Preparation method of polyvinyl acetate emulsion

A technology of polyvinyl acetate and polyvinyl alcohol, which is applied in the field of preparation of polyvinyl acetate emulsion, can solve the problems of emulsion adhesive performance decline, influence on use performance, poor dilution stability, etc., and achieve good adhesive performance, The effect of easy implementation and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 40 parts of water into the reactor, then add 3 parts of 1788, 13 parts of 0588, and 6 parts of 1797 to dissolve, then add 50 parts of vinyl acetate and stir evenly. The temperature of the reaction system was controlled at 68° C., and 0.2 parts of reducing agent (zinc formaldehyde sulfoxylate) and 0.2 parts of oxidizing agent (hydrogen peroxide) were added. After 30 minutes, the temperature of the reaction system was controlled to 80°C, and 10 parts of vinyl acetate, 0.1 part of sodium bicarbonate, 0.2 parts of oxidant (hydrogen peroxide) and 10 parts of water were added dropwise, and the addition was completed within 60 minutes. Cool down, filter, and discharge.

Embodiment 2

[0025] The polyvinyl acetate emulsion prepared in embodiment 1 is carried out dilution stability test experiment

[0026] Detection method

[0027] (1) In a 100mL beaker, weigh 15 grams of synthetic emulsion and 15 grams of distilled water, and stir well.

[0028] (2) Take a 10mL centrifuge tube, weigh its weight m1, and record the weight m2 (about 10 grams) of the diluted emulsion poured into the tube.

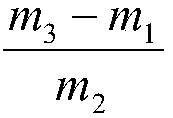

[0029] (3) Put the centrifuge tube into the centrifuge, centrifuge at a speed of 2600 rpm for 4 minutes, take it out and invert the centrifuge tube for 5 minutes, dry the mouth of the tube, and weigh the sediment weight m3 in the tube. The formula for calculating the dilution stability parameter is:

[0030]

[0031] The smaller the value of the dilution stability parameter, the better the dilution stability of the emulsion.

[0032] The dilution stability parameter of the obtained polyvinyl acetate copolymer emulsion was 0.94%.

Embodiment 3

[0035] Add 42 parts of water into the reactor, then add 5 parts of 1788, 10 parts of 0588, and 10 parts of 1797 to dissolve, then add 45 parts of vinyl acetate and stir evenly. The temperature of the reaction system was controlled at 68° C., and 0.2 parts of reducing agent (sodium formaldehyde sulfoxylate) and 0.2 parts of oxidizing agent (tert-butyl hydroperoxide) were added. After 30 minutes, the temperature of the reaction system was controlled to 80°C, and 15 parts of vinyl acetate, 0.12 parts of sodium bicarbonate, 0.2 parts of oxidant (tert-butyl hydroperoxide) and 10 parts of water were added dropwise, and the addition was completed within 60 minutes. Cool down, filter, and discharge. The dilution stability parameter of the obtained polyvinyl acetate copolymer emulsion was 0.85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com