Preparation of carboxy silicon oil emulsion

A technology of carboxyl silicone oil and emulsion, which is applied in the field of preparation of carboxyl modified silicone oil emulsion, can solve the problems of difficult hydrolysis of siloxane, and achieve the effect of good centrifugal stability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1. Preparation of ester-modified silicone oil

[0043] Add 153.5 grams of 10-undecylenic acid methyl ester in 500ml four-necked bottle, heat to 80 ℃, add chloroplatinic acid catalyst (consumption is the 20ppm of total reactant amount), begin to add dropwise to system containing 50 grams of high hydrogen-containing silicone oil with a hydrogen content of 1.55%, control the dropping rate and heating rate, and keep the system temperature between 80-150°C. Removal of low boilers by pressure distillation to obtain ester-modified silicone oil modified with methyl undecanic acid. Infrared spectroscopy analysis found that at 2155cm -1 The Si-H absorption peak at has disappeared, indicating that the active hydrogen in the hydrogen-containing silicone oil has completely reacted. The product is a yellow transparent liquid with a certain viscosity, the refractive index n D 20 It is 1.4560, and η (20°C) is 152cp.

Embodiment 2

[0044] Embodiment 2. Preparation of ester-modified silicone oil

[0045] Replace methyl undecylenate with 165 grams of 10-undecylenic acid ethyl ester, repeat above-mentioned reaction, can obtain undecylenic acid ethyl ester modified ester group modified silicone oil. The product is a yellow transparent liquid with a certain viscosity, the refractive index n D 20 It is 1.4570, and η (20°C) is 160cp.

Embodiment 3

[0046] Embodiment 3. The preparation of carboxyl silicone oil emulsion

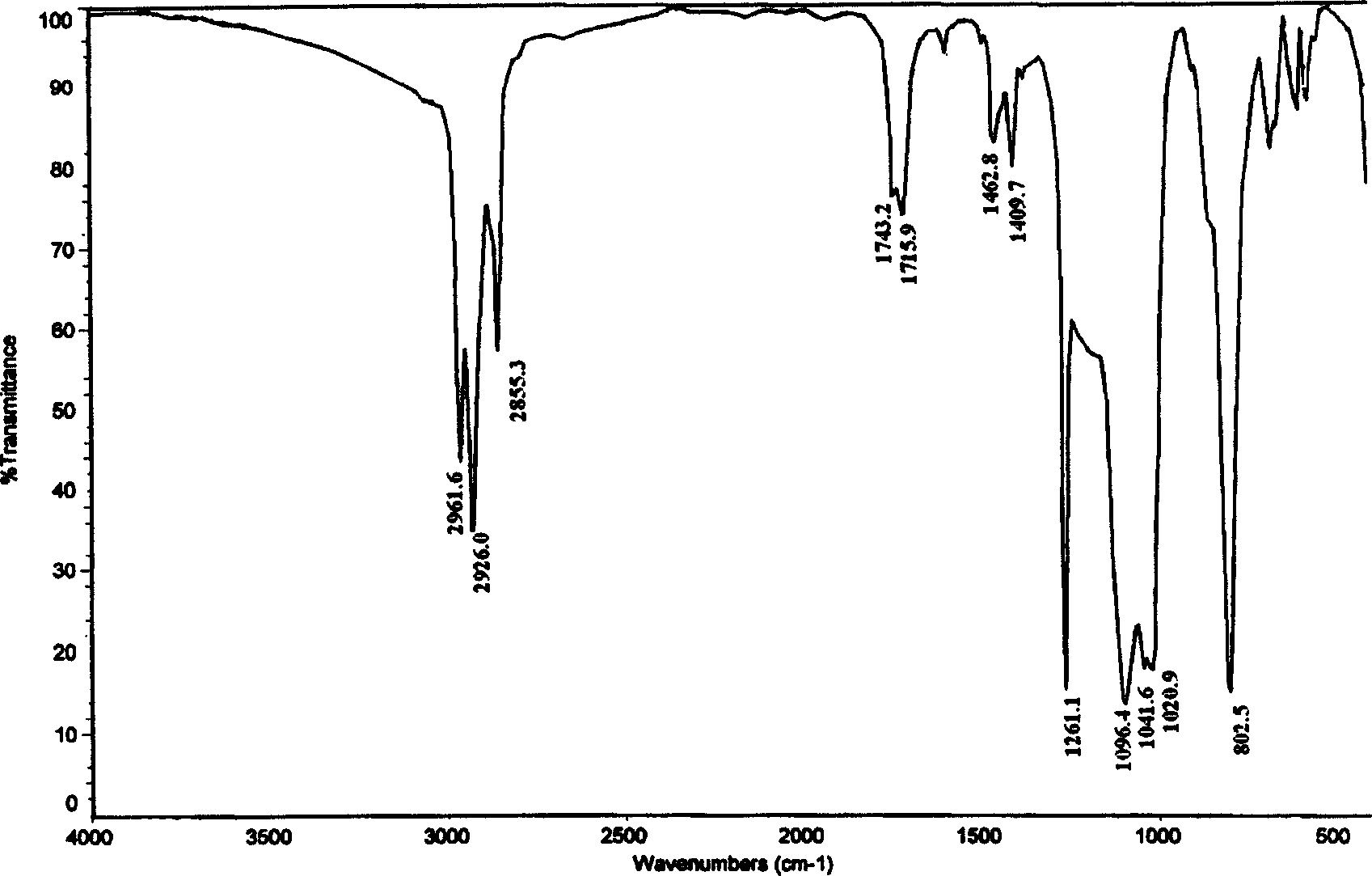

[0047] In the 500ml four-necked bottle, add 50 grams of ester-modified silicone oil in Example 2, 75 grams of octamethylcyclotetrasiloxane, 200 grams of water, 41 grams of dodecylbenzenesulfonic acid, heat up and stir and be incubated at 80 DEG C of reaction 8 hours, sampling is carried out infrared spectroscopic analysis, finds that ester group is mostly hydrolyzed (see attached figure 1 ), among them, at 1715.9cm -1 The absorption peak at is the carbonyl absorption peak in the carboxyl group, and the 1743cm -1 The absorption peak at is the carbonyl absorption peak in the unreacted ester group, at 3500-2500cm -1 A broad and weak carboxyl absorption peak appears. After the reactant was cooled, 42.4 g of 25% sodium bicarbonate aqueous solution was added, stirred at room temperature for 30 minutes, and the stirring was stopped to obtain a viscous yellowish-brown carboxy silicone oil emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com