Method for preparing super-fine high-purity neodymia oxide by using Pr-Nd enriched material

A technology of enrichment and neodymium oxide, which is applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problem of low extraction rate and separation efficiency of rare earth, poor crystallization and precipitation of neodymium oxalate, and difficult to reach product use Requirements and other issues to achieve the effect of improving product quality, reducing investment in equipment and reagents, and improving the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

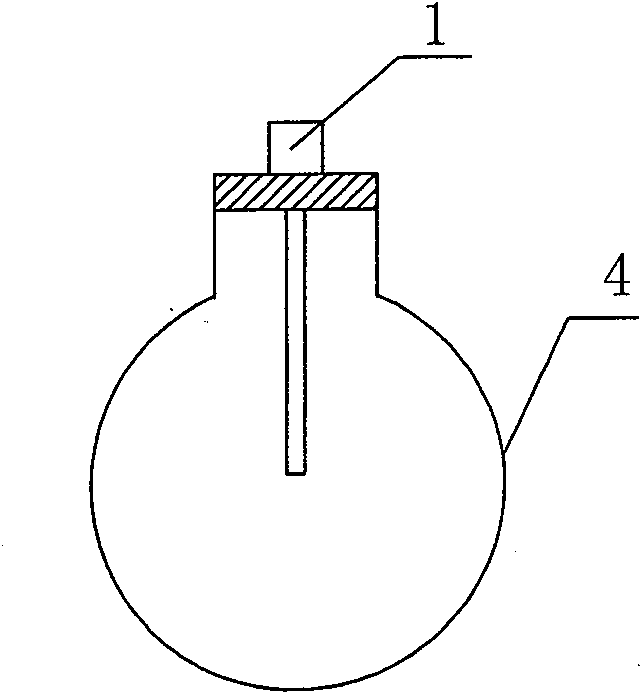

[0025] Main equipment: extraction kettle with probe-type ultrasonic generator, crystallization kettle with probe-type ultrasonic generator.

[0026] Main raw materials: praseodymium-neodymium Pr-Nd enrichment, HNO 3 , TBP extractant, kerosene, NH 4 HCO 3 .

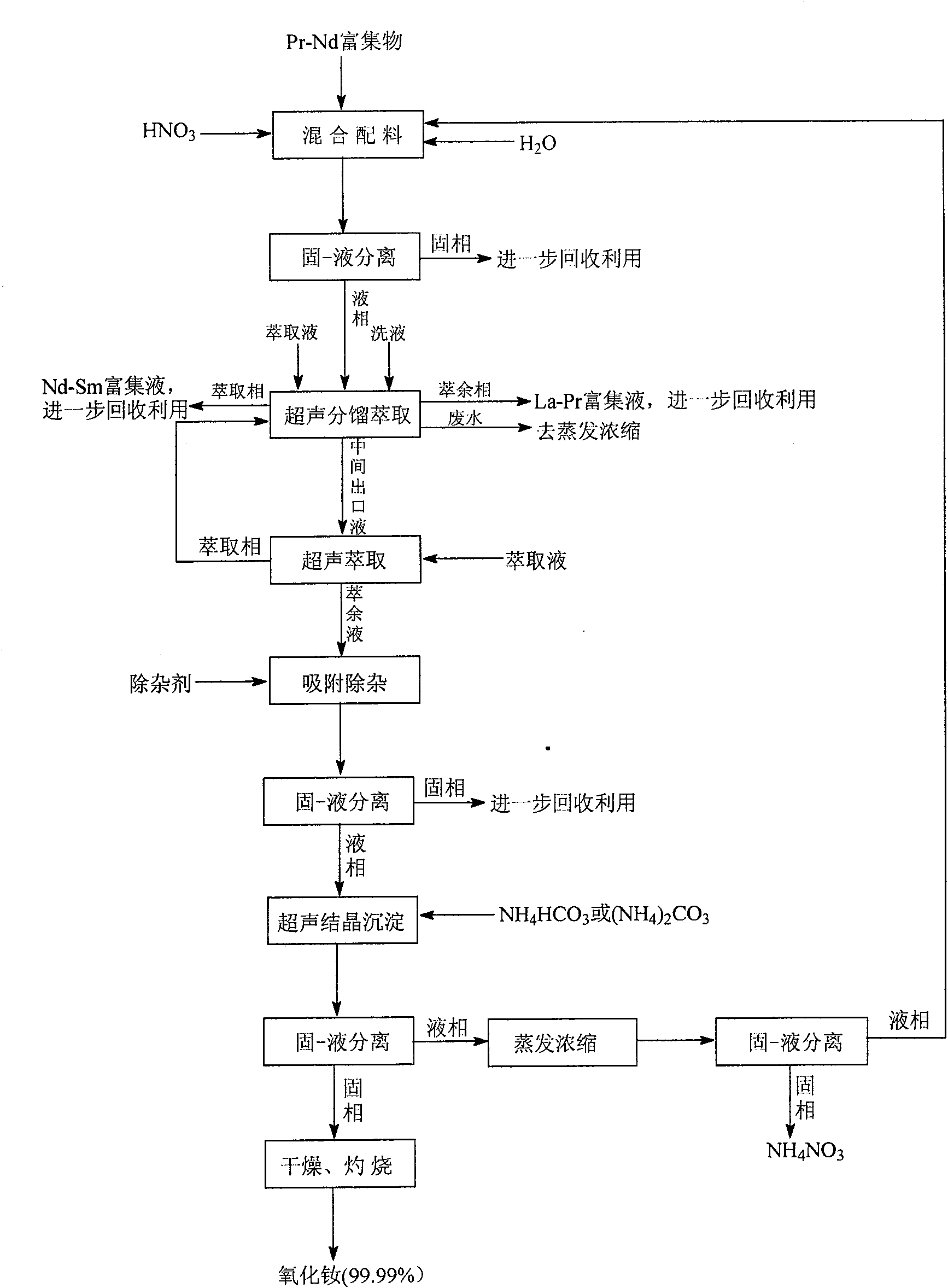

[0027] like figure 1 and figure 2 As shown, a method for preparing ultrafine high-purity neodymium oxide from a praseodymium-neodymium Pr-Nd enrichment is to use the praseodymium-neodymium Pr-Nd enrichment as a raw material, and the steps of the method are as follows:

[0028] (1) Mixing batching: carry out mixing batching with praseodymium-neodymium Pr-Nd, nitric acid, water, through solid-liquid separation, remove insoluble impurity, obtain praseodymium-neodymium Pr-Nd enrichment material liquid, the concentration of rare earth in the feed liquid is 0.1-2.3mol / L;

[0029] (2) Ultrasonic fractionation extraction: In an extraction kettle with a probe-type ultrasonic generating device, add praseodymium-neodymium Pr-N...

Embodiment 2

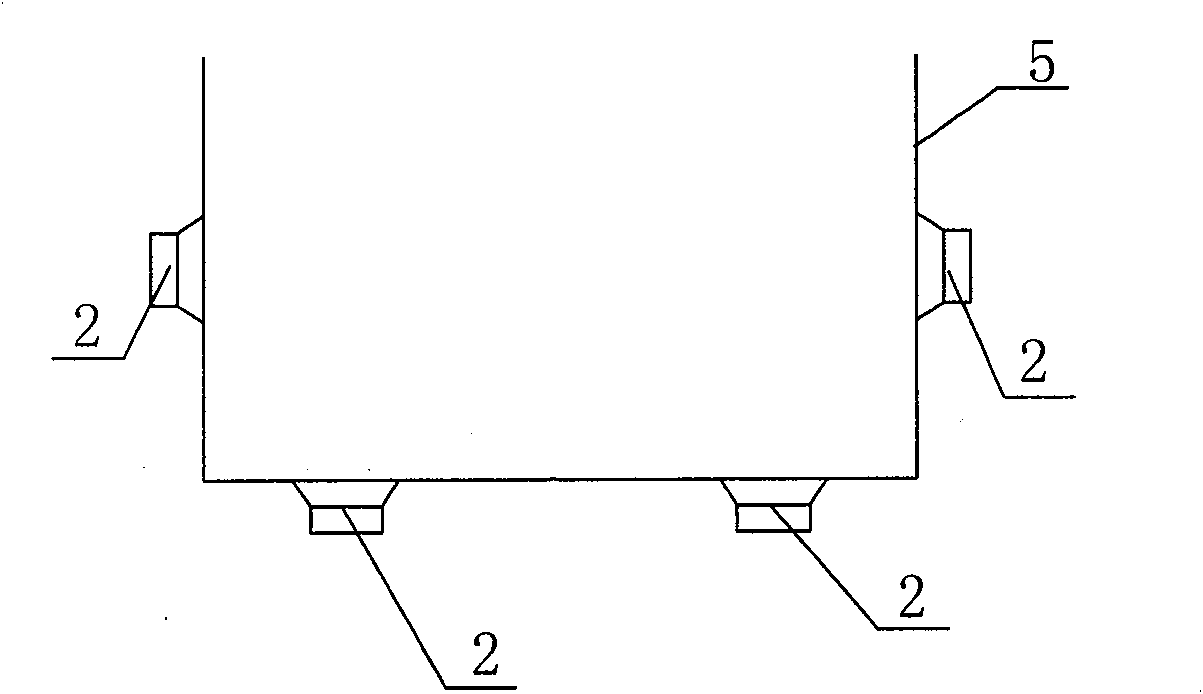

[0037] Main equipment: extraction tank with vibrator-type ultrasonic generator, crystallization tank with vibrator-type ultrasonic generator.

[0038] Main raw materials: praseodymium-neodymium Pr-Nd enrichment, HNO 3 , TBP extractant, sulfonated kerosene, (NH 4 ) 2 CO 3 .

[0039] like figure 1 and image 3 As shown, a method for preparing ultrafine high-purity neodymium oxide from a praseodymium-neodymium Pr-Nd enrichment is to use the praseodymium-neodymium Pr-Nd enrichment as a raw material, and the steps of the method are as follows:

[0040] (1) Mixing batching: carry out mixing batching with praseodymium-neodymium Pr-Nd, nitric acid, water, through solid-liquid separation, remove insoluble impurity, obtain praseodymium-neodymium Pr-Nd enrichment material liquid, the concentration of rare earth in the feed liquid is 0.1-2.3mol / L;

[0041] (2) Ultrasonic fractionation extraction: In the extraction tank with vibrator-type ultrasonic generating device, add praseodymium...

Embodiment 3

[0049] Main equipment: extraction tube with vibrating plate ultrasonic generating device, crystallization tube with vibrating plate ultrasonic generating device.

[0050] Main raw materials: praseodymium-neodymium Pr-Nd enrichment, HNO 3 , TBP extractant, No. 200 gasoline, NH 4 HCO 3 .

[0051] like figure 1 and Figure 5 As shown, a method for preparing ultrafine high-purity neodymium oxide from a praseodymium-neodymium Pr-Nd enrichment is to use the praseodymium-neodymium Pr-Nd enrichment as a raw material, and the steps of the method are as follows:

[0052] (1) Mixing batching: carry out mixing batching with praseodymium-neodymium Pr-Nd, nitric acid, water, through solid-liquid separation, remove insoluble impurity, obtain praseodymium-neodymium Pr-Nd enrichment material liquid, the concentration of rare earth in the feed liquid is 0.1-2.3mol / L;

[0053] (2) Ultrasonic fractionation extraction: In the extraction tube with a vibrating plate type ultrasonic generating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com