Synthesis of modified aqueous epoxy resin and method for preparing antiseptic rusty paint

A technology of water-based epoxy resin and anti-corrosion tape, which is applied in the direction of anti-corrosion coatings and coatings, and can solve the problems of base material resin storage stability, water-based epoxy resin anti-corrosion coating film, water resistance, and corrosion resistance. Achieve storage stability, high physical and mechanical properties, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

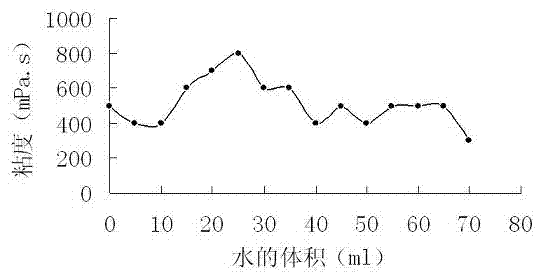

[0012] The specific embodiment one: the synthesis of the modified water-based epoxy resin of the present embodiment is realized according to the following steps: one, mix Span60 and Tween20 by mass ratio 1.3:1 to obtain a composite emulsifier; two, mix liquid by mass ratio 87:13 Add epoxy resin E-51 and compound emulsifier into a 500ml four-necked flask equipped with a thermometer, a stirring device and a reflux condenser, heat it in a water bath to 70°C, stir at a speed of 300r / min until it is evenly mixed, and add distilled water dropwise When the viscosity of the system is reduced from 500mPa.s to 300mPa.s, an epoxy resin emulsion is obtained; 3. Add the initiator and monomer dropwise to the epoxy resin emulsion, and react at 90°C for 3-4 hours to complete the modified water-based The synthesis of epoxy resin; wherein in step three, initiator is potassium persulfate, and the addition amount of initiator accounts for 0.1%~0.5% of monomer quality; In step three, monomer is α-m...

specific Embodiment approach 2

[0031] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the distilled water is added dropwise at a rate of 60-100 drops / min in step 2 until the viscosity of the system rises to 810mPa.s, and then 10-20 drops / min The speed of min is added dropwise until the viscosity of the system is reduced to 300mPa.s. Other steps and parameters are the same as those in Embodiment 1.

[0032] In this embodiment, the viscosity of the system rises to 810 mPa.s, which is a process close to phase inversion.

specific Embodiment approach 3

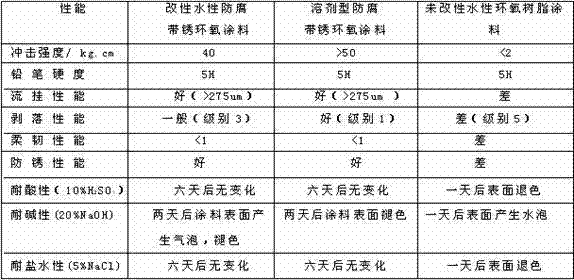

[0033] Specific embodiment three: the preparation method of the modified water-based epoxy resin anti-corrosion rust coating in this embodiment is realized according to the following steps: 1. Take 90-95 parts of modified water-based epoxy resin, 0.2-0.5 parts by mass and number of parts Corrosion inhibitor, 0.5-1 part of defoamer, 10 parts of anti-rust agent, 10 parts of curing agent and 5-10 parts of deionized water; 2. The modified water-based epoxy resin, corrosion inhibitor and anti-rust Mix the agent and stir evenly, then place it on a conical mill and grind it at a speed of 50-70r / min for 3 hours, then add the weighed defoamer, curing agent and deionized water, and stir evenly to obtain the modified water-based epoxy resin Resin anti-corrosion coating with rust; wherein in step 1, the corrosion inhibitor is sodium nitrite, the defoamer is tributyl phosphate, the rust inhibitor is medium chrome yellow, and the curing agent is diethylene triamine.

[0034] In this embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com