Waterborne polyurethane composite material with high thermal conductivity and preparation method thereof

A technology of water-based polyurethane and composite materials, applied in the direction of polyurea/polyurethane adhesives, non-polymer adhesive additives, adhesive types, etc. The effect of good performance, excellent mechanical performance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] a. Main reaction raw materials and proportion composition:

[0036] raw material mass (g) millimole (mmol) Isophorone diisocyanate 6.72 30.24 Modified Graphene Oxide Powder 0.17 14.15 Dimethylolpropionic acid 0.84 6.25 1,4-Butanediol 0.79 8.4 Triethylamine 0.633 6.24 Dibutyltin dilaurate 0.15 0.25 Deionized water 39.9 2215 Trimethylolpropane 0.168 1.25 Polytetrahydrofuran ether diol 8.29 8.29

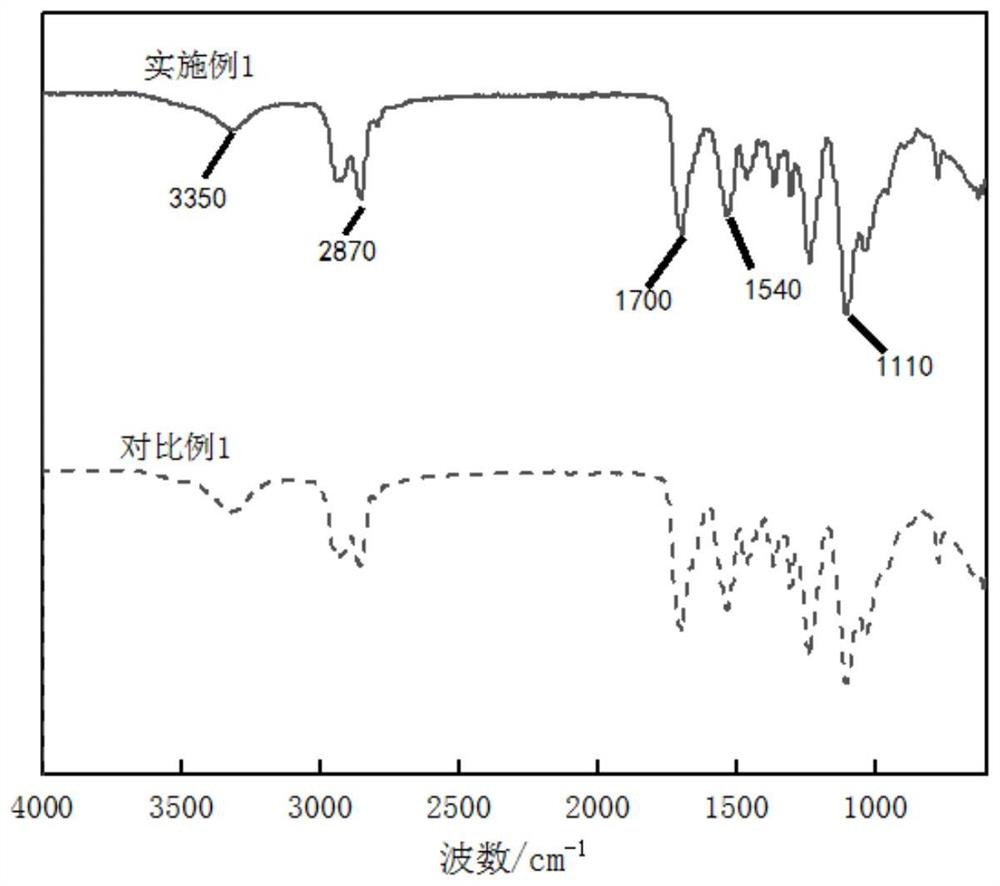

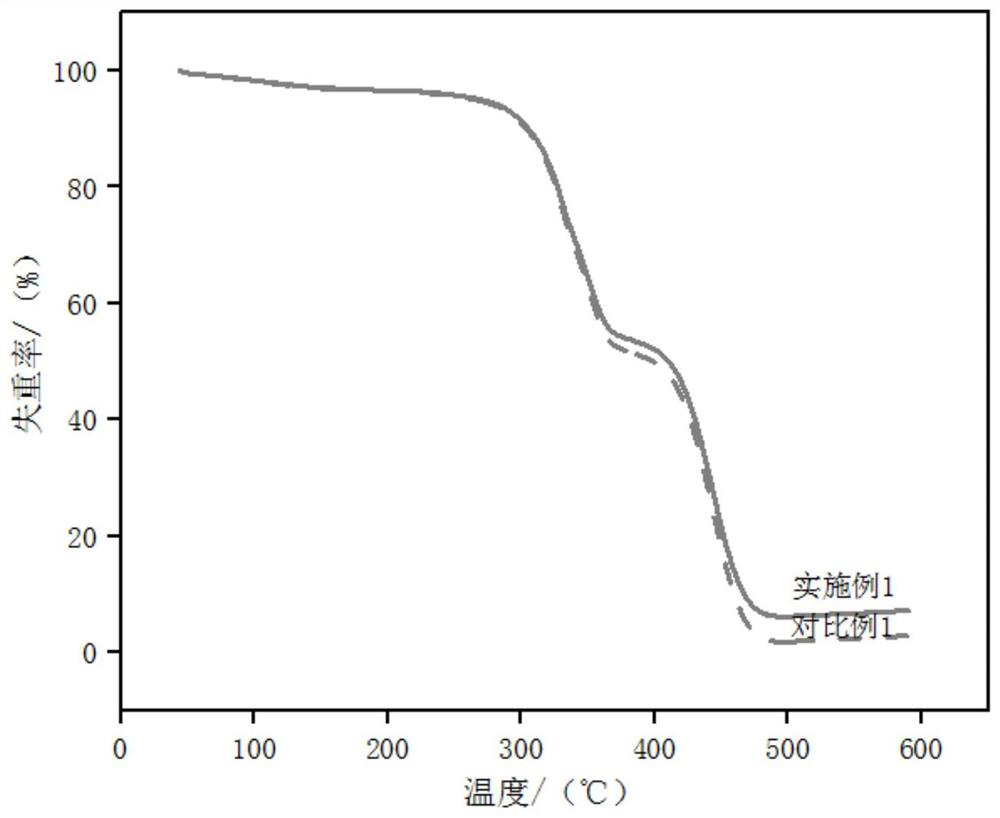

[0037] The reaction raw material diisocyanate is isophorone diisocyanate, the modified graphene oxide powder is modified by 3-aminopropyltriethoxysilane, the hydrophilic chain extender is dimethylol propionic acid, and small molecule chain extension The agent is 1,4-butanediol, the neutralizing agent is triethylamine, the organotin catalyst is dibutyltin dilaurate, deionized water, the internal crosslinking agent is trimethylolpropane, and the hydroxyl-terminated diol is polytetrahydrofuran Ether gly...

Embodiment 2

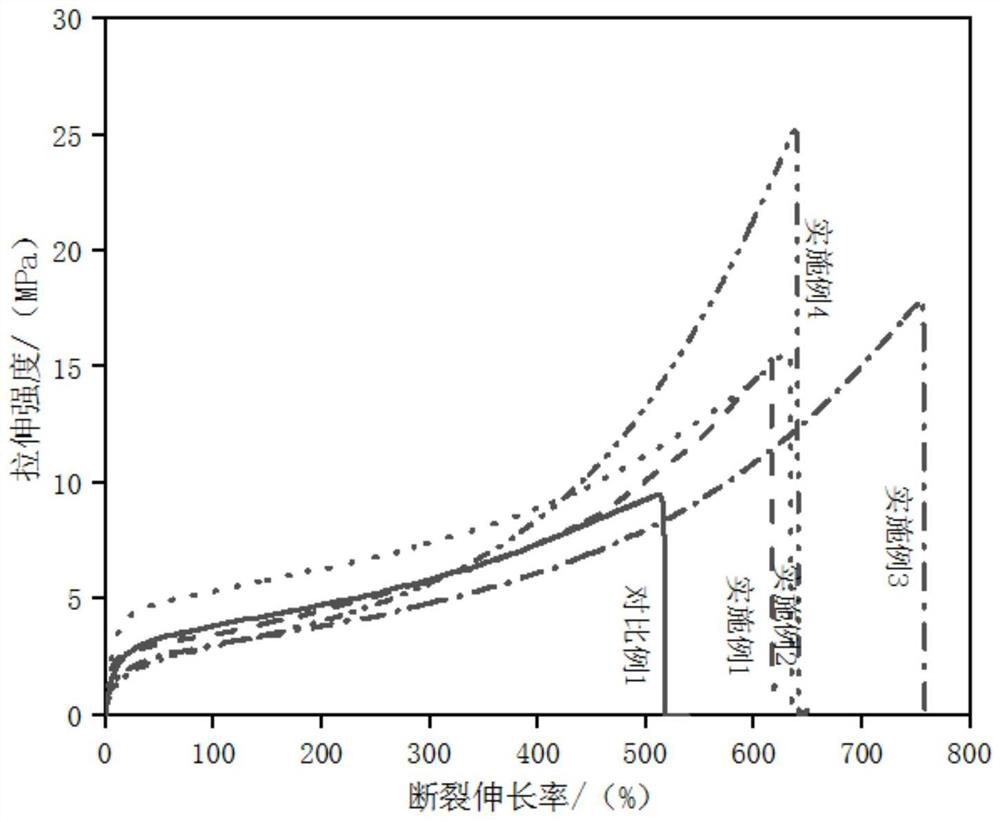

[0044] Compared with Example 1, the above-mentioned steps are not changed, but the addition amount of G2 is changed, and the addition amount is 0.343gG2 Acetone dispersion liquid, promptly obtains composite water-based polyurethane emulsion, is recorded as ARGO-WPU-2, its solidification Content, particle size, and stability were tested, and the solid content of the emulsion was 30.8%, the average particle size of the emulsion was 48.22mm, and the emulsion was centrifugally stable. Then take the emulsion and pour it into a circular tetrachlorethylene mold with a diameter of 4 cm, dry it at room temperature for 48 hours, and then dry it in a vacuum oven for 24 hours to obtain a waterborne polyurethane composite material with a mass fraction of 2% and high thermal conductivity. It is tested for thermal conductivity, water absorption, tensile strength, elongation at break, and pencil hardness. When the mass fraction is 2%, the thermal conductivity of the composite film is 0.62W / (m...

Embodiment 3

[0046] Compared with Example 1, the above-mentioned steps are not changed, but the addition amount of G2 is changed, and the addition amount is 0.520gG2 Acetone dispersion liquid, promptly obtains composite water-based polyurethane emulsion, is recorded as ARGO-WPU-3, its solidification Content, particle size, and stability were tested, and the solid content of the emulsion was 32.1%, the average particle size of the emulsion was 57.55mm, and the emulsion was stable in centrifugation. Then take the emulsion and pour it into a circular tetrachlorethylene mold with a diameter of 4 cm, dry it at room temperature for 48 hours, and then dry it in a vacuum oven for 24 hours to obtain a waterborne polyurethane composite material with a mass fraction of 3% and high thermal conductivity. It is tested for thermal conductivity, water absorption, tensile strength, elongation at break, and pencil hardness. When the mass fraction is 3%, the thermal conductivity of the composite film is 0.65...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com