Oxidized polyethylene wax micro-emulsion composition and preparation method thereof

A technology of oxidized polyethylene wax and composition, which is applied in textiles, papermaking, fiber treatment, etc., can solve the problems of rare patents, and achieve the effects of good acid and alkali resistance, uniform distribution, and controllable particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 220g oxidized polyethylene wax Luwax OA6 (BASF, melting point 126-133°C), 24g AEO-9 (SINO SURFACTANT), 18g AC-1215 (Jiangsu Haian Petrochemical Plant), 4g glycerol polyoxyethylene ether (SINO SURFACTANT), 5g potassium hydroxide (Chinese medicine reagent), 2g sodium metabisulfite (Chinese medicine reagent), 4g 5-diethylamino-2-pentanol (Chinese medicine reagent), 8g 5-amino-1-pentanol (Chinese medicine reagent) and 208g deionized Add water to a 1-liter high-pressure emulsification kettle (CJF-1, Shanghai Chengming Instrument Equipment Co., Ltd.), seal it, and start stirring (500 rpm). Raise the temperature to 150°C and keep the temperature for 30 minutes. Next, add 230 g of deionized water at 95-100° C. into the emulsification kettle, and keep the temperature at 150° C. for 30 minutes. Rapidly cool to room temperature, filter, and discharge to obtain light yellow translucent oxidized polyethylene wax nanoemulsion.

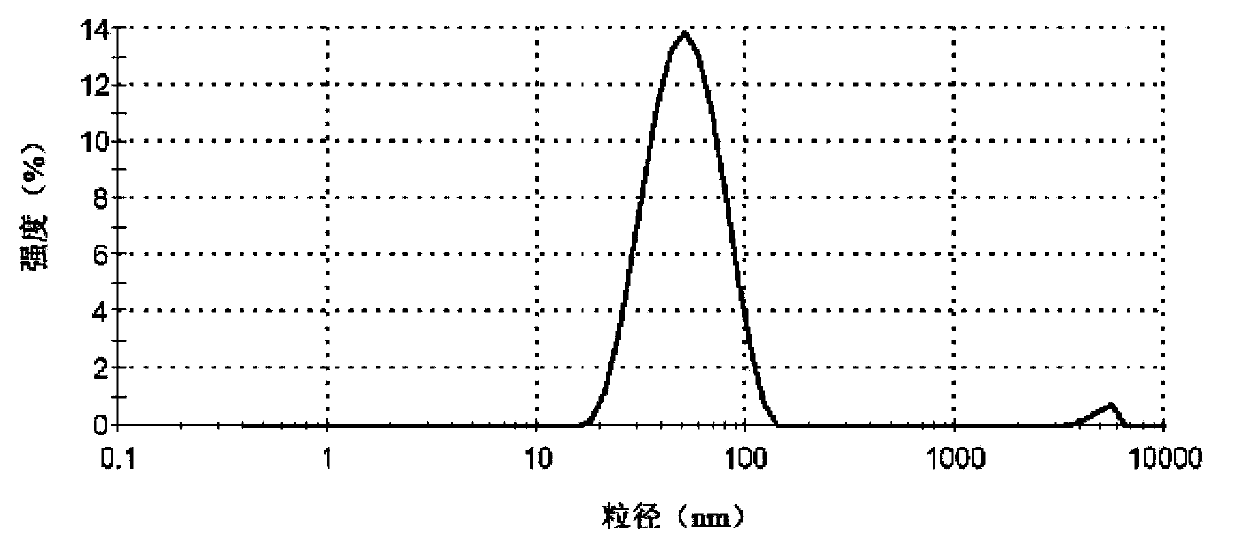

[0047] Gained wax emulsion is measured with Zetasizer...

Embodiment 2

[0049] Mix 180g oxidized polyethylene wax Licowax PED 191 (Clariant, melting point 123°C), 24g Pingpingjia O-15 (Jiangsu Haian Petrochemical Plant), 24g AC-1210 (Jiangsu Haian Petrochemical Plant), 2g trimethylolpropane Polyoxyethylene ether (SINO SURFACTANT), 7g potassium hydroxide (National Medicine Reagent), 1.8g sodium metabisulfite (National Medicine Reagent), 2g diethylaminopropanol (National Medicine Reagent), 12g 2-amino-2-methyl-propanol (Sinopharm Reagent) and 180g of deionized water were added to a 1-liter high-pressure emulsification kettle (CJF-1, Shanghai Chengming Instrument Equipment Co., Ltd.), sealed, and started stirring (500 rpm). Raise the temperature to 135°C and keep the temperature for 60 minutes. Next, add 280 g of deionized water at 95-100° C. into the emulsification kettle, and keep the temperature at 135° C. for 20 minutes. Rapidly cool to room temperature, filter, and discharge to obtain milky white translucent oxidized polyethylene wax nanoemulsi...

Embodiment 3

[0052] 150g oxidized polyethylene wax AC-330 (Honeywell, melting point 137°C), 20g 1310 (Jiangsu Haian Petrochemical Factory), 20g AC-1812 (Jiangsu Haian Petrochemical Factory), 10g glycerol polyoxyethylene ether (SINO SURFACTANT ), 10g potassium hydroxide (Chinese medicine reagent), 5g sodium metabisulfite (Chinese medicine reagent), 4g 2-ethylamino-1-butanol (Chinese medicine reagent), 16g 5-amino-1-pentanol (Chinese medicine reagent) and 160g Add ionized water into the high-pressure emulsification kettle (CJF-1, Shanghai Chengming Instrument Equipment Co., Ltd.), seal it, and start stirring (500 rpm). Raise the temperature to 160°C and keep the temperature for 60 minutes. Next, add 320 g of deionized water at 95-100° C. to the emulsification tank, and keep the temperature at 160° C. for 30 minutes. Rapidly cool to room temperature, filter, and discharge to obtain milky white translucent oxidized polyethylene wax nanoemulsion.

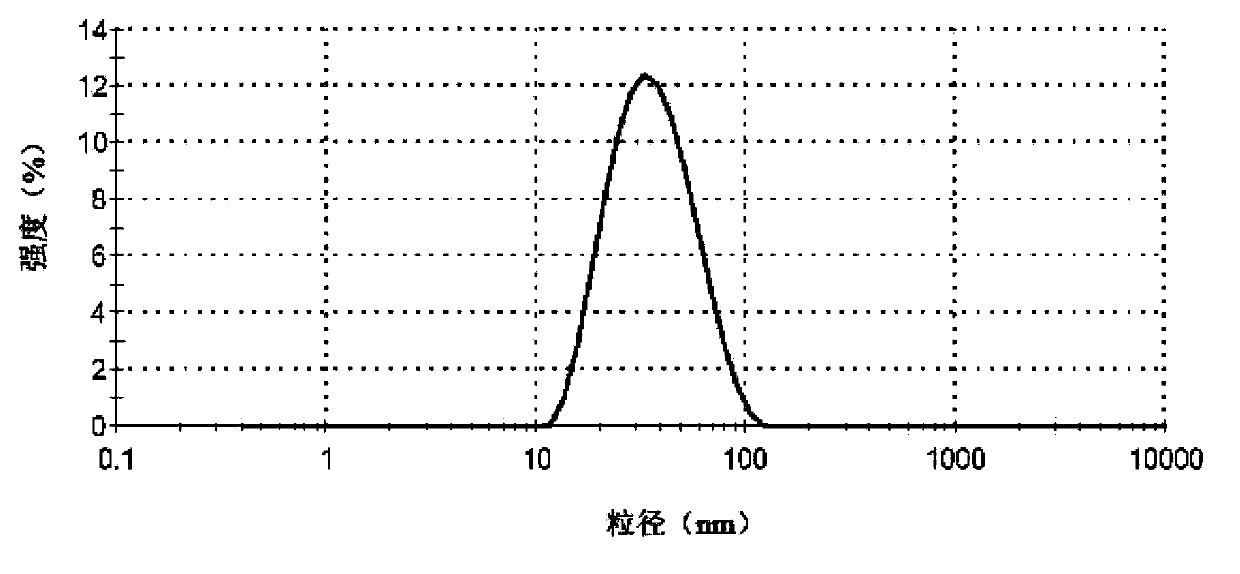

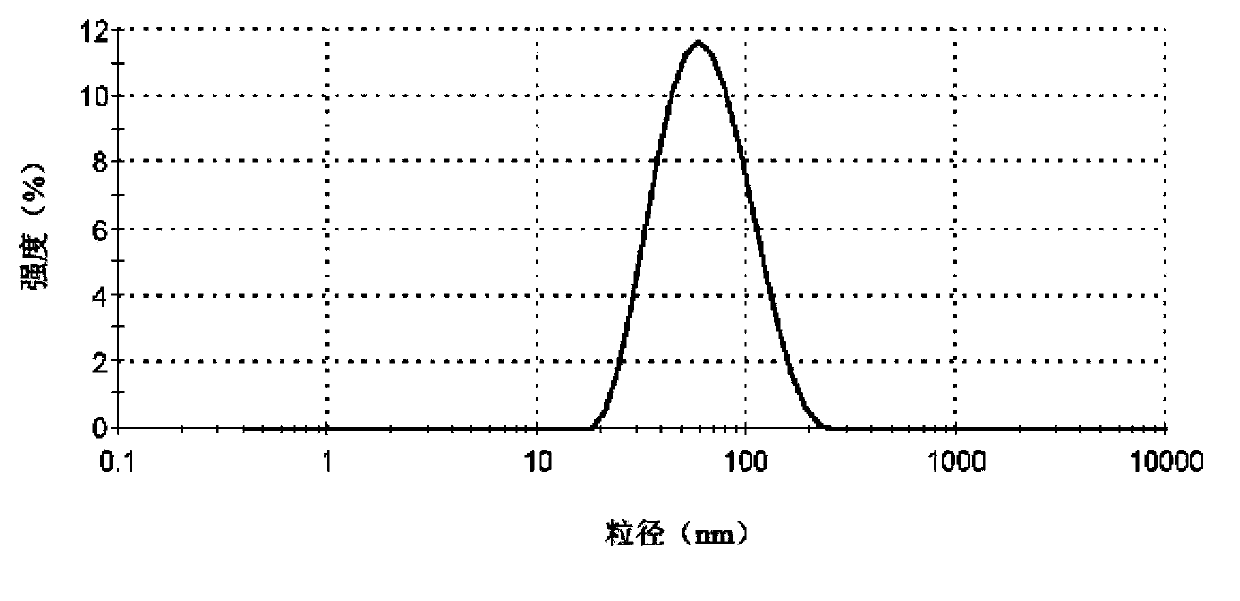

[0053] Gained wax emulsion is measured with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com