Organosilicon softening finishing agent with ice-cold feeling and preparation method of organosilicon softening finishing agent

A soft finishing agent and silicone technology, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problems of amino silicone oil emulsion demulsification, soft performance decline, pH value increase, etc., and achieve excellent centrifugal stability and improved hydrophilicity , solve the effect of yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

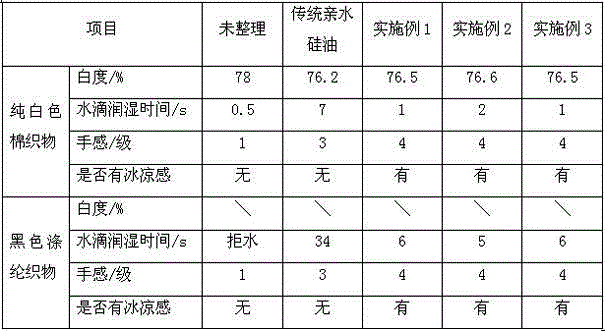

Examples

Embodiment 1

[0038] A kind of organosilicon softening agent with ice-cold feeling, described organosilicon softening agent is made up of the raw material of following weight part:

[0039] Hydrophilic ternary copolymerized silicone 30 parts

[0040] Micro-encapsulated icy particles 5 servings

[0041] Glacial acetic acid 1.2 parts

[0042] 63.8 parts of water.

[0043] The preparation method of the hydrophilic ternary copolymerization organosilicon comprises the following steps:

[0044] A. Add 450.45kg of amino polyether with a molecular weight of 2003 and 950.45kg of isopropanol into the reactor for stirring, and raise the temperature to 80°C, then add 500kg of epoxy silicone oil with a molecular weight of 8000 to the reactor for 14 hours to obtain Ternary copolymerized silicone oil;

[0045] B. Then, at 80°C, add 133.06 kg of epoxy polyether with a molecular weight of 500 to the above-mentioned ternary copolymerized silicone oil, and react for 14 hours to prepare a hydrophilic silic...

Embodiment 2

[0054] A kind of organosilicon softening agent with ice-cold feeling, described organosilicon softening agent is made up of the raw material of following weight part:

[0055] Hydrophilic ternary copolymerized silicone 32 parts

[0056] Micro-encapsulated icy particles 6 servings

[0057] Glacial acetic acid 1.28 parts

[0058] 60.72 parts of water.

[0059] The preparation method of the hydrophilic ternary copolymerization organosilicon comprises the following steps:

[0060] A. Add 357.14kg of amino polyether with a molecular weight of 900 and 857.14kg of isopropanol into the reactor for stirring, and raise the temperature to 80°C, then add 500kg of epoxy silicone oil with a molecular weight of 6000 to the reactor for 14 hours to obtain Ternary copolymerized silicone oil;

[0061] B. Then, at 80°C, add 111.43 kg of epoxy polyether with a molecular weight of 900 to the above-mentioned ternary copolymerized silicone oil, and react for 15 hours to prepare a hydrophilic sili...

Embodiment 3

[0070] A kind of organosilicon softening agent with ice-cold feeling, described organosilicon softening agent is made up of the raw material of following weight part:

[0071] Hydrophilic ternary copolymerized silicone 34 parts

[0072] Microcapsule ice-cooling particles 6.4 servings

[0073] Glacial acetic acid 1.36 parts

[0074] 58.24 parts of water.

[0075] The preparation method of the hydrophilic ternary copolymerization organosilicon comprises the following steps:

[0076] A. Add 301.20kg of amino polyether with a molecular weight of 600 and 801.20kg of isopropanol into the reactor for stirring, and raise the temperature to 80°C, then add 500kg of epoxy silicone oil with a molecular weight of 4000 to the reactor for 14 hours to obtain Ternary copolymerized silicone oil;

[0077] B. Then add 48.07kg of 2,3-epoxypropyltrimethylammonium chloride to the above ternary copolymerized silicone oil at 80°C and react for 13 hours to prepare hydrophilic silicone oil;

[0078...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com