A hydraulic automatic dip-coating machine

A fully automatic, all-in-one machine technology, applied to the surface coating liquid device, coating, etc., can solve the problems of slow production rhythm, waste of paint production steps, scrapping of the whole tank of paint, etc., to speed up the production rhythm and stabilize the centrifugal force Good performance, avoid waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

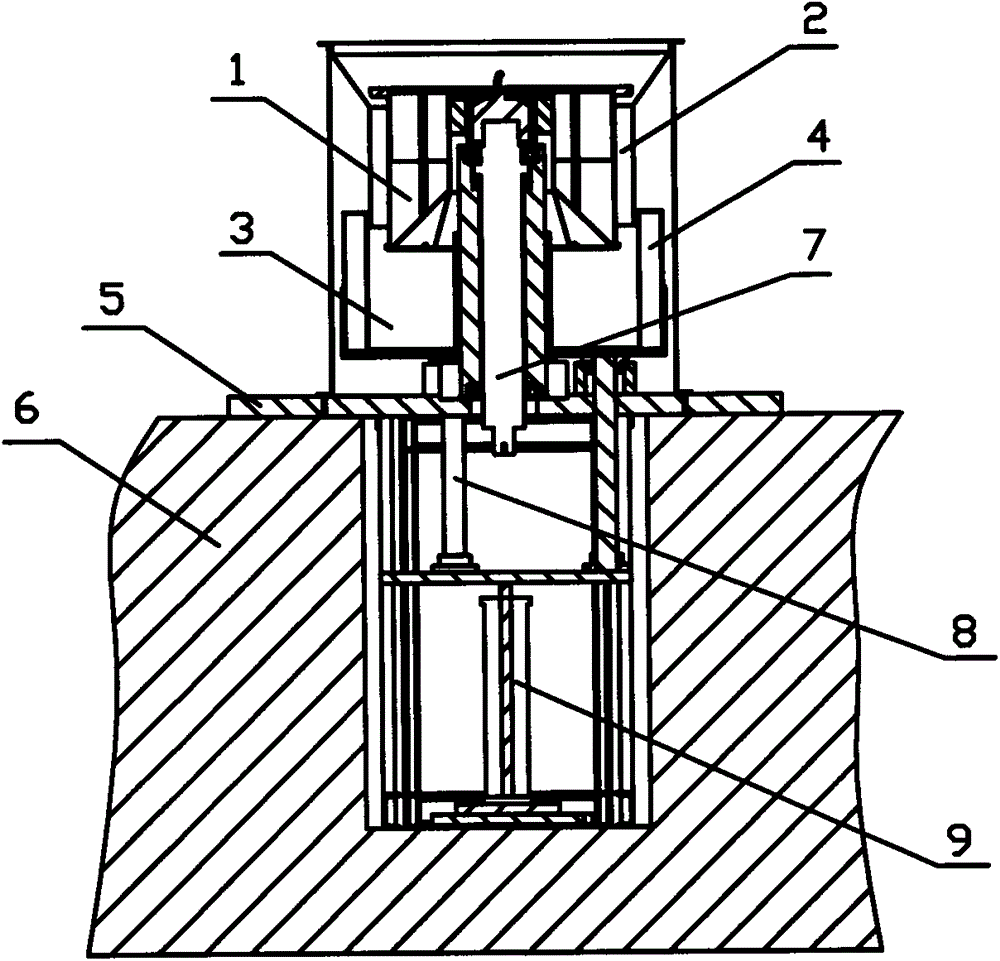

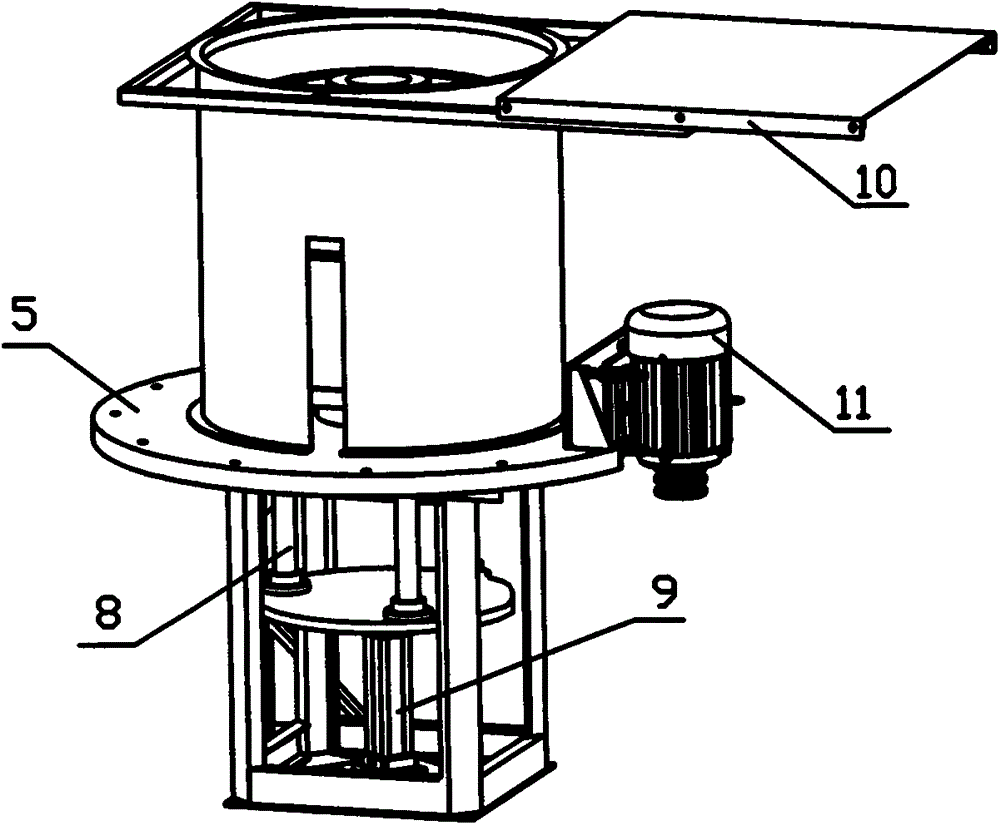

[0012] A hydraulic fully automatic dip-coating integrated machine, comprising a body, a dip-coating device inside the body and a motor 11 arranged outside the body, an organic cover 10 is arranged on the top of the body, and the dip-coating device includes a material frame 1, an annular coating liquid tank 3 and The liquid coating tank automatic lifting system 9 connected with the annular coating liquid tank 3, the center of the annular coating liquid tank 3 is provided with the main shaft 7 whose bottom end is connected with the motor 11, the top of the main shaft 7 is fixedly connected with the material frame 1, and the annular coating liquid tank The inner wall of 3 is provided with an annular water-cooling tank 4, the upper edge of the material frame 1 is surrounded by a liquid retaining frame 2, a gap is provided between the liquid retaining frame 2 and the outer wall of the material frame 1, and the outer diameter of the liquid retaining frame 2 is smaller than the annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com