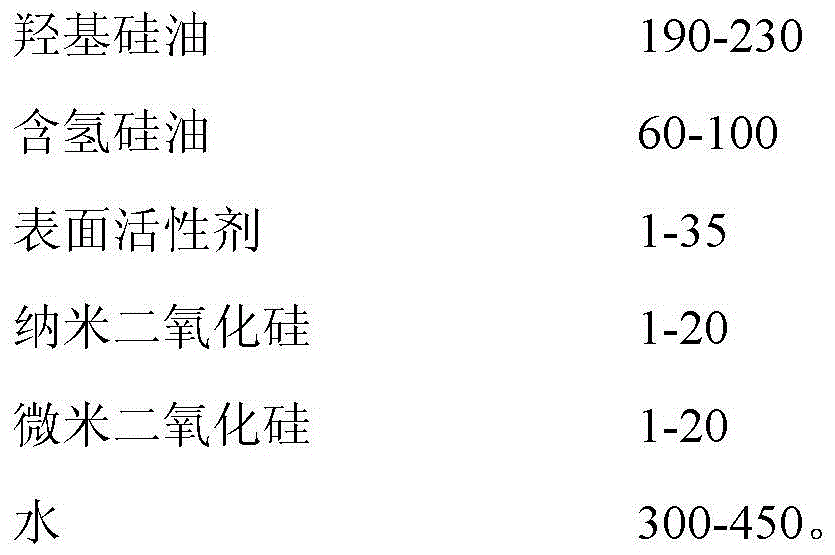

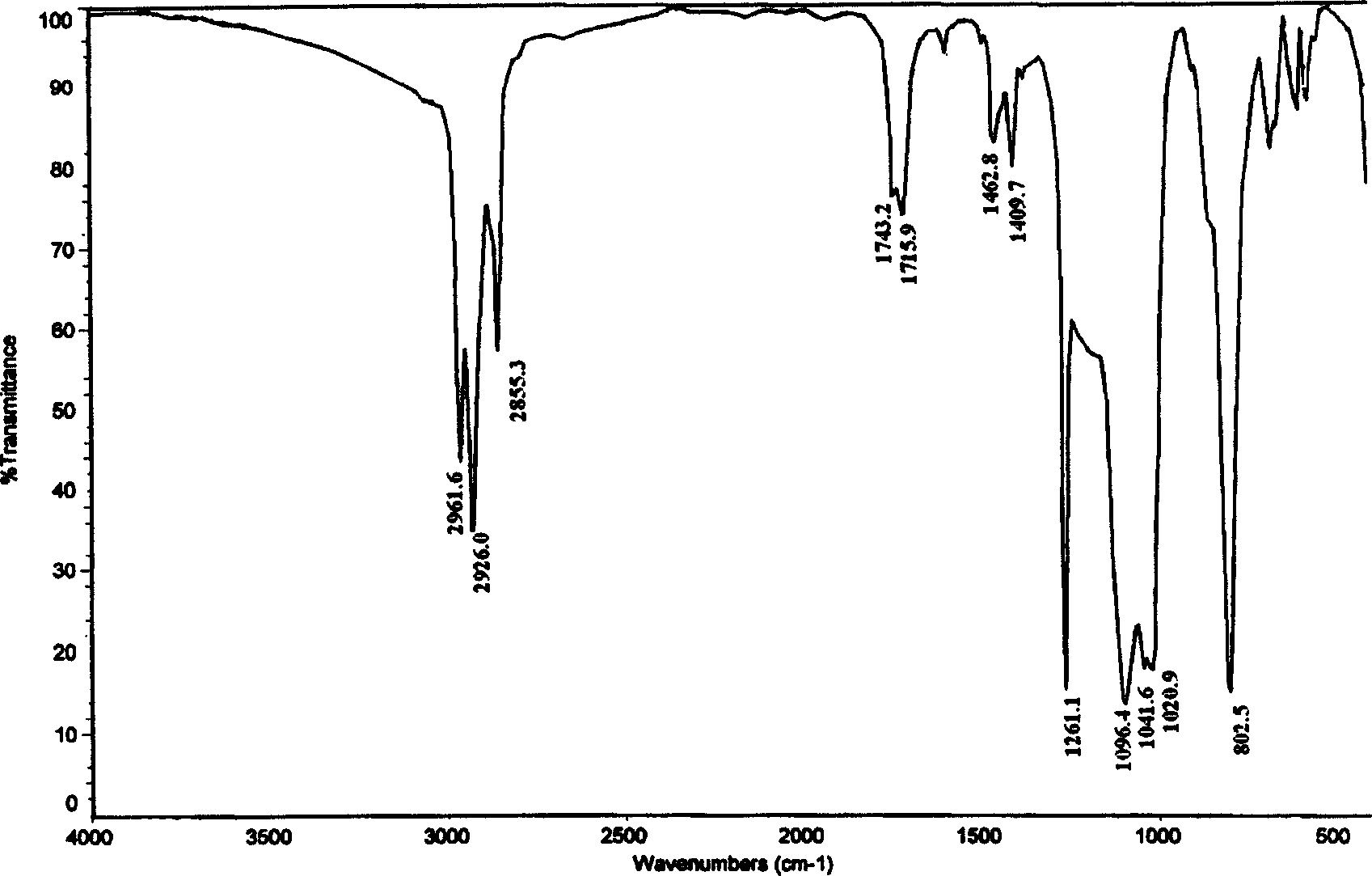

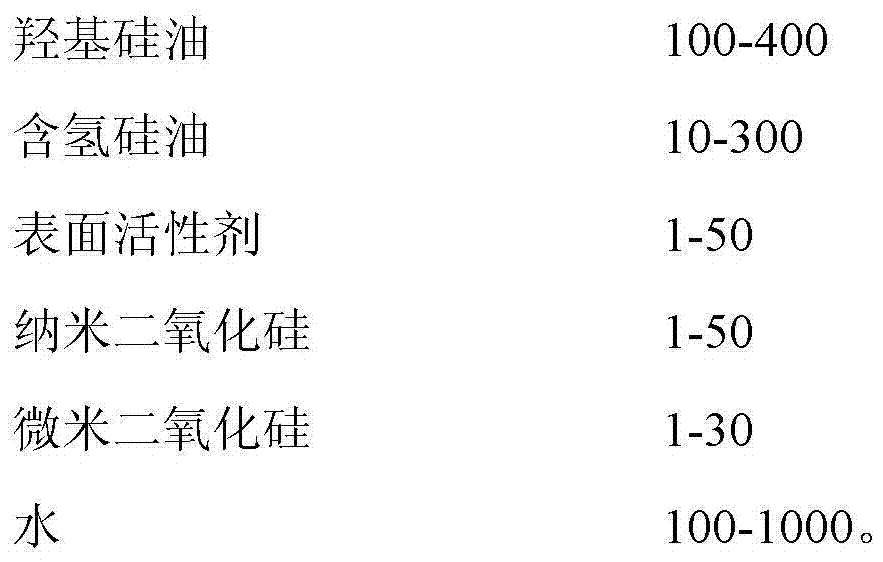

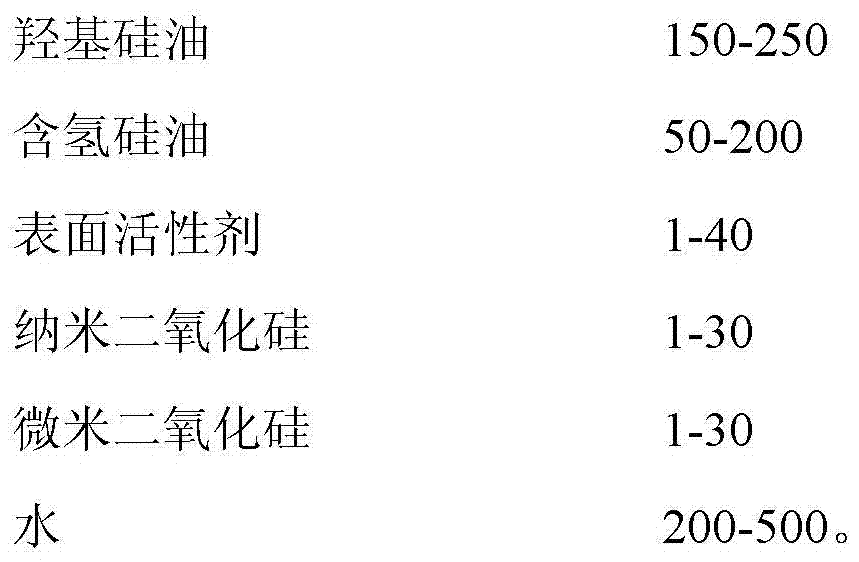

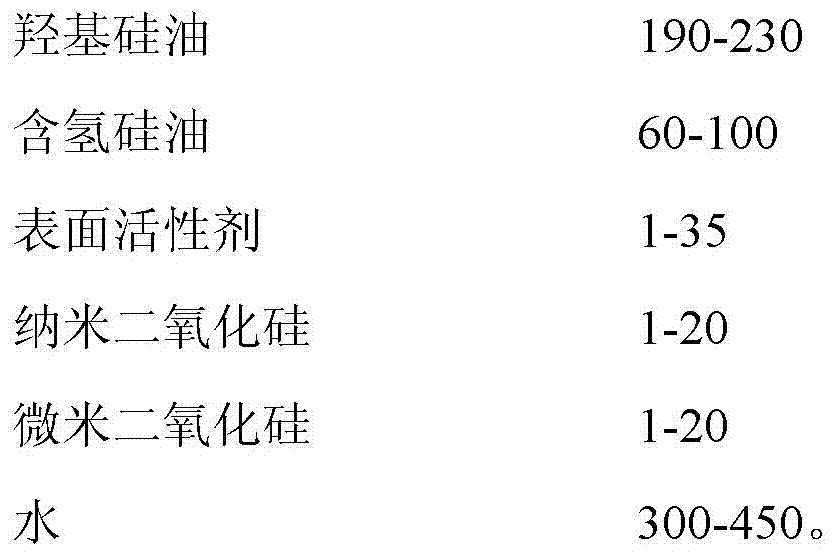

Wood waterproof agent, method for preparing wood waterproof agent, and method for preparing waterproof wood by utilizing wood waterproof agent

ActiveCN105729600AReduce treatment concentrationLow costWood treatment detailsPressure impregnationEmulsionHydrogen

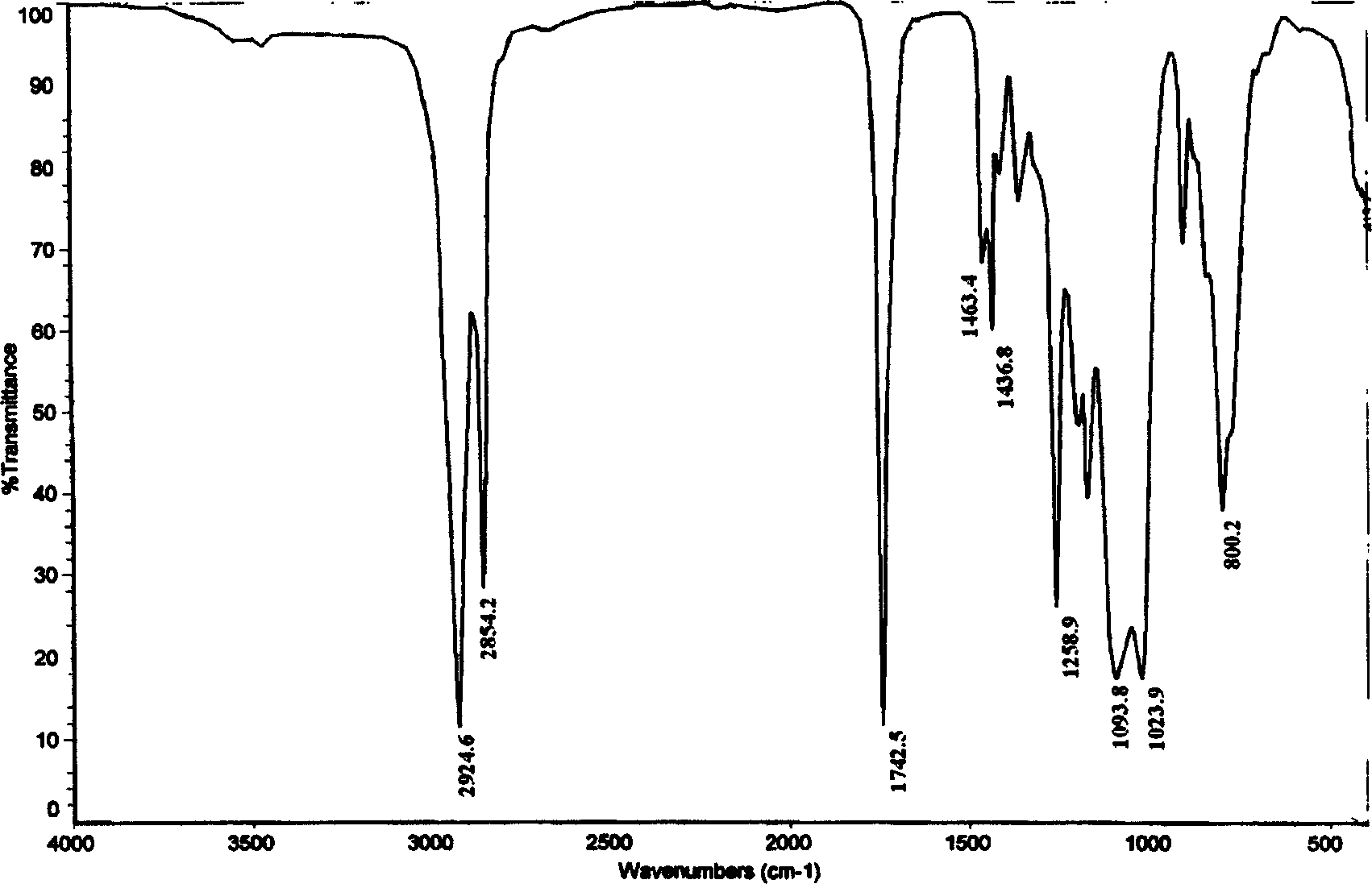

The invention provides a wood waterproof agent adopting a silicone emulsion, a method for preparing the wood waterproof agent, and a method for preparing waterproof wood by utilizing the wood waterproof agent. The method for preparing the wood waterproof agent comprises the following steps: first, preparing a silicone oil emulsion primary liquid which contains hydroxyl silicone oil, hydrogen-containing silicone oil, a surfactant, nano-silicon dioxide, micron-silicon dioxide and water; then, diluting the silicone oil emulsion primary liquid into silicone oil emulsions of different concentrations; and finally, adding a catalyst for uniform dissolution and mixing. When the silicone oil emulsion wood waterproof agent provided by the invention is utilized for vacuum-pressurization pretreatment of wood, the waterproof performance and size stability of the wood can be improved, the hygroscopicity of the wood can be reduced, and the contact angle between the treated wood surface and water is larger than 140-150.

Owner:BEIJING FORESTRY UNIVERSITY +1

Method for preparing cinnamon oil microemulsion

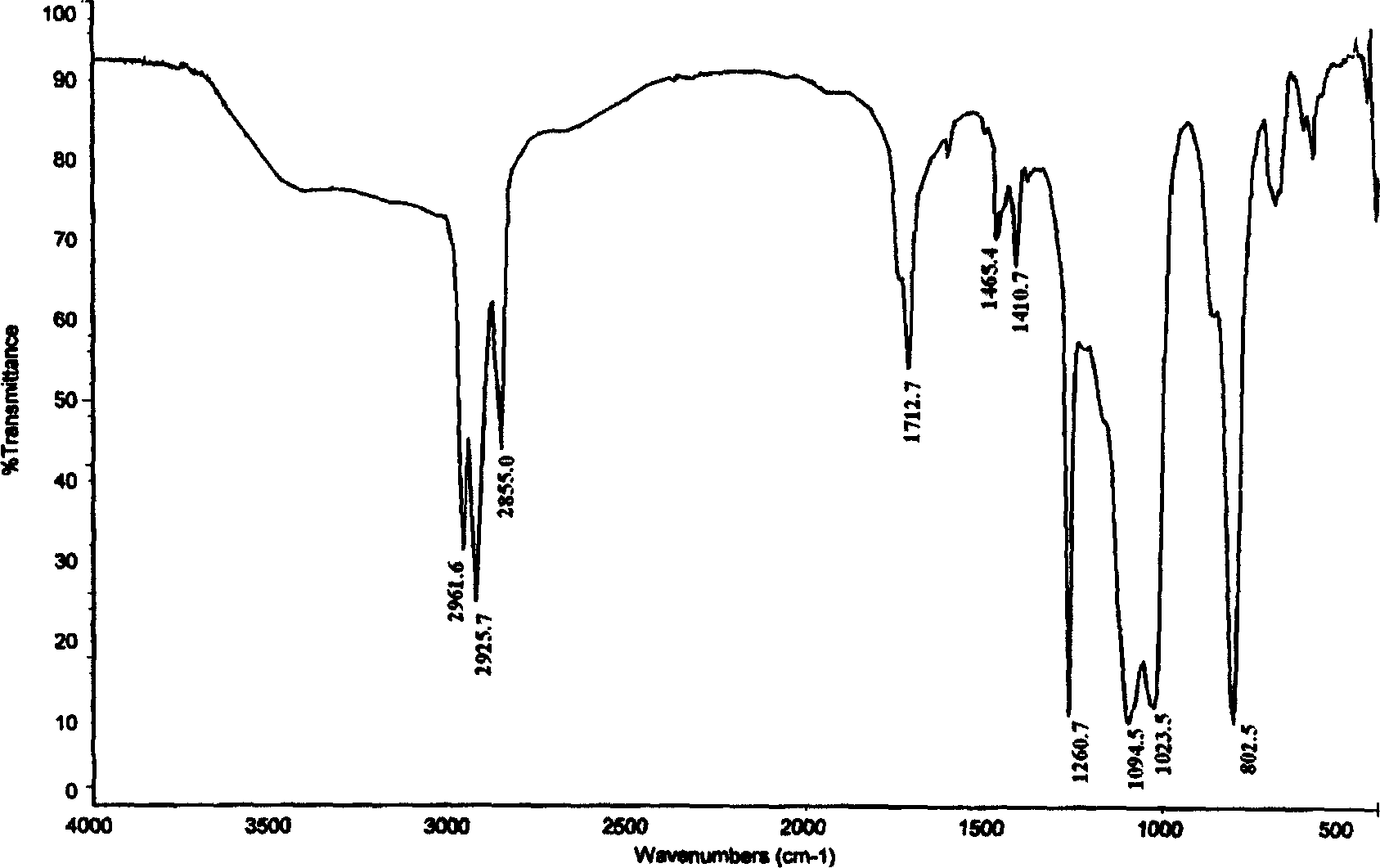

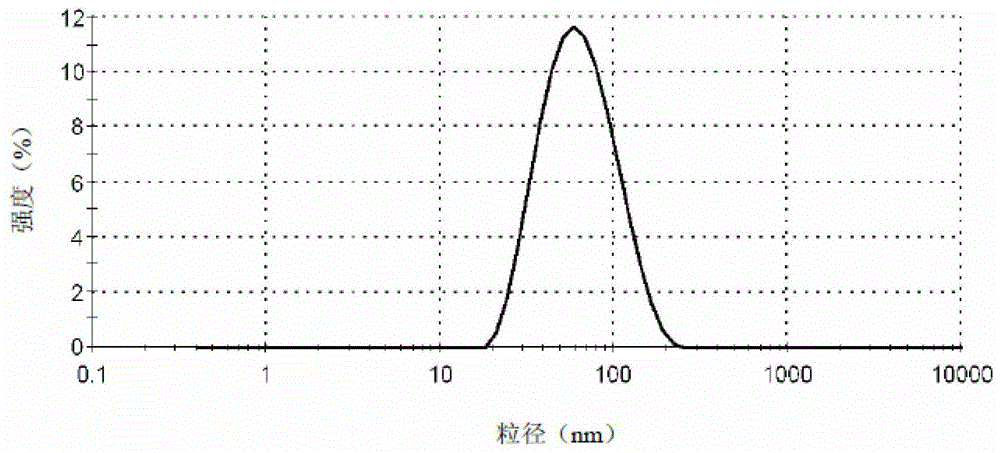

The invention discloses a method for preparing cinnamon oil microemulsion, which is a cinnamon oil microemulsion system comprising the components of cinnamon oil, a composite emulsifier, an auxiliary emulsifier, deionized water and the like. Every 100 ml of the microemulsion contains 2 to 17 g of cinnamon oil, 20 to 35 g of composite emulsifier, 10 to 15 g of auxiliary emulsifier, 2 to 18 g of dispersing agent and the balance deionized water. The components are uniformly stirred by magnetic force at 20 to 60 DEG C to obtain the microemulsion which is packed and sterilized. The invention adopts a small amount of emulsifier, has simple process and ensures high oil carrying capacity of the prepared microemulsion and high bioavailability. The particle size of the microemulsion is between 25 and 40 nm, the oil carrying capacity is 2 to 17% and the entrapment efficiency is 80%.

Owner:NANCHANG UNIV

Preparation of carboxy silicon oil emulsion

Carboxy silicone latex emulsion is produced by: reacting the mixture of the ester group modified silicone oil, small molecular oxosilance, emulsifier, accelerating agent-dodecyl benzene sulflnic acid and water at 70-95deg.C for 5-15 hours, neutralizing by adding the sodium acid carbonate after the reactor is cooled. Its composition comprises (wt%): the use level of the ester group modified silicone oil and small molecular oxosilance is controlled by the termination product that the chain joint of organic silicon which contains carboxy has the 0.5-30% of all chain joint of organic silicon, 0.1-10% of the emolsifier, and 3-30% of the accelerating agent -dodecyl benzene sulflnic acid. It features: hydrolyzing of the ester group and polymerizing of oxosilance generate at the same time. Through the adjustment of the use level of dodecyl benzene sulflnic acid and non-ionic emolsifier, the grain size of the carboxy silicone oil latex emulsion can be modified, even the micro-latex emulsion will generate.

Owner:NANJING UNIV

Preparation method of DHA microemulsion

The invention relates to a preparation method of a DHA microemulsion which comprises the following components in percent by mass of 2-20 percent of DHA algae oil, 0-5 percent of dispersing agent, 15-35 percent of compound emulsifying agent, 5-15 percent of assisting emulsifying agent and the balance of deionized water. The preparation method comprises the steps of: uniformly stirring the algae oil, the dispersing agent, the compound emulsifying agent and the assisting emulsifying agent by using a magnetic stirrer according to the proportion; slowly dropping the deionized water at a temperature of 25-80 DEG C under the stirring and regulating the optimal stirring speed with the generation of phase change to obtain the DHA microemulsion. The prepared DHA microemulsion has less consumption of the emulsifying agent, particle diameter of 43nm-50nm, loading rate of 2-20 percent and entrapment rate of 75 percent.

Owner:NANCHANG UNIV

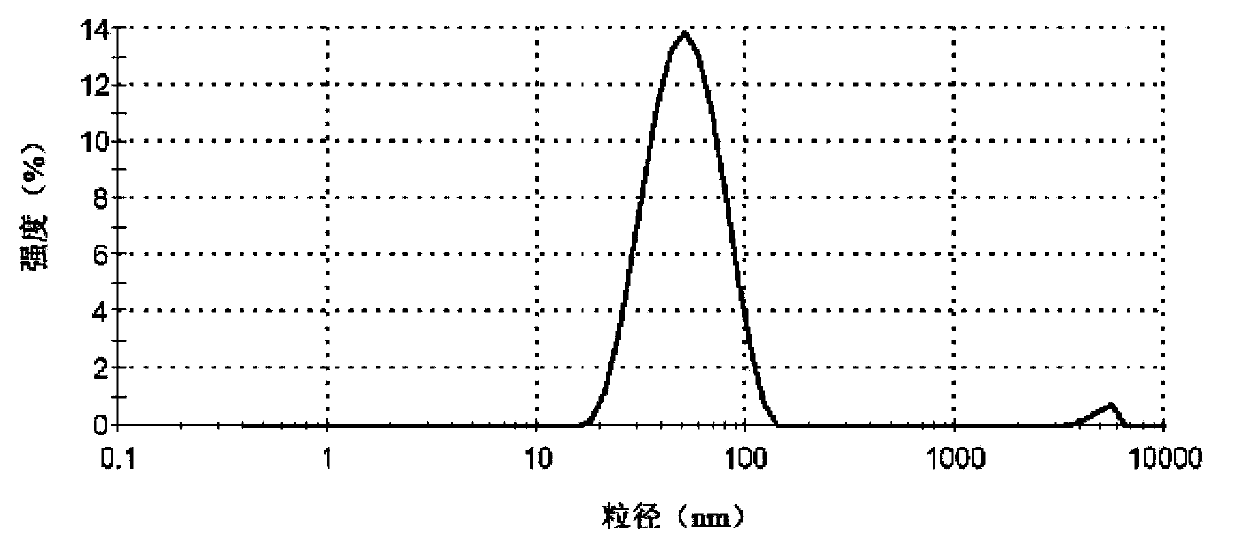

Oxidized polyethylene wax micro-emulsion composition and preparation method thereof

The present invention discloses an oxidized polyethylene wax micro-emulsion composition and a preparation method thereof. The micro-emulsion composition comprises: 1) 15-35 wt% of an oxidized polyethylene wax with a melting point of 110-150 DEG C, 2) 3-15 wt% of a nonionic surfactant, 3) 0.5-5 wt% of an organic alcohol amine auxiliary emulsifying agent, and 4) 50-80 wt% of water. The micro-emulsion composition can be prepared by using a multi-step high temperature emulsification method, and has characteristics of particle size of less than 100 nm, uniform distribution, centrifugal stability, good acid resistance stability and good alkali resistance stability. In addition, the micro-emulsion composition can be diluted with cold water in any proportions while no particle is precipitated, and the storage stability exceeds more than 6 months.

Owner:浙江震东新材料有限公司

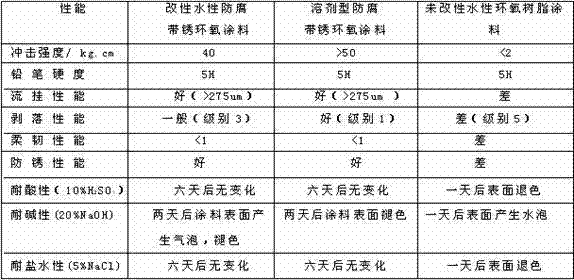

Synthesis of modified aqueous epoxy resin and method for preparing antiseptic rusty paint

ActiveCN101775108AGood water dispersibilityGood storage stabilityAnti-corrosive paintsEpoxySynthesis methods

The invention discloses synthesis of modified aqueous epoxy resin and a method for preparing antiseptic rusty paint, relating to synthesis of epoxy resin and a method for preparing paint. The invention solves the problems of the traditional aqueous epoxy resin antiseptic paint that storing stability of base material resin and water resistance and corrosion resistance of an aqueous epoxy resin antiseptic paint coating film can not be met simultaneously. the synthesis method of modified aqueous epoxy resin comprises the steps of: mixing Span 60 with Tween 20, adding E-51; heating and stirring, and dropwise adding distilled water till the system viscosity is suddenly reduced; and finally dropwise adding an initiating agent and a monomer to carry out heating reaction. The method for preparing antiseptic rusty paint comprises the steps of: mixing the modified aqueous epoxy resin, a corrosion inhibitor and a rust preventing agent, stirring and grinding; adding a defoaming agent, a curing agent and deionized water; and stirring the mixture to obtain the modified aqueous epoxy resin antiseptic rusty paint. The invention simultaneously meets the storing stability of the base material resin of the aqueous epoxy resin antiseptic paint and the water resistance and the corrosion resistance of the aqueous epoxy resin antiseptic paint coating film.

Owner:HARBIN INST OF TECH

Solid lipid sunscreen particles coated with high-concentration sun screener and preparation method of solid lipid sunscreen particles

InactiveCN105030554AEvenly dispersedGood centrifugal stabilityCosmetic preparationsToilet preparationsSunscreen agentsSoluble polymer

The invention provides solid lipid sunscreen particles coated with a high-concentration sun screener. The solid lipid sunscreen particles consist of the following components in percentage by weight: 0-25% of a solid sun screener, 5-60% of a liquid sun screener, 1-20% of solid lipid, 0-10% of liquid lipid, 1-15% of a solid emulsifying agent, 0.01-20% of an additive, 0-0.5% of a water-soluble polymer, 0.01-0.8% of a preservative and the balance of deionized water. The invention also provides a preparation method of the sunscreen particles, and the preparation method comprises the following steps: melting and uniformly dispersing an oil phase consisting of the solid lipid, the liquid lipid, the emulsifying agent and the sun screeners at 50-95 DEG C to obtain an oil phase, and heating a water phase consisting of the water-soluble polymer, the additive and the deionized water to 50-95 DEG C at the same time; homogenizing the water phase, adding the oil phase, uniformly mixing, and then performing ultrasonic or high-pressure homogenization; and finally, stirring to cool to the room temperature. The particle size range of the coated solid lipid sunscreen particles is between 100nm and 5 microns.

Owner:SHANGHAI INST OF TECH

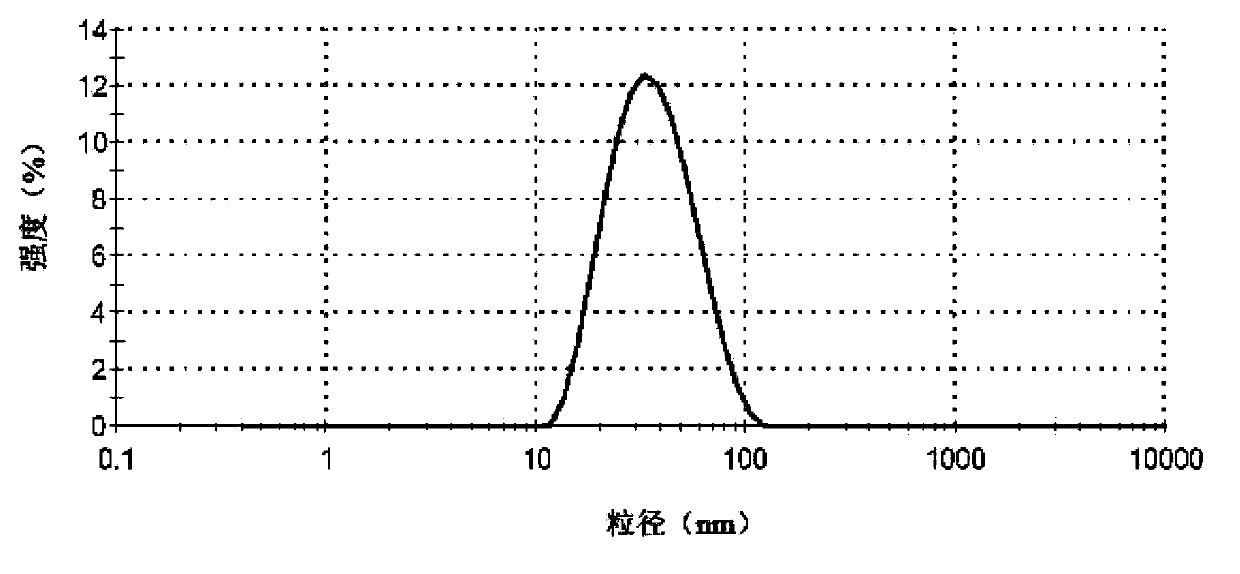

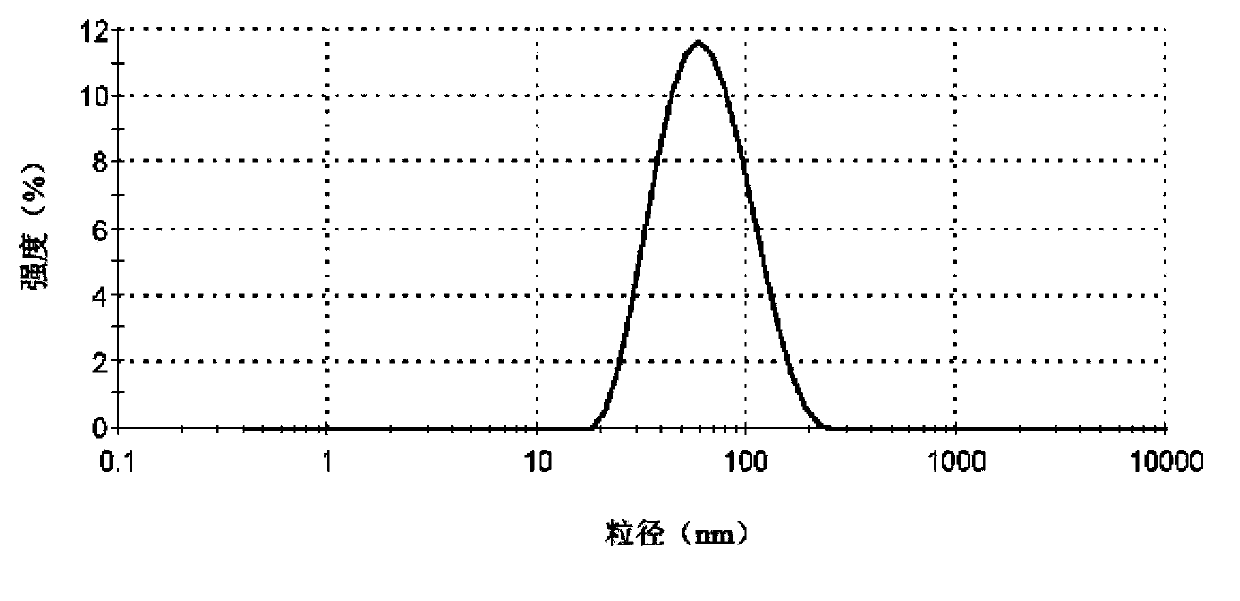

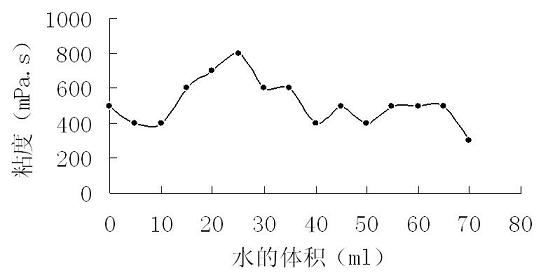

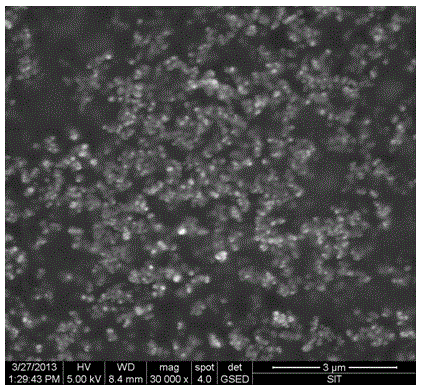

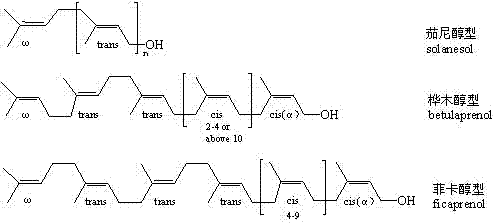

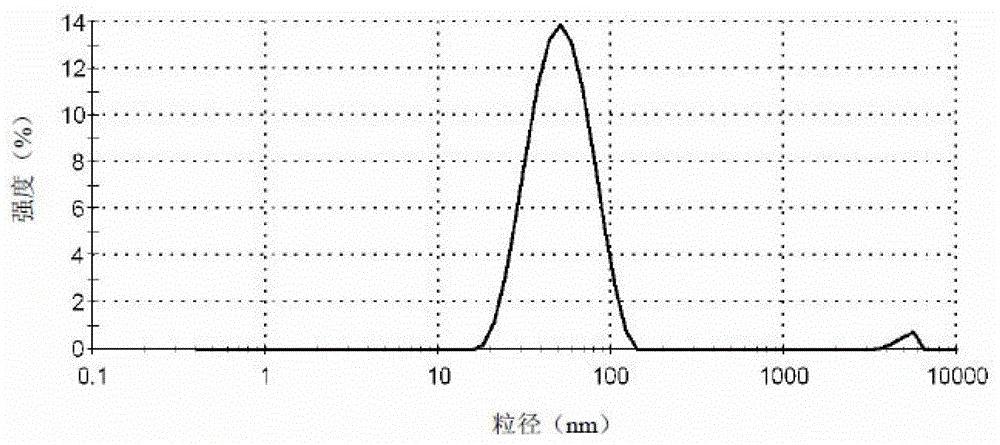

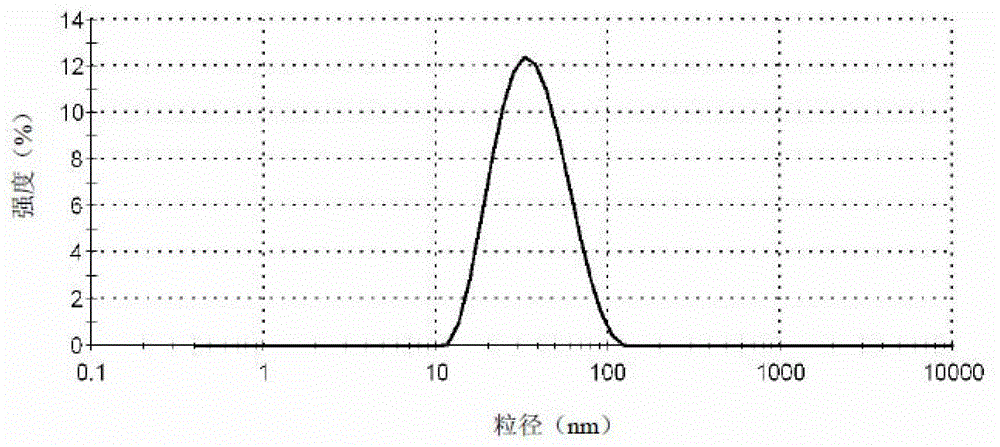

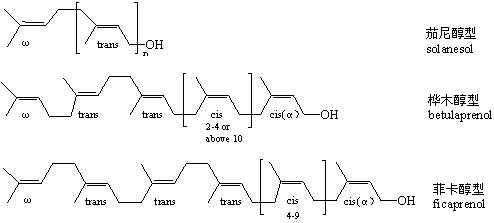

Preparation method for polyprenol microemulsion with bacteriostatic activity

ActiveCN104706594AAverage particle size distributionArranged in orderAntibacterial agentsOrganic active ingredientsProcess engineeringOil phase

The invention provides a preparation method for a polyprenol microemulsion with bacteriostatic activity. The preparation method comprises the following steps: with polyprenol as a raw material, mixing an emulsifier with a co-emulsifier and then adding polyprenol to form an oil phase; carrying out stirring and adding deionized water, wherein the obtained system temporarily becomes turbid and then becomes clear again; after stabilization of the system, continuing adding a great amount of deionized water with stirring under a heating condition so as to realize phase inversion, wherein the system turns turbid from clear; and finally allowing temperature to rise and carrying out high speed stirring for a certain period of time, wherein the polyprenol microemulsion is obtained when the system becomes clear. The invention has the following advantages: the polyprenol microemulsion with good water dispersibility is prepared from fat-soluble polyprenol grease; and the preparation method is simple, effectively improves water dispersibility, physical properties and bacteriostatic biological activity of polyprenol and broadens the application scope of fat-soluble polyprenol in the industries of food, health products and cosmetics and industries related to biological medicine.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

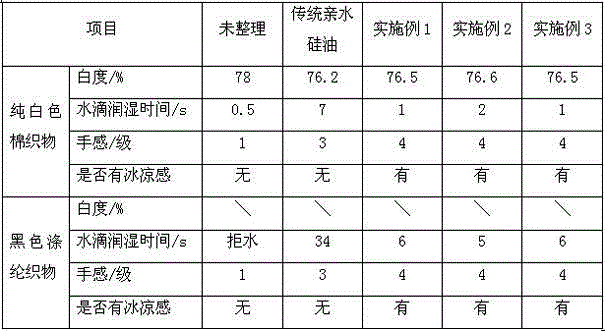

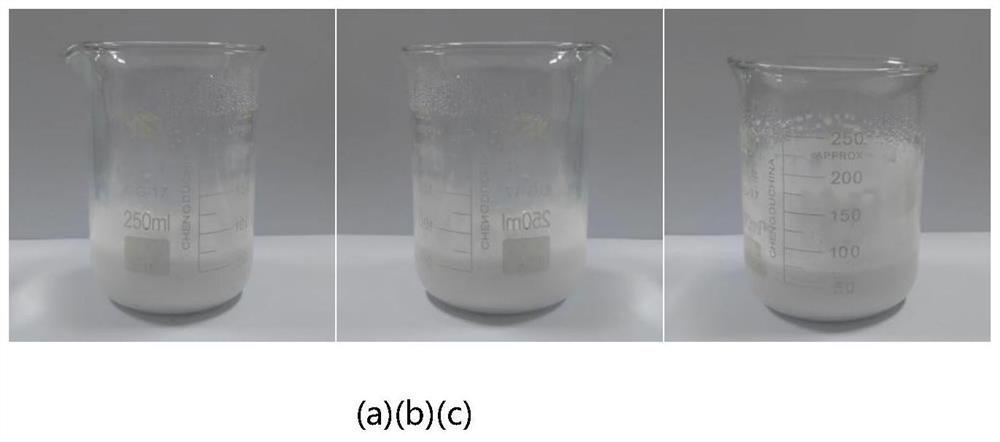

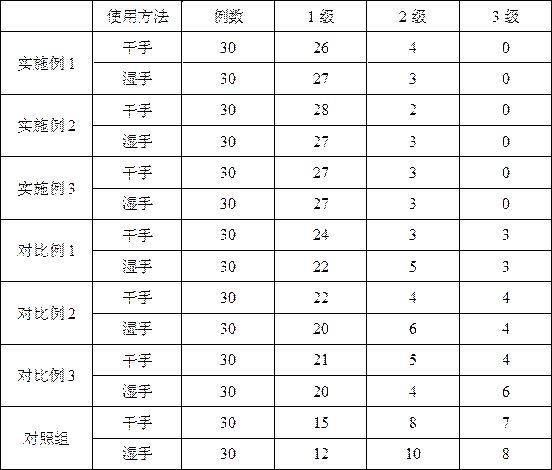

Organosilicon softening finishing agent with ice-cold feeling and preparation method of organosilicon softening finishing agent

The invention relates to the technical field of printing and dyeing auxiliaries, particularly to an organosilicon softening finishing agent with ice-cold feeling and a preparation method of the organosilicon softening finishing agent. The organosilicon softening finishing agent consists of the following raw materials in parts by weight: 10-60 parts of hydrophilic ternary copolymerized organosilicon, 0.1-30 parts of microcapsule ice-cold particles, 0.4-2.4 parts of glacial acetic acid and 20-70 parts of water. The preparation method comprises the following steps: adding hydrophilic ternary copolymerized organosilicon into an emulsifying machine, turning on the emulsifying machine, adding glacial acetic acid, then gradually adding distilled water for emulsification, after silicone oil is changed into a uniform emulsifiable solution, gradually adding the microcapsule ice-cold particles which are 0.1-30 in parts by weight into the emulsifiable solution, and when the microcapsule ice-cold particles are fully dissolved, turning off the emulsifying machine so as to obtain the organosilicon softening finishing agent. The organosilicon softening finishing agent has excellent hydrophilicity, excellent yellowing resistance and excellent launderability, and has the ice-cold feeling that common silicone oil cannot compare.

Owner:广东科特新材料技术有限公司

Vegetable oil composition, application thereof in cosmetics, face cleaning oil and preparation method thereof

InactiveCN109846760AImprove securityHigh makeup removal efficiencyCosmetic preparationsMake-upOil and greaseVegetable oil

The invention belongs to the technical field of cosmetics. The invention discloses a vegetable oil composition. The composition consists of grape seed oil, sun flower seed oil, sweet almond oil, oliveoil and jojoba seed oil in a weight ratio of (1-10):(1-10):(1-10):(1-10):(0.2-5). The invention also discloses face cleaning oil and a preparation method thereof. The face cleaning oil of the presentinvention includes the vegetable oil composition of the present invention, vegetable essential oil, a mixed emulsifier of polyglycerol-3 ricinoleate and polysorbate-85, and tocopherol acetate. The face cleaning oil disclosed by the invention is high in safety, can be used for deeply cleaning color makeup and dirt, is high in makeup removal efficiency, is refreshing and not greasy while effectively cleaning the skin, can be used for effectively resisting bacteria and diminishing inflammation on the skin, and has the effect of repairing the skin. Besides, the face cleaning oil disclosed by theinvention has good performance stability. The preparation method of the face cleaning oil is simple, has low equipment requirement, and is easy for industrial production.

Owner:杭州舒彩网络科技有限公司

Preparation method of water-based carbon fiber sizing agent

InactiveCN108486891ASimple preparation processShort preparation timeCarbon fibresGrip property fibresEpoxyFiber

Owner:NANTONG UNIVERSITY

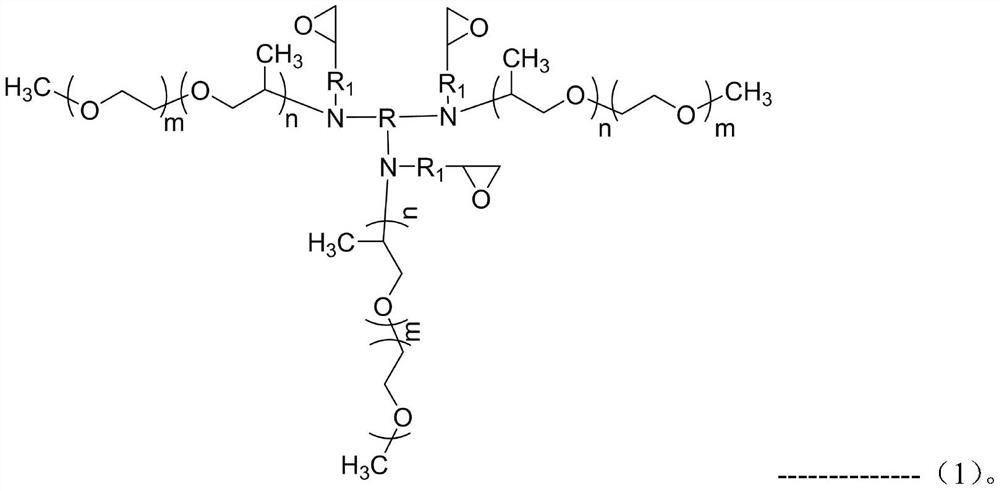

Emulsifier for branched chain reaction type epoxy resin and preparation method thereof

The invention discloses an emulsifier for branched chain reaction type epoxy resin and a preparation method thereof. The emulsifier contains the following molecular structures: N1 is monoamine polyether amine, P is a trifunctional epoxy monomer or a trifunctional acrylate monomer, and Q is a bifunctional epoxy monomer. The preparation method comprises the following steps: reacting a P monomer withmonoamine polyether amine N1 to obtain an intermediate product; and reacting the intermediate product with a Q bifunctional epoxy monomer to obtain the emulsifier. The structure of the prepared emulsifier contains an epoxy group, the emulsifier has good compatibility with epoxy resin, and the epoxy resin emulsion prepared from the emulsifier has good storage stability, centrifugal stability and freeze-thaw stability; meanwhile, the structure of the epoxy resin emulsion contains an epoxy group, so that the epoxy resin emulsion can participate in a curing reaction to enter a cured product network, and a cured coating has excellent medium resistance; the synthesis process is simple, the structure is clear, and no catalyst is needed.

Owner:NANCHANG HANGKONG UNIVERSITY

Wet and dry cleansing oil and preparation method thereof

PendingCN114376946ARefreshing and non-greasyNo acneCosmetic preparationsMake-upPolyolPhysical chemistry

The invention belongs to the technical field of cosmetics, and particularly relates to wet and dry cleansing oil and a preparation method thereof. 15 to 25 parts of an emulsifier; 1 to 5 parts of polyol; 1-3 parts of deionized water; 0.1 to 1 part of an antioxidant; and 0.01 to 0.2 part of essence. The components are matched for use, and the final formula achieves the effects of safety, mildness, capability of deeply cleaning cosmetics and dirt, freshness and no greasiness by optimizing the component content, and has a good makeup removal effect under the condition of dry and wet hands. The cleansing oil disclosed by the invention is very excellent in smell, color, centrifugal stability, cold-resistant stability and heat-resistant stability. And the preparation method is simple, low in equipment requirement and easy for industrial production.

Owner:广州睿新生物科技有限公司

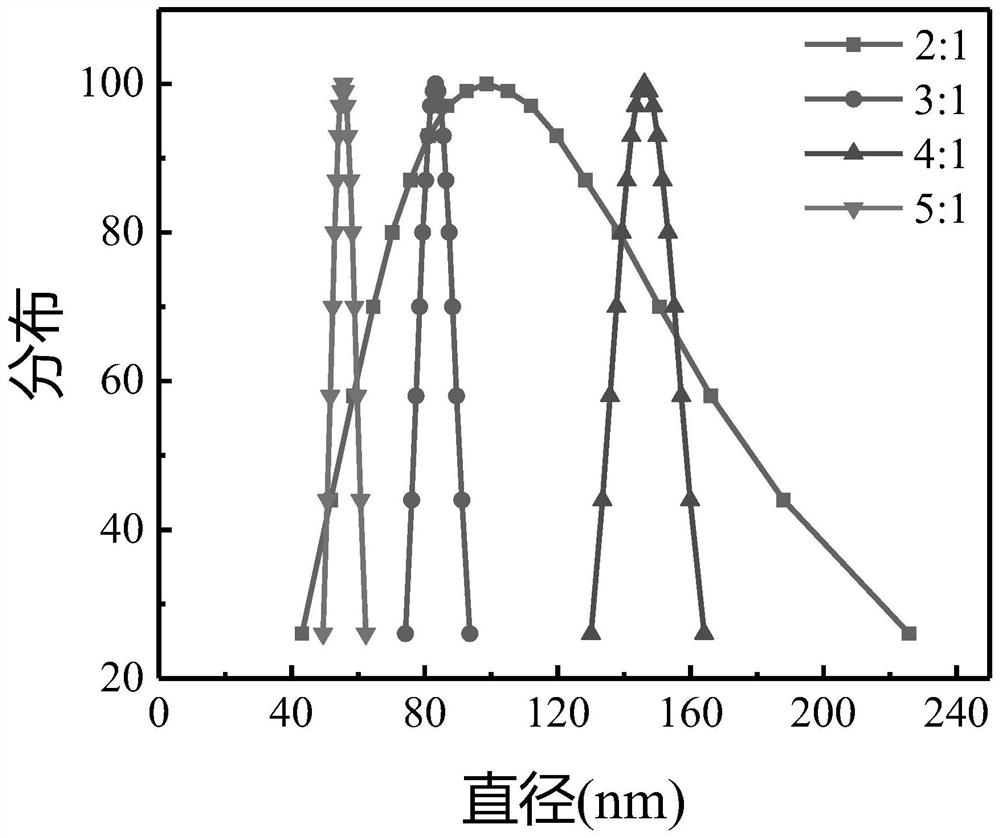

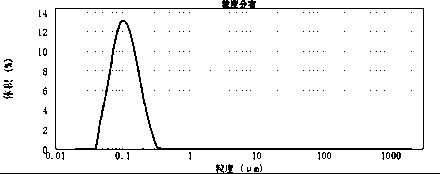

Oiling agent for splitting waste polyester-cotton fabric and preparation method thereof

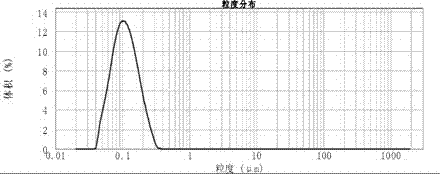

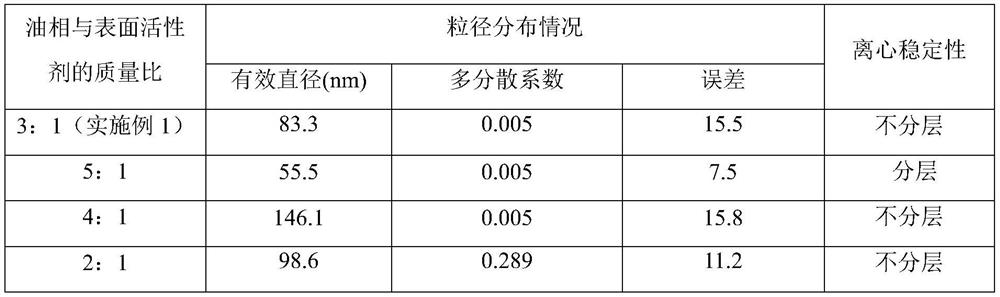

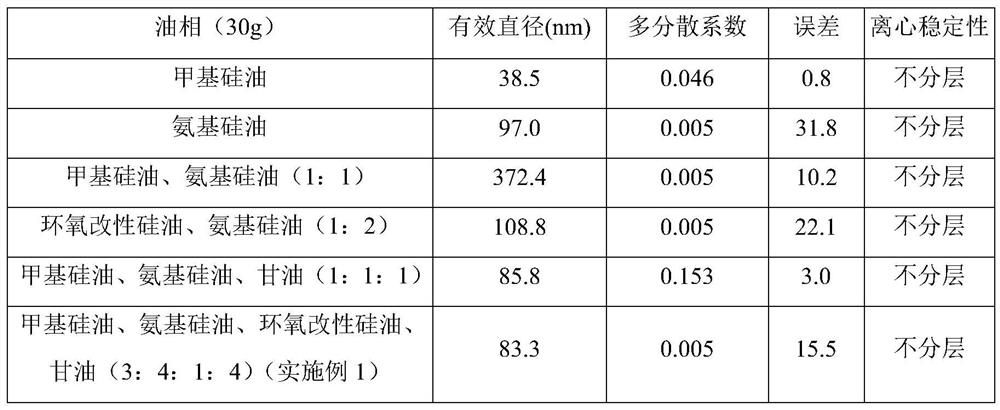

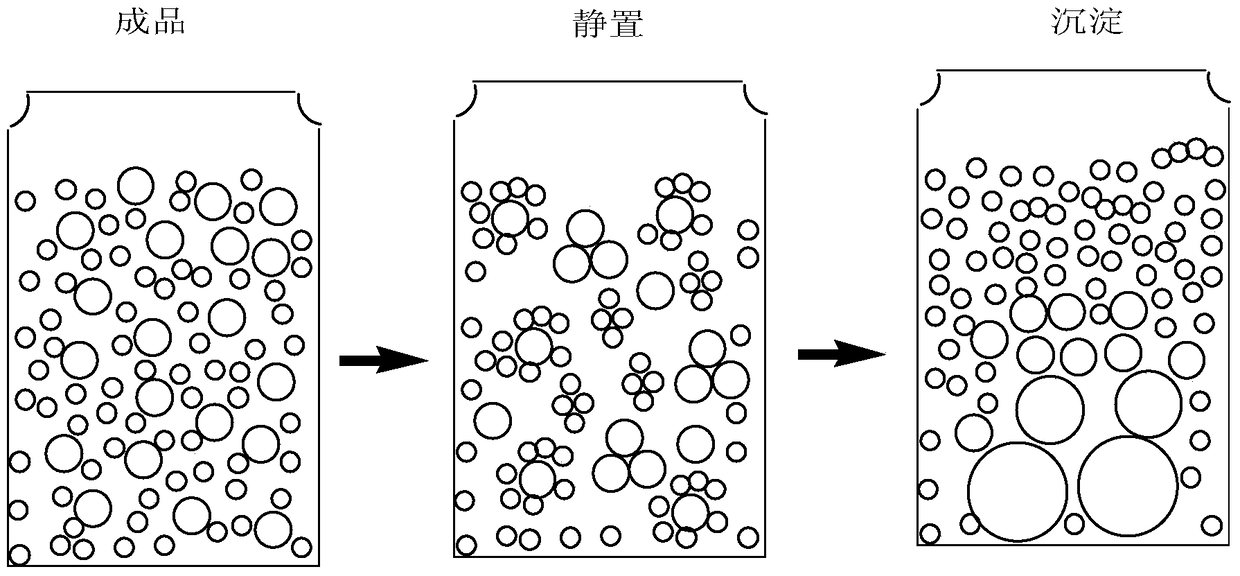

ActiveCN113373686AImproved particle size distributionNo stratificationVegetal fibresArtificial filament chemical after-treatmentEpoxyPolyester

The invention discloses an oiling agent for splitting a waste polyester-cotton fabric and a preparation method thereof, and belongs to the field of textile materials. The method for preparing the oiling agent comprises the following steps of (1) uniformly mixing an oil phase and a surfactant to obtain a crude emulsion, wherein the oil phase is a mixture of dimethyl silicone oil, amino silicone oil, epoxy modified silicone oil and glycerol in a mass ratio of 3: 4: 1: 4, and the surfactant is a mixture of polyoxyethylene lauryl ether, Tween 80 and poly dimethyl diallyl ammonium chloride in a mass ratio of 6: 3: 1; and (2) slowly dropwise adding a water phase into the crude emulsion, and carrying out high-speed shearing emulsification to obtain a composite emulsion, namely the oiling agent for splitting, wherein the mass ratio of the oil phase to the surfactant to the water phase is (20 to 50): (9 to 11): (40 to 180). The particle size distribution of the oiling agent for splitting provided by the invention is low and ranges from 50 nm to 150 nm; and the centrifugal stability is better, and the phenomena of layering and floating oil are avoided.

Owner:JIANGNAN UNIV

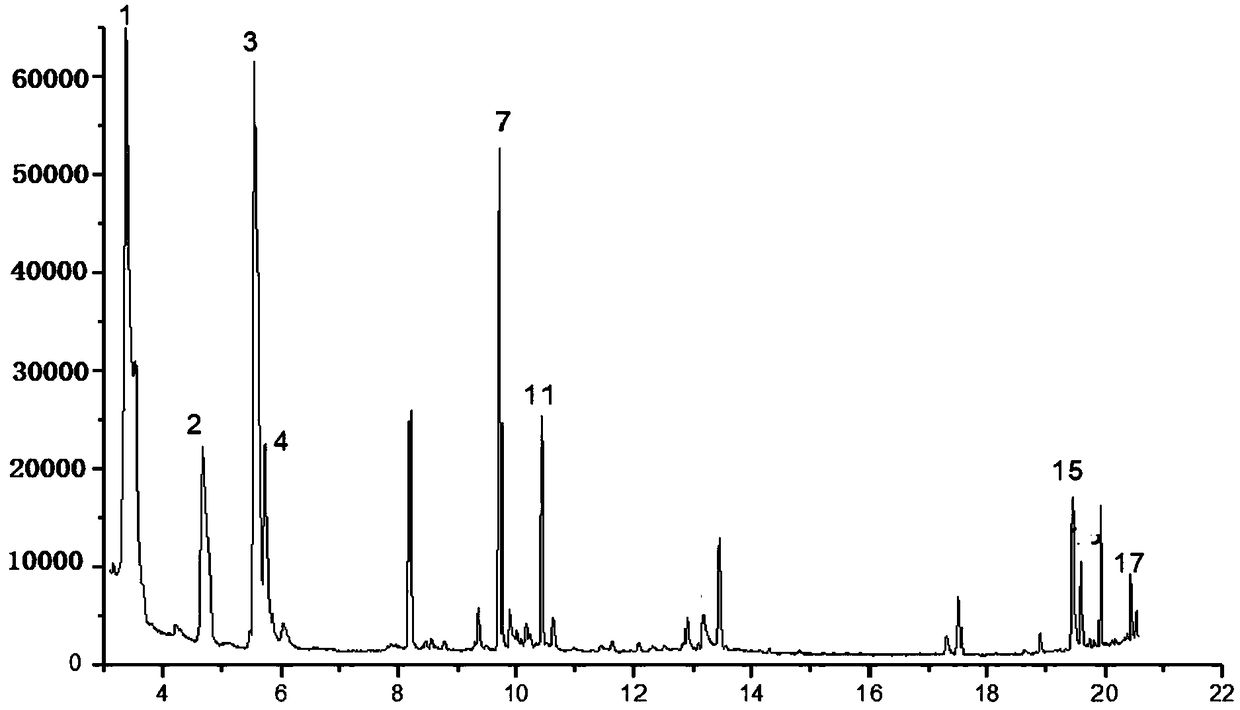

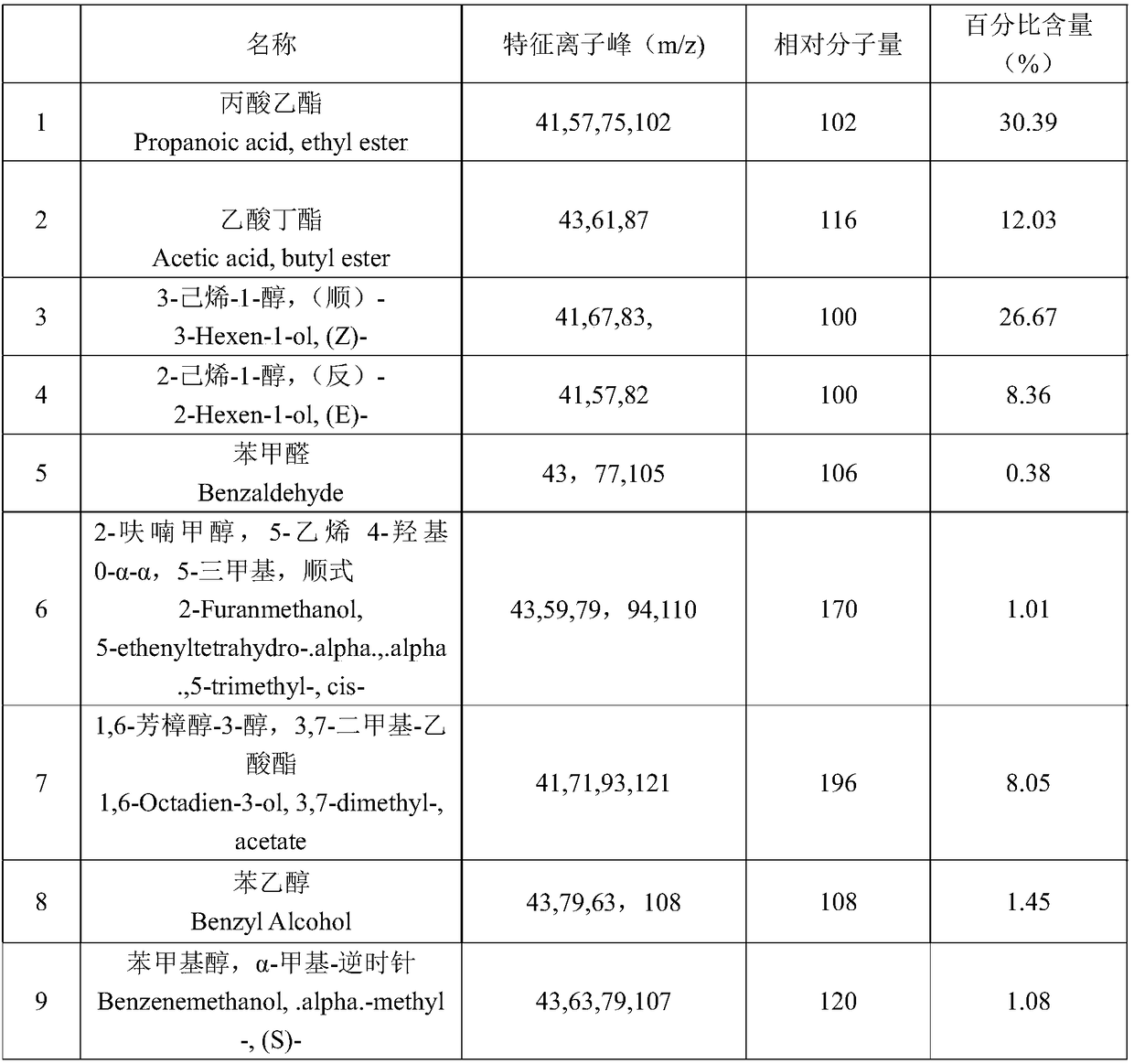

Fresh tea leaf essential oil toner and preparation method thereof

PendingCN108938528AAntioxidantPromote circulationCosmetic preparationsToilet preparationsVitamin CAdditive ingredient

The invention discloses a fresh tea leaf essential oil toner and a preparation method thereof. The fresh tea leaf essential oil toner is prepared from the following raw materials in parts by weight: 5-8 parts of fresh tea leaf essential oil, 10-15 parts of dendrobium officinale leaf extracting solution, 4-8 parts of butanediol, 0.8-1.6 parts of pure plant emulgator, 0.5-1.0 part of sodium hyaluronate and 70-80 parts of deionized water. In the invention, the natural plant fresh tea leaves and dendrobium officinale leaves are taken as raw materials; the fresh tea leaf essential oil toner is richin nutritional ingredients, such as esters, alcohols, terpene, polysaccharide, vitamin C and protein and has a pleasant fragrance; all the components interact with each other; contents of the components are optimized, so that the final formula is green and natural, safe and mild, nontoxic, harmless and non-irritant, and has the effects of oxidation resistance, anti-aging, antisepsis and anti-inflammation properties and the effects of promoting epithelial cell regeneration and repairing injured skin. The preparation method disclosed by the invention is simple in technical process, simple in operation and suitable for large scale production.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

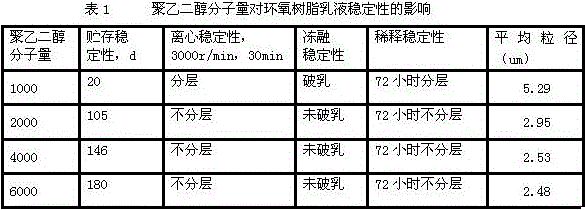

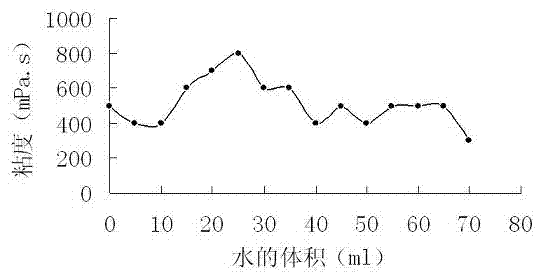

A kind of preparation method of epoxy resin emulsion

The invention discloses a preparation method of epoxy resin emulsion, and relates to the field of epoxy resin emulsion and emulsifying preparation of the epoxy resin emulsion. Polyether urethane with the epoxy group as the end group serves as reactive emulsifier, and high-speed mixing is carried out in cooperation with the phase inversion technology to prepare the epoxy resin emulsion. The dispersion phase particles of the emulsion are fine, particle size distribution is concentrated, the emulsion has very good centrifugal stability, freezing and thawing stability and dilution stability, and compared with the epoxy resin emulsion in the prior art, solidified coatings have higher toughness, strength, adhesive force and water resistance.

Owner:大余松瀛化工有限公司

Synthesis of modified aqueous epoxy resin and method for preparing antiseptic rusty paint

ActiveCN101775108BGood water dispersibilityGood storage stabilityAnti-corrosive paintsEpoxyDistilled water

The invention discloses synthesis of modified aqueous epoxy resin and a method for preparing antiseptic rusty paint, relating to synthesis of epoxy resin and a method for preparing paint. The invention solves the problems of the traditional aqueous epoxy resin antiseptic paint that storing stability of base material resin and water resistance and corrosion resistance of an aqueous epoxy resin antiseptic paint coating film can not be met simultaneously. the synthesis method of modified aqueous epoxy resin comprises the steps of: mixing Span 60 with Tween 20, adding E-51; heating and stirring, and dropwise adding distilled water till the system viscosity is suddenly reduced; and finally dropwise adding an initiating agent and a monomer to carry out heating reaction. The method for preparingantiseptic rusty paint comprises the steps of: mixing the modified aqueous epoxy resin, a corrosion inhibitor and a rust preventing agent, stirring and grinding; adding a defoaming agent, a curing agent and deionized water; and stirring the mixture to obtain the modified aqueous epoxy resin antiseptic rusty paint. The invention simultaneously meets the storing stability of the base material resin of the aqueous epoxy resin antiseptic paint and the water resistance and the corrosion resistance of the aqueous epoxy resin antiseptic paint coating film.

Owner:HARBIN INST OF TECH

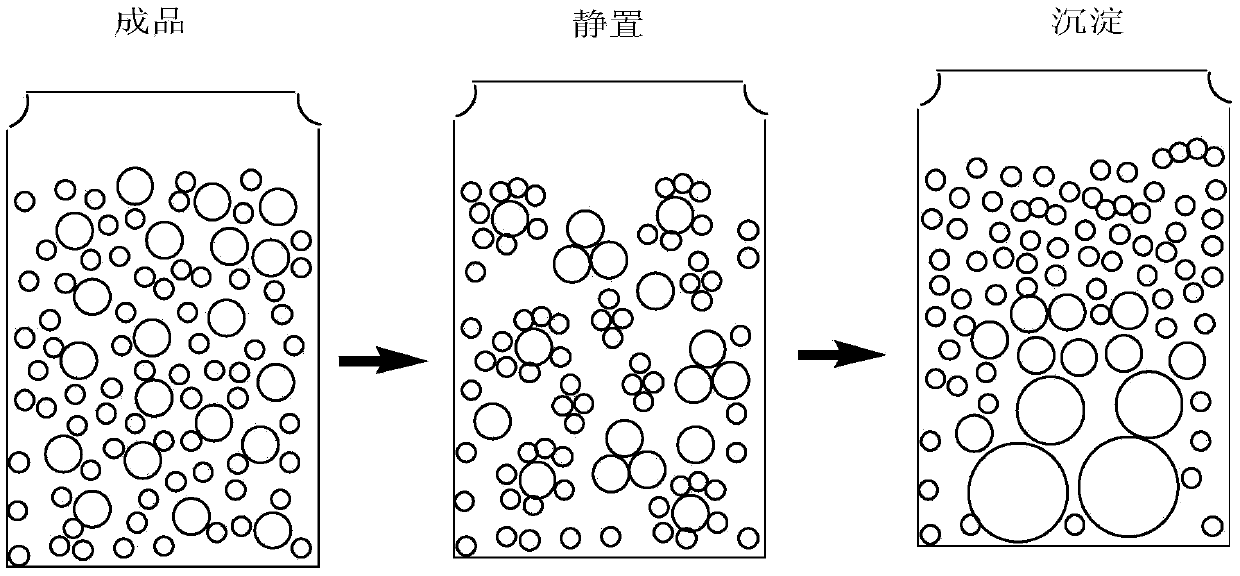

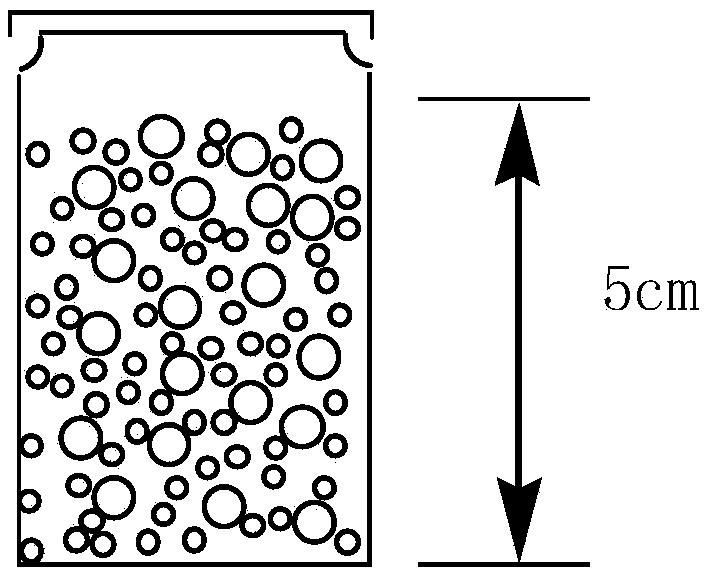

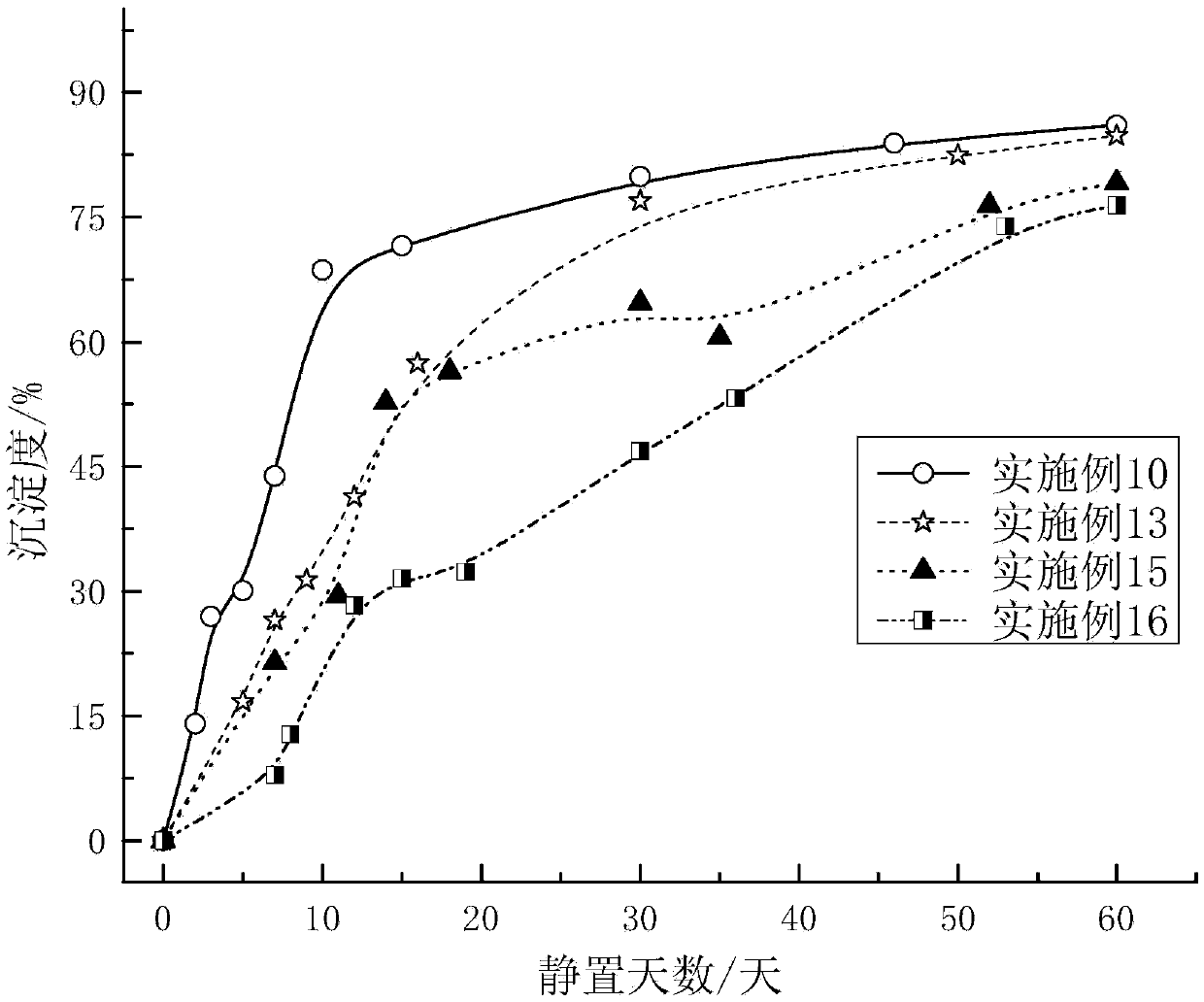

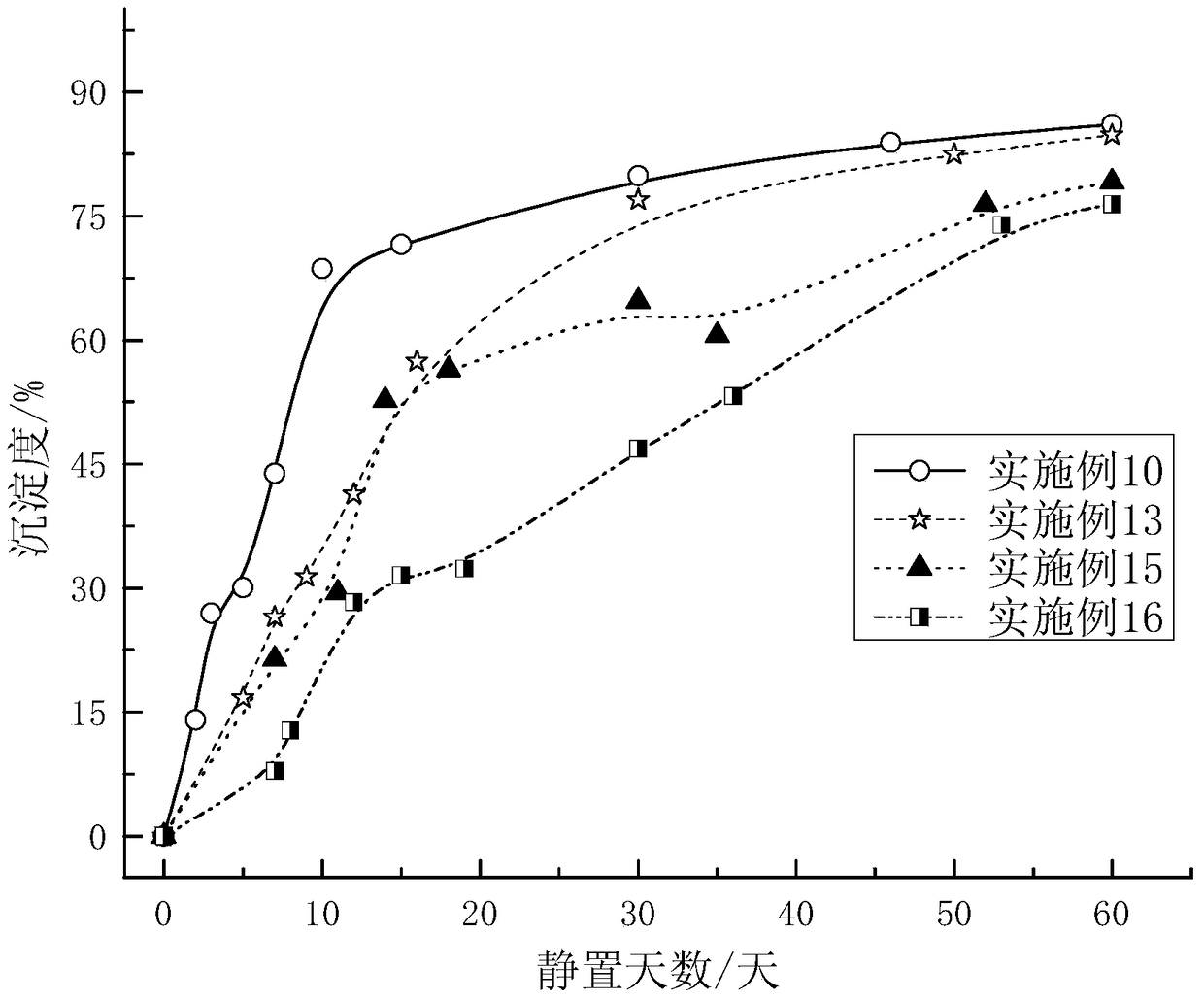

Disperse dye paste capable of effectively retarding precipitation and preparation method

ActiveCN106700653AImprove storage performanceImprove dyeing performanceOrganic dyesDyeing processUreaPrecipitation

The invention discloses a disperse dye paste capable of effectively retarding precipitation. The disperse dye paste is characterized by comprising urea with a weight of 0.05 to 0.5 time of the total weight of a disperse dye component, and a dispersant with a weight of 0.6 to 6 times of the total weight of the disperse dye component, wherein the disperse dye component is one or more selected from compounds as shown in a formula in the specification. In the formula, R1 is H or -NO2; R2 and R3 are selected from the group consisting of H, or -Cl, -Br, -CN, -CF3, -NO2 and -COOR8; R4 and R5 are selected from the group consisting of H, or alkyl, alkoxy and -NHCOR9; R6 and R7 are selected from the group consisting of alkyl, alkoxy, or alkyl or alkoxy with an H substituted by -OH, -CN or -Ph; and R8 and R9 are alkyl. The disperse dye provided by the invention is a liquid dye, and has high dyeing rate, good deep dyeing properties and excellent dyeing fastness; and compared with an ordinary commercial disperse dye paste, the disperse dye paste provided by the invention has the following advantages: the aggregation and precipitation rate of dye particles is significantly reduced, and better storage stability is obtained.

Owner:ZHEJIANG DIBANG CHEM

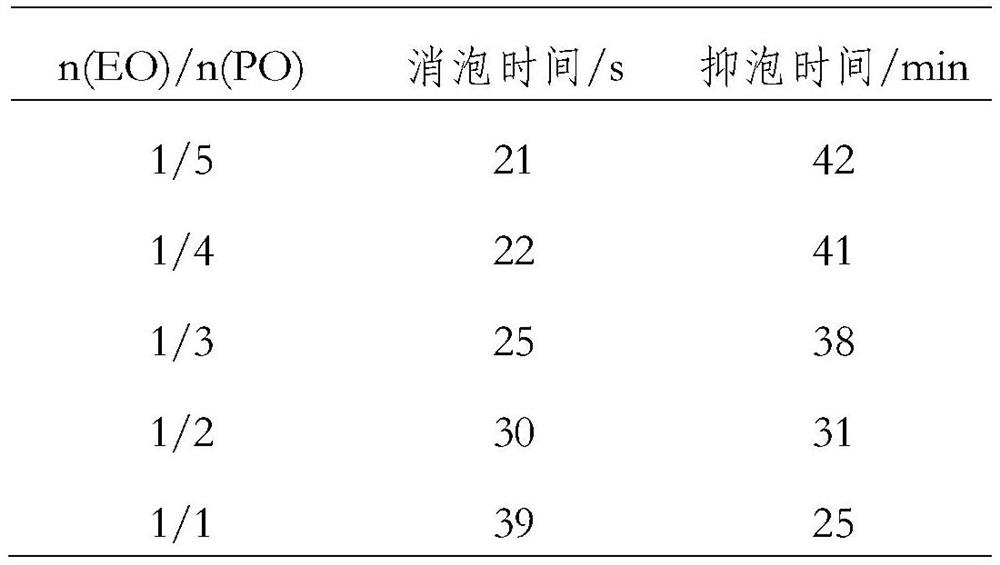

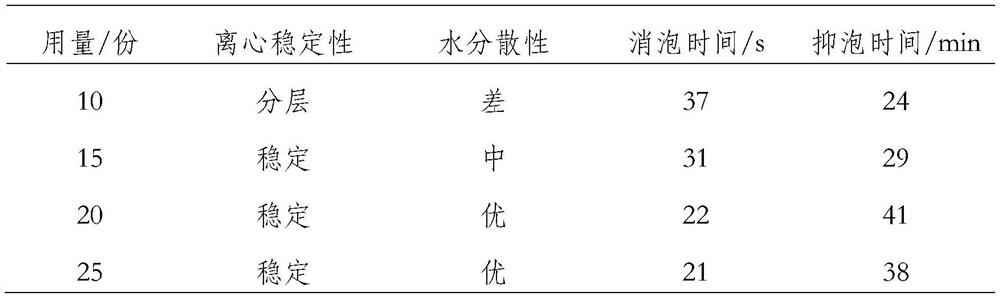

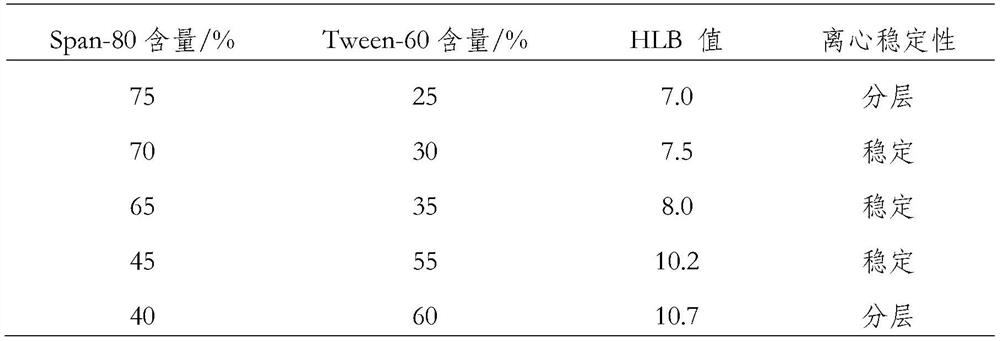

A kind of organosilicon defoamer and preparation method thereof

ActiveCN111871010BPromote formationGood defoaming effectFoam dispersion/preventionFood additiveCentrifugation

The invention discloses a silicone defoamer and a preparation method thereof, which comprises the following components in parts by mass: 15-20 parts of polyether-modified polydimethylsiloxane, 10-15 parts of polyether, Composite emulsifier 3-7 parts, dispersant 0.5-2 parts, food additive 0-0.1 parts, stabilizer 1-1.5 parts. Compared with commercially available defoamers, the silicone defoamer prepared by the present invention has little difference in defoaming performance and foam suppression performance, but the centrifugal demulsification time of the silicone defoamer prepared by the present invention is longer and the stability is higher. The commercially available defoamer is greatly improved, and the water dispersibility is better than that of the commercially available defoamer, and the performance is more balanced.

Owner:JINHU JINLING NEW MATERIAL SCI & TECH

Oxidized polyethylene wax microemulsion composition and preparation method thereof

The present invention discloses an oxidized polyethylene wax micro-emulsion composition and a preparation method thereof. The micro-emulsion composition comprises: 1) 15-35 wt% of an oxidized polyethylene wax with a melting point of 110-150 DEG C, 2) 3-15 wt% of a nonionic surfactant, 3) 0.5-5 wt% of an organic alcohol amine auxiliary emulsifying agent, and 4) 50-80 wt% of water. The micro-emulsion composition can be prepared by using a multi-step high temperature emulsification method, and has characteristics of particle size of less than 100 nm, uniform distribution, centrifugal stability, good acid resistance stability and good alkali resistance stability. In addition, the micro-emulsion composition can be diluted with cold water in any proportions while no particle is precipitated, and the storage stability exceeds more than 6 months.

Owner:浙江震东新材料有限公司

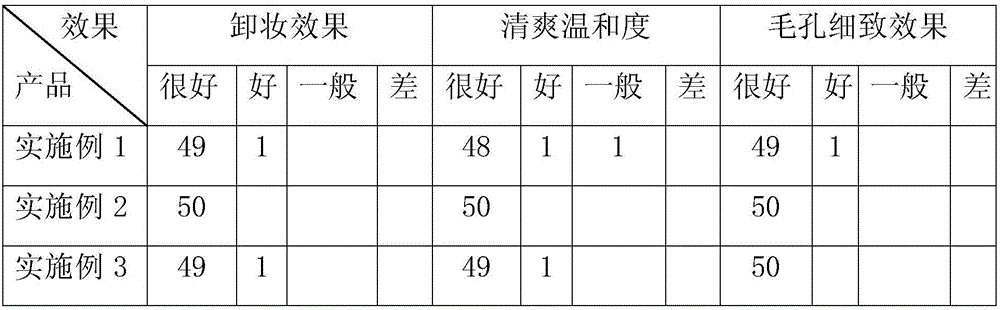

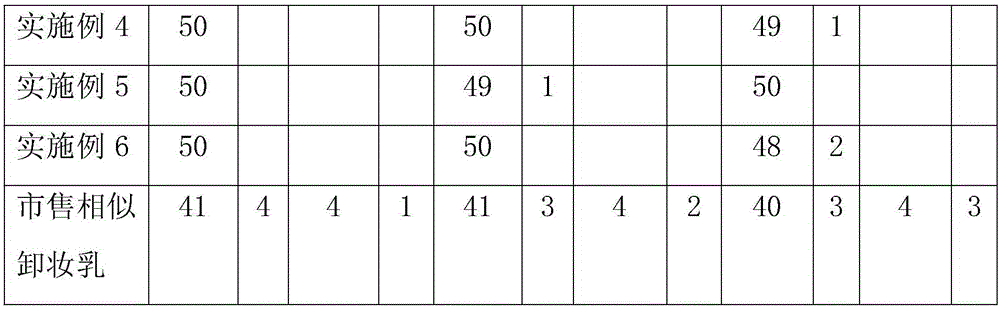

Pore refining type makeup removing lotion and preparation method thereof

InactiveCN105997537AEnhance anti-inflammatoryGuarantee structureCosmetic preparationsMake-upAdditive ingredientCutin

The invention provides a pore refining type makeup removing lotion. The lotion is characterized by being prepared from, by weight, 5-10% of tea oil, 5-10% of squalane, 5-15% of emulgator, 3-6% of plant essential oil, 3-8% of plant extracts, 2-6% of tartaric acid, 0.25-2.5% of natural moisturizing factor (NMF), 0.1-0.6% of plant ingredient anti-allergic agent, 0.1-0.6% of antioxidant and 40-80% of deionized water according to the total weight percentage of 100%. According to the technical scheme as a whole, all the components are used in cooperation; by optimizing the component contents, the final formula has quite good effects on removing makeup, removing cutin, refining pores, repairing skin and resisting bacteria and eliminating inflammation; in addition, the makeup removing lotion is quite excellent in flowability, appearance, centrifugal stability, cold resistance stability and heat resistance stability.

Owner:CANTON DAMEKISS DAILY CHEM FACTORY LIMITED

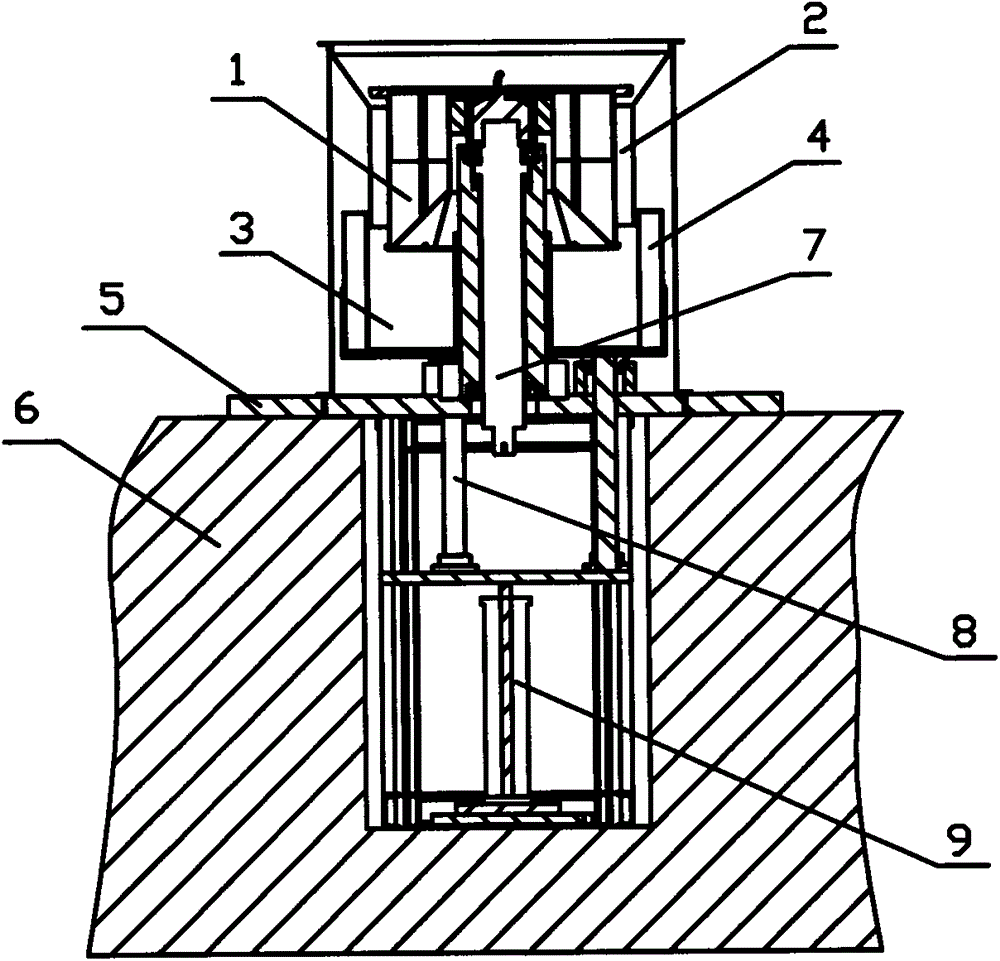

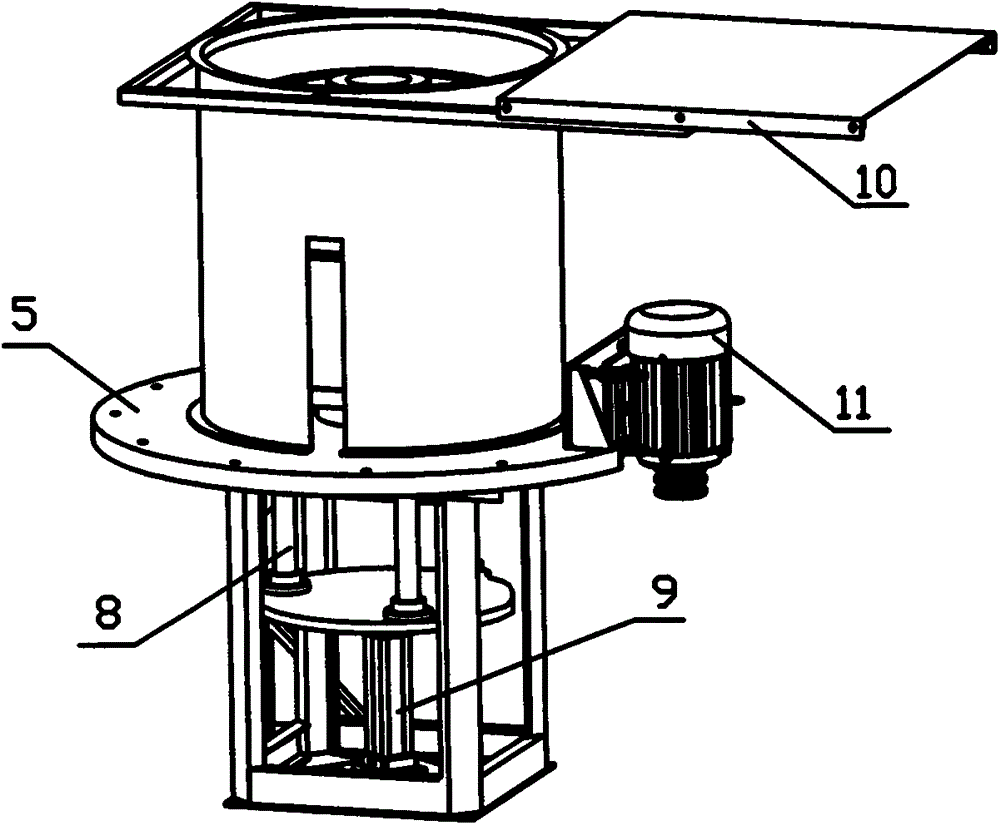

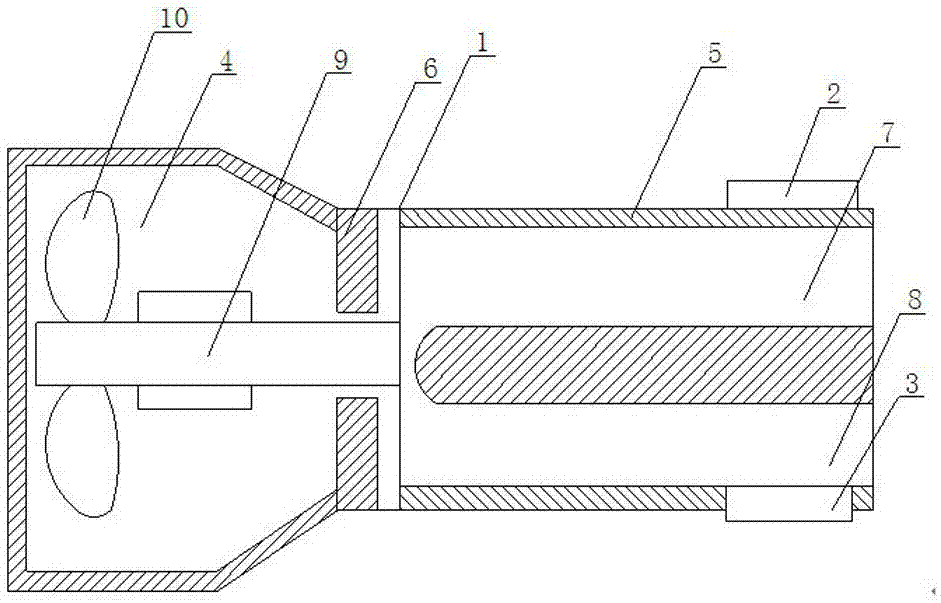

A hydraulic automatic dip-coating machine

ActiveCN103934147BQuick updateAvoid wastingLiquid surface applicatorsCoatingsAgricultural engineeringElectric machinery

The invention discloses a full-automatic hydraulic dipping and coating all-in-one machine which comprises a dipping and coating device, a motor (11) and a machine cover (10), wherein the dipping and coating device comprises a material frame (1), a ring-shaped liquid coating groove (3), and an automatic liquid coating groove lifting system (9) connected with the ring-shaped liquid coating groove (3); the center of the ring-shaped liquid coating groove (3) is provided with a main shaft (7), and the bottom end of the main shaft (7) is connected with the motor (11); the top end of the main shaft (7) is fixedly connected with the material frame (1); the inner wall of the ring-shaped liquid coating groove (3) is provided with a ring-shaped water-cooling groove (4); the periphery of the upper edge of the material frame (1) is surrounded by a liquid retention frame (2); a gap is formed between the liquid retention frame (2) and the outer wall of the material frame (1); the external diameter of the liquid retention frame (2) is smaller than the internal diameter of the ring-shaped water-cooling groove (4). The full-automatic hydraulic dipping and coating all-in-one machine has the beneficial effects of being rapid in production step, rapid in coating update and relatively good in centrifugal stability, and being capable of avoiding the waste of a great deal of coating.

Owner:CHANGZHOU GAOKEXIU MACHINERY

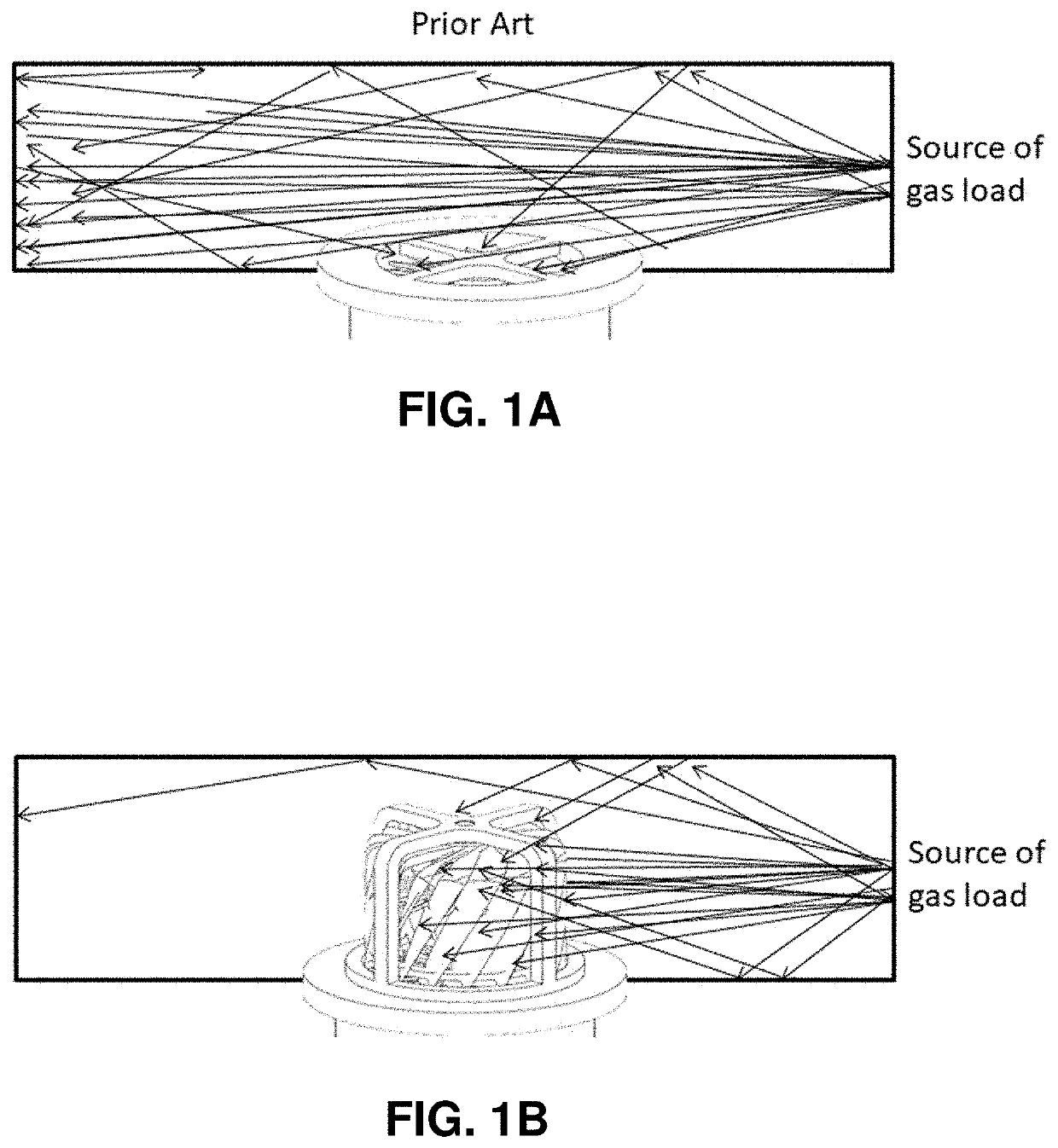

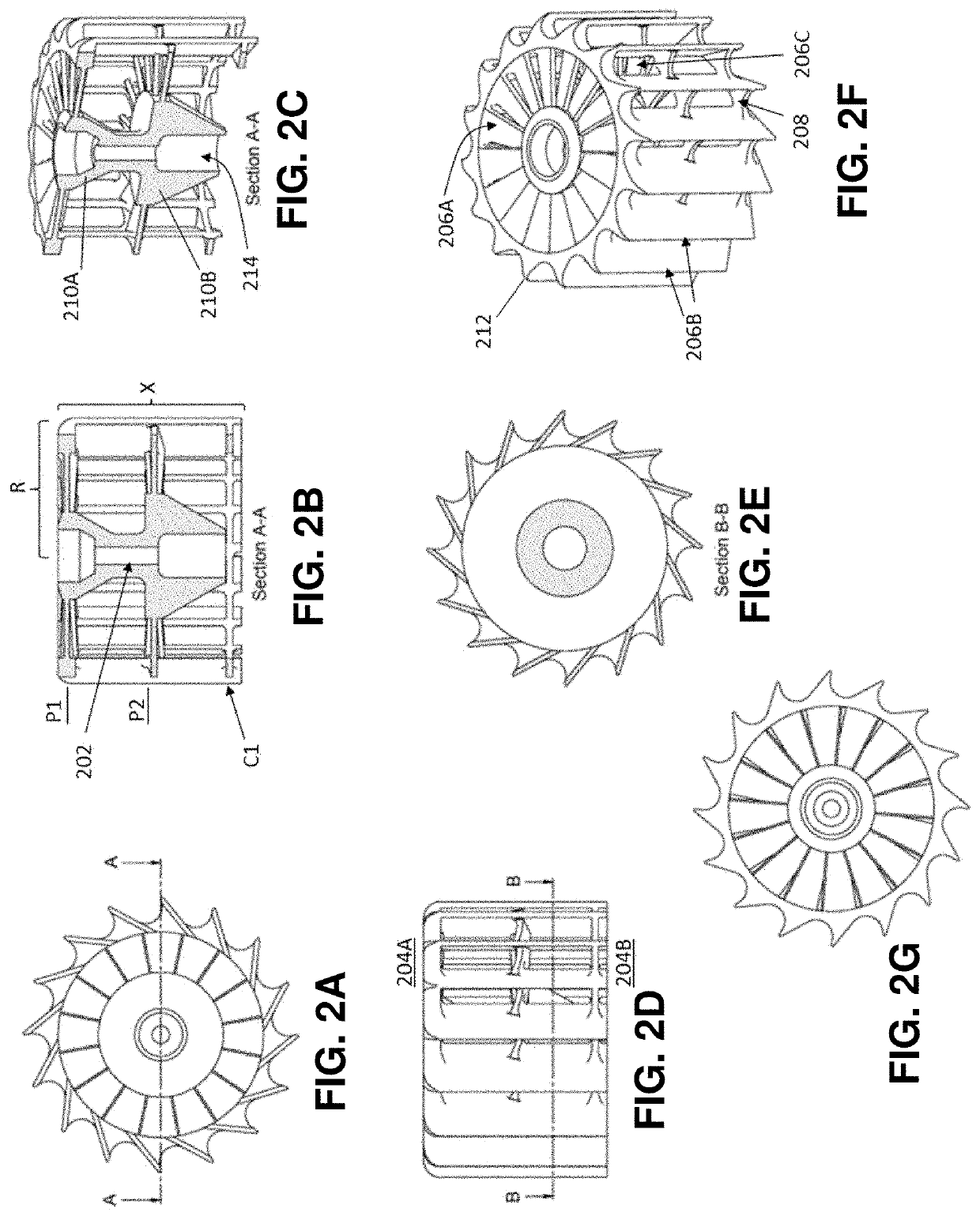

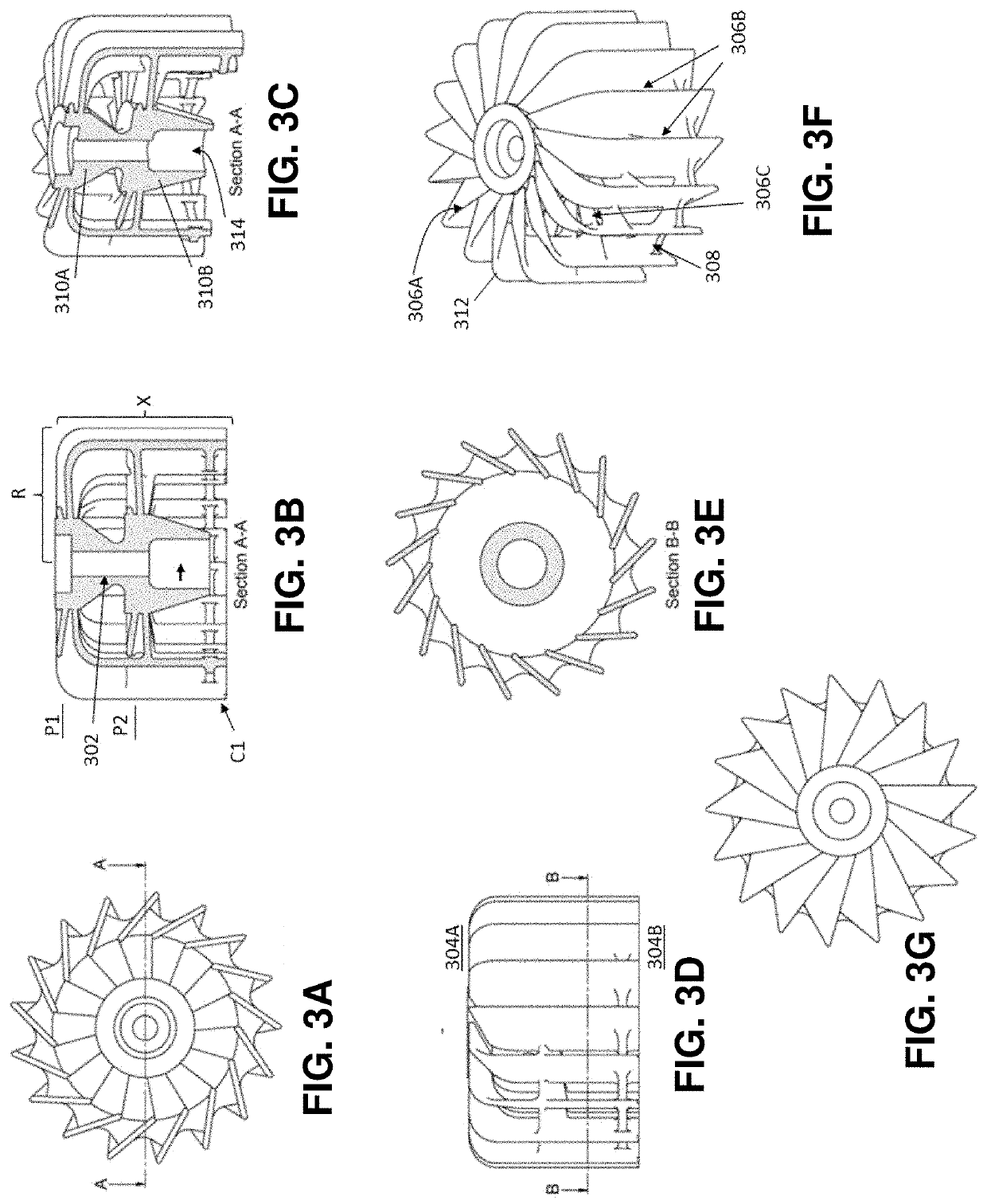

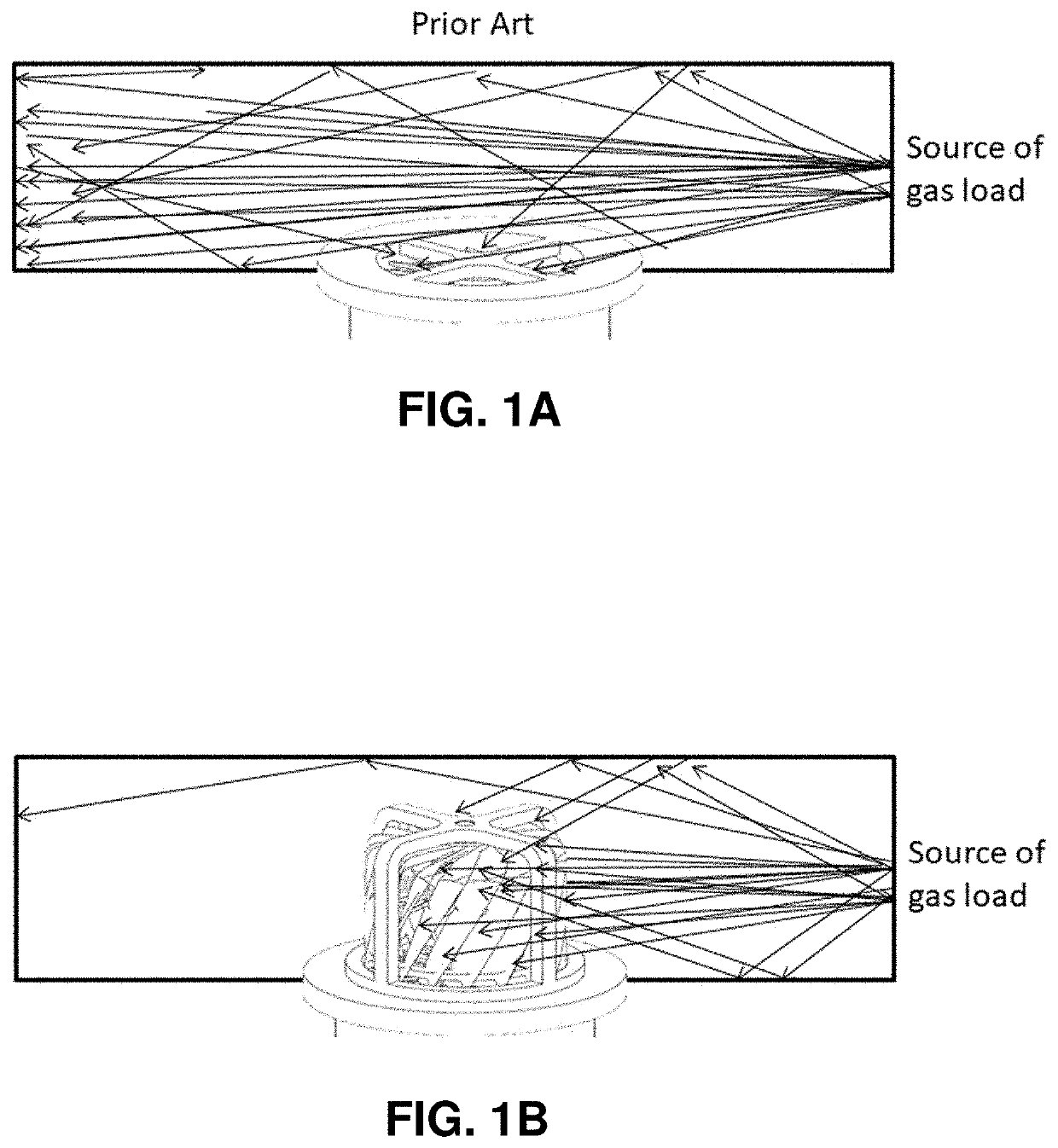

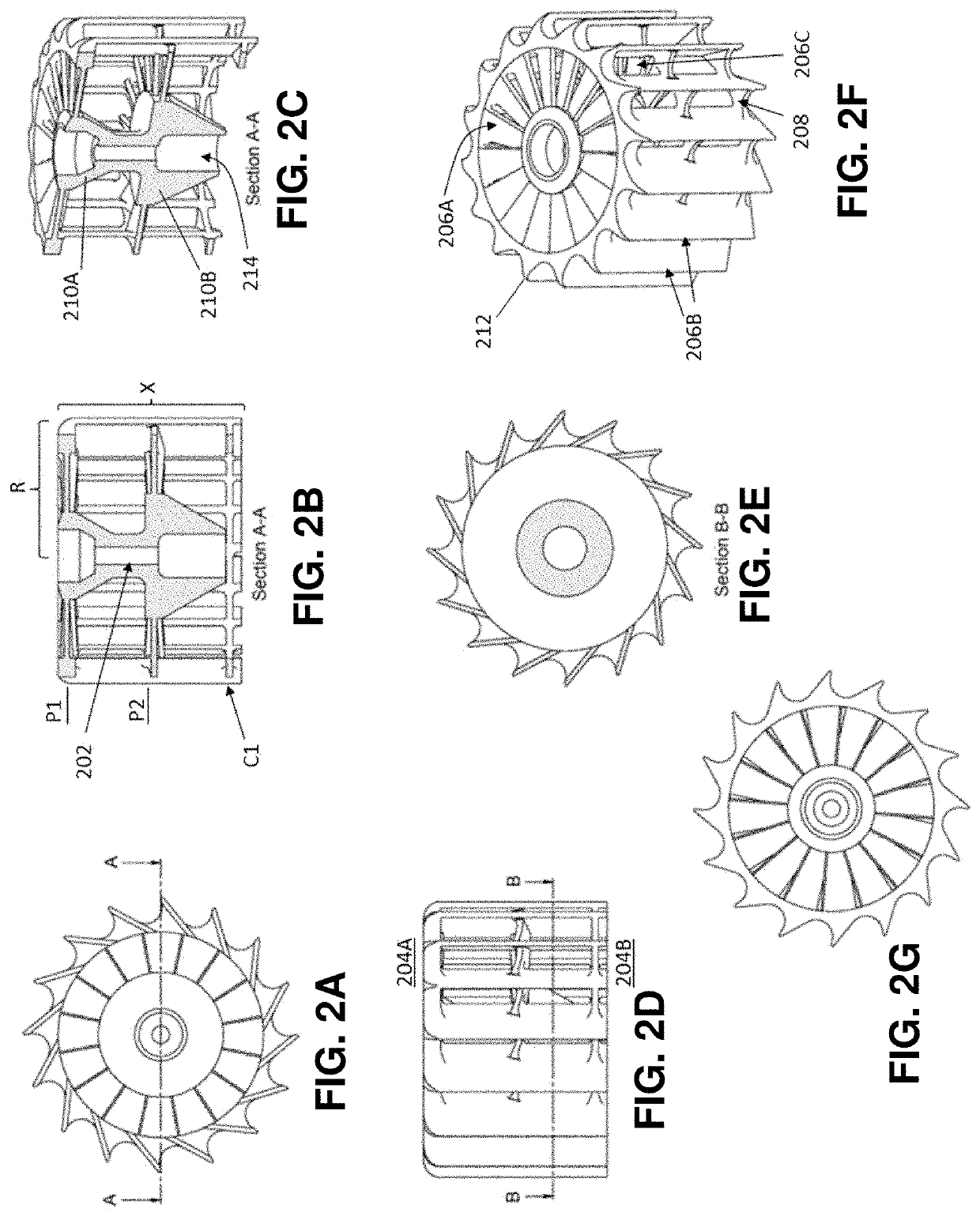

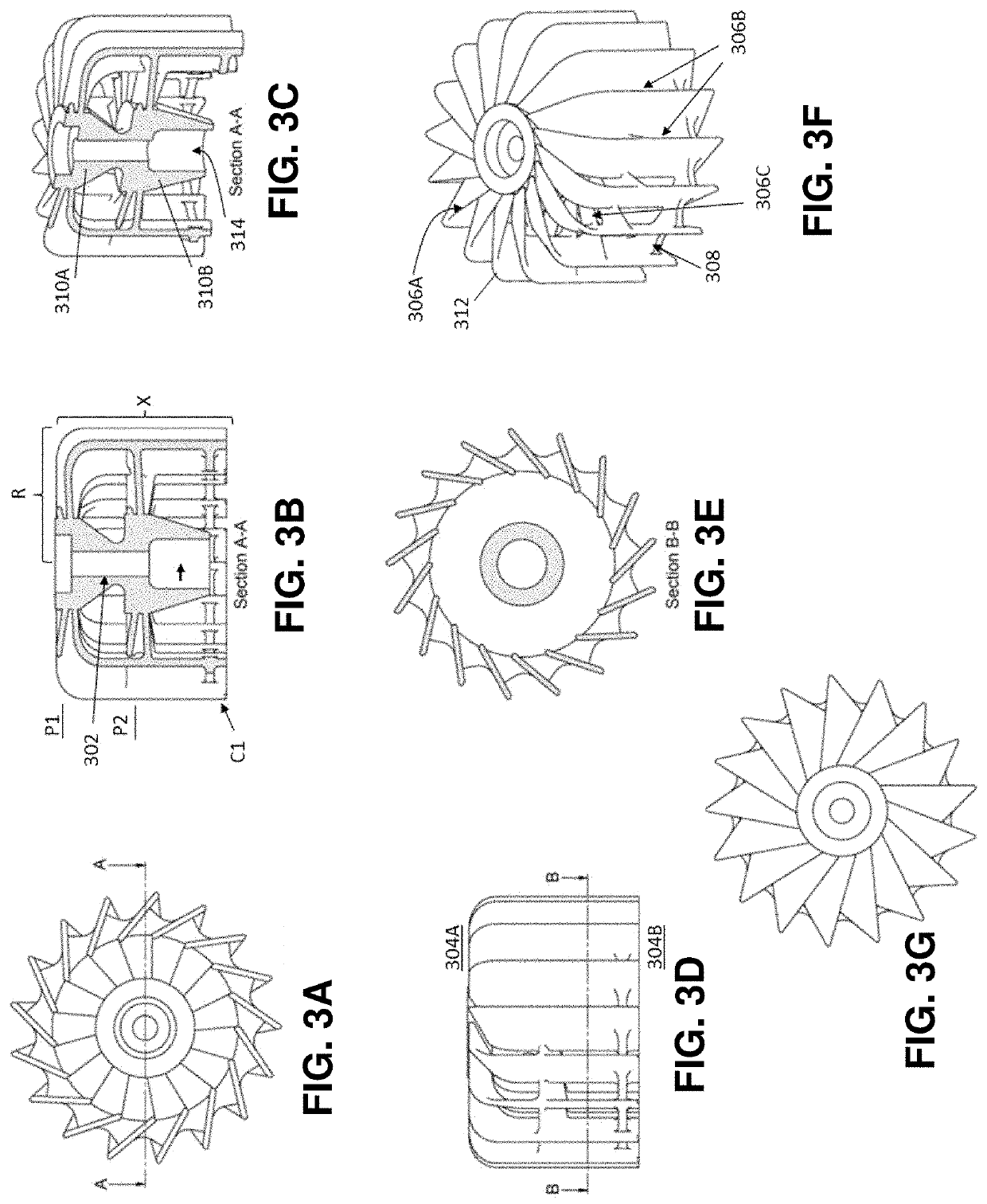

Turbo molecular pump for mass spectrometer

ActiveUS20200058479A1Optimize pumping speedSmall motorTurbinesAdditive manufacturing apparatusEngineeringMass analyzer

The invention relates to turbo molecular pumps enabling high pumping speed. The disclosure suggests using one or more cage-like rotor stages to optimize pumping speed on vacuum systems with low gas flows and low ultimate pressures. This allows for a smaller motor as well as smaller overall form factor and makes it well suited, in particular, for compact mass spectrometers and desk-top mass spectrometers.

Owner:BRUKER DALTONIK GMBH & CO KG

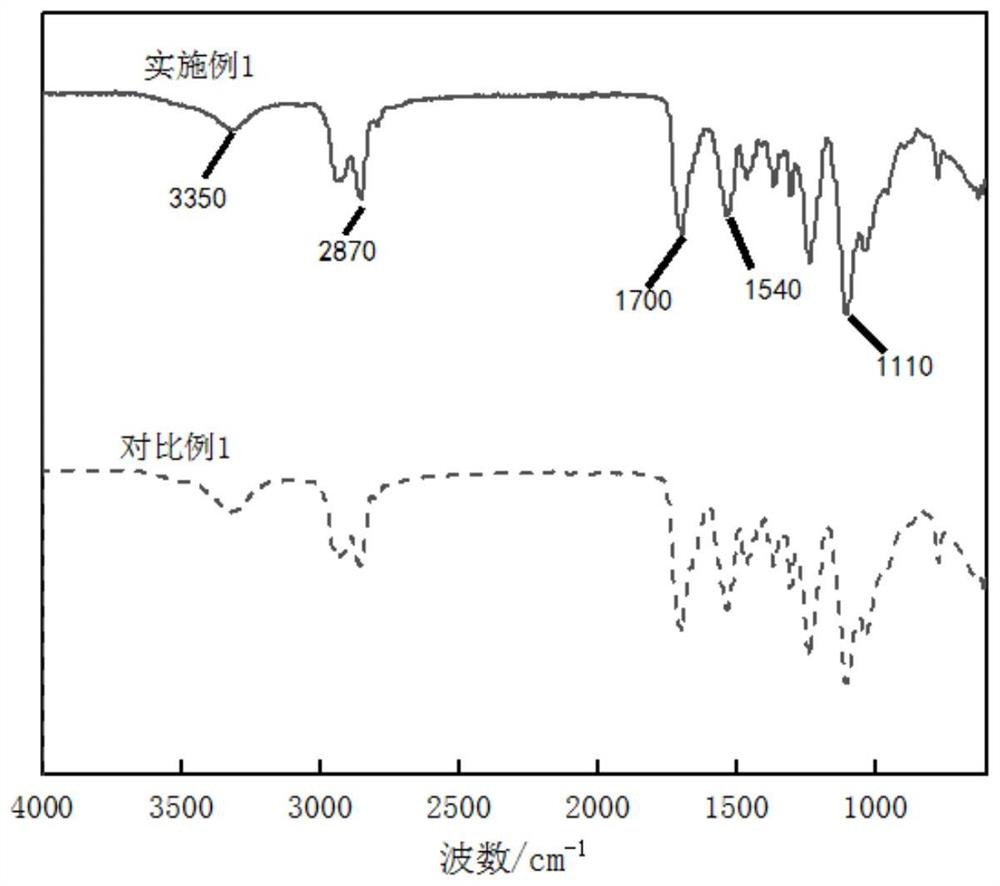

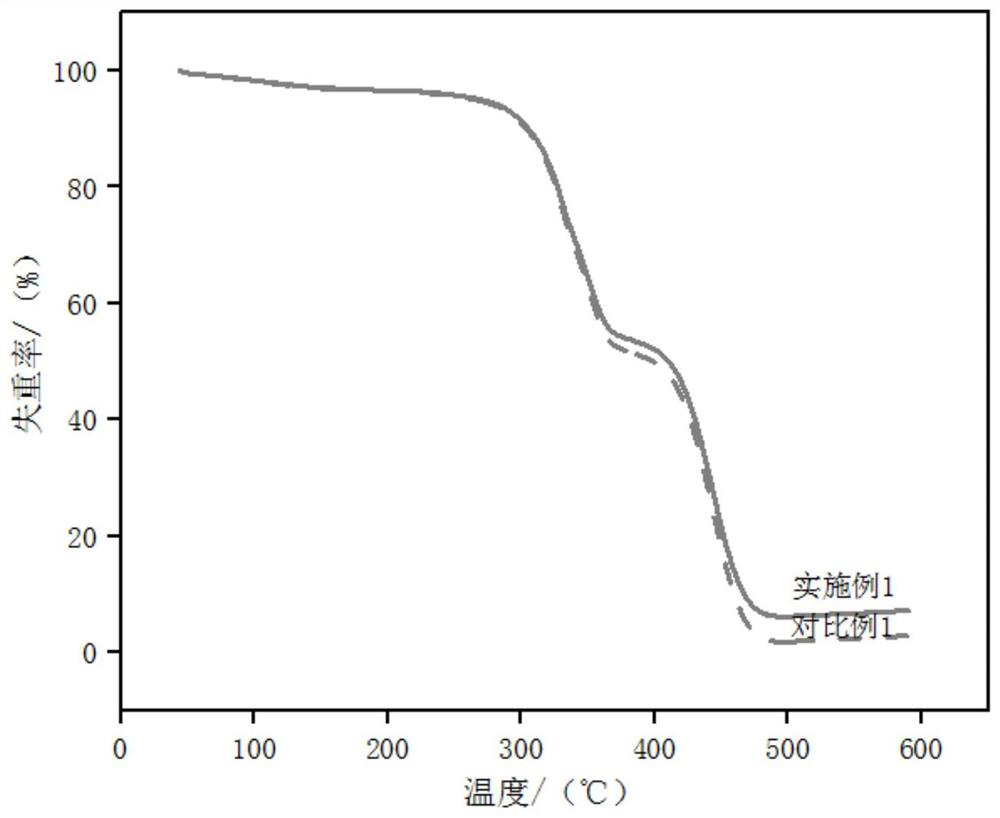

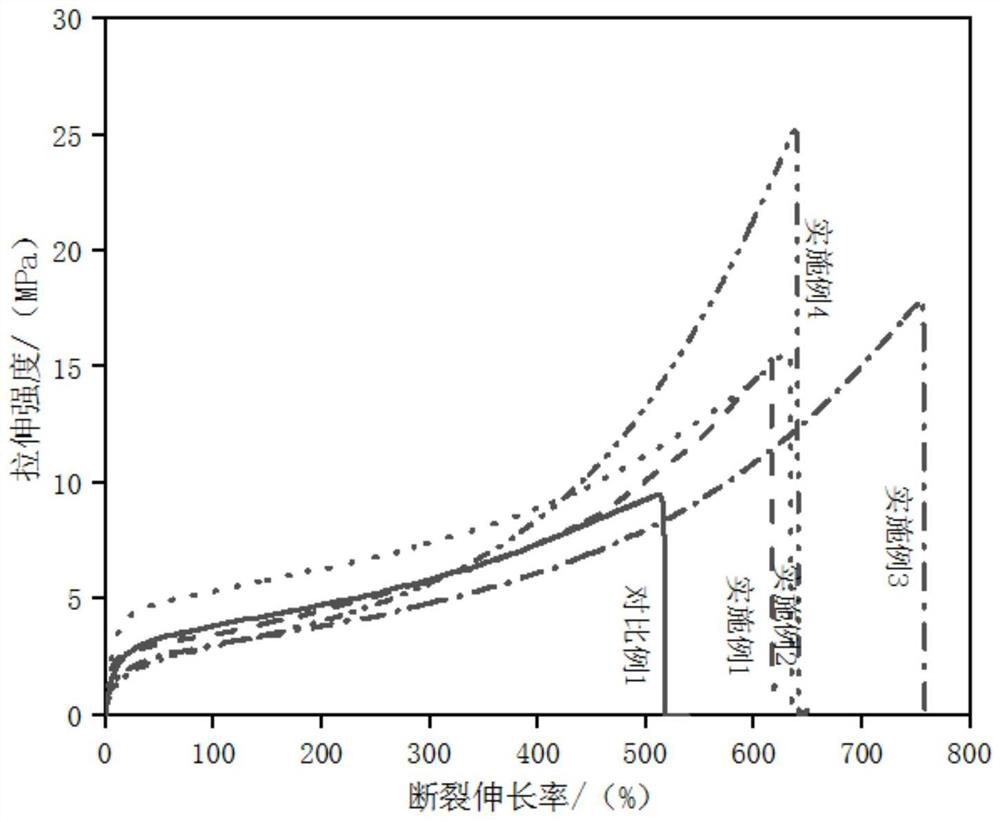

Waterborne polyurethane composite material with high thermal conductivity and preparation method thereof

PendingCN114045146AGood dispersionImprove thermal conductivityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCross linkerColloidal particle

The invention discloses a waterborne polyurethane composite material with high thermal conductivity. Firstly, a cross-linking waterborne polyurethane composite emulsion is prepared from macromolecular dihydric alcohol, diisocyanate, a hydrophilic chain extender, a micromolecular chain extender, a neutralizer, deionized water, modified graphene powder and an internal cross-linking agent. The average colloidal particle size of the prepared waterborne polyurethane composite emulsion is 40.00-60.00 mm, the solid content is about 30%, and the centrifugal stability of the composite emulsion is very good. After the composite emulsion is dried to form a film, the pencil hardness is 1H-2H, the water absorption rate is 20-40%, the ethanol swelling rate is 10-35%, the tensile strength is 10-25MPa, the elongation at break is 500-800%, and the heat conductivity coefficient is 0.3-0.7 W / (m.K). When the filling mass fraction is 3%, the heat conductivity coefficient of the composite adhesive film is 0.65 W / (m.K), the tensile strength is 17.9 MPa, the elongation at break is 754%, and at the moment, the waterborne polyurethane composite film is excellent in performance in all aspects.

Owner:XIANGTAN UNIV

A kind of disperse dye slurry that effectively slows down precipitation and its preparation method

ActiveCN106700653BGood centrifugal stabilitySmall particle sizeOrganic dyesDyeing processDisperse dyeSlurry

The invention discloses a disperse dye paste capable of effectively retarding precipitation. The disperse dye paste is characterized by comprising urea with a weight of 0.05 to 0.5 time of the total weight of a disperse dye component, and a dispersant with a weight of 0.6 to 6 times of the total weight of the disperse dye component, wherein the disperse dye component is one or more selected from compounds as shown in a formula in the specification. In the formula, R1 is H or -NO2; R2 and R3 are selected from the group consisting of H, or -Cl, -Br, -CN, -CF3, -NO2 and -COOR8; R4 and R5 are selected from the group consisting of H, or alkyl, alkoxy and -NHCOR9; R6 and R7 are selected from the group consisting of alkyl, alkoxy, or alkyl or alkoxy with an H substituted by -OH, -CN or -Ph; and R8 and R9 are alkyl. The disperse dye provided by the invention is a liquid dye, and has high dyeing rate, good deep dyeing properties and excellent dyeing fastness; and compared with an ordinary commercial disperse dye paste, the disperse dye paste provided by the invention has the following advantages: the aggregation and precipitation rate of dye particles is significantly reduced, and better storage stability is obtained.

Owner:ZHEJIANG DIBANG CHEM

Preparation method of waterborne epoxy resin emulsion

The invention discloses a preparation method of a waterborne epoxy resin emulsion, and relates to preparation of a waterborne epoxy resin emulsion and an emulsifying agent for the waterborne epoxy resin emulsion. The waterborne epoxy resin emulsion uses the emulsifying agent prepared from octylphenol polyoxyethylene ether, polyoxyethylene sorbitan monolaurate and sodium lauryl sulfate as a composite system, and is prepared under the actions of high shear and ultrasonic and in combination with a phase reversing technology. The prepared epoxy resin emulsion has the characteristics of fine dispersed phase particles, concentrated particle size distribution, good centrifugal stability, freeze-thaw stability, dilution stability and the like; compared with the conventional epoxy resin emulsion, the waterborne epoxy resin emulsion provided by the invention has the advantages as follows: the cured coating has stronger toughness, strength, adhesion and water resistance.

Owner:QINGDAO SENMEIKE CHEM TECH CO LTD

Turbo molecular pump for mass spectrometer

ActiveUS11037773B2Optimized for speedSmall motorTurbinesAdditive manufacturing apparatusElectric machineryEngineering

The invention relates to turbo molecular pumps enabling high pumping speed. The disclosure suggests using one or more cage-like rotor stages to optimize pumping speed on vacuum systems with low gas flows and low ultimate pressures. This allows for a smaller motor as well as smaller overall form factor and makes it well suited, in particular, for compact mass spectrometers and desk-top mass spectrometers.

Owner:BRUKER DALTONIK GMBH & CO KG

Preparation method of polyprenol microemulsion with antibacterial activity

ActiveCN104706594BMeet the requirements of biological activity experimentsArranged in orderAntibacterial agentsCosmetic preparationsAlcoholAntibacterial activity

The invention provides a preparation method for a polyprenol microemulsion with bacteriostatic activity. The preparation method comprises the following steps: with polyprenol as a raw material, mixing an emulsifier with a co-emulsifier and then adding polyprenol to form an oil phase; carrying out stirring and adding deionized water, wherein the obtained system temporarily becomes turbid and then becomes clear again; after stabilization of the system, continuing adding a great amount of deionized water with stirring under a heating condition so as to realize phase inversion, wherein the system turns turbid from clear; and finally allowing temperature to rise and carrying out high speed stirring for a certain period of time, wherein the polyprenol microemulsion is obtained when the system becomes clear. The invention has the following advantages: the polyprenol microemulsion with good water dispersibility is prepared from fat-soluble polyprenol grease; and the preparation method is simple, effectively improves water dispersibility, physical properties and bacteriostatic biological activity of polyprenol and broadens the application scope of fat-soluble polyprenol in the industries of food, health products and cosmetics and industries related to biological medicine.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Water pump structure

InactiveCN107237755AFit closelySimple structurePump componentsRadial flow pumpsImpellerWorking fluid

The invention discloses a water pump structure, which comprises a pump body. A water inlet is opened above the pump body and a water outlet is opened below. The pump body is divided into a working part and a fluid part. The working part and the fluid part are separated by a protruding part. A compartment is arranged in the inner part, a pump core is arranged in the working part, the top of the pump core is located in the protruding part, and an impeller is installed at the end of the pump core. The invention has the beneficial effects of simple structure, convenient use and operation, high safety, good stability, tight cooperation of water pumps, improved work efficiency, and improved centrifugal stability by adopting the impeller.

Owner:太仓市宇航造纸机械厂

A kind of wood waterproofing agent, its preparation method and the method for using waterproofing agent to prepare waterproof wood

ActiveCN105729600BReduce treatment concentrationLow costWood treatment detailsPressure impregnationHydrogenEmulsion

The invention provides a wood waterproof agent adopting a silicone emulsion, a method for preparing the wood waterproof agent, and a method for preparing waterproof wood by utilizing the wood waterproof agent. The method for preparing the wood waterproof agent comprises the following steps: first, preparing a silicone oil emulsion primary liquid which contains hydroxyl silicone oil, hydrogen-containing silicone oil, a surfactant, nano-silicon dioxide, micron-silicon dioxide and water; then, diluting the silicone oil emulsion primary liquid into silicone oil emulsions of different concentrations; and finally, adding a catalyst for uniform dissolution and mixing. When the silicone oil emulsion wood waterproof agent provided by the invention is utilized for vacuum-pressurization pretreatment of wood, the waterproof performance and size stability of the wood can be improved, the hygroscopicity of the wood can be reduced, and the contact angle between the treated wood surface and water is larger than 140-150.

Owner:BEIJING FORESTRY UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com