Halogen-free lead-free soldering paste and preparation method thereof

A technology of halogen-free lead-free solder paste and lead-free solder, which is applied in the field of halogen-free lead-free solder paste and its preparation, can solve the problems of storage, short service life, poor welding of solder paste, and reduced insulation resistance, etc., and achieve long storage life , Improve solderability, improve wettability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

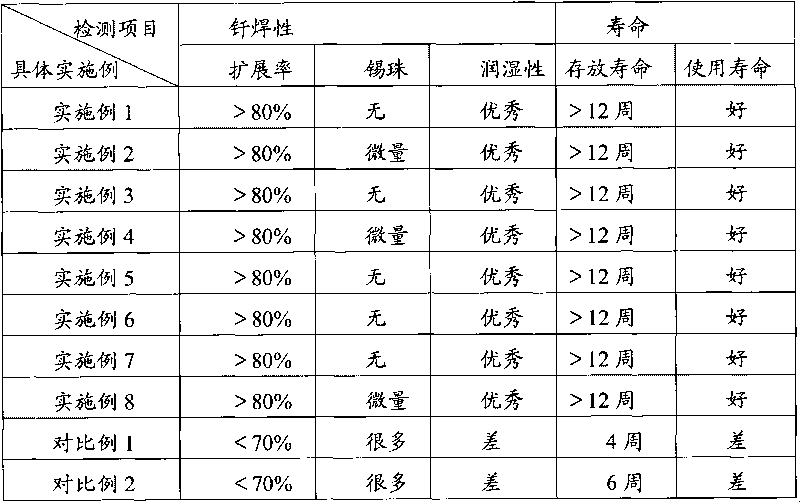

Examples

Embodiment 1

[0035] Flux raw materials: polymerized rosin 25g, hydrogenated rosin 20g, modified hydrogenated castor oil 4g, hydrogenated castor oil wax 2g, methyl succinic acid 4g, stearic acid amide 1g, triethanolamine 1.3g, phytic acid 0.7g combination and terpineol 42g.

[0036] Preparation method: first mix 1.3g of triethanolamine and 0.7g of phytic acid and stir for 5 minutes until the reaction is complete, then cool at room temperature for use. Mix 25g of polymerized rosin, 20g of hydrogenated rosin and 42g of terpineol and dissolve at a temperature of 150°C, then add 4g of modified hydrogenated castor oil, 2g of hydrogenated castor oil wax, and then add 4g of methyl succinic acid after completely dissolving, After the above materials are completely dissolved, cool them down. When cooling to 80±10°C, add stearic acid amide 1g, triethanolamine 1.3g and phytic acid 0.7g composition, and continue cooling to room temperature to obtain flux. 12g is mixed with 88g of Sn / Ag3 / Cu0.5 solder a...

Embodiment 2

[0038] Flux raw materials: polymerized rosin 30g, hydrogenated rosin 20g, modified hydrogenated castor oil 3g, hydrogenated castor oil wax 3g, succinic anhydride 3g, methyl succinic acid 2g, stearic acid amide 1g, N,N-dimethyl Cetylamine 1.9g, phytic acid 1.1g, diethylene glycol monobutyl ether 20g and ethylene glycol hexyl ether 15g.

[0039] Preparation method: first mix 1.9g of N,N-dimethylhexadecylamine and 1.1g of phytic acid and stir for 5 minutes until the reaction is complete, then cool at room temperature for use. 30 g of polymerized rosin, 20 g of hydrogenated rosin, 20 g of diethylene glycol monobutyl ether, and 15 g of ethylene glycol hexyl ether are mixed together and dissolved at a temperature of 150° C., and then 3 g of modified hydrogenated castor oil and 3 g of hydrogenated castor oil wax are added, completely After dissolving, add 3g of succinic anhydride and 2g of methylsuccinic acid. After the above materials are completely dissolved, cool down. When coolin...

Embodiment 3

[0041] Flux raw materials: polymerized rosin 40g, hydrogenated rosin 10g, modified hydrogenated castor oil 1g, hydrogenated castor oil wax 4g, succinic anhydride 4g, stearic acid amide 2g, triethanolamine 2.2g, phytic acid 1.8g and diethyl Diol monobutyl ether 35g.

[0042] Preparation method: first mix 2.2g of triethanolamine and 1.8g of phytic acid and stir for 5 minutes until the reaction is complete, then cool at room temperature for use. Mix 40g of polymerized rosin, 10g of hydrogenated rosin and 35g of diethylene glycol monobutyl ether to dissolve together at a temperature of 150°C, then add 1g of modified hydrogenated castor oil, 4g of hydrogenated castor oil wax, and then add succinic anhydride after completely dissolving 4g, the above materials are completely dissolved and then cooled, and when cooled to 80±10°C, add 2g of stearic acid amide, 2.2g of triethanolamine and 1.8g of phytic acid, and continue to cool to room temperature to obtain flux. Mix 11g of flux with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com