Wood waterproof agent, method for preparing wood waterproof agent, and method for preparing waterproof wood by utilizing wood waterproof agent

A water repellent, wood technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of inability to react to form chemical bonds, inability to firmly fix, loss of superphobicity, etc., to achieve easy control of process conditions, reduce moisture absorption performance, The effect of reducing the water absorption of wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 1. Preparation of wood waterproofing agent

[0057] 1. Preparation of silicone oil emulsion stock solution

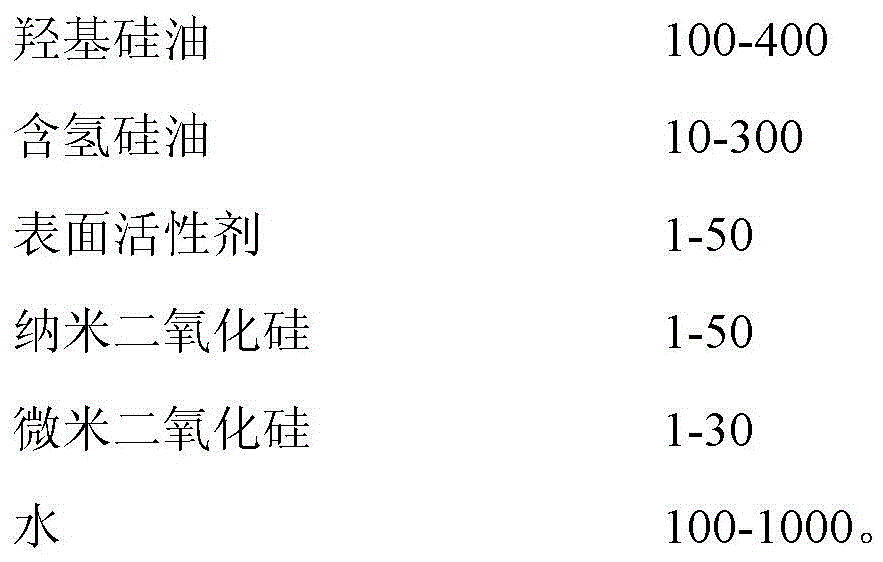

[0058] 1A) Prepare raw materials according to the following weight ratio (g)

[0059]

[0060]

[0061] Wherein, the hydroxyl content of the hydroxy silicone oil is 8%; the hydrogen-containing silicone oil is methyl hydrogen-containing silicone oil with a hydrogen content of 1.6%; the anionic surfactant sodium lauryl sulfate is selected as the surfactant; The particle size is 16-50nm; the particle size of micron silica is 1300-6000 mesh;

[0062] 1B) First, mix the hydroxyl silicone oil and the hydrogen-containing silicone oil evenly, then add the surfactant, nano-silica, micro-silica and water in turn, and stir well; then stir for 30min at a stirring speed of 6000rpm; then put Put the mixed material in an ultrasonic cleaner for ultrasonic treatment to make a silicone oil primary emulsion, wherein the ultrasonic treatment time is 10min; the ultrasonic fre...

Embodiment 2

[0074] 1. Preparation of wood waterproofing agent

[0075] 1. Preparation of silicone oil emulsion stock solution

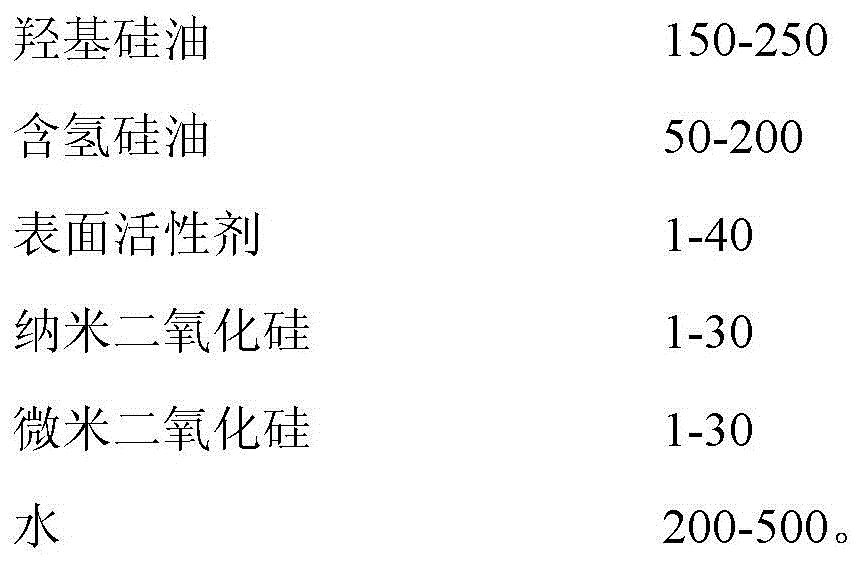

[0076] 1A) Prepare raw materials according to the following weight ratio (g)

[0077]

[0078] Wherein, the hydroxyl content of the hydroxy silicone oil is 6%; the hydrogen-containing silicone oil is methyl hydrogen-containing silicone oil with a hydrogen content of 1.2%; the surfactant is an anionic surfactant sodium dodecylsulfonate; nano silicon dioxide The particle size of micron silica is 16-50nm; the particle size of micron silica is 1300-2000 mesh;

[0079] 1B) First, mix the hydroxyl silicone oil and the hydrogen-containing silicone oil evenly, then add the surfactant, nano-silica, micro-silica and water in sequence, and stir well; then stir for 30 minutes at a stirring speed of 10,000 rpm; then Put the mixed material into an ultrasonic cleaner for ultrasonic treatment to make a silicone oil primary emulsion, wherein the ultrasonic treatment time is ...

Embodiment 3

[0089] 1. Preparation of wood waterproofing agent

[0090] 1. Preparation of silicone oil emulsion stock solution

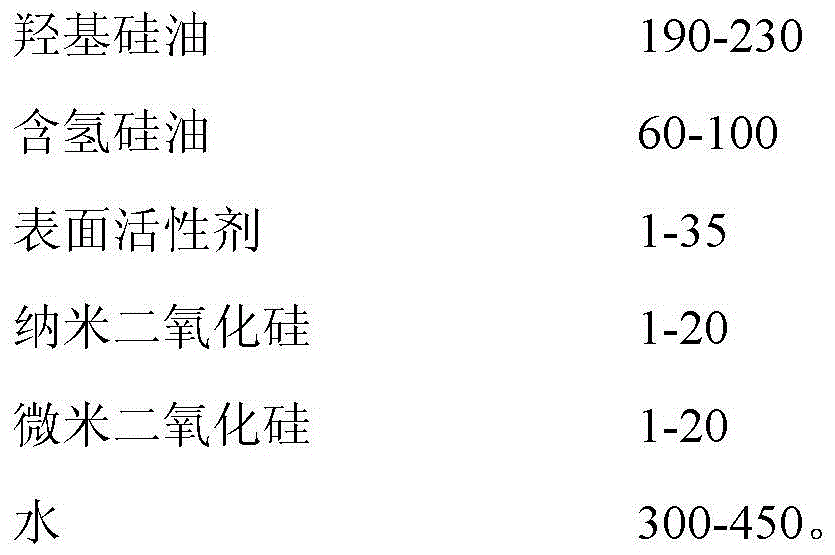

[0091] 1A) Prepare raw materials according to the following weight ratio (g)

[0092]

[0093] Wherein, the hydroxyl content of the hydroxy silicone oil is 4%; the hydrogen-containing silicone oil is a methyl hydrogen-containing silicone oil with a hydrogen content of 1.0%; the surfactant is a nonionic surfactant alkylphenol polyoxyethylene ether (OP-10 ); the particle size of nano silicon dioxide is 16-50nm; the particle size of micron silicon dioxide is 4000-6000 mesh;

[0094] 1B) First, mix the hydroxyl silicone oil and the hydrogen-containing silicone oil evenly, then add the surfactant, nano-silica, micro-silica and water in turn, and stir well; then stir for 30min at a stirring speed of 8000rpm; then Put the mixed material into an ultrasonic cleaner for ultrasonic treatment to make a silicone oil primary emulsion, wherein the ultrasonic treatment time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com