A nozzle for preparing nanoparticle by internal mixing supercritical fluid method

A supercritical fluid, internal mixing technology, applied in the direction of liquid injection device, injection device, etc., can solve the problems of small shear force of nozzle, wide particle size distribution area, poor atomization effect, etc. Small particle size, good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

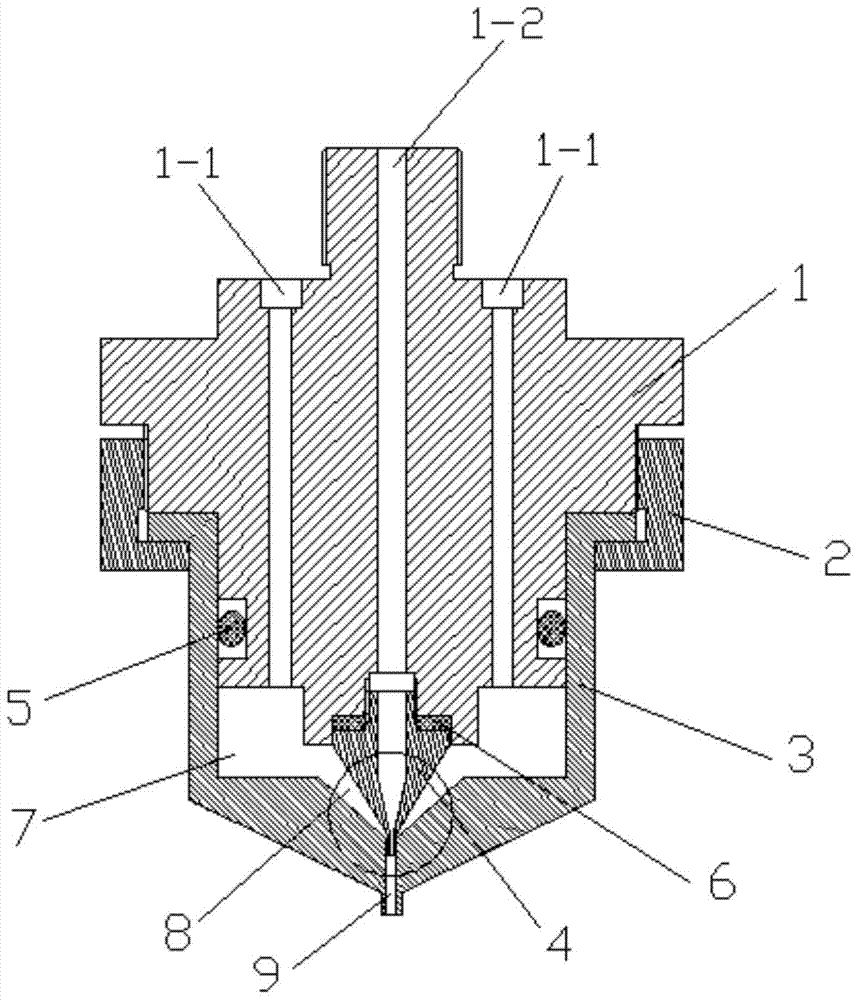

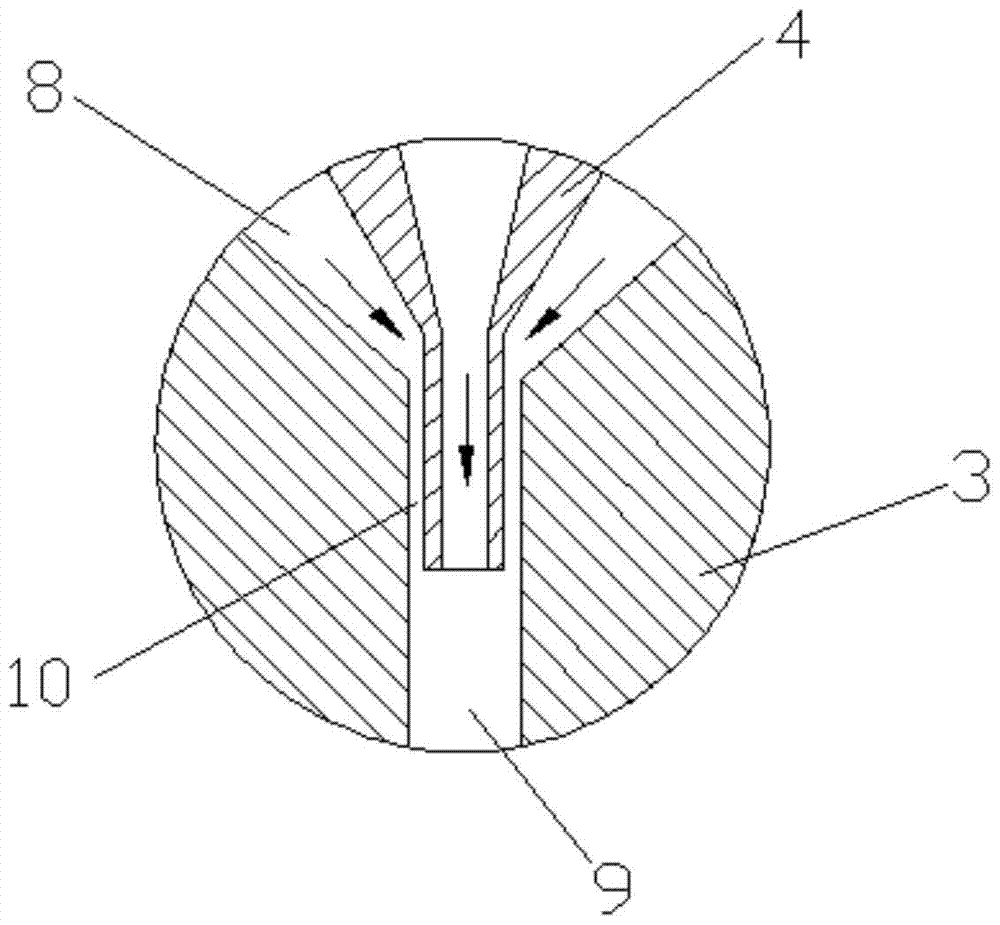

[0012] like figure 1 and figure 2 As shown in the figure, an internally mixed supercritical fluid method in this embodiment prepares a nozzle for nano-particles, including a guide base 1, a pressure cap fastening ring 2, an air cap 3, a pinhole liquid spray head 4, a sealing ring 5 and a gasket 6, the lower end of the guide base 1 is connected with the upper end of the pinhole liquid spray head 4, and the liquid outlet of the material solution through holes 1-2 of the guide base 1 is connected to the pinhole liquid spray head 4 The liquid inlet of the air cap 3 is connected to each other, the gasket 6 is arranged at the junction of the guide base 1 and the pinhole liquid jet head 4, the upper part of the air cap 3 is set on the lower part of the guide base 1 through the pressure cap fastening ring 2, and the needle The head of the hole liquid jet head 4 is inserted into the micro-hole of the air cap 3 to form a coaxial annular gap 10, and a high-speed turbulent flow zone is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com