Binder and preparation method thereof

A binder and curing agent technology, which is applied in the binder used in road paving and its preparation field, can solve the problems of large wetting angle, difficulty in water penetration, blockage, etc., and achieve the effect of strong wetting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A binder, containing A component, B component, diluent and coloring pigment iron oxide red, the following are all in mass percentage; wherein A component is 70% low molecular weight (300-800) epoxy Equivalent (<190) bisphenol A glycidyl ether epoxy resin, 3% polythiol resin, 6% iron oxide with a mass ratio of 1-2:1-3:1-3:1-2, Metal aluminum, graphite and silicon dioxide, 5% of hydrophilic resin and 2% of tertiary amine catalyst, described hydrophilic resin is to introduce hydrophilic group in resin molecule by chemical reaction, make this resin become the self-emulsifying property Reactive resin; the content of the B component accounts for 10%, which is composed of boron trifluoride-N, N-dimethylaniline, Mannich addition polyamines, and aromatic amines, wherein boron trifluoride-N, N-dimethylaniline accounts for 35% of the total mass of component B, Mannich addition polyamine accounts for 30% of the total mass of component B, and aromatic amine accounts for 35% of the t...

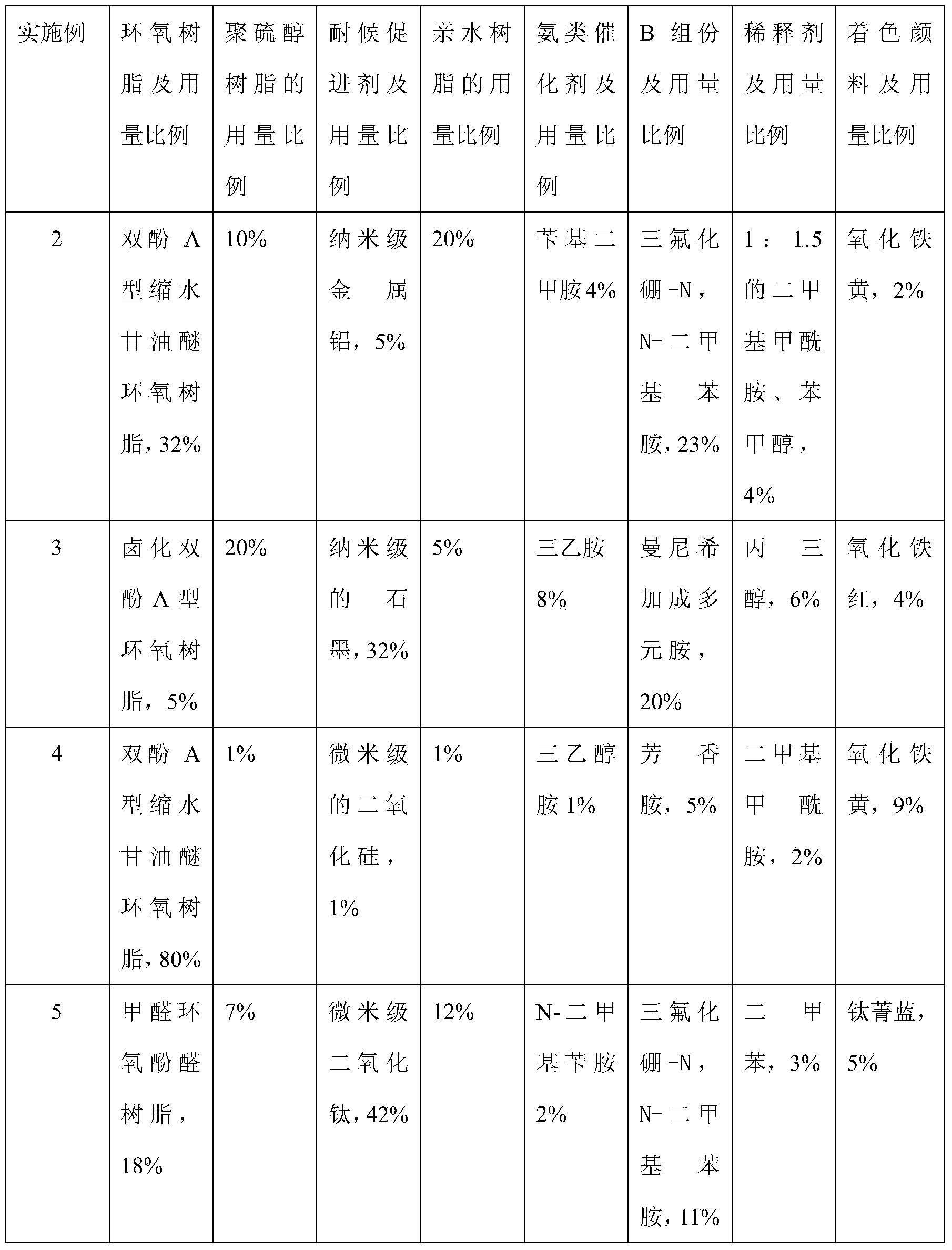

Embodiment 2~8

[0025] Embodiment 2~8: the raw material component of following table, all is mass percentage content and mass ratio, all the other are with embodiment

[0026] Same as in 1.

[0027]

[0028]

Embodiment 9

[0030] The binder prepared in Example 1 was mixed with the aggregate natural sand, and the binder accounted for 5% of the aggregate mass as a road paving material.

[0031] 1. Determination method of water permeability coefficient Determination of water permeability:

[0032] According to the method stipulated in the CJJT135-2009 permeable cement concrete pavement technical regulations, the detection requirement is >0.5mm / s, and the CJJ945-2007 permeable brick requires a permeability coefficient>0.1mm / s. The measured permeability coefficient of the above paving materials is 0.1mm / s- Within the range of 1.0mm / s, it meets the requirements of the national specification.

[0033] 2. Filtration performance:

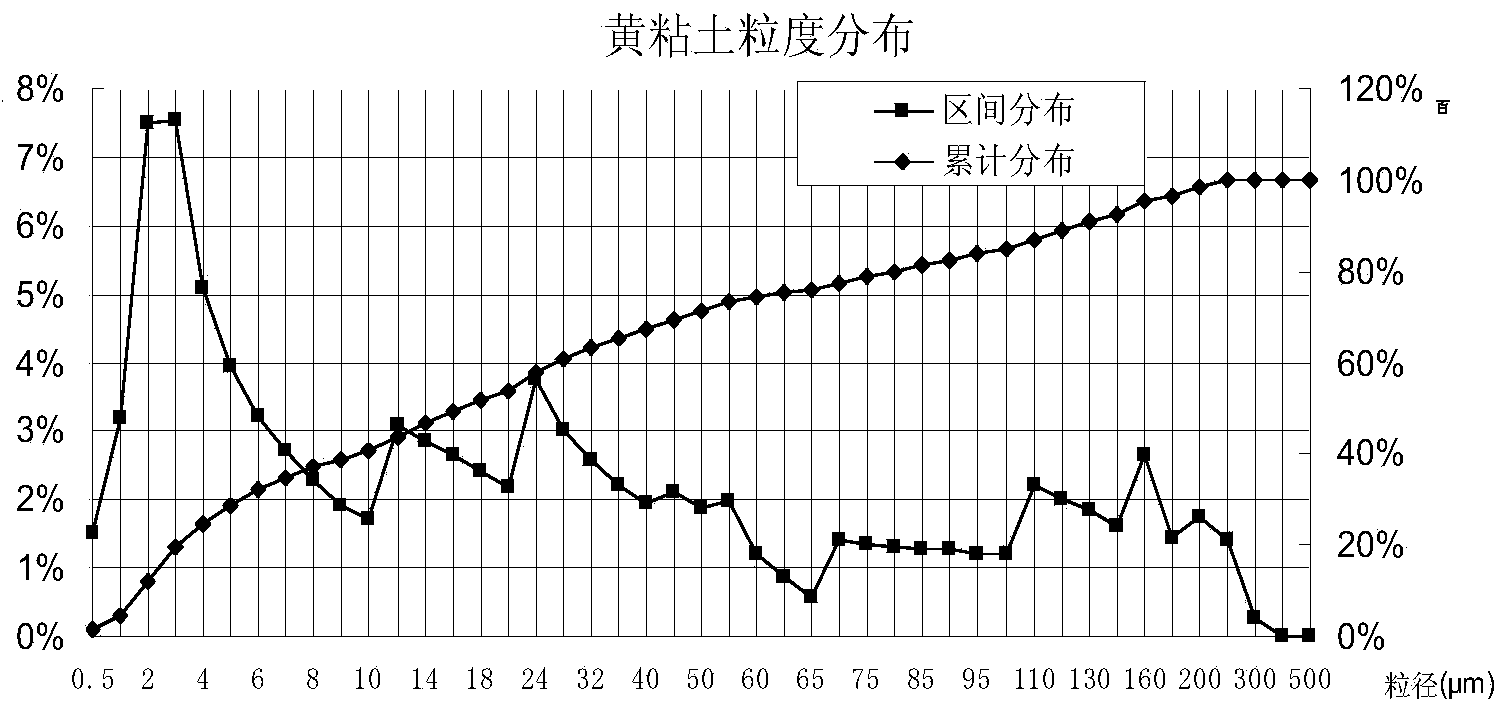

[0034] Experimental method: filter the powder with a particle size of figure 1 As shown in the test with coal ash solution, the 1-15 micron coal ash powder only exists on its upper surface and does not enter the interior of the road pavement structure. figure 2 In order to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com