Disperse dye paste capable of effectively retarding precipitation and preparation method

A technology for disperse dyes and sizing, applied in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of decreased stability of dye colloidal suspension, difficult to uniformly disperse dye particles, larger particles, etc., to improve storage stability Good properties, excellent dyeing and finishing fastness, and the effect of reducing the average particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0056] Without adding urea, after selecting disperse dyes and dispersants for grinding, adjust them into finished disperse dye slurry. The experimental data are according to Table 1:

[0057] Table 1

[0058]

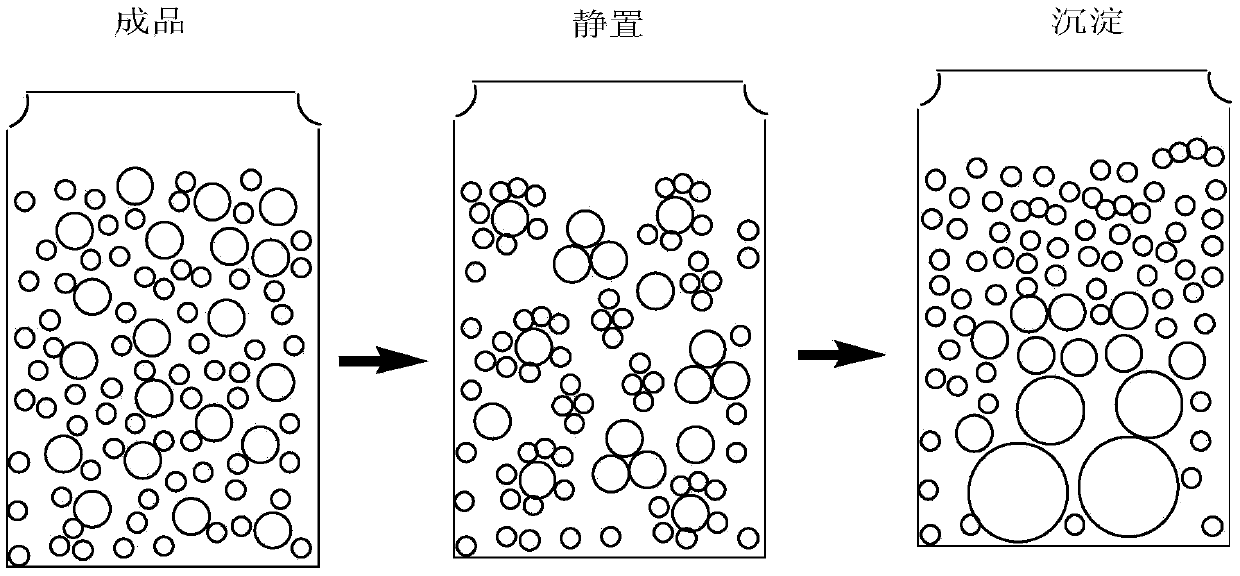

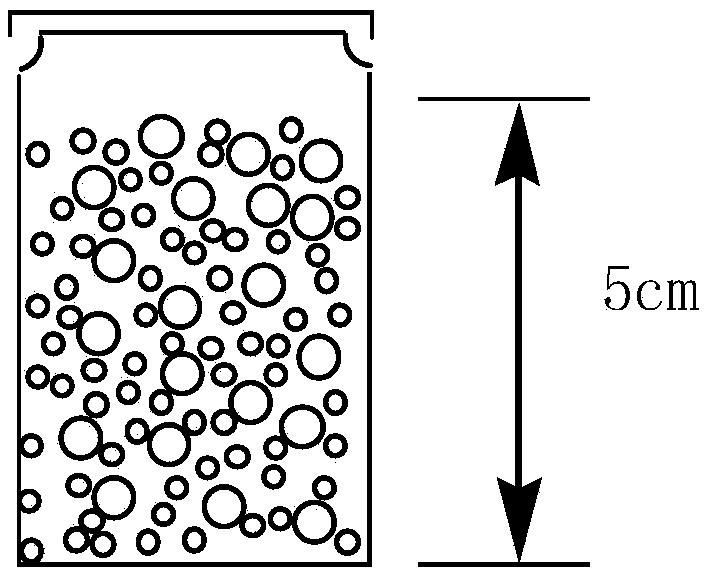

[0059] Precipitation effect detection

[0060] After the disperse dye slurry prepared in the above-mentioned Examples 1-3 was left to stand for a certain period of time, the sedimentation degree was tested according to the method described above, and the results are shown in Table 2:

[0061] Table 2

[0062] Example Sedimentation % / 7 days Sedimentation % / 30 days Sedimentation % / 60 days

[0063] 1 45.49 80.17 83.17 2 30.52 67.33 73.43 3 18.04 54.64 68.54

[0064] From the test results in Table 2, it can be seen that the amount of dispersant has a significant effect on the precipitation rate of disperse dye slurry. With the increase of the amount of dispersant, the degree of precipitation decreases, and the precipit...

Embodiment 4~9

[0066] Without adding urea, after selecting disperse dyes and dispersants for grinding, adjust the pH value of the slurry with phosphoric acid to make finished disperse dye slurry. The experimental data are according to Table 3:

[0067] table 3

[0068]

[0069] Precipitation effect detection

[0070] After the disperse dye slurry prepared in the above-mentioned Examples 4-9 was left to stand for a certain period of time, the sedimentation degree was tested according to the method described above, and the results are shown in Table 4:

[0071] Table 4

[0072] Example Sedimentation % / 7 days Sedimentation % / 30 days Sedimentation % / 60 days 4 44.78 81.68 83.94 5 40.18 82.21 84.46 6 39.15 79.39 82.65 7 43.46 80.14 85.15 8 46.18 84.86 86.33 9 48.85 85.2 88.32

[0073] The pH value of the finished disperse dye slurry is generally 7 to 8. Too high or too low will affect the storage performance and use performance of ...

Embodiment 10~17

[0075] After the disperse dye, dispersant, and urea are mixed and ground, the finished disperse dye slurry is prepared. The experimental data is according to Table 5:

[0076] table 5

[0077]

[0078]

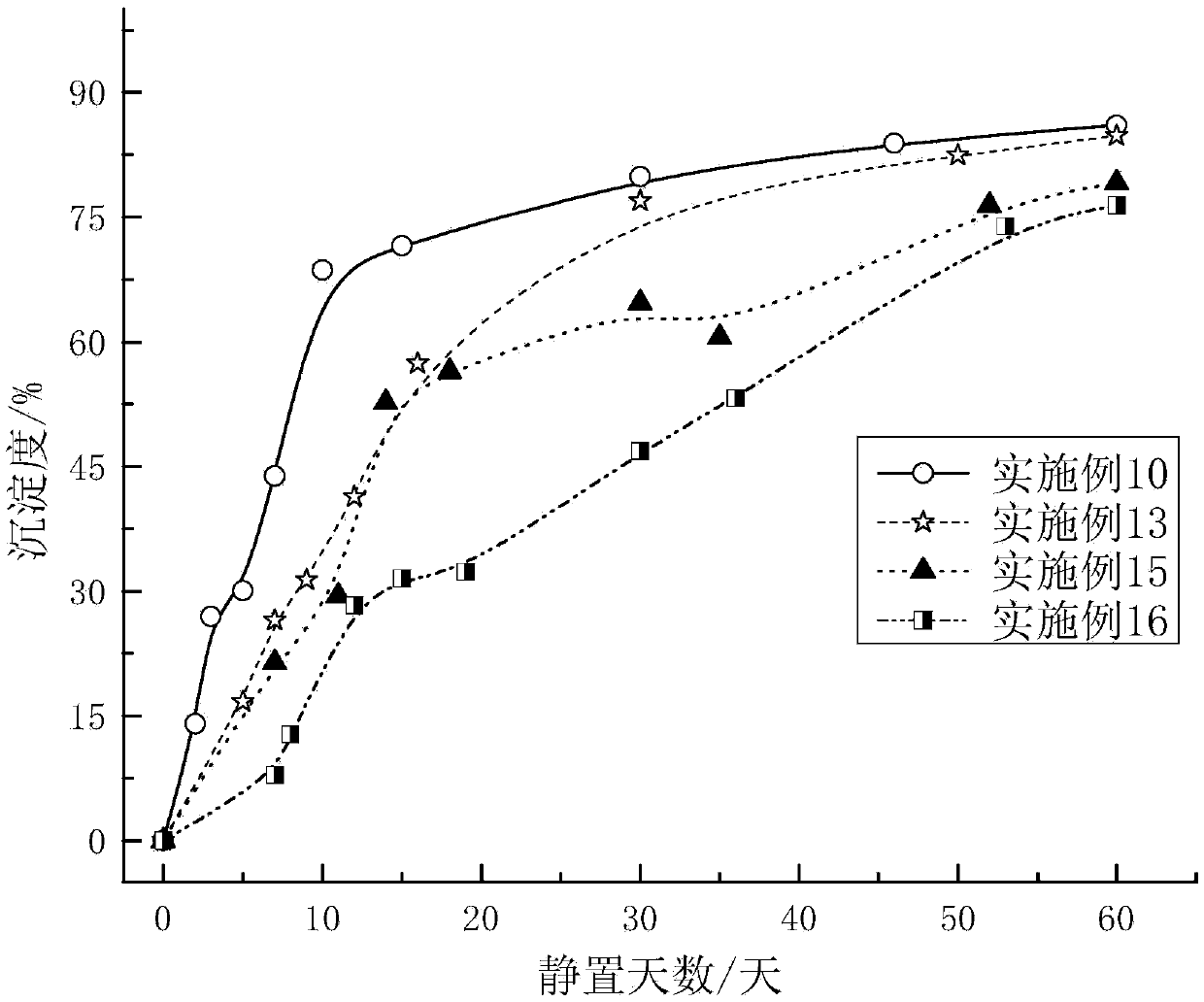

[0079] Precipitation effect detection

[0080] After the disperse dye slurry prepared in the above-mentioned Examples 10-17 was left to stand for a certain period of time, the sedimentation degree was tested according to the method described above, and the results are shown in Table 6:

[0081] Table 6

[0082] Example Sedimentation % / 7 days Sedimentation % / 30 days Sedimentation % / 60 days 10 43.83 79.85 86.04 11 39.89 78.96 85.81 12 35.41 77.65 85.13 13 26.21 76.96 84.8 14 25.13 71.22 82.27 15 21.37 64.66 79.12 16 7.85 46.83 76.42 17 6.58 40.16 75.18

[0083] It can be seen from the test results of the precipitation degree in Table 6 that with the increase of the amount of urea, the precipitati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com