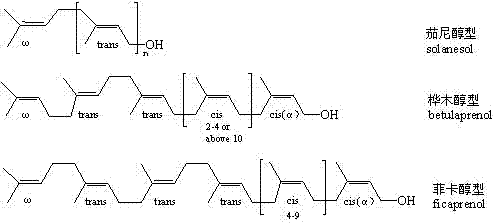

Preparation method for polyprenol microemulsion with bacteriostatic activity

A technology of polyprenol and bacteriostatic activity is applied in the field of preparation of polyprenol microemulsion, which can solve the problems of affecting biological activity research and development, low bioavailability, large molecular weight of polyprenol, etc. The effect of stability, maintaining biological activity and improving synergistic bacteriostatic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The definition formula of emulsifier HLB value is: HLB 混合 =HLB a *W a / (W a +W b )+HLB b *W b / (W a +W b ), where W a Represents the mass score of Span-80, HLB a Represents the HLB value of Span-80, W b Represents the quality score of Tween-80, HLB b Represents the HLB value of Tween-80.

[0035] Emulsification conditions: polyprenol 10 g, emulsifier 20 g, stirring speed 10000 r / min, emulsification temperature 60 ℃, stirring time 10 min, investigate the effect of HLB value (8-12) of compound emulsifier on emulsion particle size The effect of size. After the emulsification was completed, 15 ml of the emulsions were taken out, cooled to room temperature, placed in a centrifuge at 8000 r / min for 20 min, and the stratification was observed.

[0036] HLB value State after centrifugation 8 obvious stratification 8.5 slightly layered 9 slightly layered 9.5 no stratification 10 no stratification 10.5 no stratification...

Embodiment 2

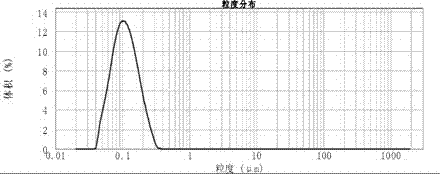

[0041]Emulsification conditions: polyprenol 10 g, stirring speed 10000 r / min, emulsification temperature 60 ℃, stirring time 10 min, investigate the ratio of compound emulsifier to polyprenol [m(emulsifier):m(polyprenol) pentenol) = (1 ~ 2): 1] on the particle size of the emulsion. The obtained emulsion was subjected to particle size analysis, and the results are shown in Table 3.

[0042] Ratio of emulsifier to polyprenol Average particle size (nm) 1:1 4202 1.25:1 2121 1.5:1 921 1.75:1 283 2:1 625

[0043] The results showed that the average particle size of the emulsion was the smallest when the ratio of emulsifier to polyprenol was 1.75:1, so it was determined that the ratio of emulsifier to polyprenol was 1.75:1 as the optimum value.

[0044] Example 3 Single factor investigation of stirring speed

Embodiment 3

[0045] Emulsification conditions: polyprenol 10 g, emulsifier 20 g, emulsification temperature 60 ℃, stirring time 10 min, to investigate the effect of stirring speed on emulsion particle size. The obtained emulsion was subjected to particle size analysis, and the results are shown in Table 4.

[0046] Stirring speedr / min Average particle size (nm) 5000 1360 10000 354 15000 124 20000 119

[0047] The results show that the average particle size of the emulsion is relatively close when the stirring speed is 15000 r / min and 20000 r / min, considering the economical efficiency of the actual operation, it is determined that the stirring speed is 15000 r / min is the best value.

[0048] Example 4 Single factor investigation of emulsification temperature

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com