Flexible flame-retardant polyester curing agent with star-like branched structure, and synthesis method thereof

A branched structure, flame-retardant polyester technology, applied in the field of flexible flame-retardant polyester curing agent and its synthesis, can solve the problems of inability to combine organically, achieve high flame-retardant efficiency, optimized electrical properties, and easy control of conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

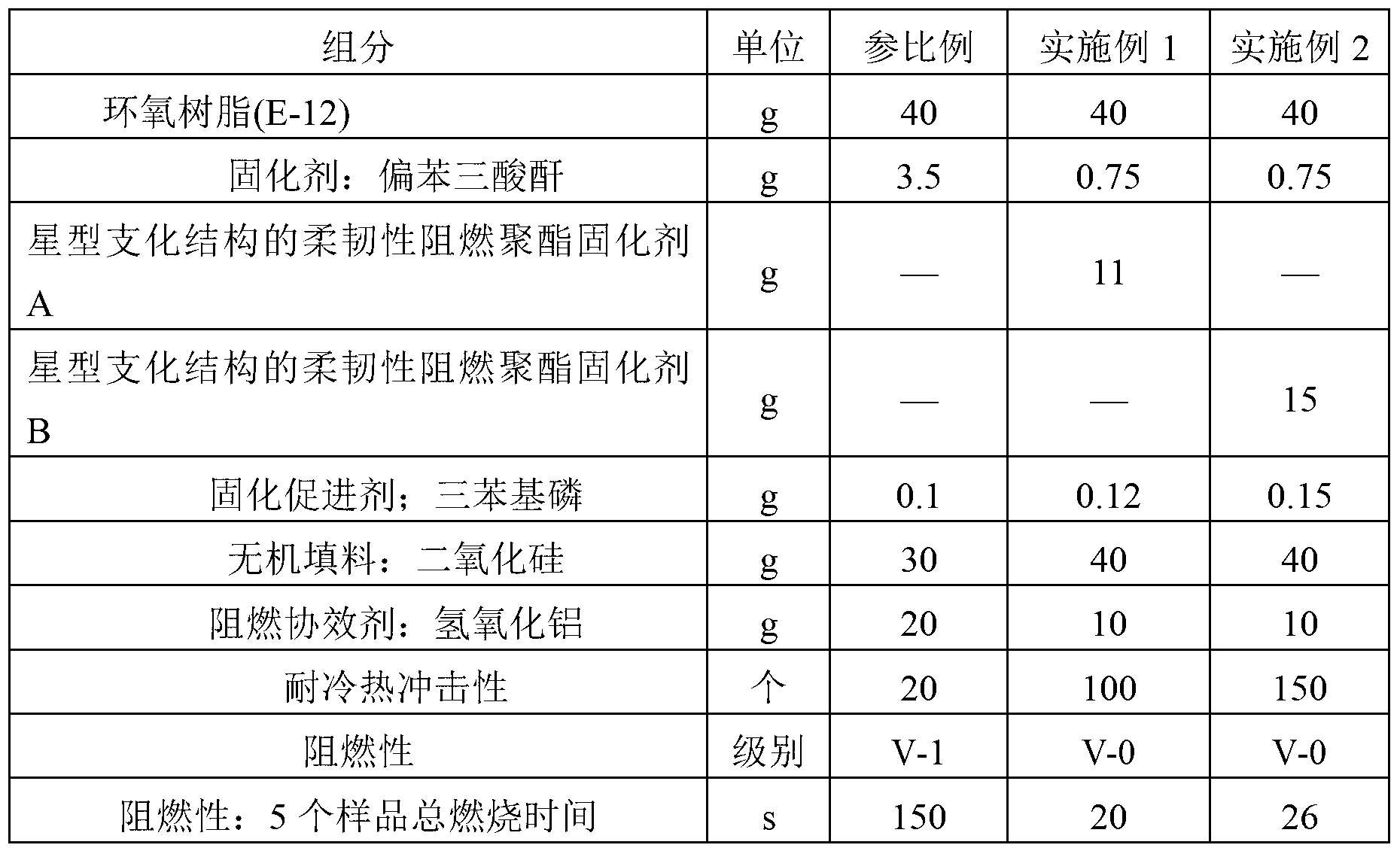

Embodiment 1

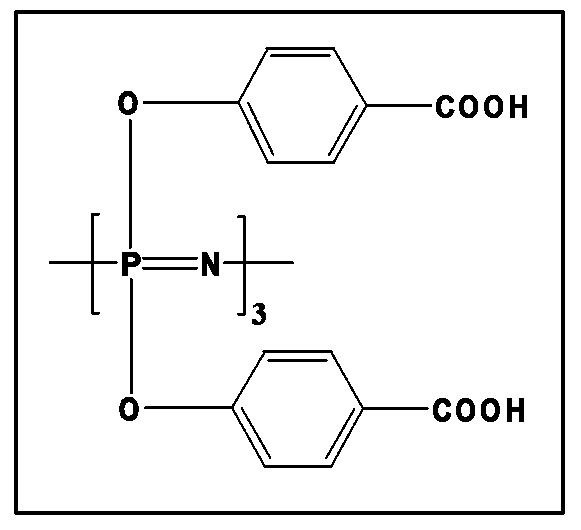

[0036] A method for synthesizing a flexible flame-retardant polyester curing agent (A) with a star-shaped branched structure, the steps are as follows:

[0037] (1) Add 22.49g of ethylene glycol and 170g of neopentyl glycol to a 1L four-neck flask equipped with a heating mantle, stirrer, thermometer, distillation column and condenser, heat to about 120°C and stir to melt, then add 13.25g of hexyl Diacid, 15.06g of isophthalic acid and 0.22g of monobutyltin oxide are protected by nitrogen gas. After they are dissolved, the temperature is slowly raised to 150°C to start the esterification reaction, and by-product water flows out. During the reaction, the distillation column is controlled The temperature is not higher than 100°C, and then carry out segmented esterification reaction, heating reaction at 150-180°C for 2-4 hours, heating at 180-220°C for 1-3 hours, when no by-product water flows out, cool down to 100-120°C between.

[0038] (2) Add 289.25g of hexa(4-carboxyphenoxy)...

Embodiment 2

[0043] A method for synthesizing a flexible flame-retardant polyester curing agent (B) with a star-shaped branched structure, the steps are as follows:

[0044](1) Add 48.47g of ethylene glycol and 190g of neopentyl glycol to a 1L four-neck flask equipped with a heating mantle, stirrer, thermometer, distillation column and condenser, heat to about 120°C and stir to melt, then add 114.25g of hexyl Diacid, 86.59g of isophthalic acid and 0.44g of monobutyltin oxide are protected by nitrogen gas. After they are dissolved, the temperature is slowly raised to 150°C to start the esterification reaction, and by-product water flows out. During the reaction, the distillation column is controlled The temperature is not higher than 100°C, and then carry out segmented esterification reaction, heating reaction at 150-180°C for 2-4 hours, heating at 180-220°C for 1-3 hours, when no by-product water flows out, cool down to 100-120°C between.

[0045] ⑵Add 207.82g of hexa(4-carboxyphenoxy)cyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com